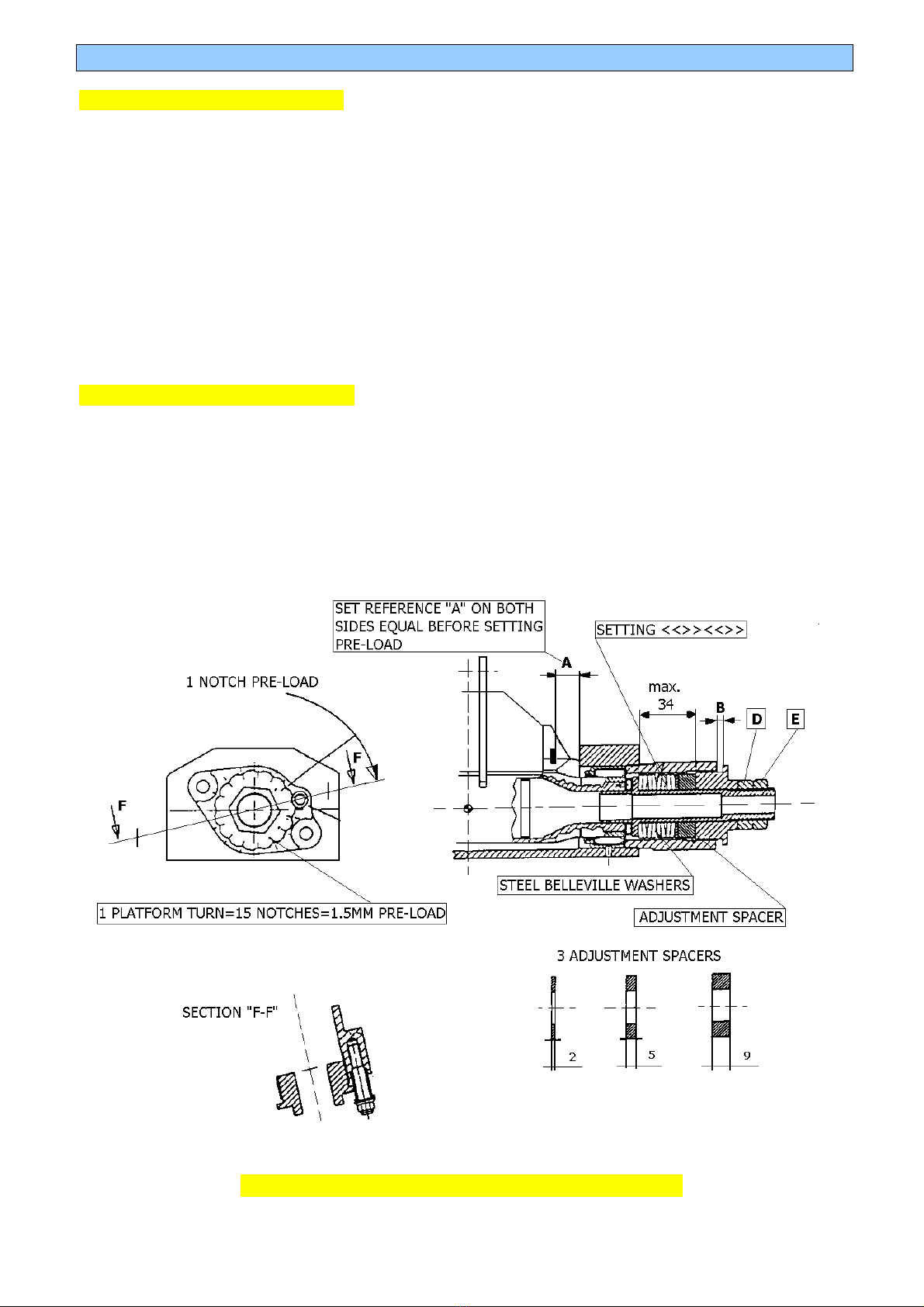

9 FRONT ANTI-ROLL AND ROLL PRE-LOAD

You can use each of the Belleville stacks with or without pre-load. There are two types of

pre-load, described in detail here below. The limit of the system is the rocker touching the

magnesium support when moving laterally.

Double stiffness pre-load

•Within the pre-load range, the stiffness is double the stiffness of one stack, both stacks are

working

•Passed the pre-load, the stiffness gets back to the nominal stiffness of one stack

Infinite stiffness pre-load is accomplished with an additional nut and a counter nut

•Within the pre-load range, the rocker doesn’t move at all

•Passed the pre-load, the stiffness gets back to the nominal stiffness of one stack

•The choice of a pre-load setting, or the non pre-loaded setting might be based on the car’s

balance exigencies, tyre wear, drivers’ preference etc…. Pre-load settings generally help for

sharper turn-in characteristic.

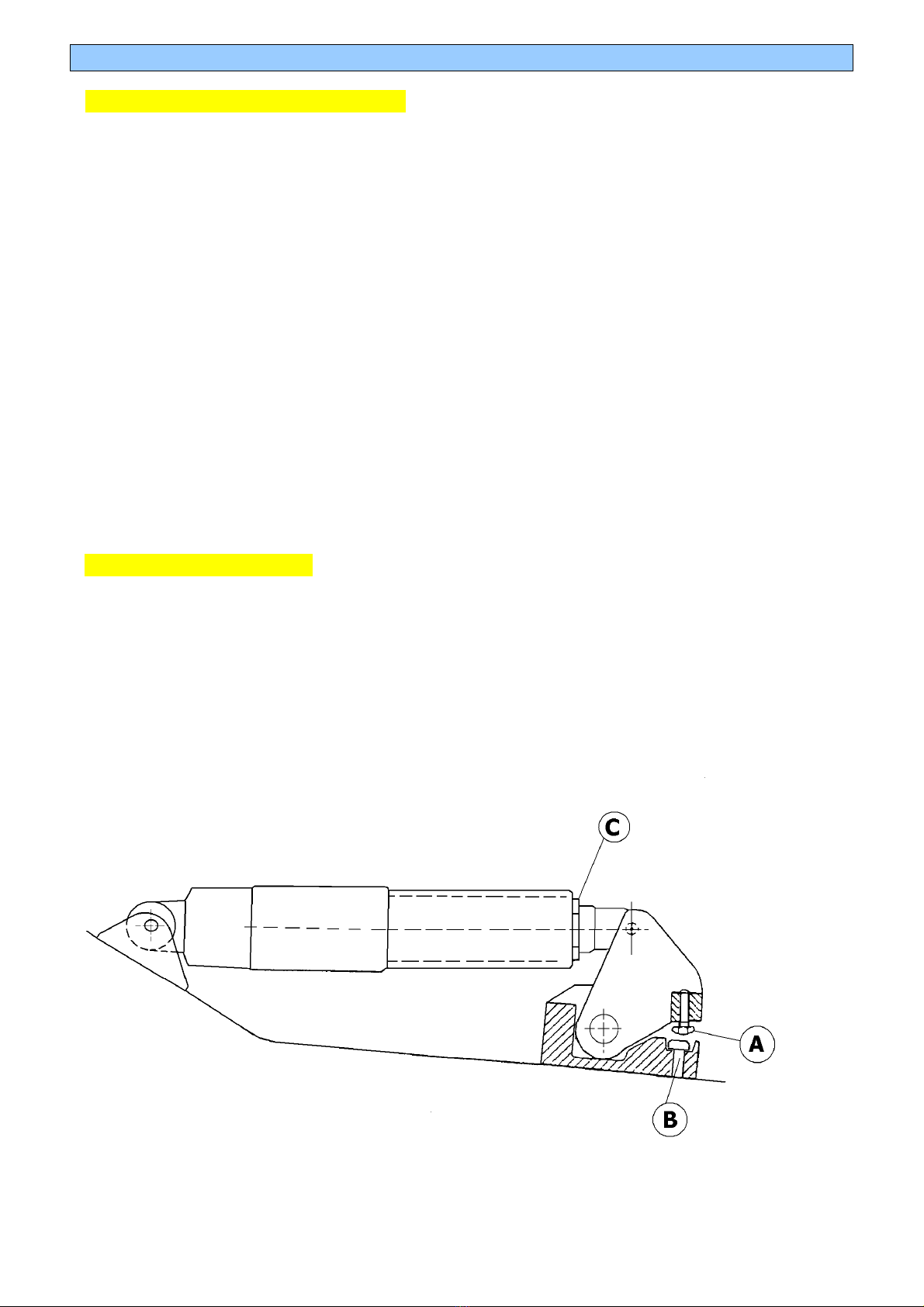

•Clearance between the platform and the rocker (B) shall not be more than 6.5mm when

platform just touches the Belleville stack, with no pre-load.

•The amount of pre-load is the difference between the current and the free length of the

Belleville stack.

•For any Belleville stack, in running condition, rocker lateral motion and the chosen pre-load

must never reach the "Maximum Deflection" (see Table 6), to avoid a sudden lateral locking

of the rocker.

•Once the rocker overcomes the pre-load, the total stiffness reduces to the nominal stiffness

of one Belleville stack. You may like to work within the roll pre-load range under certain

conditions (turn-in…) and wish to pass over the pre-load range in some others (mid-corner,

curbs…). Set accurately the transition point (pre-load level) between the two conditions, since

the stiffness change is sudden and affects transient car behaviour.

You can achieve a progressive load / displacement characteristic by combining in series two different

stacks or a regressive load / displacement ratio by fitting an appropriate pre-load. Total length of

any stack should be maximum 34 mm.

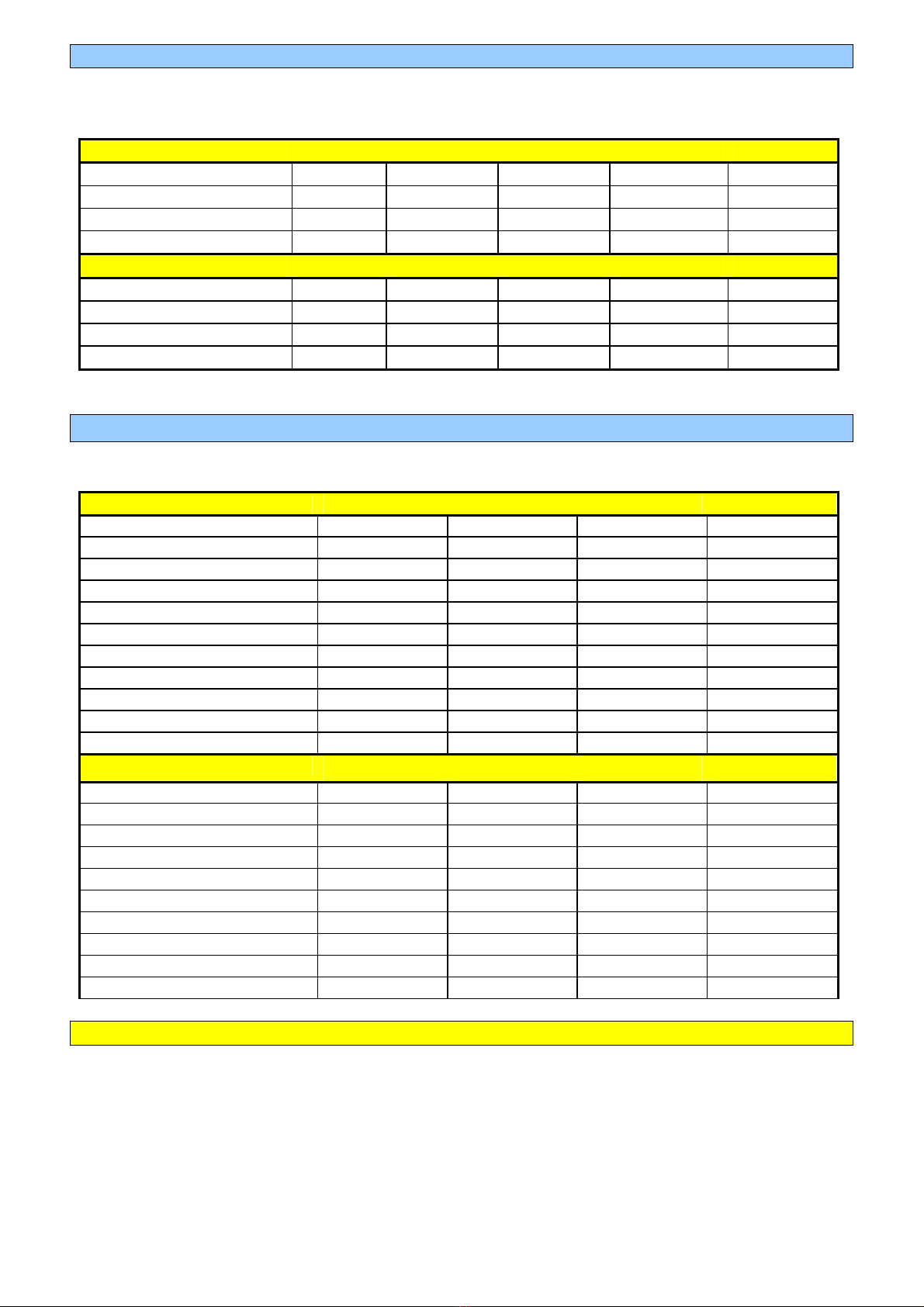

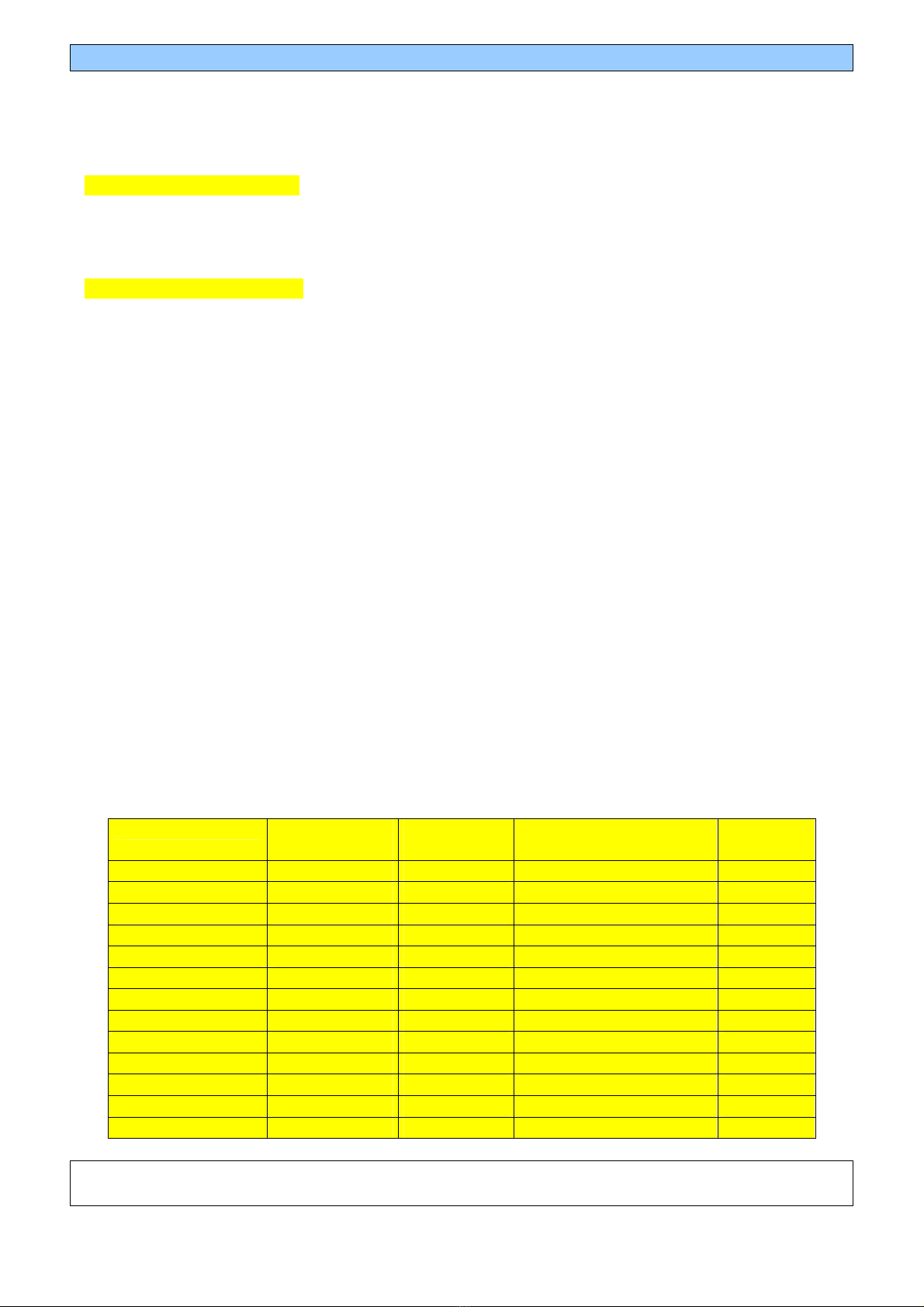

BELLEVILLE STACK CONFIGURATIONS (Belleville thickness 2.0mm)

Stack configuration Max deflection

mm Stack width

mm Nominal stack stiffness

Kg/mm (no pre-load) Maximum

notches

<<<<>>>> 1.12 17.50 2504 8

<<<>>> 1.12 13.50 1796 8

<<<>>><<< 1.69 20.25 1197 12

<<>><< 1.69 14.25 761 12

<<>><<>> 2.25 19.00 571 17

<<>><<>><< 2.81 23.75 457 22

<>< 1.69 8.25 362 14

<><> 2.25 11.00 272 17

<><>< 2.81 13.75 218 22

<><><> 3.37 16.50 181 26

<><><>< 3.93 19.25 155 28

<><><><> 4.50 22.00 136 34

<><><><><> 5.62 27.50 109 44

Note: the front rocker lateral movement has been increased from the previous (F399-301) maximum

6mm to about 10mm on the F302/3/4 car.