5

1. GENERAL DESCRIPTION

DARAY’s Bilite is the world-renowned dental operating light which employs twin-beam

technology to eliminate shadows in the oral cavity. The light produces a wide, virtually

cold, rectangular light patch with extremely sharp edges.

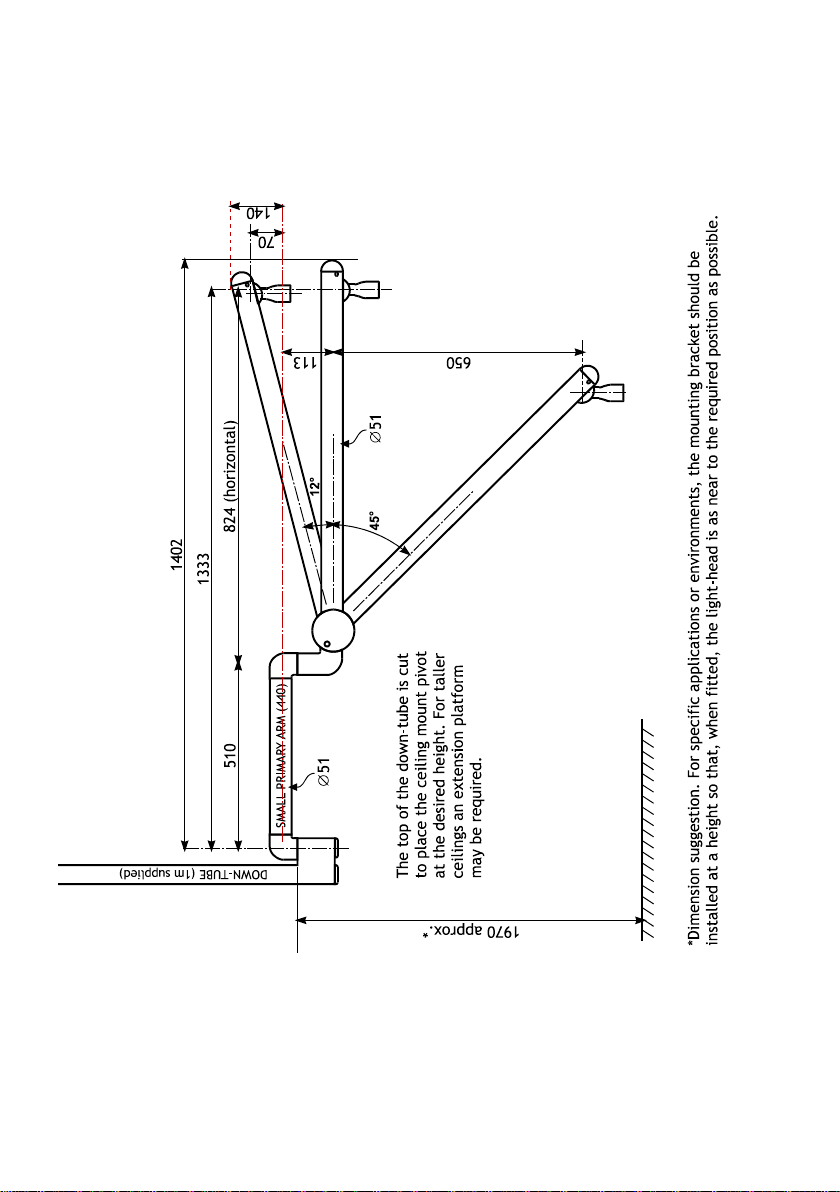

The light head is mounted on DARAY’s sophisticated balanced suspension arm which is light

to move and does not drift once positioned. The Bilite features variable-intensity control on

the wall and ceiling-mounted models, and all versions operate from a safe, low voltage fed

through the suspension arm to the light head.

DARAY’s extremely quick and simple lamp-bar change is retained, allowing blown bulbs to

be swapped quickly without risk of burnt fingers.

The ceiling or wall light comprises 4 parts: a mounting, a variable-intensity power-supply

module, a suspension arm, and the light head. The power-supply module is fitted with an

IEC inlet so the mains may be supplied via a plug-in flex from a standard mains socket. This

arrangement can readily be converted using a parts kit supplied as standard for use where

the mains-electrical supply cables are ‘chased’ into a wall. The power-supply module is

fastened to the wall-mount bracket for the BLLW and can be screwed to the wall to power

the BLLC.

The unit-mounted BLL comes with the light head, suspension arm and separate transformer

for mounting with the chair-package utilities.

2. SPECIFICATION

Light intensity at 0.7m 0 - 26,000 lux

Colour temperature 3,600K

Patch size at 0.7m 300 x 200 mm

230V 50Hz, class 1 (earthed)

Arm reach 1650mm

Jib arm vertical movement +15° to -45°

12V 55W DARAY’s part no: LB1024

2.1 Serial numbers and labelling

Each Bilite is allocated a unique serial number located on the inside of the slip-ring housing,

and is identified by a label affixed to the power-supply module.