2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol

on your pump or in this manual, look for one of the fol-

lowing signal words and be alert to the potential for personal

injury.

warns about hazards that will cause serious per-

sonal injury, death or major property damage if ignored.

warns about hazards that can cause serious per-

sonal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this manual

and on pump.

Hazardous pressure. Under certain conditions,

submersible pumps can develop extremely high pressure.

Install a pressure relief valve capable of passing entire pump

flow at 75 PSI.

Do not allow pump, piping, or any other system compo-

nent containing water to freeze. Freezing may damage

system, leading to injury or flooding. Allowing pump or system

components to freeze will void warranty.

Hazardous voltage. Can shock, burn or cause

death. To avoid dangerous or fatal electric shock hazard, use

pump only in an effluent system. DO NOT install pump in an

open body of water ( a lake, swimming pool, etc.).

Install, ground and wire pump according to local and

Canadian Electrical Code or National Electrical Code

requirements that apply.

Disconnect electrical power supply before installing or

servicing pump.

Make sure pump nameplate voltage and frequency match

line voltage and frequency of power supply.

1. Install pump according to all plumbing, pump and well

code requirements.

2. Install an all leg disconnect switch in the power supply

near the pump.

3. Two-wire motors are equipped with automatic thermal

overload protection which will open the circuit and stop

the motor when a thermal overload (excessive heating)

exists. When motor cools, overload will rest and motor will

restart automatically. This can cause the pump to start

unexpectedly and without warning.

GENERAL

Inspect pump for delivery damage. Report any damage to ship-

ping carrier or to Sta-Rite immediately.

Have any installation, repair, or service work done by your

Sta-Rite dealer.

Never run pump dry.

LIMITED WARRANTY

Sta-Rite warrants to the original consumer of the products listed below, that they will be free from defects in material and work-

manship for the Warranty Period from the date of original installation or manufacture as noted.

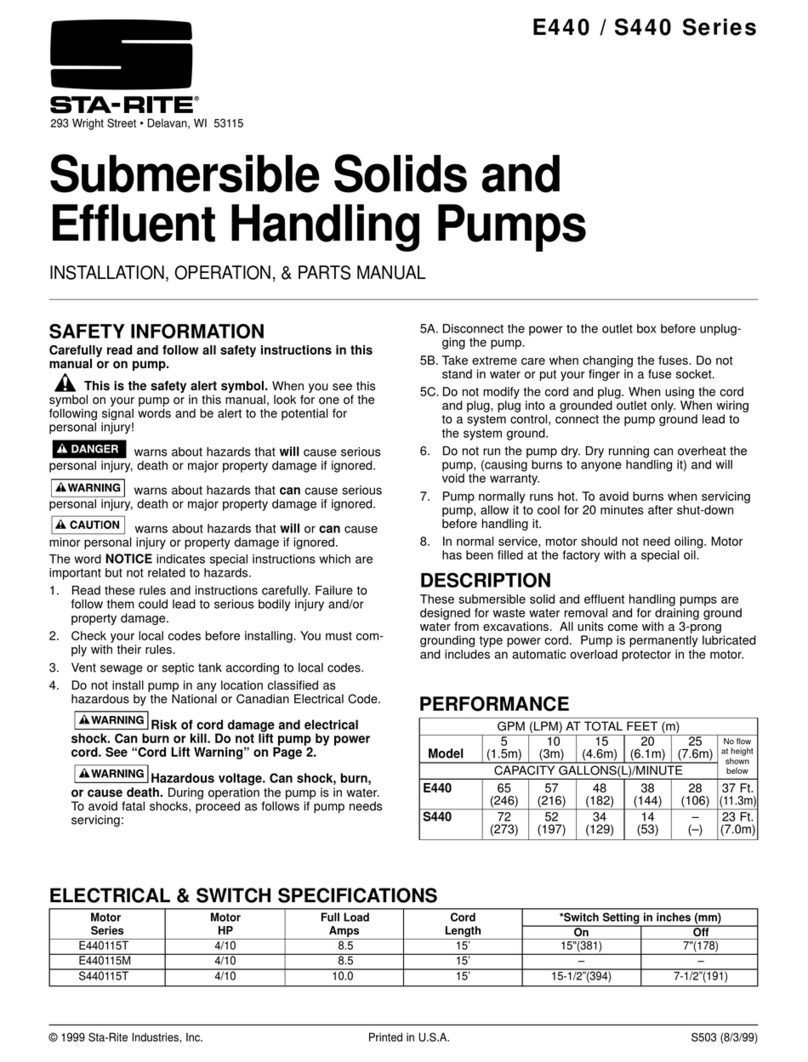

Product Warranty Period

4” Submersible Pump Products 1 year

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or main-

tenance. In the event a three phase submersible motor is operated with single phase power through a phase converter, or if three-

leg ambient compensated, extra-quick trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite’s only duty is to repair or replace defective products (at Sta-Rite’s choice). Buyer agrees to pay

all labor and shipping charges associated with this warranty and to request warranty service through the installing dealer as soon

as a problem is discovered. If warranty service is requested more than 30 days after the Warranty Period has ended, it will not

be honored.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WAR-

RANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of limitations on

the duration of an implied warranty, therefore, the limitations or exclusions herein may not apply. This warranty sets forth spe-

cific legal rights and obligations, however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, Inc. 293 Wright St., Delavan, WI 53115