DATA PRECISION 938 User manual

Instruction

Manual

for

MODEL

938

Hand-Held,

Pocket-Portable

3

1

/2

Digit

CAPACITANCE

METER

Publication

No

42-5124

■□ATA

PRECISION

42-5124

MODEL

938

PROPRIETARY

NOTICE

The

information

contained

in

this

publication

is

derived

in

part

from

proprietary

and

patent

data

of

the

Data

Precision

Corporation.

This

information

has

been

prepared

for

the

express

purpose

of

assisting

operating

and

maintenance

personnel

in

the

efficient

use

of

the

instrument

described

herein.

Publication

of

this

information

does

not

convey

any

rights

to

use

or

reproduce

it

or

to

use

for

any

purpose

other

than

in

connection

with

the

installation,

operation

and

maintenance

of

the

equipment

described

herein.

First

Edition

arch,

1979

Copyright

1979

DATA

PRECISION

CORPORATION

Printed

in

USA

all

rights

reserved.

42-5124

MODEL

938

CONTENTS

1

INTRODUCTION

1.1

General

Description

1.2

Operating

Features

2

SPECIFICATIONS

2.1

Capacitance

easurement

2.2

Functional

Characteristics

2.3

Power

2.4

Accessories

Supplied

2.5

Options

/

Accesories

3

OPERATION

AND

RECALIBRATION

3.1

General

3.2

Unpacking

&

Repacking

odel

938

3.3

Installing

(or

Replacing)

the

Battery

3.4

Operating

Controls

&

Indicators

3.5

aking

easurements

with

odel

938

3.6

Recalibrating

odel

938

3.7

Operation

4

PRINCIPLES

OF

OPERATION

4.1

Basic

Concepts

4.2

System

Block

Diagram

4.3

Signal

Conditioning

Details

4.4

Signal

Conditioning

Control

Logic

4.5

A/D

Converter

Details

4.6

Display

4.7

Power

Supply

5

MAINTENANCE

5.1

General

5.2

Trouble

Shooting

Strategy

5.3

Safety

Precautions

and

Procedures

5.4

Closed-Case

Trouble

Shooting

5.5

Open-Case

Details

6

PARTS

LISTS

6.1

Ordering

Information

Reference

Schematic

42-5124

MODEL

938

mtispiece

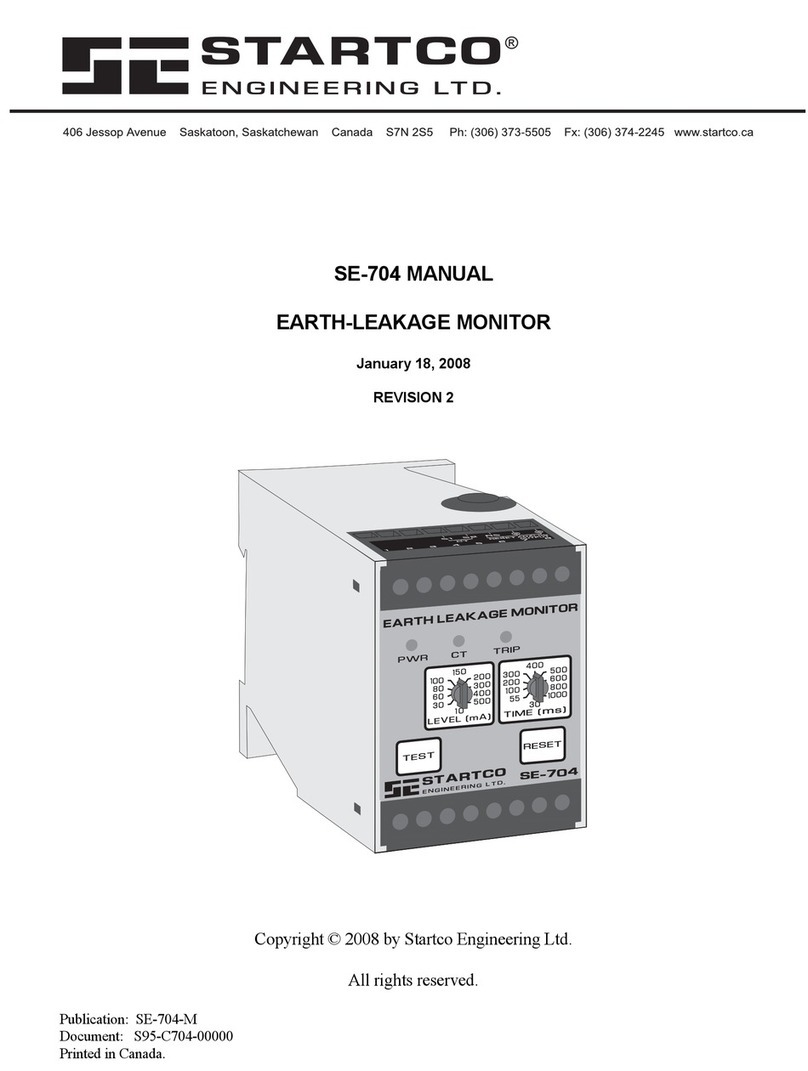

Model

938

Digital

Capacitan

ce

Meter

MODEL

938

INTRODUCTION

Chapter

1

INTRODUCTION

1 1

GENERAL

DESCRIPTION

Data

Precision

Model

938

Digital

Capacitance

Meter

(Frontis

piece)

is

a

hand-held,

portable,

field

and

laboratory,

3

1

/z-digit

capacitance

meter.

It

employs

a

unique

circuit

(patent

pending)

that

provides

accuracy,

stability,

and

noise

immunity

not

previously

obtainable

in

low-cost

capacitance

meters.

The

meter's

eight

(8)

range

scales,

providing

the

user

with

nominal

full

scale

values

from

200

pF

to

2000

gF

(in

decade

steps),

with

corresponding

resolutions

from

0.1pF

to

1

gF,

make

this

instrument

a

useful

tool

in

a

wide

range

of

applications.

Reduced

component

count,

the

use

of

low-powered

C OS

IC

’

s,

and

the

use

of

a

liquid

crystal

display

all

contribute

to

reliable

performance

over

an

extended

battery

life

(100

to

200

hours

with

normal

usage).

Optionally,

an

accessory

Battery

Eliminator

(Data

Precision

odel

BE9)

may

be

used

to

power

the

instrument

from

local

ac

sources.

The

BE9

is

available

for

each

of

the

standard

supplies

(100VAC,

117VAC,

200VAC,

or

240VAC).

The

odel

938

is

assembled

in

the

new

Data

Precision

standard

hand-held

mini

case

configuration,

molded

of

high-impact

Noryl*

plastic,

and

resistant

to

shock

and

vibration

in

even

the

most

stringent

of

field

environmental

applications.

The

odel

938

is

supplied

with

battery

and

spare

fuse,

and

is

ready

to

use

as

soon

as

the

battery

iS

installed

in

the

case

(see

Chapter

3).

The

front

panel

includes

standard

banana-jack

recep

tacles,

as

well

as

recessed

spring-clip

connectors

with

select

able

spacing

for

capacitor

leads

of

varying

separations.

A

stan

dard

banana-plug

to

alligator

clips

test

lead

set

(T9)

is

included

in

the

standard

configuration.

‘

Registered

trademark.

1-1

42-5124

MODEL

938

1 2

OPERATING

FEATURES

odel

938

input

circuitry

is

protected

by

a

1/4-amp

Fast-Bio

fuse

against

input

overloads.

The

liquid

crystal

display

assembly

is

built

around

large

(0.5")

digits,

and

is

easily

read

under

a

wide

range

of

ambient

lighting

conditions,

indoors

or

out.

The

decimal

point

is

automatically

positioned

in

the

display

by

the

action

of

selecting

the

range

scale,

so

that

the

results

may

be

read

directly

in

the

units

established

by

the

range

scale

selected.

The

full

scale

range

values

are

printed

adjacent

to

the

range-scale

-select

pushbuttons,

and

include

the

capacitance

units,

as

well

as

the

values.

Out-of-range

values

are

indicated

by

blanking

all

but

the

SD

and

decimal

point.

This

prevents

erroneous

readings,

while

at

the

same

time

providing

an

indication

of

an

operable

meter.

The

meter

also

contains

a

sense

and

display

cir

cuit

to

Indicate

when

the

battery

(or

ac

source

power)

is

low.

Ap

pearance

of

the

LO

BAT

display

indicates

that

the

battery

is

below

7

volts,

or

that

the

ac

source

is

at

a

lower

voltage

than

specified.

One

internal

trimmer

is

used

to

calibrate

the

meter

for

accuracy

on

all

ranges.

One

external

thumbwheel

adjusts

the

zero

and

simplifies

the

meter

use

from

one

application

to

another

where

different

levels

of

stray

capacitance

to

affect

the

measurement

results.

1-2

MODEL

938

SPECIFICATIONS

Chapter

2

SPECIFICATIONS

2 1

CAPACITANCE

MEASUREMENT

NOMINAL

RANGE

MAX

IN-RANGE

DISPLAY

RESOLUTION

200

pF

199.9

pF

0.1

pF

2

nF

1.999

nF

1

pF

20

nF

19.99

nF

10

pF

200

nF

199.9

nF

100

pF

2

m

F

1.999

m

F

1000

pF

20

m

F

19.99

m

F

0.01

m

F

200

m

F

199.9

m

F

0.1

m

F

2000

m

F

1999

m

F

1

m

F

Accuracy

(1

yr ,

23°C

±

5°C):

±(0.1%

Reading

+

1

digit

+

0.5pF)

Except

±(1.0%

reading

+

1

digit)

on

2000

m

F

range).

Temperature

Coefficient:

±(0.01%

input

+

0.01

%range)/°C

Except

±(0.02%

input

+

0.02%

range)/°C

on

200

pF

and

2000

m

F

range.

Excitation

Voltage:

2.8

volts

peak,

maximum

High

input

terminal

is

always

more

positive

than

low

ter

minal

Measurement

Technique:

Dual-slope

integrating

A/D

converter;

measures

ratio

of

change

in

charge

to

change

in

voltage

(Capacitance).

Overload:

Input

protected

by

1/4

amp

250V

fuse

Controls:

Eight

range

push

buttons,

On/Off,

and

zero

adjust.

2-1

42-5124

MODEL

938

2 2

FUNCTIONAL

CHARACTERISTICS

Display

0.5"

(13mm)

liquid

crystal

Reading

Rate:

2.0

readings

/sec.

Overload

Indication:

Blanking

of

all

digits

except

SD

and

decimal

point

Calibration

Adjustments:

One

internal

adjustment

for

accuracy

One

front-panel

adjustment

for

zero

2.3

POWER

Power

Supply:

9V

standard

battery

or

optional

battery

eliminator

BE9

Battery

Life:

Approximately

200

hours

on

alkaline

or

100

hours

on

car

bon

zinc

battery

with

normal

usage

2 4

PHYSICAL

&

ENVIRONMENTAL

Size:

6.75"L

x

3.5"W

x

1.5"H

(170mm

x

89mm

x

38mm)

2 4

ACCESSORIES

SUPPLIED

Operator

’

s

and

aintenance

anual

Warranty

Card,

Certificate

of

Conformance

,

and

Final

Test

and

Calibration

Certification

in

a

combined

document

9V

Battery

Spare

Fuse

Banana

plug

to

alligator

clips

Test

Leads

(T9)

2 5

OPTIONS/ACCESSORIES

Test

Leads

with

alligator

clips

........................................................

T9

Banana

plug

mounted

test

clip

...................................................

LC1

Battery

Eliminator

.........................................................................

BE9

2-2

MODEL

938

OPERATION

&

RECALIBRATION

Chapter

3

OPERATION

AND

RECALIBRATION

3 1

GENERAL

Chapter

3

contains

instructions

for

installing

(or

replacing)

the

battery,

for

connecting

the

odel

938

to

make

a

measurement,

for

recalibrating

the

capacitance-meter,

and

hints

for

obtaining

the

high

performance

designed

into

the

instrument.

3 2

UNPACKING

AND

REPACKING

THE

MODEL

938

a

As

shown

in

Figure

2-1,

the

odel

938

is

placed

in

a

water

proof

plastic

wrapper,

securely

fitted

between

molded

plastic

foam

shock

isolators,

and

placed

with

the

documentation

and

battery

in

the

shipping

carton.

When

unpacked,

you

should

find:

(1)

odel

938

Digital

Capacitance-meter

(2)

Certificate

of

Conformance,

Factory

Test

Certification,

and

Warranty

Card

(combined

in

one

document)

(3)

Spare

1/4A

250V

3AG

Fast

Bio

Fuse,

inside

multimeter

bottom

cover

(4)

9V

zinc-carbon

battery,

outside

of

multimeter.

(5)

Test

lead

set

T9

(6)

Instruction

manual

b.

Carefully

examine

these

articles,

noting

especially

the

match

ing

serial

numbers

of

the

instrument

and

the

test

certification.

Inspect

the

packing

case

and

the

instrument

for

any

signs

of

damage

during

shipment

and

report

immediately

to

the

carrier.

Fill

out

and

return

the

warranty

card

to

register

your

instrument

and

to

establish

your

warranty

service

interval.

c

Accessories,

such

as

test

leads

and

battery

eliminator,

may

have

been

ordered.

These

will

be

shipped

in

their

own

con

tainers.

d

Retain

the

packing

material

for

reshipment.

When

shipping

odel

938,

use

foam

liners

and

pack

in

original

carton,

if

available.

If

new

wrapping

and

shipping

container

must

be

used,

wrap

the

instrument

in

at

least

3

inches

of

shock

isolating

material,

such

as

bubble

plastic,

and

fasten

securely

in

the

con

tainer.

3-1

42-5124

MODEL

938

Figure

3-1

Model

938

Shipping

Configuration

3 3

INSTALLING

(OR

REPLACING)

THE

BATTERY

Figure

3-2

illustrates

the

procedure

for

installing

(or

replacing)

the

battery

in

odel

938

Capacitance-meter.

Proceed

as

follows:

(1)

Be

sure

power

switch

is

OFF.

(2)

Remove

any

input

connections.

(3)

Remove

the

fastening

screw

holding

the

bottom

cover

in

place.

(4)

Remove

the

bottom

cover.

(5)

Remove

old

battery

(if

replacing

it).

(6)

Attach

the

battery

clip

to

the

9V

battery.

(7)

Place

the

battery

in

the

battery

space.

(8)

Replace

the

bottom

cover

and

its

fastening

screw.

3-2

MODEL

938

OPERATION

&

RECALIBRATION

Figure

3-2

Installing

(or

Replacing)

Battery

in

Model

938

3 4

OPERATING

CONTROLS

&

INDICATORS

Figure

3-3

illustrates

the

operating

features

of

the

odel

938

C- eter.

The

range

switches

are

interlocked

so

that

only

one

range

selection

may

be

operative

at

any

one

time.

(Note,

however,

that

all

switches

may

be

placed

in

the

“

out

”

position

if

the

selected

range

pushbutton

is

not

pushed

all

the

way

in.)

Table

3-1

describes

the

items

referenced

in

the

illustration

and

the

functions

performed

by

each.

3-3

42-5124

MODEL

938

Figure

3-3

Model

938

Front

Panel

Features

3-4

MODEL

938

OPERATION

&

RECALIBRATION

MODEL

938

OPERATING

CONTROLS

&

FEATURES

Table

3-1

FIG

BEE

NAME/DESCRIPTION

FUNCTION

1.

Display

value

3

full

decades

plus

1 SD

(3Vz

digits);

liquid

crystal;

automatic

positioning

of

decimal

point.

2.

LO

BAT

Display

message

when

battery

(or

line

voltage

when

using

Battery

Eliminator)

is

less

than

the

present

level.

Normal

operation

is

possible

for

a

few

hours

after

the

LO

BAT

indica

tion

first

appears.

3.

Eight

range

pushbut

tons

Interlocked

switches.

Depress

ing

one

switch

automatically

releases

another

in

the

set

of

eight.

4.

Capacitor

lead

con

nectors

Spring

contacts

spaced

for

convenient

insertion

of

capacitor

leads.

Polarized

for

use

with

polarized

capacitors.

5.

Test

Lead

input

con

nectors

Standard

banana

jack

input

connectors.

Polarized

for

use

with

polarized

capacitors.

6.

Range

Scale

Decal

Range

scale

units

and

max

imum

display

(+

1)

associated

with

each

of

the

range

selec

tion

buttons.

Note

that

the

scale

values

are

expressed

as

1

count

more

than

the

max

imum

value

of

capacitance

(2.000,

20.00

,

200.0,

2000)

although

the

maximum

display

is

1999

counts

in

each

case.

7.

ZERO

Thumbwheel

adjustment

of

the

zero

value

of

the

disolav.

8.

ON

Two-position

slide

switch.

3-5

42-5124

MODEL

938

3 5

MAKING

MEASUREMENTS

WITH

MODEL

938

CAUTION

A

maximum

excitation

voltage

of

2.8

volts

(peak)

is

applied

to

the

capacitor

under

test.

Observe

the

polarity

conventions

for

polarized

capacitors.

3 5 1

General

Follow

the

sequence

below

when

making

measurements.

1.

Select

the

range

switch

for

the

maximum

expected

capacitance.

2.

Turn

power

ON.

3.

Check

the

zero

display.

Before

connecting

the

capacitor

under

test

(but

after

inserting

any

test

leads

or

test

fixtures),

rotate

the

front-panel

thumbwheel

for

a

zero

display.

Note

that

the

maximum

offset

that

may

be

introduced

with

the

thumbwheel

is

about

20pF,

and

that

a

negative

value

is

possible

with

the

thumbwheel

use.

4.

Insert

the

capacitor

leads

into

the

spring

contact

connec

tors

(or

into

the

test

fixture,

or

connect

alligator

clips

to

the

capacitor

leads.)

Do

not

hold

the

capacitor

5.

Read

the

display.

The

value

is

direct

reading

in

the

electrical

units

(picofarads,

nanofarads,

or

microfarads)

indicated

at

the

selected

range

switch.

If

the

three

less

significant

digits

are

blanked

(indicating

an

Out-of-Range

measurement),

select

the

next

higher

range

scale.

If

the

display

indicates

one

or

more

leading

zero

’

s,

shift

to

the

next

lower

range

scale

to

improve

the

resolution

of

the

measurement.

3 5 2

Powering

the

Model

938

a.

The

odel

938

is

normally

powered

from

a

standard

9V

carbon-zinc

battery

of

the

transistor

radio

type.

A

Data

Precision

Battery

Eliminator,

odel

BE9,

may

be

used

to

convert

the

in

strument

to

line

operation,

and

its

use

effectively

removes

the

battery

from

the

circuit.

b

The

odel

938

incorporates

a

battery

(or

battery

eliminator)

voltage

sense

circuit.

A

low

voltage

output

from

these

power

sources

is

indicated

in

the

display

by

LO

BAT

Appearance

of

the

LO

BAT

indication

when

using

the

battery

eliminator

is

in

dicative

of

a

low

ac

source

voltage.

When

using

internal

battery,

a

LO

BAT

display

indicates

a

nominal

battery

output

of

less

than

7V

and

that

approximately

20%

of

the

battery

life

remains.

The

3-6

MODEL

938

OPERATION

&

RECALIBRATION

battery

should

be

replaced

(or

shift

to

use

of

a

Battery

Eliminator)

as

soon

as

possible

after

the

appearance

of

the

LO

BAT

indication.

However,

in-spec

measurements

may

still

be

made

for

several

hours

after

the

LO

BAT

appears

before

the

in

strument

becomes

inaccurate.

A

weak

or

dead

battery

should

be

removed

promptly

to

prevent

possible

damage

because

of

leakage

3 6

RECALIBRATING

THE

MODEL

938

3 6 1

General

The

odel

938

requires

two

adjustments

to

obtain

in-spec

perfor

mance

on

all

range

scales.

One

of

the

adjustments

is

internal

gain

trimmer

R4.

It

calibrates

the

reference

voltage

that

is

developed

by

capacitor

discharge

for

the

dual

slope

integrating

A/D

converter.

The

second

adjustment

is

a

front-panel-

accessible

zero

potentiometer

R8,

by

which

up

to

20pF

offset

may

be

introduced

to

compensate

for

interal

and

lead

stray

cpacitances.

The

design

incorporates

sufficiently

high

quality,

precise

,

and

stable

components

to

assure

overall

specified

performance

with

these

two

adjustments.

The

odel

938

is

designed

to

remain

in

calibration

for

at

least

12

months.

Recalibration,

when

required,

should

be

performed

as

described

in

the

paragraphs

that

follow.

3 6 2

Access

to

Calibrating

Adjustment

R4

Remove

the

back

cover

of

the

multimeter

and

locate

the

access

hole

in

the

inner

shield

cover.

See

Figure

3-2,

referenced

earlier

when

installing

the

battery.

The

adjusting

potentiometer

is

mounted

on

the

pcv

board,

and

its

shaft

is

accessible

through

the

hole

that

is

identified

by

the

label

R4

printed

on

the

shield

cover.

3 6 3

Recalibrating

Procedure

(1)

Set

up

the

meter

with

the

lead

configuration

to

be

used

in

the

recalibration.

Insert

any

test

fixture

(Kelvin

clip,

e.g.)

or

con

nect

any

test

leads

to

be

used

later,

t

Remember

that

even

very

short

leads

may

have

a

significant

effect.)

(2)

Select

the

200pF

measurement

range.

(3)

Adjust

the

front-panel

control

R8

for

000

display.

Back

off

the

thumbwheel

position

one

half

turn

from

a

negative

display

(4)

Connect

a

standard

capacitor

whose

value

is

near

full

scale

on

one

of

the

higher

ranges,

and

is

known

to

within

±0.05%.

(5)

Select

the

appropriate

range

scale.

(6)

Adjust

R4

for

a

display

equal

to

the

known

capacitance.

(7)

Remove

the

standard

capacitor.

Replace

bottom

cover.

3-7

42-5124

MODEL

938

3 7

OPERATION

3 7 1

Operating

Controls

&

Indicators

Table

3-1

described

the

odel

938

C- eter

controls

and

in

dicators

that

are

shown

in

Figure

3-3.

Refer

to

paragraph

3.4.

3 7 2

Hints

for

Improved

Operation

The

ideal

capacitor

exhibits

no

electrical

performance

except

that

of

capacitance;

it

would

convert

all

the

“

storing

”

energy

into

charge,

would

be

able

to

hold

that

charge

indefinitely,

and

would

be

able

to

deliver

all

the

energy

represented

by

its

charge

into

a

load

without

loss.

While

many

laboratory

standard

capacitors

approach

this

ideal

with

more

or

less

success,

all

capacitors

contain

elements

intrinsic

to

their

design

that

cause

departures

from

ideal

in

all

realizable

capacitor

elements.

Figure

3-4

illustrates

two

of

the

more

important

equivalent

resitance

elements

that

affect

capacitor

performance,

—

-

and

measurement

of

capacitance

values.

These

resistances

exist

in

a

distributed

fashion,

but

are

drawn

as

shown

in

the

illustration

for

ease

in

analysis.

The

series

resistance

Rs

introduces

losses

in

the

charge

and

discharge

actions,

while

the

parallel

resistance

Rp

serves

to

drain

the

stored

charge.

The

odel

938

measurement

technique

is

hardly

affected

by

the

series

resistance

Rs

because

the

Capacitance

eter

measures

changes

in

the

stored

charge

and

changes

in

the

charging

voltage,

and

does

not

depend

upon

the

absolute

values,

except

when

radically

different

from

ideal.

However,

the

parallel

resistance

Rp

parallels

the

range-selected

precision

resistor

in

the

odel

938

measuring

circuit,

and,

depending

upon

the

relative

values

of

the

leakage

resistance

and

that

of

the

selected

range,

may

have

a

visible

effect

on

the

display

value

when

measuring

leaky

capacitors.

In

most

cases,

the

resulting

measurement

remains

within

the

performance

specification.

easured

values

that

exceed

the

capacitor

specified

tolerances

will,

therefore,

be

valid

indicators

of

degraded

components.

Measurements

of

very

low

capacitances

should

be

performed

us

ing

extremely

short

leads

and

a

Kelvin

clip

in

order

to

avoid

in

troducing

any

stray

capacitance.

When

using

the

optional

test

leads,

remember

that

the

leads

in

troduce

a

measurable

capacitance

to

the

measurement.

As

a

first

approximation,

the

test

lead

capacitance

may

be

measured

by

opening

the

leads

at

the

tips,

recording

the

open

circuit

value,

3-8

MODEL

938

OPERATION

&

RECALIBRATION

and

subtracting

that

value

value

from

the

display

results.

However,

in

order

for

this

correction

to

be

valid,

the

succeeding

capacitor

measurements

must

be

made

with

all

other

measure

ment

conditions

exactly

the

same.

The

existence

of

a

leaky

capacitance

may

be

detected

if

the

value

changes

significantly

as

the

scales

are

changed.

Since

the

shift

to

a

lower

range

scale

introduces

more

resistance

in

the

discharge

cycle

(see

principles

of

operation),

the

effect

of

the

in

ternal

leaky

resistance

is

minimized

on

the

lower

range

scales.

9

Q

d0

Figure

3-4

Equivalent

Capacitor

Schematic

3-9

■3

42-5124

MODEL

938

NOTES:

3-10

MODEL

938

PRINCIPLES

OF

OPERATION

Chapter

4

PRINCIPLES

OF

OPERATION

4 1

BASIC

CONCEPTS

4 1 1

Capacitance

The

electrical

property

of

capacitance

describes

the

ability

of

a

component

to

store

charge

when

subject

to

an

electric

potential

(voltage).

All

matter

exhibits

this

property

to

a

greater

or

lesser

extent.

Personnel

on

an

assembly

line,

for

example,

may

store

a

charge

when

they

introduce

friction

while

walking

across

a

carpet.

That

charge

poses

a

potential

danger

to

some

integrated

circuits

if

it

should

be

discharged

through

the

components

of

the

IC,

and

care

must

be

taken

to

“

ground

”

personnel

working

with

charge-sensitive

components.

Capacitors

are

electronic

com

ponents

specifically

designed

to

store

charge.

Figure

4-1

Charging

a

Capacitor

through

a

Resistor

4-1

I-3

42-5124

MODEL

938

If

there

are

no

charge-storing

units

in

series

with

the

capacitor,

the

capacitor

will

develop

a

charge

equal

to

the

potential

applied

to

it,

as

shown

in

Figure

4-1.

The

illustration

includes

a

resistive

component

in

series

with

the

capacitor

that

acts

to

impede

the

flow

of

current,

or

the

rate

of

storing

charge.

However,

as

long

as

there

is

a

relatively

long

charging

time,

the

charge

on

the

capacitor

will

develop

a

potential

across

the

capacitor

equal

to

the

applied

voltage.

This

charging

phenomenon

is

also

il

lustrated

graphically

in

Figure

4-1.

In

an

ideal

capacitor

(with

no

resistive

components)

the

charge

will

remain

without

change

un

til

the

capacitor

is

connected

in

a

circuit

that

allows

the

flow

of

current,

and

the

reduction

in

charge.

Figure

4-2

illustrates

the

capacitor

discharge

when

connected

to

a

resistance

component.

The

measurement

of

capacitance

(the

ability

to

store

charge

under

the

“

pressure

”

of

a

voltage

“

force

”

)

is

often

accomplished

by

observing

the

effects

on

the

capacitor

voltage

when

the

capacitor

stored

charge

is

connected

to

a

precisely

known

charg

ing

or

discharging

circuit

for

a

precise

time

interval.

(The

measurement

of

the

amount

of

stored

charge

is

also

possible,

but

with

more

elaborate

and

expensive

equipment.)

As

shown

in

Figure

4-3,

the

reduction

in

charge

is

directly

proportional

to

the

time

of

the

current

flow

and

to

the

amount

of

capacitance.

Or,

to

obtain

the

capacitance

from

this

relationship,

the

capacitance

is

the

change

in

charge

per

change

in

voltage

Figure

4-2

Charge

and

Discharge

Cycles

of

a

Capacitor

4-2

MODEL

938

PRINCIPLES

OF

OPERATION

4 1 2

Capacitance

Measurement

The

ratio

definition

as

stated

in

the

previous

paragraph,

is

the

basis

for

the

measurement

as

performed

in

the

odel

938

Capacitance- eter.

That

is,

the

instrument

uses

a

dual-slope

analog-to-digital

converter

that

digitizes

the

ratio

of

the

change

in

charge

to

the

change

in

voltage.

The

charge

reduction

is

ac

complished

by

connection

to

a

circuit

that

allows

current

to

flow,

and

this

current

is

averaged

over

an

integral

number

of

cycles

as

a

measure

the

value

of

the

change

in

charge.

The

voltage

difference

between

the

values

across

the

capacitor

at

the

start

and

at

the

end

of

the

discharge

cycle

is

the

denominator

in

the

ratio

meaurement.

The

A/D

converter

develops

the

digitized

value

of

this

ratio

for

display

in

the

liquid

crystal

display.

AQ1

CURRENT

THROUGH

R

IN

*3

Figure

4-3

Relationship

of

Capacitance

to

the

Change

of

Charge

and

Change

of

Voltage

4 2

SYSTEM

BLOCK

DIAGRAM

4 2 1

General

Figure

4-4

is

a

simplified

block

diagram

of

the

instrumentation

of

the

odel

938

Capacitance- eter.

The

illustration

is

prepared

in

some

detail

with

respect

to

those

elements

that

instrument

the

basic

concepts

of

capacitance

measurement

described

briefly

in

the

previous

paragraphs.

Other

functioning

elements

are

includ

ed

in

block

form.

Their

circuit

operation

will

be

described

in

greater

detail

in

later

paragraphs

of

this

chapter.

4-3

42-5124

MODEL

938

Figure

4-4

System

Block

Diagram

4-4

MODEL

938

PRINCIPLES

OF

OPERATION

As

shown

in

the

illustration,

the

A/D

converter

operates

on

the

values

of

voltage

connected

to

two

pairs

of

inputs:

the

INPUT

and

the

REFERENCE

A

sequence

of

switching

actions

perform

ed

by

the

four

output

signals

of

a

control

logic

programming

block

determine

the

the

circuit

configurations

that

develop

values

of

the

voltage

signals

for

each

of

these

two

inputs

to

the

A/D

converter.

The

four

phases

in

the

signal

conditioning

pro

cess

are:

4>1,

4>2,

<i>3,

and

4>4

<i>1:

During

which

the

capacitor

to

be

measured

(Cy)

is

charg

ed

to

an

initial

nominal

value

depending

upon

the

value

of

capacitance

and

the

range

scale

selected

(but

not

exceeding

2.8

volts).

$2:

During

which

Capacitor

C4

and

C5

are

charged

in

series

to

the

initial

value

of

the

capacitor

under

test.

4>3:

During

which

the

capacitor

under

test

Cy

is

discharged

through

a

range-selected

resistor.

The

resulting

current

is

averaged

over

a

number

of

cycles

of

this

interval

and

converted

into

a

voltage

on

C3

by

the

filtering

action

of

R9

and

C3.

4>4:

During

which

the

value

of

the

C

t

voltage

at

the

end

of

the

discharge

interval

of

4>3

is

stored

on

C4.

As

a

result,

the

voltage

on

C5

represents

the

difference

between

the

initial

and

final

values

of

capacitance

on

C

t

-

It

is

the

REFERENCE

input

to

the

A/D.

Figure

4-5

derives

the

result

in

a

more

rigorous

fashion.

4-5

42-5124

MODEL

938

4.2.2

The

Capacitor

initial

Charge

When

Switch

A

(Figure

4-4)

is

closed

during

4>1,

the

capacitor

under

test,

Cy

is

charged

rapidly

to

some

nominal

value,

limited

to

2.8

volts.

The

voltage

level

on

the

capacitor

is

connected

to

the

non

inverting

input

of

amplifier

Z1-1,

which

draws

no

current

(and

therefore

no

charge)

from

the

capacitor.

The

amplifier

output

drives

a

FET

follower

that

is

cut

off

during

4>3.

The

voltage

ap

pears

across

the

voltage

divider

R4,

R5,

and

R6

(of

which

R4

is

a

variable

resistance

with

which

to

adjust

the

gain

of

the

stage).

During

<i>2,

Switch

B

is

closed,

and

capacitors

C4

and

C5

in

series

are

charged

with

the

scaled

value

of

the

initial

Cy

voltage.

4 2 3

The

Capacitor

Discharge

Interval

During

<t>3,

Switch

C

is

closed

(Figure

4-4),

connecting

the

charg

ed

capacitor

to

the

range-selected

value

of

load

resistance

through

which

to

partially

discharge

the

capacitor.

During

repeated

cycles

of

this

phase,

the

filter

action

of

R9

and

C3

acts

as

an

averaging

operation,

storing

the

average

value

of

the

cur

rent

as

a

voltage

across

03.

This

value

is

connected

as

the

IN

PUT

to

the

A/D

converter.

4.2.4

The

Voltage

Change

easurement

During

T4,

Switch

D

closes

(Figure

4-4),

connecting

the

scaled

output

from

amplifier

Z1-1

to

C4.

Since

C4

and

C5

in

series

had

previously

been

charged

with

the

initial

value

of

the

charged

capacitor,

capacitor

C5

now

retains

the

value

of

the

difference

between

the

two

samplings.

This

becomes

the

input

to

the

REFERENCE

terminals

of

the

A/D

converter.

4 2 5

Zero

Adjustment

Adjustment

to

zero

on

all

ranges

is

accomplished

by

subtracting

a

current

proportional

to

the

Reference

voltage

from

the

discharge

current

flowing

in

the

range-selected

load

resistance.

This

is

limited

to

±20pF.

4 2 6

Range

Scale

Selection

Range

scale

conditioning

of

the

two

signals

(difference

in

charge

and

difference

in

voltage)

is

accomplished

by

several

methods.

For

full

scale

values

of

200pF,

2nF,

20nF,

and

200nF,

the

resistance

divider

introduces

a

proportionate

load

for

the

discharge

cycle

of

the

capacitor,

and,

therefore,

a

proportionate

current

to

be

averaged

for

the

A/D

INPUT

signal.

For

the

higher

end

of

the

range

scales

(2uF,

20uF,

200uF,

and

2000uF),

the

charge-discharge

timing

cycle

is

changed

by

range-alteration

of

4-6

MODEL

938

PRINCIPLES

OFOPERATION

the

control

logic

timing

circuit.

The

interval

is

lengthened

by

fac

tors

of

10

to

obtain

a

greater

voltage

change

during

the

discharge

phase

for

large

value

capacitors.

4 2 6

Display

The

display

is

driven

directly

from

the

A/D

converter

integrated

circuit.

Each

of

the

three

full

digits

is

configured

by

a

combina

tion

of

1

to

7

segments,

each

driven

by

a

separate

line

from

the

A/D.

The

liquid

crystal

back

plane

is

driven

by

a

square

wave

signal,

and

the

appropriate

sgment

in

each

digit

is

driven

by

an

out-of-phase

component

at

the

same

frequency

as

the

back

plane.

A

single

line

from

the

A/D

drives

the

most

significant

digit

“

1

”

,

and

another

line

drives

the

polarity

sign

(not

used

in

the

C- eter).

Range

selection

activates

Exclusive

OR

gates

for

the

decimal

point

drives;

the

other

input

to

each

gate

is

the

back

plane

drive

signal.

A

low

battery

sensing

circuit,

comparing

the

battery

(or

Batter

Eliminator)

output

with

an

internal

reference,

develops

a

drive

signal

for

the

LO

BAT

indicator

in

the

display.

Insertion

of

the

jack

for

the

Battery

Eliminator

removes

the

internal

battery

from

the

power

supply

circuit.

4 3

SIGNAL

CONDITIONING

DETAILS

4.3.1

Charging

and

Discharging

the

Capacitor

Refer

to

the

complete

schematic

at

the

back

of

this

manual.

Note

that

the

input

unknown

capacitance

is

paralleled

internally

with

a

capacitor

(C1)

which,

with

the

stray

capacitance

of

the

assembly,

always

provides

some

“

zero

”

capacitance

for

the

meter.

This

small

capacitance

always

charges

up

in

parallel

with

the

capacitance

under

test,

and

is

the

amount

that

is

zeroed

out

with

the

thumbwheel

adjustment

before

connecting

the

capacitor

to

be

measured.

The

capacitor

under

test

is

connected

to

the

HI

and

LO

terminals

(keeping

the

poarities

correct

for

polarized

components).

Q1

and

Q2

are

clamps,

keeping

the

voltage

at

safe

levels,

and

protecting

internal

components.

Q3

is

a

switching

transistor

that

is

turned

ON

during

<I>1

to

connect

the

rail

value

to

the

HI

terminal.

The

power

supply

circuit

described

later

keeps

the

voltage

to

be

developed

across

the

unknown

capacitance

to

a

safe

limit

of

2.8

volts

(nominal).

For

measurment

of

low

capacitance

values,

range

selection

of

100pF

to

100nF

opens

the

base

drive

to

transistor

Q6,

and

only

4-7

42-5124

MODEL

938

the

FET

Q4

is

turned

ON

during

4>3

to

connect

the

stored

charge

in

the

unknown

capacitance

to

the

discharge

circuit.

For

measurement

of

higher

capacitances,

the

<i>3

signal

turns

ON

04

and

then

06,

so

that

the

discharge

now

takes

place

through

R16

and/or

R1

1.

(

Note

that

the

measurement

of

voltage

through

R11

is,

effectively

a

4-wire

connection.)

Changes

in

range

scale

for

the

higher

ranges

is

now

accomplished

by

changing

the

number

of

repetition

cycles

for

each

of

the

charge/discharge

ac

tions

averaged.

This

is

accomplished

by

switching

connections

to

the

timing

logic

element,

Z5.

4 3 2

Measuring

the

Change

in

Charge

In

each

$1

interval,

the

capacitor

reaches

some

nominal

charged

value

(not

necessarily

the

applied

voltage),

and

the

exact

value

is

not

critical

to

the

accuracy

of

measurement.

In

each

*3

interval

the

discharging

capacitor

generates

a

current

in

the

range-

selected

resistance

paralleling

and

charging

C3.

Over

a

number

of

such

cycles,

C3

stores

a

voltage

proportional

to

the

average

value

of

the

current

generated

by

the

discharging

capacitor.

4 3 3

Measuring

the

Difference

in

Voltage

The

non-inverting

input

to

Z1-1

is

always

connected

to

the

high

side

of

the

input

connector,

and

to

the

unknown

capacitor.

The

operational

amplifier

drives

a

FET

follower

to

develop

a

current

in

the

output

resistor

divider

load

so

that

the

voltage

across

R4,

R5,

and

R6

in

series

is

equal

to

the

charge

on

the

capacitor.

(The

output

“

follows

”

the

input

capacitor

voltage.)

When

the

<i>2

control

signal

is

active,

the

scaled

output

(at

the

voltage

divider

junction

of

R5

and

R6)

appears

across

C4

and

05

in

series.

When

the

4>4

control

signal

is

active,

the

scaled

output

appears

across

C4

only.

Since

the

value

across

04

and

05

at

<i>2

is

the

value

before

discharge,

and

the

value

across

04

at

4>4

is

the

value

after

discharge,

then

the

value

remaining

on

05

is

the

dif

ference.

4 3 4

Zero

Adjustment

Transistor

Q7,

R7

and

R8

provide

a

path

for

current

flow

from

the

REFERENCE

of

the

A/D

converter

to

the

input.

The

current

in

this

path

is

controlled

by

the

value

of

the

voltage

at

the

non-inverting

input

to

Z1.

Current

will

flow

through

this

circuit

until

the

voltage

developed

across

the

two

resistances

R7

and

R8

equals

that

input

voltage.

Thus,

a

current

proportional

to

the

reference

is

drawn

from

the

discharge

current.

That

current

is

calibrated

by

adjustment

of

R8.

It

remains

a

constant

count,

even

though

each

measuring

operation

with

difference

capacitors

develops

different

INPUT

and

REFERENCE

voltages.

4-8

MODEL

938

PRINCIPLES

OF

OPERATION

Figure

4-6.

Signal

Conditioning

Waveforms

(Z5)

4 4

SIGNAL

CONDITIONING

CONTROL

LOGIC

Control

signals

for

the

signal

conditioning

circuits

are

developed

in

Z5.

The

input

to

Z5

is

the

output

from

a

master

oscillator,

crystal-

controlled

to

generate

32.768

KHz.

It

is

counted

down

to

develop

timing

waveforms

depending

upon

the

switch-selected

jumpering

shown

in

the

reference

schematic,

and

illustrated

in

Figure

4-6.

4 5

A/D

CONVERTER

DETAILS

4.5.1

Analog

Section.

The

odel

938

A/D

Converter

is

a

monolithic

C OS

chip

contain

ing

both

analog

and

digital

sections

on

the

same

chip.

Figure

4-7-

illustrates

the

analog

section,

and

includes

the

interfaces

with

discrete

elements

on

the

main

pc-board.

As

shown

in

the

il

lustration,

the

converter

consists

of

a

buffer,

integrator,

and

comparator,

configured

by

internal

switches

programmed

by

the

digital

section.

The

switches

are

identified

by

the

names

of

the

step

intervals

during

which

they

are

“

on

”

.

For

example,

the

iNT

switches

are

closed

during

Step

2,

Integration

of

the

Conditioned

Input;

The

A/Z

switches

are

closed

during

Step

1,

the

Autozeroing

step;

the

DE

switches

are

closed

during

Step

3,

Integration

of

the

Reference

Voltage.

Note

that

the

DE

switches

are

closed

in

pairs:

DE(

+

)

when

a

positive

conditioned

input

is

sensed

at

the

end

of

Step

1,

and

DE(-)

when

a

negative

conditioned

input

is

sensed

at

the

end

of

Step

2.

(The

steps

of

the

A/D

conversion

are

not

synchronized

with

the

four

phases

of

the

signal

conditioning

described

earlier.)

During

Step

1

(Autozeroing;

A/Z

switches

closed),

the

conditioned

input

is

removed

(INT

is

open);

the

A/D

input

is

shorted

to

Analog

Common,

the

integrator-comparator

loop

is

closed,

and

capacitor

C9

is

charged

with

compensating

offset

for

the

automatic

zero

ing

during

Steps

2

and

3

to

follow.

Capacitor

C6

is

charged

with

the

reference

voltage

for

later

use

in

Step

3.

4-9

42-5124

MODEL

938

During

Step

2

(INT

switches

are

closed),

the

A/D

input

is

con

nected

to

the

buffer

amplifier,

whose

output

is

connected

in

series

with

the

zero

compensation

of

the

previous

step,

and

the

net

value

charges

capacitor

C7.

During

Step

3

(DE

switches

are

closed),

the

pair

of

DE

switches

are

closed

to

connect

the

voltage

across

C6

to

the

A/D

input

with

the

proper

polarity

convention

in

order

to

reduce

the

voltage

previously

built

up

on

integrating

capacitor

C7

in

Step

2.

4.5.2

Digital

Section

of

the

A/D

Converter.

The

digital

section

of

the

A/D

converter

contains

counters

and

logic

circuitry

with

which

to

develop

the

3-step

timing

signals

and

to

generate

driving

signals

for

each

of

the

seven

segments

of

the

3

full

display

decades,

as

well

as

the

driving

signal

for

the

SB

“

1

”

.

This

section

of

the

IC

also

includes

the

circuitry

to

determine

and

drive

the

negative

polarity

sign,

when

required,

in

the

display,

to

sense

an

out-of-range

condition,

and

to

blank

the

digits.

The

chip

also

provides

the

driving

signal

for

the

liquid

crystal

display

back

plane

in

proper

synchronism

with

the

signals

for

the

display

elements.

Figure

4-7

Analog

Section

of

the

A/D

Converter

R14

4-10

MODEL

938

PRINCIPLES

OF

OPERATION

4.5.3

Converter

Timing

The

three

steps

in

the

A/D

conversion

cycle,

that

occur

asyn

chronously

with

the

4

phases

of

the

charge/discharge

cycles

in

the

signal

conditioning

circuits,

complete

an

A/D

conversion

at

the

nominal

rate

of

2

per

second.

A

typical

waveform

pattern

for

the

A/D

timing

waveforms,

referred

to

the

output

of

the

in

tegrator,

is

shown

in

Figure

4-8.

4 6

DISPLAY

The

liquid

crystal

display

used

in

the

odel

938

is

a

low

power

device,

whose

back

plane

power

is

furnished

directly

by

the

A/D

converter

chip,

while

the

digit

segments

are

synchronously

driven

by

independent

lines

from

the

A/D

chip

(7

segment

drivers

for

each

of

3

digits,

1

driver

for

the

SD,

and

1

for

the

negative

polarity

sign).

Drivers

for

the

decimal

points

(3)

and

for

the

“

LO

BAT

”

indicator

are

gated

with

the

back

plane

power

drive

through

Exclusive

OR

gates.

4-11

42-5124

MODEL

938

4 6

POWERSUPPLY

a.

Power

for

the

odel

938

is

derived

from

either

a

9-volt

tran

sistor

radio

type

battery

or

from

a

Battery

Eliminator

(BE9).

When

a

battery

eliminator

is

used,

the

internal

battery

is

discon

nected

from

the

circuit.

b

A

low

battery

sense

circuit

in

the

odel

938

continuously

com

pares

a

fraction

of

the

battery

voltage

(or

BE9

output)

against

a

5.8V

reference

and

generates

the

“

LO

BAT

”

drive

signal

when

the

input

is

approximately

7

volts.

Figure

4-9

illustrates

the

generation

of

excitation

sup

plies

and

voltage

levels

in

the

model

938.

Figure

4-9

•

Model

938

Power

Sourcing

Schematic

4-12

MODEL

938

MAINTENANCE

Chapters

MAINTENANCE

5 1

GENERAL

CAUTION

odel

938

is

covered

by

a

one-year

warranty,

and

it

should

be

returned

to

the

factory

for

maintenance

within

the

warranty

period.

At

tempts

to

make

any

extensive

repairs

within

the

warranty

period

may

invalidate

the

warranty.

If

repairs

are

needed

after

the

warrany

period,

only

qualified

technicians

should

attempt

to

effect

such

repairs

and

should

use

test

instruments

and

standards

calibrated

within

the

accuracy

and

tolerances

of

the

instrument

specifications.

Note

that

the

warranty

does

not

cover

damage

caused

by

leaky

batteries.

odel

938

has

been

designed

with

a

minimum

number

of

com

ponents,

and

is

intended

to

deliver

years

of

reliable

service.

In

addition,

all

components

have

been

screened

and

tested,

prior

to

use,

in

an

extensive

quality

control

procedure,

and

the

final

assembly

has

been

burned

in

prior

to

final

test

and

shipment.

5 2

TROUBLE

SHOOTING

STRATEGY

Should

the

meter

performance

indicate

the

need

for

repair,

a

well-defined

strategy

should

be

used

to

isolate

the

cause

of

malfunction.

Such

a

strategy

begins

with

an

analysis

of

the

symptoms

of

malfunction

in

order

to

keep

to

a

minimum

the

repair

and

replacement

operations

within

the

meter

assembly.

uch

can

be

learned

from

an

analysis

of

the

meter

performance

under

varying

input

conditions.

Figure

5-1

illustrates

the

type

of

5-1

42-5124

MODEL

938

Figure

5-1

Trouble

Shooting

Strategy

5-2

MODEL

938

MAINTENANCE

analysis

that

may

be

used

to

isolate

the

probable

cause

of

malfunction

to

specific

circuits.

As

shown

in

the

illustration,

some

checks

may

be

made

without

opening

the

meter,

while

others

may

require

access

to

internal

circuitry.

CAUTION

Do

not

attempt

any

internal

repairs

before

observ

ing

the

cautions

and

warnings

in

paragraph

5.3.

Check

all

input

and

line

(if

BE9

is

used)

connec

tions

before

assuming

an

internal

circuit

cause

of

the

malfunction

symptom.

Read

and

understand

Chapter

4,

Principles

of

Operation,

before

attemp

ting

any

repair.

5 3

SAFETY

PRECAUTIONS

AND

PROCEDURES

a.

Remove

input

signal

connections

before

opening

the

case.

b.

Take

care

that

static

discharges

do

not

contact

static

sensitive

IC

components.

Use

grounding

straps

and

anti-static

bags

and

devices

when

handling

and

storing

these

components.

5 4

COMPONENTS

Figures

5-2

identifies

and

locates

the

components

for

con

venient

trouble

shooting.

Refer

to

chapter

4

for

waveform

and

voltage

levels

in

obtaining

test

comparisions.

5-3

42-5124

MODEL

938

Figure

5-2

Component

Location

5-4

MODEL

938

PARTS

LIST

Chapter

6

PARTS

LIST

6 1

ORDERING

REPLACEMENT

PARTS

a.

Replaceable

parts

for

odel

938

are

listed