condensing unit is mounted/integrated, must

be in accordance with the PED.

•Beware of hot and extremely cold components.

•Beware of moving components. Power supply

should be disconnected while servicing.

9 – Filling the system

•Wear protective stuff like goggles and protective

gloves.

•Never start the compressor under vacuum. Keep

the compressor switched off.

•Before charging the refrigerant, verify that the oil

level is between ¼ and ¾ on the compressor oil

sight glass. If additional oil is required please refer

to the compressors label for type of oil.

•Use only the refrigerant for which the unit is

designed for.

•Fill the refrigerant in liquid phase into the

condenser or liquid receiver. Ensure a slow

charging of the system to 4 – 5 bar for R404A /

R507, R22, R452A or R448A/R449A and approx. 2

bar for R134a and R513A.

•Do not put liquid refrigerant through suction line.

•It is not allowed to mix additives with the oil

and/or refrigerant

•The remaining charge is done until the

installation has reached a level of stable nominal

condition during operation.

•Never leave the filling cylinder connected to the

circuit.

10 – Verification before commissioning

Use safety devices in compliance with both

generally and locally applicable regulations and

safety standards.

• Verify that all electrical connections are properly

fastened and in compliance with local regulations.

•When a crankcase heater is required, it must be

energized at least 12 hours before initial start-up

and start-up after prolonged shut-down period.

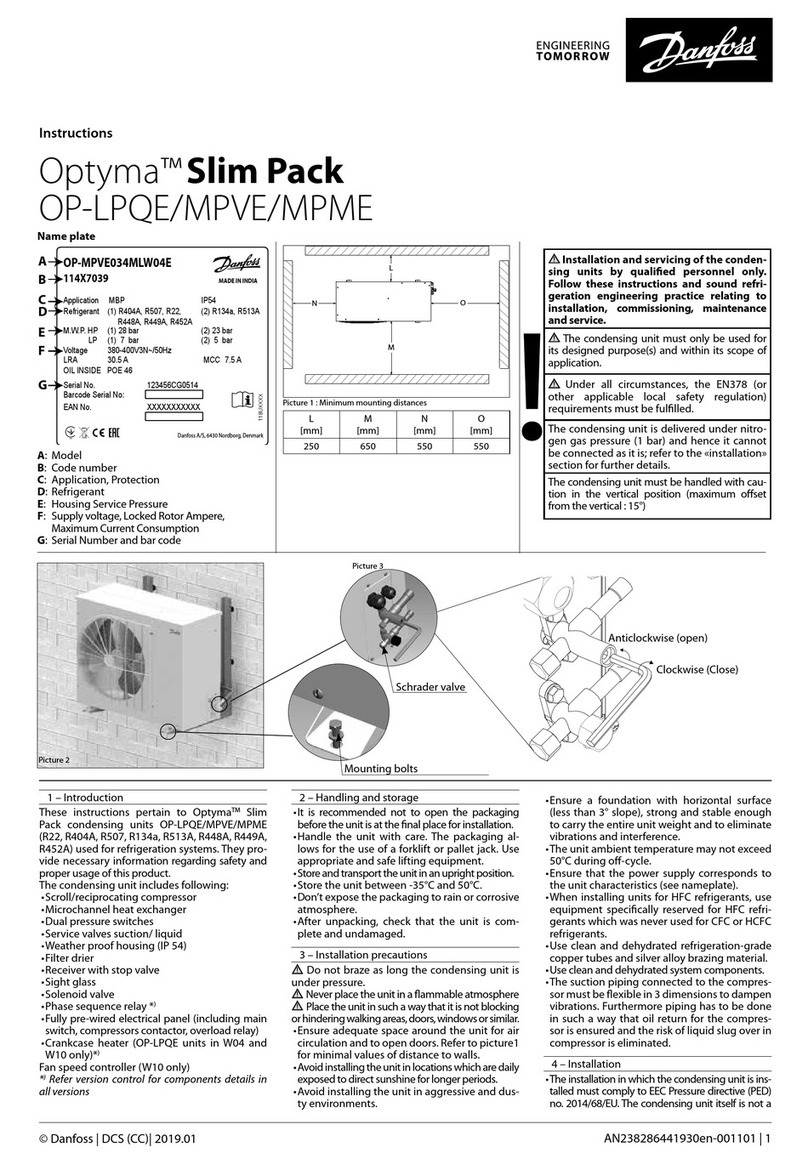

11 – Start-up

•Never start the unit when no refrigerant is

charged.

•All service valves must be in the open position.

See picture 3.

•Check compliance between unit and power

supply.

•Check that the crankcase heater is working.

•Check that the fan can rotate freely.

•Check that the protection sheet has been

removed from the backside of condenser.

•Balance the High Pressure / Low Pressure.

•Energize the unit. It must start promptly. If

the compressor does not start, check wiring

conformity, voltage on terminals and sequence

phase.

•Eventual reverse rotation of a 3-phase

compressor can be detected by following

phenomena; unit doesn’t start, the compressor

doesn’t build up pressure, it has abnormally

high sound level and abnormally low power

consumption. In such case, shut down the unit

immediately and connect the phases to their

proper terminals.

•If the rotation direction is correct the low

pressure indication on the low pressure gauge

shall show a declining pressure and the high

pressure indication on the high pressure gauge

shall show an increasing pressure.

12 – Check with running unit

•Check the fan rotation direction. Air must flow

from the condenser towards the fan.

•Check current draw and voltage.

•Check suction superheat to reduce risk of

slugging.

•When a sight glass is provided observe the oil

level at start and during operation to confirm

that the oil level remains visible.

•Respect the operating limits.

•Check all tubes for abnormal vibration.

Movements in excess of 1.5 mm require

corrective measures such as tube brackets.

•When needed, additional refrigerant in liquid

phase may be added in the low-pressure side

as far away as possible from the compressor.

The compressor must be operating during this

process.

•Do not overcharge the system.

•Never release refrigerant to atmosphere.

•Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

•Record type and amount of refrigerant charge

as well as operating conditions as a reference for

future inspections.

13 – Maintenance

Always switch off the unit at main switch

before remove fan panel.

Internal pressure and surface temperature are

dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related problems, following

Periodic maintenance is recommended:

•Verify that safety devices are operational and

properly set.

•Ensure that the system is leak tight.

•Check the compressor current draw.

•Confirm that the system is operating in a way

consistent with previous maintenance records

and ambient conditions.

•Check that all electrical connections are still

adequately fastened.

•Keep the unit clean and verify the absence of

rust and oxidation on the unit components,

tubes and electrical connections.

The condenser must be checked at least once

a year for clogging and be cleaned if deemed

necessary. Access to the internal side of the

condenser takes place through the fan panel.

Microchannel coils tend to accumulate dirt on

the surface rather than inside, which makes them

easier to clean than fin-&-tube coils.

•Switch off the unit at main switch before remove

any panel from the condensing unit.

•Remove surface dirt, leaves, fibres, etc. with

a vacuum cleaner, equipped with a brush or

other soft attachment. Alternatively, blow

compressed air through the coil from the inside

out, and brush with a soft bristle. Do not use a

wire brush. Do not impact or scrape the coil with

the vacuum tube or air nozzle.

If the refrigerant system has been opened, the

system has to be flushed with dry air or nitrogen

to remove moisture and a new filter drier has to

be installed. If evacuation of refrigerant has to

be done, it shall be done in such a way that no

refrigerant can escape to the environment.

14 - Warranty

Always transmit the model number and serial

number with any claim filed regarding this product.

The product warranty may be void in following

cases:

•Absence of nameplate.

•External modifications; in particular, drilling,

welding, broken feet and shock marks.

•Compressor opened or returned unsealed.

•Rust, water or leak detection dye inside the

compressor.

•Use of a refrigerant or lubricant not approved by

Danfoss.

•Any deviation from recommended instructions

pertaining to installation, application or

maintenance.

•Use in mobile applications.

•Use in explosive atmospheric environment.

•No model number or serial number transmitted

with the warranty claim.

15 – Disposal

Danfoss recommends that condensing

units and oil should be recycled by a

suitable company at its site.

16 - Fan speed controller setting for R134a/R513A refrigerant

FSC type Fan speed Controller

Spare part number

Refrigerant

letter For Refrigerant Factory

setting Action required

XGE-4C

061H3140 Q R404A/R452A/R507

19 bar

360°=1 turn = Approx 1.5 bar

(Clockwise rotation =

Increase pressure setting,

Counter clockwise rotation =

Decrease pressure setting)

V

R404A/R507/R448A/R449A/R452A

If refrigerant used is R134a or R513A

Turn the adjusting screw towards counter-

clockwise (-) by 6 turns to set the pressure

from 19 bar to 10 bar.

Controller will be damaged if this warning is not followed

When Fan speed Controller is at factory setting (19 bar):

- Maximum number of turns allowed in clockwise direction (+) = 4.

- Maximum number of turns allowed in anti-clockwise direction (-) = 6

Instructions

118A0665C - AN238286441930en-001401 | 3

© Danfoss | DCS (CC) | 2020.06