A comprehensive range of product

Product basics

The K4000 is a high frequency inverter designed for application up to 4000 Hz. The

K4000 family consists of several models with output ratings from 5 to 120 kVA. the

selective harmonic suppression -SHS - developed by DANAHER-MOTION, is aimed

at reducing motor losses and winding stresses without output filter.

• The KEYPAD PC560 control unit can be integrated on the front panel or supplied

as a separate remote control unit.

• The drive is equipped with a RS232 / 422 serial link. A communication protocol in

terminal mode for PC is available on request

• The UL certification of the KT4000 is in process

• The 19” rack version KL4000 will not be UL certified

Main technical data

• Input voltage, all units, 3 x 200 V to 3 x 480 V auto-ranging, no line transformer

• Output voltage VRMS : 0 … UIN, max. 3 x 460 V

• Output frequency range 0 … 4000 Hz

• Ambient temperature 40°C

• Continuous current overload 120% without time limitation

• Max current overload 150% for 1 min / every 10 min

• Short-circuit protection: suitable for use on a circuit capable of delivery not more

than 5000 ARMS symmetrical Amperes, 480 V maximum.

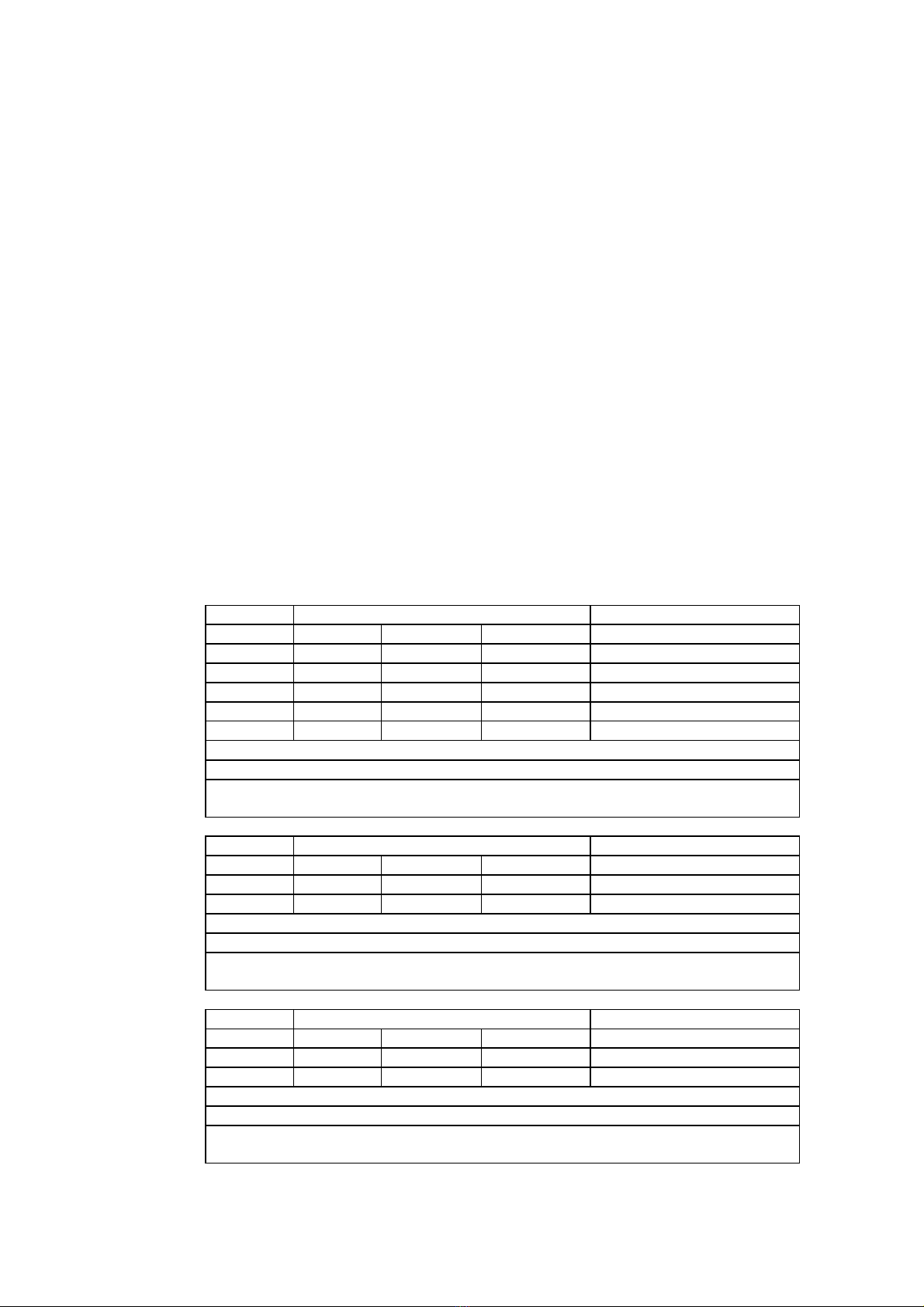

Current and Power ratings

Model Output Current ARMS Typical motor power

Nominal Continuous Peak kW @ 3 x 400 V

KT4005 5 6 10 2.5

KT4010 10 12 15 5

KT4015 15 18 23 7.5

KT4020 20 24 30 10

KT4030 30 36 45 15

Input current: All units are rated for a maximal input current of 32 ARMS

Input terminals: 10 mm2

Input cables: Minimum section 6 mm2resp. 10 AWG

Use copper conductors 75°C only

Model Output Current ARMS Typical motor power

Nominal Continuous Peak kW @ 3 x 400 V

KT4040 40 50 60 20

KT4060 60 75 90 30

Input current: All units are rated for a maximal input current of 63 ARMS

Input terminals: 35 mm2

Input cables: Minimum section 25 mm2resp. AWG 4

Use copper conductors 75°C only

Model Output Current ARMS Typical motor power

Nominal Continuous Peak kW @ 3 x 400 V

KT4090 90 110 135 45

KT4120 120 145 180 60

Input current: All units are rated for a maximal input current of 160 ARMS

Input terminals: 70 mm2

Input cables: Minimum section 50 mm2resp. AWG 1

Use copper conductors 75°C only

S476-gb-0348 User Manual K4000 Page 7 / 48