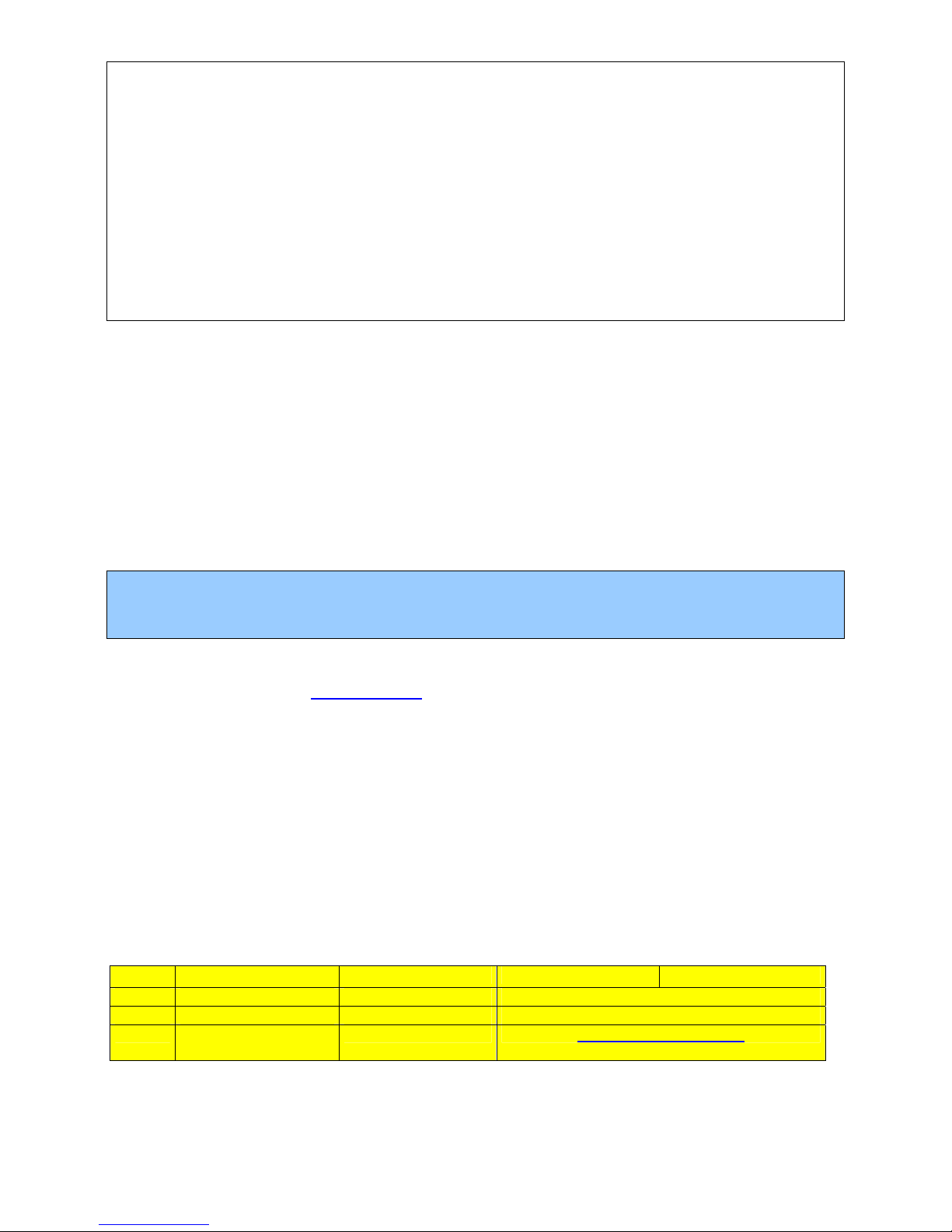

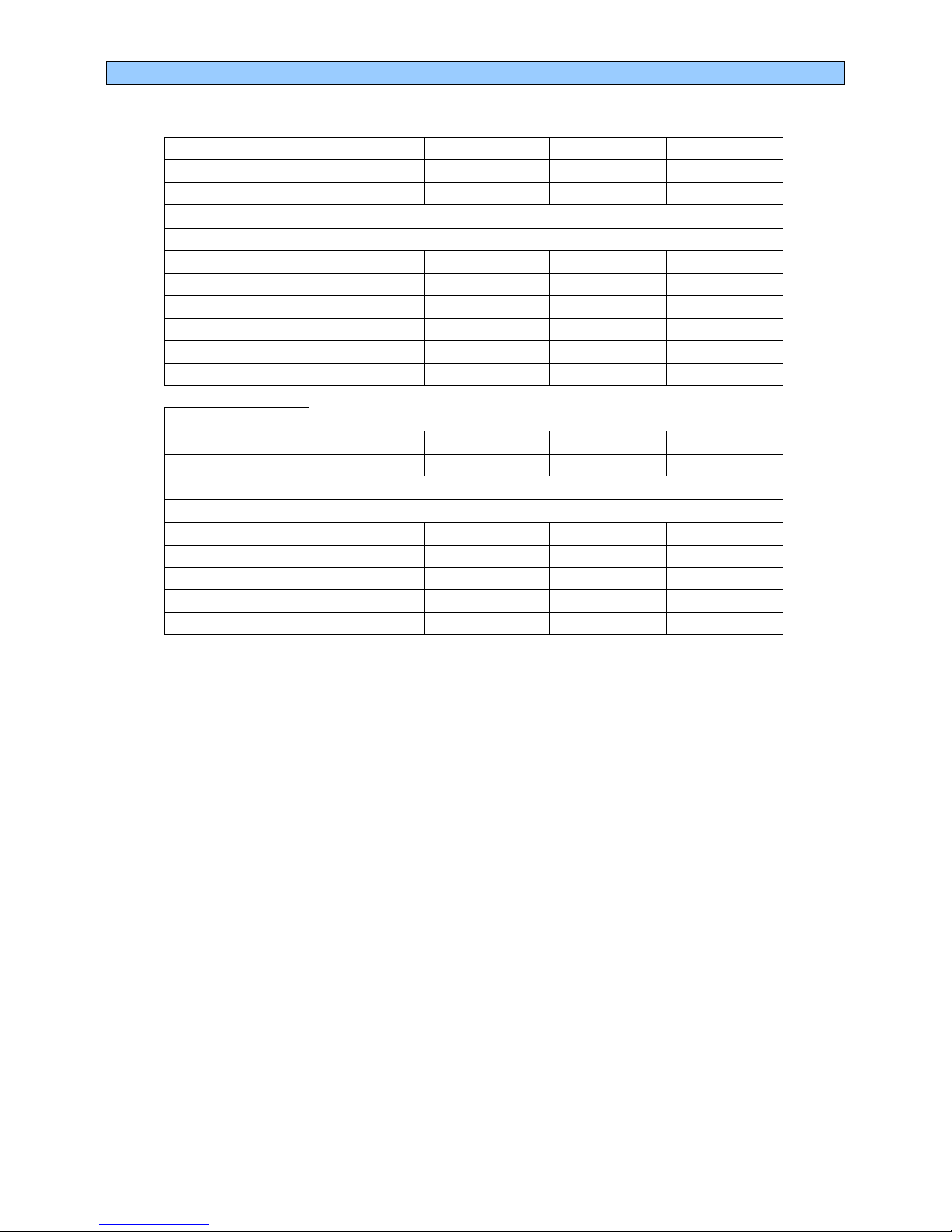

FRONT ROLL BAR VALUES 10

¾The values shown below are in kg/mm [daN/mm] at one end of the blade while the other end

is locked.

¾The values below are measured on the ARB isolated from the car. You may use the Motion

Ratio’s from page 5 to calculate the ARB stiffness

at ground

.

¾On various ARB’s we suggest not to use the 115mm blade.

ARB BLADE BLADE POSITION

1 2 3 4 5

T-13 solid B-270 3,0 3,1 3,4 3,9 4,0

B-245 3,8 3,9 4,2 4,7 4,8

B-221 5,0 5,1 5,4 5,9 6,0

B-170 10,0 10,2 10,7 11,4 11,6

B-115

T-18x2,5 B-270 5,5 6,0 7,4 9,4 10,0

B-245 6,9 7,4 9,0 11,1 11,8

B-221 9,5 10,1 11,8 14,2 15,0

B-170 21,0 22,2 25,7 30,5 32,0

B-115

T-20x2,0 B-270 6,5 7,1 8,7 10,8 11,5

B-245 8,0 8,6 10,4 12,7 13,5

B-221 11,0 11,8 13,5 17,0 18,0

B-170 24,0 25,3 28,9 33,9 35,5

B-115

T-30x5,0 B-270 8,5 10,7 17,1 25,7 28,5

B-245 11,1 13,8 21,7 32,3 35,8

B-221 16,0 19,4 29,3 42,7 47,0

B-170 41,5 47,8 66,2 91,0 99,0

B-115 187,0 190,0 198,5 210,0 213,8

6 7

5 POINTS ARB 30x2,0 70,0 99,0 150,0 250,0 545,0 - -

7 POINTS ARB 25x2,0 26,5 33.9 44.4 60.3 85.5 129.0 213,1

¾Since there have been some quality problems with the

T 13 Solid

we replaced this ARB by a

slightly stiffer new ARB, the T-14.5mm Solid. In its softest position with the 270 blade the

stiffness is 4,1kg/mm, in its stiffest position using the 170 blade the stiffness is 16,1kg/mm.

-