Data Flow Systems TCU800 User manual

Installation and

Operation Manual

TCU800

Data Flow Systems, Inc.

Preliminary

Intentionally left blank.

Data Flow Systems, Inc. assumes no responsibility for any errors that may appear in this

document, nor does it make any commitment to update the information contained herein.

However, questions regarding the information contained in this document are welcomed.

Data Flow Systems also reserves the right to make changes to the specications of the

TCU800 and to the information contained in this document at any time without notice.

This document contains information related to special features and functions that are

only available when the TCU is utilized in a DFS TAC II SCADA System. These special

features and functions may not be available when the TCU800 is utilized in a 3rd party

SCADA System. If you are unsure about the availability of a feature or function, please

contact DFS for clarication.

© Data Flow Systems, Inc.

605 N. John Rodes Blvd., Melbourne, FL 32934

Phone 321-259-5009

Fax 321-259-4006

www.dataowsys.com

DFS-00540-011-01

This document was last updated November 17, 2020.

Notice

Data Flow Systems, Inc.

Intentionally left blank.

i

TCU800 User Manual

Preface iii

Purpose of this Manual.....................................................................................................................................................................................................iii

Document Conventions....................................................................................................................................................................................................iii

Abbreviations Used in this Manual..................................................................................................................................................................................iii

1. Safety Precautions 1

General Precautions..........................................................................................................................................................................................................1

Connecting/Disconnecting the TCU.................................................................................................................................................................................1

Protecting against Electrostatic Discharge........................................................................................................................................................................1

2. Product Overview 2

Description.......................................................................................................................................................................................................................2

Features............................................................................................................................................................................................................................3

Compatibility....................................................................................................................................................................................................................4

PIN Names/Wiring Denitions........................................................................................................................................................................................5

3. Unit Overview 9

User Interaction................................................................................................................................................................................................................9

Hand-Off-Auto (HOA) Switches.....................................................................................................................................................................................10

Soft Touch Button............................................................................................................................................................................................................10

USB Ports........................................................................................................................................................................................................................11

Touchscreen.....................................................................................................................................................................................................................11

Monitoring and Control...................................................................................................................................................................................................12

Digital Output Control.....................................................................................................................................................................................................13

Analog Input Monitoring.................................................................................................................................................................................................13

Serial Connectivity...........................................................................................................................................................................................................14

Phase Voltage Monitoring................................................................................................................................................................................................14

Internal Monitoring..........................................................................................................................................................................................................15

Automatic/Manual Control..............................................................................................................................................................................................15

Level Sensing Transducers..............................................................................................................................................................................................16

Internal Phase Monitor....................................................................................................................................................................................................17

Outputs.............................................................................................................................................................................................................................17

Touchscreen.....................................................................................................................................................................................................................18

Electrical Protection........................................................................................................................................................................................................18

Battery Backup (Optional)..............................................................................................................................................................................................18

Principles of Operation...................................................................................................................................................................................................19

Discrete System (Contact Closure Devices)...................................................................................................................................................................19

Analog System (Pressure Transducer)............................................................................................................................................................................21

4. Setup 27

Mounting Instructions.....................................................................................................................................................................................................27

Electrical Installation and Wiring Diagrams....................................................................................................................................................................28

Bias Voltage Source Options............................................................................................................................................................................................33

Installed in RTU...............................................................................................................................................................................................................44

5. User Interface 45

6. Operating Procedures 49

Conguring the Pump Control Process............................................................................................................................................................................49

Main Settings....................................................................................................................................................................................................................50

Alarm Outputs..................................................................................................................................................................................................................51

Floats................................................................................................................................................................................................................................51

Radio................................................................................................................................................................................................................................52

Auxiliary...........................................................................................................................................................................................................................54

Analog..............................................................................................................................................................................................................................55

Pump Monitoring..............................................................................................................................................................................................................57

Phase Monitoring.............................................................................................................................................................................................................57

Contents

ii

MODBUS.........................................................................................................................................................................................................................58

Derived Flow....................................................................................................................................................................................................................59

TCU Settings....................................................................................................................................................................................................................59

Radio Test Mode...............................................................................................................................................................................................................60

Reset Pump Stats..............................................................................................................................................................................................................61

Time..................................................................................................................................................................................................................................61

Auto Conguration...........................................................................................................................................................................................................61

Device Manager................................................................................................................................................................................................................62

Calibrate PMA..................................................................................................................................................................................................................62

Factory Reset....................................................................................................................................................................................................................62

Telemetry Conguration...................................................................................................................................................................................................64

7. Viewing and Troubleshooting Alarms 69

AC Power Fault................................................................................................................................................................................................................69

Auxiliary Input Alarm......................................................................................................................................................................................................70

DC Bias Fault...................................................................................................................................................................................................................70

Float Sequence Fault........................................................................................................................................................................................................71

High Well Alarm...............................................................................................................................................................................................................71

Phase Sequence Fault........................................................................................................................................................................................................71

Phase Voltage Fault...........................................................................................................................................................................................................72

Motor Starter Fault............................................................................................................................................................................................................72

Motor Stop Fault...............................................................................................................................................................................................................73

Transducer Fault................................................................................................................................................................................................................74

Leaving the Alarms Screen...............................................................................................................................................................................................75

8. Modbus Support 76

Appendix

A. Technical Specications 83

B. Checkout Procedure for Pump Controller 84

Step 1: Electrical Termination Review.............................................................................................................................................................................84

Step 2: Operations Testing................................................................................................................................................................................................85

C. Maintenance and Troubleshooting 87

Blown Fuse.......................................................................................................................................................................................................................87

TCU Replacement............................................................................................................................................................................................................88

D. Parts List 89

E. Mounting Instructions 96

F. Well Volume Calculations 101

G. Adding a RIO to the TCU 102

TCU Replacement............................................................................................................................................................................................................102

Congure RIO for Learn Mode........................................................................................................................................................................................103

Mount RIO and Wire AC Power and I/O.........................................................................................................................................................................104

Connect RIO to TCU........................................................................................................................................................................................................104

Place the RIO in Learn Mode...........................................................................................................................................................................................105

Conguring the TCU to Poll the RIO...............................................................................................................................................................................105

Verify Communication Between TCU and RIO...............................................................................................................................................................106

Add and Congure the RIO’s I/O in HT4 or Third-Party HMI........................................................................................................................................106

H. CT Module 108

i

I. TCU Transducer Conguration Examples 114

4-20 mA or 0-5 VDC Transducer with High Float (Pump Down Mode).........................................................................................................................114

4-20 mA or 0-5 VDC Transducer with Floats Backup (Pump Down Mode)...................................................................................................................116

4-20 mA or 0-5 VDC Transducer with Analog Input 2 as Backup (Pump Down Mode).................................................................................................119

Discrete System (Pump Down Mode)...............................................................................................................................................................................121

J. Polling the TCU - DFS Point and Modbus Registers 124

Pump Control Application by Module Letter and Point...................................................................................................................................................124

Pump Control Application by Modbus Register...............................................................................................................................................................130

K. Support, Service, and Warranty 143

Support and Service..........................................................................................................................................................................................................143

Technical Product Assistance............................................................................................................................................................................................143

Return Authorization (RA) Procedure..............................................................................................................................................................................143

Notice................................................................................................................................................................................................................................144

Warranty............................................................................................................................................................................................................................144

Questions or Comments on this Manual...........................................................................................................................................................................145

Glossary 146

ii

Intentionally left blank.

iii

Purpose of this Manual

This manual is a reference guide for installing and operating the TCU800 (Telemetry Control Unit). It contains information

meant to guide and assist in the installation and conguration procedure. This includes mounting and wiring instructions,

product features and specications, I/O listings, instructions for integrating with telemetry, information on Modbus

compatibility, and instructions for conguring and using the TCU’s pump control process. Refer to this manual when

designing, installing, conguring, or troubleshooting systems that use Data Flow Systems’ TCU. For information on

customizing the TCU’s operations, contact DFS.

Document Conventions

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchal information.

• Bold italic type is used for emphasis.

• All CAPITALIZED ITALIC type is used for terminal names.

Abbreviations Used in this Manual

H-O-A – Hand-Off-Auto

I/O – Input/Output

PCU – Pump Control Unit

PLC – Programmable Logic Controller

RTU – Remote Terminal Unit

SCU – Supervisory & Control Unit

TCU – Telemetry Control Unit

BEM – Bus Extender Module

STAT – Status

SSH – Secure Shell

RX – Receive

TX – Transmit

VA C – Voltage Alternating Current

VDC – Voltage Direct Current

Preface

ii

Intentionally left blank.

1

Data Flow Systems, Inc.

1. Safety Precautions

Review the following information before installing, servicing, or replacing the TCU or any of its components.

General Precautions

• Carefully read the installation and wiring instructions before connecting the TCU to its power source.

• If the TCU is to be installed into an existing control panel, make sure all sources of power are de-energized (including

those fed by external sources) before starting the installation.

• Do not work on the TCU or connect/disconnect any of its cables during periods of lightning activity.

• To prevent overheating the TCU, do not operate it in an area that exceeds the recommended temperature range of

-10°C to 60°C (14°F to 140°F). When using the recommended backup battery, the upper temperature limit is 50°C

(122°F).

• Ensure that the unit is connected to earth ground during normal use.

• Precautionary measures must be observed when installing, operating, and servicing the TCU in order to prevent shock.

• All wiring should conform to federal, state, and local electrical codes.

• Read and follow all precautions displayed on the TCU’s side-mounted labels.

Connecting/Disconnecting the TCU

When connecting the TCU:

1. Ensure the cables to be connected to the TCU are routed with sufcient strain relief.

2. Integrate all required wires and connect to the TCU.

3. Close circuit breakers as required; the TCU will start up as soon as power is applied.

When disconnecting the TCU:

1. Power down the unit.

2. Remove all sources of power, including those fed by external sources.

3. Remove all cables connected to the TCU including the ground cable.

4. Move the cables ensuring they will not become entangled in or caught on anything in the surrounding area.

Even if the LCD screen and status LED are not lit, assume the TCU is still powered. The TCU may be in the off

state, and AC power may still be present. To remove power, the external circuit breaker must be opened. Note

that TCU power and 3 phase power may be on separate circuit breakers.

2

Chapter 2

2. Product Overview

Description

The TCU800 is a highly integrated pump controller running an embedded Linux operating system. It is designed to

be backward compatible with its predecessor (TCU001) while including additional feature enhancements to expand its

operability.

There are several options for using the TCU’s multiple input/output (I/O) points:

• They can be used in the default pump control application.

• They can be used with custom logic (i.e. Ladder logic). Contact DFS for more information.

Additionally, the TCU:

• Can communicate with and manipulate the I/O points of up to 15 remote modules via a radio or network link.

• Can be incorporated into a Remote Terminal Unit (RTU) by using a Bus Extender Module (BEM).

The default pump control application program enables the TCU to be easily implemented in lift station or storage tank

applications. The TCU contains all the hardware and software needed to control up to three motor starters.

Placing custom logic on the TCU enables it to perform a variety of automated tasks when interfaced with other telemetry

Modbus-capable devices and equipment (DFS equipment or other devices using RS-485 or RS-232). Custom logic can

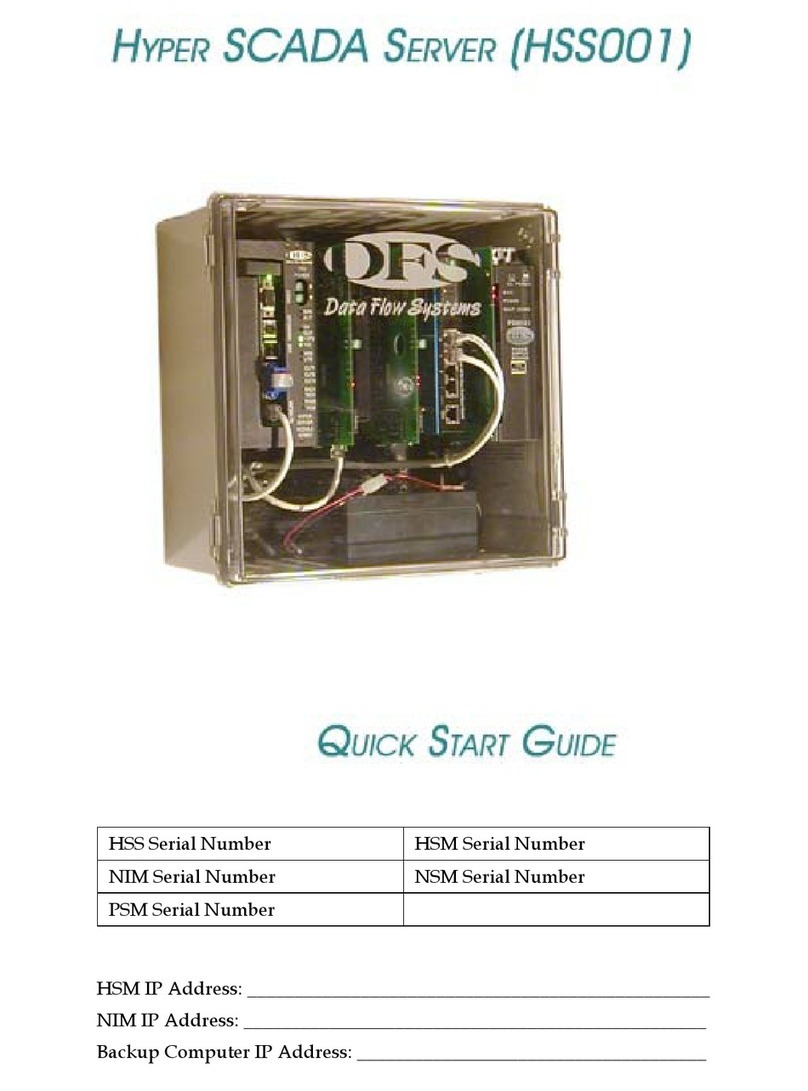

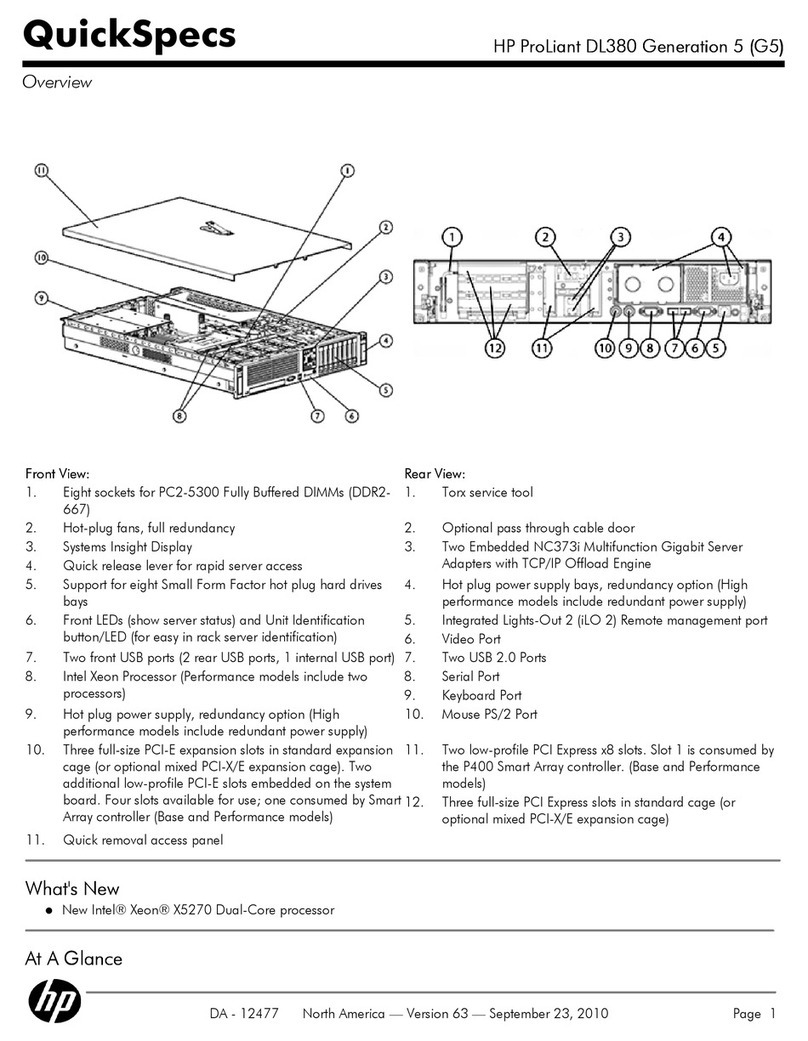

Hand-Off-Auto switches

Connectorized terminals P2 & P4

Receive & transmit LEDs Power/Home button

LCD touchscreen display

Connectorized terminals P1 & P3

Two USB ports (service port)

Ground screw

Alarm LED

Status LED

Pump Status LEDs

3

Product Overview

True RMS AC Phase Monitor True RMS AC phase monitor produces voltage readings for single- and three-phase

power.

H-O-A Switches

The H-O-A switches are fail-safe; they remain operational even if the TCU fails or

loses power. They will continue to function in the “Hand” and “Off” positions with the

TCU in a faulted state or powered down.

Integrated Radio The TCU’s integrated digital radio is on-site programmable and can run in legacy or a

high-speed mode.

Battery Backup with

Integrated Charger

The TCU supports a 12VDC sealed lead acid battery and a 3 amp maximum current

charger.

Display / Interface

A touch screen LCD provides a large area for displaying data and menu navigation.

One soft-touch home button allows the user to power up/down the TCU with a single

touch, and seven LEDs provide system status at a glance.

Serial Connectivity

Standard RS-232 Modbus radio interface acts as an interface (slave only) to external

industry standard radios.

RS-485 Modbus half-duplex serial interface (master only) enables communication

with industry standard devices and VFD motor controllers.

Network Adapter An integrated 10/100 network adapter allows remote access via SSH client over a local

area network.

USB/Service Port

Three full speed USB 2.0 ports (2 external/1 internal) storing station address, cong-

uration proles, and pump statistics. Provides Ethernet connectivity with additional

USB-to-ETH adapter.

Protection Protective features include an integrated, regulated power supply, surge protection,

and isolation on all I/Os, and an externally-accessible fuse.

Protocols Supported Protocols supported are Modbus (ASCII/RTU) over RS485 or RS232, TAC II and DFP

3.0 over radio and BEM, and DFS NIM and Modbus TCP over TCP/IP.

Pump Run Time Meters Elapsed run time, average run time, and pump cycle counters are provided in software

for each pump.

Self-Monitoring

Self-monitoring capabilities include radio current, temperature, battery voltage/

charging current, AC power, bias fault, process and error logging with option to backup

to a USB drive.

control and monitor the six onboard digital outputs, 18 digital inputs and four analog inputs. It also features an expansion

card slot which can be used to add additional I/O points for specialized applications, such as controlling VFD pumps.

Features

4

Chapter 2

Compatibility

Please note that the PCU, PCU TAC Pack, SCU, and SCU TAC Pack are not “upward” compatible with the TCU800.

DFS’ Sales Department can provide assistance with ensuring that your system has appropriate replacement units on hand.

Contact DFS’ Sales Department (321-259-5009 or sales@dataowsys.com) for more information.

When comparing the TCU001 and the TCU800, use the following table to review features that have been removed,

replaced, and added to the TCU800.

Custom Logic Capable of running custom programming. Supports ladder logic or scripting that re-

places the default pump control application. Contact DFS for more information.

Connectorized Wire

Terminals

Four connectorized wire terminals allow servicing or replacement of the unit without

disconnecting wires.

Mounting Options Mounting options allow the TCU to be mounted to a front panel as well as mounted

ush against or stood off from the back plate of a control panel.

Legacy TCU001 Operation

The TCU800 is backward compatible with the TCU001. Existing TCU001

congurations can be transferred to the TCU800. For detailed instructions, see the

compatibility chart below.

Enclosure Anodized aluminum, sealed and shielded when connected to Earth ground via

grounding screw.

Inputs/Outputs

18 Digital Inputs supporting voltage-driven signals (Pulse input can be used with

pulse-type ow meters and rain gauges)

6 Digital Outputs (4 solid-state relays designed to drive inductive loads & 2 electrome-

chanical relays designed to drive horn and light)

4 Analog Inputs for well level and auxiliary measurement

5

Product Overview

PIN Names/Wiring Denitions

Pump Control Applications

Top Connector 1: P1

PIN# Name Description Electrical Rating Module

Address

P1-1 PHASE_C Phase C of the three-phase power monitor 120-240VAC, 60HZ,

10mA, 3-phase

C4

P1-2 PHASE_B Phase B of the three-phase power monitor 120-240VAC, 60HZ,

10mA, 3-phase

C3

P1-3 PHASE_A /

PHASE_N

Phase A of the three-phase power monitor in 3-Wire

(delta)

Neutral of the three-phase power monitor in 4-Wire

(wye)

120-240VAC, 60HZ,

10mA, 3-phase

B11

P1-4 PHASE_A Phase A of the three-phase power monitor in 4-Wire

(wye) only

120-240VAC, 60HZ,

10mA, 3-phase

--

P1-5 AC_PWR AC power 120VAC, 60HZ, 0.5-1.5A B9

P1-6 AC_NEUT AC neutral 120VAC, 60HZ, 0.5-1.5A --

P1-7 TGND Safety ground (Earth) Ground --

P1-8 BAT+ Backup battery positive terminal <24V / Not Rated --

P1-9 BAT- Backup battery negative terminal <24V / Not Rated --

By default, the TCU800’s new digital and analog inputs are disabled so as not to conict with any pre-congured MODBUS

devices that may be occupying modules H through O. In order to enable the new I/O, which will be dynamically assigned

at the next available module space, see procedure on page 82.

Added

Expansion card slot - allows for future expansion of I/O using a DFS TCU800 expansion card

Ethernet/USB - internal base 10/100 Mbps support and 3 full speed USB ports (2 external, 1 internal)

Additional I/O - 6 extra digital inputs and 2 extra analog inputs (replaces address strap connector)

Protection & robustness - improved protection and durability of phase monitor adapter, digital outputs, and serial

communication buses (all electrically isolated)

Replaced

TCU001 TCU800

Address strap USB personality drive stores conguration and backs up logs and statistics

Microcontroller Linux-based operating system allows for advanced programmability and

upgrade-ability

Keypad and input LEDs Capacitive touch screen and LCD display

Service Port USB-to-Ethernet adapter

Removed

Autodialler - no longer available

6

Chapter 2

Top Connector 2: P3

PIN# Name Description Electrical Rating Module

Address

P3-1 C_CT+ C-phase current transformer positive connection <24V / Not Rated

P3-2 C_CT- C-phase current transformer negative connection <24V / Not Rated

P3-3 B_CT+ B-phase current transformer positive connection <24V / Not Rated

P3-4 B_CT- B-phase current transformer negative connection <24V / Not Rated

P3-5 A_CT+ A-phase current transformer positive connection (wye

setup only)

<24V / Not Rated

P3-6 A_CT- A-phase current transformer negative connection

(wye setup only)

<24V / Not Rated

P3-7 ANALOG3+ 0-5VDC or 0-10VDC or 4-20mA signal from trans-

ducer; return signal at P3-8; jump P3-9 to P3-8 to use

as a 4-20mA input

<24V / Not Rated I1*

P3-8 ANALOG3- - return signal for ANALOG3+ (P3-7) <24V / Not Rated

P3-9 SHUNT 250Ω shunt resistor; jump to P3-8 to use a 4-20mA

signal for ANALOG3+ (P3-7)

<24V / Not Rated

P3-10 ANALOG4+ 0-5VDC or 0-10VDC or 4-20mA signal from trans-

ducer; return signal at P3-11; jump P3-12 to P3-11 to

use as a 4-20mA input

<24V / Not Rated I2*

P3-11 ANALOG4- - return signal for ANALOG4+ (P3-10) <24V / Not Rated

P1-10 BEMGND Isolated ground (wire to BEM001, pin 12) <24V / Not Rated --

P1-11 BEM_PWR Isolated power (wire to BEM001, pin 10) <24V / Not Rated --

P1-12 BEM_CTS Isolated clear to send (wire BEM001, pin 6) <24V / Not Rated --

P1-13 BEM_RXD Isolated receive data (wire to BEM001, pin 4) <24V / Not Rated --

P1-14 BEM_TXD Isolated transmit data (wire to BEM001, pin 2) <24V / Not Rated --

P1-15 BEM_RTS Isolated request to send (wire to BEM001, pin 8) <24V / Not Rated --

P1-16 ALM_HORN Load side of alarm horn relay (NO) 120VAC, 60HZ, 1A,

0-24VDC, 1A

B5

P1-17 ALM_LITE Load side of alarm light relay (NC) 120VAC, 60HZ, 1A,

0-24VDC, 1A

B6

P1-18 ALM_PWR Line side of alarm relays 120VAC, 60HZ, 2A,

0-24VDC, 2A

--

P1-19 AUX_OUT Load side of auxiliary relay 120-240VAC, 60HZ, 1A,

Pilot Duty

B4

P1-20 AUX_PWR Load side of auxiliary relay 120-240 VAC, 60HZ, 1A --

P1-21 MTR3_STR Load side of motor starter 3 relay 120-240 VAC, 60HZ, 1A,

Pilot Duty

B3

P1-22 MTR2_STR Load side of motor starter 2 relay 120-240 VAC, 60HZ, 1A,

Pilot Duty

B2

P1-23 MTR1_STR Load side of motor starter 1 relay 120-240 VAC, 60HZ, 1A,

Pilot Duty

B1

P1-24 STRT_PWR Line side of motor start relays 120-240 VAC, 60HZ, 3A --

7

Product Overview

Bottom Connector 1: P2

PIN# Name Description Electrical Rating Module

Address

P2-1 MTR1_RUN Motor 1 run digital monitor input 10-30VAC/DC, 10mA A1

P2-2 MTR2_RUN Motor 2 run digital monitor input 10-30VAC/DC, 10mA A2

P2-3 MTR3_RUN Motor 3 run digital monitor input 10-30VAC/DC, 10mA A3

P2-4 EXT_PM External phase monitor digital monitor input 10-30VAC/DC, 10mA A4

P2-5 IN_COM_1 Common return for motor run and external phase

monitor input

10-30VAC/DC, 100mA

RTN

--

P2-6 LOW_LVL Low Level digital monitor input 10-30VAC/DC, 10mA A5

P2-7 OFF_LVL Off Level digital monitor input 10-30VAC/DC, 10mA A6

P2-8 LEAD_LVL Lead Level digital monitor input 10-30VAC/DC, 10mA A7

P2-9 LAG1_LVL Lag1 Level digital monitor input 10-30VAC/DC, 10mA A8

P2-10 LAG2_LVL Lag2 Level digital monitor input 10-30VAC/DC, 10mA A9

P2-11 HIGH_LVL High Level digital monitor input 10-30VAC/DC, 10mA A10

P2-12 AUX_IN Auxiliary digital monitor input; supports pulse count-

ing

10-30VDC, 10mA A12

P2-13 ALM_SIL Alarm Silence Switch digital monitor input 10-30VAC/DC, 10mA B7

P2-14 IN_COM_2 Common return for input level, aux inputs, and alarm

silence switch

10-30VAC/DC, 100mA

RTN

--

P2-15 ISOGND Internally supplied 24VDC bias source return (isolated) <24V / Not Rated --

P2-16 ISO+24V Internally supplied 24VDC bias source voltage (isolat-

ed)

<24V / Not Rated B10

P2-17 TXD_232 RS-232 transmit data to external device <24V / Not Rated --

P2-18 RXD_232 RS-232 receive data from external device <24V / Not Rated --

P2-19 GND RS-232 ground <24V / Not Rated --

P3-12 SHUNT 250Ω shunt resistor; jump to P3-11 to use a 4-20mA

signal for ANALOG4+ (P3-10)

<24V / Not Rated

P3-13 SHIELD Internally connected to chassis ground; cable shield

for analog monitor signals

Ground

P3-14 IN_COM_3 Common return for thermal and seal failure digital

outputs

10-30VAC/DC, 100mA

RTN

P3-15 MTR3_

THERM

Motor 3 temperature monitor input 10-30VAC/DC, 10mA H6*

P3-16 MTR2_

THERM

Motor 2 temperature monitor input 10-30VAC/DC, 10mA H5*

P3-17 MTR1_

THERM

Motor 1 temperature monitor input 10-30VAC/DC, 10mA H4*

P3-18 MTR3_SEAL Motor 3 moisture seal monitor input 10-30 VAC/DC, 10mA H3*

P3-19 MTR2_SEAL Motor 2 moisture seal monitor input 10-30 VAC/DC, 10mA H2*

P3-20 MTR1_SEAL Motor 1 moisture seal monitor input 10-30 VAC/DC, 10mA H1*

*When the new I/O is enabled, it will move to the next available module if H and I are already congured.

8

Chapter 2

Bottom Connector 2: P4

PIN# Name Description Electrical Rating Module

Address

P4-1 Unused Reserved for future use; do not connect Not connected --

P4-2 RS485_GND RS-485 serial ground reference <24V / Not Rated --

P4-3 RS485_B RS-485 serial interface B <24V / Not Rated --

P4-4 RS485_A RS-485 serial inferface A <24V / Not Rated --

P4-5 SHIELD Internally connected to chassis ground; Cable shield for

RS-485 or RS-232

Ground --

P4-6 EX_GND_

RAD

RS-232 signal ground <24V / Not Rated --

P4-7 RTS_RAD RS-232 request to send <24V / Not Rated --

P4-8 EX_TXD_

RAD

RS-232 transmit data to external device <24V / Not Rated --

P4-9 EX_RXD_

RAD

RS-232 recieve data from external device <24V / Not Rated --

P4-10 CTS_RAD RS-232 clear to send <24V / Not Rated --

P4-11 SDI12_GND SDI-12 return/ground <24V / Not Rated --

P4-12 SDI12_DATA SDI-12 data <24V / Not Rated --

P4-13 SDI12_PWR 12VDC power supply for SDI-12 bus devices <24V / Not Rated --

P4-14 Unused Reserved for future use; do not connect Not Connected --

P2-20 SHIELD Internally connected to chassis ground; cable shield for

analog monitor signals

Ground --

P2-21 ANALOG2+ 4-20 mA signal from transducer; - signal at pin P2-23;

internal 250Ω shunt permanently connected

<24V / Not Rated C2

P2-22 ANALOG1+ 0-5VDC or 0-10VDC or 4-20 mA signal from trans-

ducer; - signal at pin P2-24 to P2-23 to use as 4-20 mA

input

<24V / Not Rated C1

P2-23 ANALOG- - signal return for both ANALOG1+ at P2-22 and

ANALOG2+ at P2-21

<24V / Not Rated --

P2-24 SHUNT 250Ω shunt resistor; jump to P2-23 to use a 4-20 mA

signal for ANALOG1+ at P2-22

<24V / Not Rated --

9

Unit Overview

3. Unit Overview

The following sections describe what the available features of the TCU800 are and how they monitor and operate various

parts of the pump control systems. The descriptions are from the perspective of the TCU800 as a unit interacting with a

pump control system.

User Interaction

The TCU800 provides local statuses and has mechanisms for user control locally and remotely. The interaction points are

the following: faceplate, USB ports, touch screen, and serial connectivity. The front of the TCU800 is called the faceplate.

It consists of LEDs, a soft touch button, access for USB ports, HOA switches, and a touch screen. The main purposes of

the faceplate are to provide the user with the status of the system at a glance, TCU800 operation, manual pump operation,

and conguration access.

LEDs

LEDs allow the user to quickly determine the statuses of pumps, pump control processes, radio trafc, and alarms. All

LEDs are red.

Pump Status

On/Off: A pump status LED, located under each HOA switch, is on when an associated pump is running. The LED is

off when an associated pump is stopped. The running/stopped status of a pump is provided via the digital input Motor

# Status, where # is the associated pump number 1, 2, or 3.

Flashing: A pump status LED will ash when an associated pump is overridden via telemetry or a motor start or stop

fault has occurred. Flashing will continue for a fault until the pump has properly run or the HOA switch for that pump

is taken out of Auto.

Alarm

On/Off: The alarm LED is on when any alarming condition is active, and all active alarming conditions have been

acknowledged. The LED is off when all alarming conditions are clear.

Flashing: The alarm LED will ash when there is an alarming condition that has not been acknowledged or cleared.

Flashing will continue until every alarming condition present has been acknowledged or cleared. Some alarms clear

without user action, causing the alarm light to stop ashing and clear (if no other alarming conditions are present).

Status

On/Off: The status LED is used to verify the control program is running. When the status LED is not illuminated, the

logic process is no longer running.

Flashing: The status LED will ash during system start up.

Start up Sequence: The status LED (with all other LEDs) illuminates when the power is applied to the TCU800. The

LEDs will remain on for 15 seconds and then turn off. After an additional 5 seconds, the status LED will ash until the

system has completed the start up. The status LED will now remain illuminated.

10

Chapter 3

RX/TX

Blinking: The RX/TX LEDs blink (on to off) when a message is received or transmitted, respectively.

Stuck On/Off: If either LED is constantly on or off, there may be an issue in hardware or software.

Hand-Off-Auto (HOA) Switches

The TCU800 face plate has three fail-safe HOA switches corresponding to the three pumps it can control. Each switch

controls only the associated pump, individually. The switches have three positions: left (Hand), center (Off), and right

(Auto). If pump starter power is present, then the switches allow hand and off operation of pumps regardless of the state

of the software or power to the unit.

Hand

Placing the switch in the hand position overrides the automatic output of the TCU800 and forces the corresponding pump

on.

Off

Placing the switch in the off position overrides the automatic output and remote control of the TCU800 and forces the

corresponding pump off.

Auto

Placing the switch in the auto position allows automatic operation of the corresponding pump. The state of the pump is

being controlled by the operating logic program and telemetry override and disabled statuses. See the telemetry control

section for more information.

Motor Fault Reset

If a motor starter fault occurs, it is reset by placing the corresponding HOA switch in Hand or Off.

Soft Touch Button

The TCU800 has a single soft touch button labeled with a home symbol. The button is located on the right side of the face-

plate, below the Alarm LED and above the USB ports. The purposes of the button are as follows: to power the unit on or

off, to wake up the display, to return to the home screen, and to acknowledge alarms to prevent the alarm horn sounding.

Powering Off a Unit

Press and hold the button for approximately 3 to 5 seconds. When the blue TCU800 screen appears, release the button.

Failure to release the button within 6 seconds will cause a complete reboot instead of a shut down.

Powering On a Unit

If the unit was powered off according to the previous section, then the unit will power on with a single press of the button.

Rebooting a Unit (with Software Timer)

Press and hold the button for approximately 10 seconds. The unit will shut down as in the previous section, however, it will

Other manuals for TCU800

1

Table of contents

Other Data Flow Systems Server manuals

Popular Server manuals by other brands

NEC

NEC NEC Express5800 Series user guide

Bull

Bull NovaScale T810B F2 manual

Dell

Dell PowerEdge 2800 Specifications

SpectraLink

SpectraLink NetLink SVP010 Installation, configuration and administration

BITMAIN

BITMAIN ANTMINER S19a installation guide

DEC

DEC DECstation 5000 Model 100 Series Maintenance Guide