Datasensing SH4 BASE-STANDARD Installation and operation manual

SH4 BASE-STANDARD

PRODUCT REFERENCE GUIDE

Safety Light Curtains

Datasensing S.r.l.

Strada S. Caterina 235

41122 Modena

Italy

Tel. +39 059 420411

Fax +39 059 253973

© 2022 Datasensing S.r.l. and /or its affiliates

All rights reserved. Without limiting the rights under copyright, no part of this documentation may be repro-

duced, stored in or introduced into a retrieval system, or transmitted in any form or by any means, or for any

purpose, without the express written permission of Datasensing S.r.l. Owners of Datasensing products are

hereby granted a non-exclusive, revocable license to reproduce and transmit this documentation for the

purchaser's own internal business purposes. Purchaser shall not remove or alter any proprietary notices,

including copyright notices, contained in this documentation and shall ensure that all notices appear on any

reproductions of the documentation. Electronic versions of this document may be downloaded from the

Datasensing website (www.datasensing.com).

Disclaimer

Datasensing has taken reasonable measures to provide information in this manual that is complete and

accurate, however, Datasensing shall not be liable for technical or editorial errors or omissions contained

herein, nor for incidental or consequential damages resulting from the use of this material. Datasensing

reserves the right to change any specification at any time without prior notice.

Trademarks

Datasensing and the Datasensing logo are trademarks of Datasensing S.r.l.

Patents

See www.patents.datasensing.com for patent list.

This product is covered by one or more of the following patents:

Utility patents: IT1363719, IT1427575, US10188007

ORIGINAL INSTRUCTIONS (ref. 2006/42/EC)

PRODUCT REFERENCE GUIDE

iii

TABLE OF CONTENTS

PREFACE .................................................................................................................VII

About this Manual .......................................................................................................... vii

Manual Conventions .......................................................................................................................... vii

Technical Support .......................................................................................................... vii

Support Through the Website ........................................................................................................... vii

Warranty ...................................................................................................................... viii

CHAPTER 1.

GENERAL INFORMATION.......................................................................1

Model Description ............................................................................................................ 3

Compliance ...................................................................................................................... 4

European Declaration of Conformity ..................................................................................................4

UKCA Declaration of Conformity ........................................................................................................4

CHAPTER 2.

INSTALLATION .....................................................................................6

Package Contents ............................................................................................................ 6

Precautions to be observed for the choice and installation .................................................. 7

How to choose the device ................................................................................................. 8

Detection capability .............................................................................................................................8

Height of the detection zone ...............................................................................................................9

Minimum installation distance .........................................................................................................10

Practical examples ....................................................................................................................11

Typical applications ........................................................................................................ 12

Example 1: Operating point protection on drilling machines ..........................................................12

Example 2: Bending presses ............................................................................................................12

Example 3: Paper cutting machines .................................................................................................13

Example 4: Milling machines ............................................................................................................13

Safety information ......................................................................................................... 14

General information on device positioning ....................................................................... 15

Minimum distance from reflecting surface (DSR) ...........................................................................16

Distance between homologous devices ...........................................................................................17

Emitter and receiver orientation ......................................................................................................19

Use of deviating mirrors ...................................................................................................................19

Controls after first installation .........................................................................................................20

CHAPTER 3.

MECHANICAL MOUNTING.................................................................... 22

CHAPTER 4.

ELECTRICAL CONNECTIONS................................................................ 26

Pin-out and configuration pin connection ......................................................................... 26

Notes on connections .......................................................................................................................28

Example: connection to the safety relay SE-SR2 ....................................................................28

CHAPTER 5.

ALIGNMENT PROCEDURE.................................................................... 31

Alignment ...................................................................................................................... 31

Alignment Procedure (Standard models only) ................................................................................32

User interface indication with light curtain in alignment mode ......................................................33

SH4-XX-XXXX-X ........................................................................................................................33

LED meanings ...........................................................................................................................33

SH4-X-XXXX-X-X models ..........................................................................................................35

CONTENTS

iv

SH4 BASE-STANDARD

LED meanings ...........................................................................................................................35

CHAPTER 6.

FUNCTIONS ........................................................................................ 36

Restart mode .................................................................................................................37

Automatic Restart (All models) ........................................................................................................37

Manual Restart (Standard models only) ..........................................................................................38

Configuration of Restart mode .................................................................................................38

Reset (Standard models only) .........................................................................................39

EDM (Standard models only) ...........................................................................................40

Configuration .....................................................................................................................................40

Test ...............................................................................................................................41

Emission Range Selection (SH4-x-xxxx-X models only) ...................................................42

CHAPTER 7.

USER INTERFACE DIALOGUE .............................................................. 43

LED meanings ...........................................................................................................................43

RX Side dialogue ...............................................................................................................................44

TX Side dialogue ................................................................................................................................46

SH4-X-XXXX-X-X Models ...............................................................................................47

LED meanings ...........................................................................................................................47

RX Side dialogue ...............................................................................................................................48

TX Side dialogue ................................................................................................................................50

CHAPTER 8.

PERIODICAL CHECKS.......................................................................... 52

General information and useful data ................................................................................53

CHAPTER 9.

DEVICE MAINTENANCE....................................................................... 54

Product disposal .............................................................................................................54

APPENDIX A.

TECHNICAL DATA............................................................................. 55

APPENDIX B.

AVAILABLE MODELS AND RESPONSE TIMES..................................... 58

Models ...........................................................................................................................58

Pairing table ......................................................................................................................................59

Response Times .............................................................................................................59

SH4-14-XXXX-X-X models ................................................................................................................59

SH4-30-XXXX-X-X models ................................................................................................................59

SH4-2/3/4-XXXX-X-X models ...........................................................................................................60

APPENDIX C.

OVERALL DIMENSIONS ..................................................................... 62

SH4-14-XXXX-X-X .........................................................................................................62

SH4-30-XXXX-X-X .........................................................................................................63

SH4-2/3/4-xxxx-x-x ......................................................................................................64

APPENDIX D.

INCLUDED ACCESSORIES.................................................................. 66

Metal Angled fixing Bracket ............................................................................................66

APPENDIX E.

ACCESSORIES................................................................................... 68

Brackets ........................................................................................................................68

Metal Angled Fixing Bracket ............................................................................................................68

Angled fixing bracket mounting with orientable and anti-vibration supports ...............................69

Rotating Bracket ...............................................................................................................................70

Protective tubes and stands ............................................................................................71

Protective Stands ..............................................................................................................................71

Mounting kit ..............................................................................................................................71

Plate Kit for Protective Stands .........................................................................................................72

Mounting with SG-P SB ............................................................................................................72

Columns and floor stands .................................................................................................................73

Mirrors ..........................................................................................................................74

Deviating mirrors ..............................................................................................................................74

Mounting kit for SG-DM with SE-S column and floor stands .........................................................75

CONTENTS

PRODUCT REFERENCE GUIDE

v

Mounting kit SG-DM on SG-PSB (ST-PS-DM) .................................................................................75

Connection cables .......................................................................................................... 76

5-pole M12 cables (Receiver main connector Base models only) ..................................................76

8-pole M12 cables (Receiver main connector Standard models only) ...........................................76

5-pole M12 cables (Transmitter main connector) ...........................................................................76

Cascade cables (5-poles M12 male/female) ....................................................................................76

Safety Units ................................................................................................................... 78

Safety unit ..........................................................................................................................................78

EDM relay box ....................................................................................................................................78

Couple arms ......................................................................................................................................79

SH-T-ARMS ...............................................................................................................................79

SH-L-ARMS ...............................................................................................................................79

Connection Box .................................................................................................................................80

APPENDIX F.

CASCADE SYSTEM ............................................................................ 82

Overview ....................................................................................................................... 82

Connection .................................................................................................................... 84

RX connection ....................................................................................................................................84

TX connection ....................................................................................................................................85

Protected Area .............................................................................................................. 86

Operation ...................................................................................................................... 86

User Interface dialogue .................................................................................................. 87

LED meanings ...........................................................................................................................87

RX Side dialogue ................................................................................................................................88

TX Side dialogue ................................................................................................................................89

Response Time .............................................................................................................. 90

Recovery Time ............................................................................................................... 90

APPENDIX G.

GLOSSARY........................................................................................ 92

CONTENTS

vi

SH4 BASE-STANDARD

PRODUCT REFERENCE GUIDE

vii

PREFACE

ABOUT THIS MANUAL

This Product Reference Guide (PRG) is provided for users seeking advanced technical

information, including connection, programming, maintenance and specifications. The

Quick Reference Guide (QRG) and other publications associated with this product can

be downloaded free of charge from the website listed on the back cover of this manual.

Manual Conventions

The symbols listed below are used in this manual to notify the reader of key issues or

procedures that must be observed when using the laser marker:

TECHNICAL SUPPORT

Support Through the Website

Datasensing provides several services as well as technical support through its website.

Log on to (www.datasensing.com).

For quick access, from the home page click on the search icon , and type in the name of

the product you’re looking for. This allows you access to download Data Sheets, Manu-

als, Software & Utilities, and Drawings.

NOTE: Notes contain information necessary for properly diagnosing,

repairing and operating the safety light curtain.

CAUTION: This symbol advises you of actions that could damage equipment

or property.

WARNING: This symbol advises you of actions that could result in harm or

injury to the person performing the task.

PREFACE

viii

SH4 BASE-STANDARD

WARRANTY

Datasensing warrants that the Products shall be free from defects in materials and workmanship

under normal and proper use during the Warranty Period. Products are sold on the basis of

specifications applicable at the time of manufacture and Datasensing has no obligation to

modify or update Products once sold. The Warranty Period shall be three years from the date of

shipment by Datasensing, unless otherwise agreed in an applicable writing by Datasensing.

Datasensing will not be liable under the warranty if the Product has been exposed or subjected

to any: (1) maintenance, repair, installation, handling, packaging, transportation, storage,

operation or use that is improper or otherwise not in compliance with Datasensing’s instruction;

(2) Product alteration, modification or repair by anyone other than Datasensing or those

specifically authorized by Datasensing; (3) accident, contamination, foreign object damage,

abuse, neglect or negligence after shipment to Buyer; (4) damage caused by failure of a

Datasensing-supplied product not under warranty or by any hardware or software not supplied

by Datasensing; (5) any device on which the warranty void seal has been altered, tampered with,

or is missing; (6) any defect or damage caused by natural or man-made disaster such as but not

limited to fire, water damage, floods, other natural disasters, vandalism or abusive events that

would cause internal and external component damage or destruction of the whole unit,

consumable items; (7) use of counterfeit or replacement parts that are neither manufactured

nor approved by Datasensing for use in Datasensing-manufactured Products; (8) any damage or

malfunctioning caused by non-restoring action as for example firmware or software upgrades,

software or hardware reconfigurations etc.; (9) loss of data; (10) any consumable or equivalent

(e.g. cables, power supply, batteries, etc.); or (11) any device on which the serial number is

missing or not recognizable.

THE DATASENSING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

WHETHER WRITTEN, EXPRESS, IMPLIED, STATUTORY OR OTHERWISE, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE. DATASENSING SHALL NOT BE LIABLE FOR ANY DAMAGES SUSTAINED BY BUYER

ARISING FROM DELAYS IN THE REPLACEMENT OR REPAIR OF PRODUCTS UNDER THE ABOVE.

THE REMEDY SET FORTH IN THE WARRANTY STATEMENT IS THE BUYER’S SOLE AND EXCLUSIVE

REMEDY FOR WARRANTY CLAIMS. NO EXTENSION OF THIS WARRANTY WILL BE BINDING UPON

DATASENSING UNLESS SET FORTH IN WRITING AND SIGNED BY DATASENSING'S AUTHORIZED

REPRESENTATIVE. DATASENSING'S LIABILITY FOR DAMAGES ON ACCOUNT OF A CLAIMED

DEFECT IN ANY PRODUCT DELIVERED BY DATASENSING SHALL IN NO EVENT EXCEED THE

PURCHASE PRICE OF THE PRODUCT ON WHICH THE CLAIM IS BASED. DATASENSING SHALL NOT

BE LIABLE FOR DAMAGES RELATING TO ANY INSTRUMENT, EQUIPMENT, OR APPARATUS WITH

WHICH THE PRODUCT SOLD UNDER THIS AGREEMENT IS USED. Further details on warranty

coverage, rights and conditions are addressed under and regulated by the Terms and Conditions

of Sales of Datasensing available at https://www.datasensing.com/terms_conditions_sales.

PRODUCT REFERENCE GUIDE

1

CHAPTER 1

GENERAL INFORMATION

GENERAL DESCRIPTION

The safety light curtains are optoelectronic multi-beam devices that are used to protect

working areas that, in presence of machines, robots, and automatic systems in general,

can become dangerous for operators that can get in touch, even accidentally, with mov-

ing parts.

The light curtains are intrinsic safety systems used as accident-prevention protection

devices and are manufactured in accordance with the international Standards in force

for safety, in particular:

NORM DESCRIPTION

EN 61496-1: 2020

Safety of machinery: electro-sensitive protective equipment.

Part 1: General prescriptions and tests.

EN 61496-2: 2020

Safety of machinery: electro-sensitive protective equipment - par-

ticular requirements for equipment using active optoelectronic pro-

tective devices.

EN ISO 13849-1: 2015

Safety of machinery. Safety-related parts of control systems.

Part 1: General principles for design.

EN 61508-1: 2010

Functional safety of electrical/electronic/programmable electronic

safety-related systems.

Part 1: General requirements.

EN 61508-2: 2010

Functional safety of electrical/electronic/programmable electronic

safety-related systems.

Part 2: Requirements for electrical/electronic/programmable elec-

tronic safety-related systems.

EN 61508-3: 2010

Functional safety of electrical/electronic/programmable electronic

safety-related systems.

Part 3: Software requirements.

EN 61508-4: 2010

Functional safety of electrical/electronic/programmable electronic

safety-related systems.

Part 4: Definitions and abbreviations.

EN 62061:2005/A2:2015

Safety of machinery. Functional safety of electrical/ electronic/pro-

grammable electronic safety-related control systems.

GENERAL INFORMATION

2

SH4 BASE-STANDARD

The device, consisting in one emitting and one receiving unit housed inside strong alu-

minum profiles, generates infrared beams that detect any opaque object positioned

within the light curtain detection field.

The emitting and the receiving units are equipped with command and control functions

(no external control unit is required).

Electrical connections are made through removable pig-tails which attaches to the light

curtain through a custom connector (the same for all models) and provides one or two

M12 standard connectors from 5 to 12pin.

The synchronization between the emitter and the receiver takes place optically by

means of both the first and the last optic: no electrical connection between the two

units is required and one (of two) sync beam can be part of a blanked area.

The microprocessors guarantee the check and the management of the beams that are

sent and received through the units: the microprocessors - through some LEDs - inform

the operator about the general conditions of the light curtain and about eventual faults.

As soon as an object, a limb or the operator's body accidentally interrupts the beams

sent by the emitter, the receiver immediately switches off the OSSD output and blocks

the machine (if correctly connected to the OSSD).

The SH4 safety light curtains are used in all automation fields where it is necessary to

control and protect the access to dangerous zones. In particular they are used in Manu-

facturing industry, especially the three main vertical markets: Automotive, Electronics,

Food & Beverage. Most common vertical applications: Robotics, Metalworking, Intra-

logistic and Material Handling (incl. Packaging and Assembling), General Manufacturing.

The unit consists of modular optical units, that are made of one or more transmitter and

receiver pairs.

Each optical unit can be composed by bars containing a lot of optical units, according to

kind of model.

Receiver part is the main controller of all function, it checks and decides about safety

action in case of failure has other generic issue.

Emitter is a one task device: it runs continuously, lighting in sequence it's IR-photo emit-

ters.

NOTE: This manual contains all the information necessary for the selection

and operation of the safety devices.

However, specialized knowledge not included in this technical description

is required for the planning and implementation of a safety light curtain on

a power-driven machine.

As the required knowledge may not be completely included in this manual,

we suggest the customer to contact Datasensing Technical Service for any

necessary information relative to the functioning of the light curtains and

the safety rules that regulate the correct installation.

MODEL DESCRIPTION

PRODUCT REFERENCE GUIDE

3

MODEL DESCRIPTION

SH4 safety light curtains are described by their model description which indicates the

characteristics listed in the diagram below. Not all combinations are available. For a

complete list of combinations see the Models tab on the Product page of the website.

SH4 - xx - xxxx - x - x - x

Detection

capability or

n. of beams

Monitored

height in mm Functionality Rx main

connector

Rx secondary

connector

14 mm 300 to 2250 B = Base 5 pin M12 5 pin M12

30 mm S = Standard 8 pin M12 none

2 beams SM = Standard Muting 12 pin M12

3 beams A= Advanced

4 beams C = Cascade

NOTE: For 14/30 mm resolutions protected height starts from 300 mm up

to 2250 mm with 150 mm modularity.

BASE STANDARD STANDARD MUTING ADVANCED

FUNCTION

Automatic Restart Manual / Automatic Restart

Reset

External Device Monitoring (EDM)

Alignment Function

2-signals T Muting / L Muting

Single Override

2-signals muting dependent Override

Partial muting (half protection height)

Muting input filtering and timeout setting

Anti-interference coding

4-signals Muting

Dynamic partial muting

Partial Muting

(at beams level)

Fixed Blanking1

1. 1 Up to 5 simultaneous fixed or floating blanking zones can be used.

External signal fixed2

blanking teach-in

2. The response time depends on model height and the activation of anti interference code: for details refer to Response

times table

Floating Blanking

Reduced resolution

Integrated aimer

CONFIGURATION

- By wiring By Dip-Switch By APP via Wi-Fi

NOTE: This PRG describes the BASE and STANDARD models. For Standard

Muting and Advanced models refer to relative Product Reference Guide.

GENERAL INFORMATION

4

SH4 BASE-STANDARD

COMPLIANCE

European Declaration of Conformity

Hereby, Datasensing S.r.l. declares that the full text of the European Declaration of Con-

formity is available at: www.datasensing.com. Select the link from the downloads sec-

tion of the product page.

UKCA Declaration of Conformity

Hereby, Datasensing S.r.l. declares that the full text of the UKCA Declaration of Confor-

mity is available at: www.datasensing.com. Select the link from the downloads section

of the product page.

COMPLIANCE

PRODUCT REFERENCE GUIDE

5

6

SH4 BASE-STANDARD

CHAPTER 2

INSTALLATION

PACKAGE CONTENTS

Package contains the following objects:

• Receiver (RX)

• Emitter (TX)

• Quick Guide of safety light curtain

• Periodical checklist and maintenance schedule

• 4 angled fixing brackets and specific fasteners

• 2 additional angled fixing brackets for models with heights equal or greater than

1200 mm.

PRECAUTIONS TO BE OBSERVED FOR THE CHOICE AND INSTALLATION

PRODUCT REFERENCE GUIDE

7

PRECAUTIONS TO BE OBSERVED FOR THE CHOICE AND

INSTALLATION

• Use only matched emitter and receiver pairs with same serial no.

• The outputs (OSSD) of the ESPE must be used as machine stopping devices and

not as command devices.

• The machine must have its own START command.

• The dimension of the smallest object to be detected must be larger than the reso-

lution level of the device.

• The ESPE must be installed in an environment complying with the characteristics

indicated in Technical Data, starting on page 55.

• The ESPE must not be installed close to strong and/or flashing light sources, in par-

ticular close to the front window of receiving unit.

• The presence of intense electromagnetic disturbances could affect device’s cor-

rect operation.

• This condition shall be carefully assessed with the advice of DATALOGIC Technical

Service.

• The operating distance of the device can be reduced in presence of smog, fog or

airborne dust.

• A sudden change in environment temperature, with very low minimum peaks, can

generate a small condensation layer on the lenses and thus jeopardize correct

operation.

CAUTION: Make sure that the protection level assured by the light curtain

device is compatible with the real danger level of the machine to be con-

trolled, according to EN ISO 13849-1: 2015 or EN 62061:2005/A2: 2015.

INSTALLATION

8

SH4 BASE-STANDARD

HOW TO CHOOSE THE DEVICE

There are at least three different main characteristics that should be considered when

choosing a safety light curtain, after having evaluated the risk assessment.

Detection capability

The detection capability (or resolution) of the device is the minimum diameter that an

opaque object must have in order to obscure at least one of the beams that constitute

the detection zone and to actuate the sensing device.

The resolution is related to the part of the body to be protected.

As shown in the following figure the resolution only depends on the geometrical charac-

teristics of the lenses, diameter and distance between centers, and is independent of

any environmental and operating conditions of the safety light curtain.

Figure 1: Detection capability

The resolution value is obtained applying the following formula:

R = I + d

where:

I = Interaxes between two adjacent optics

d = Lens diameter

R = 14 mm Finger protection

R = 30 mm Hand protection

Operating distance

Protected height

R

opaque

object

d

I

HOW TO CHOOSE THE DEVICE

PRODUCT REFERENCE GUIDE

9

Height of the detection zone

The controlled height is the height protected by the safety light curtain.

In SH4-14/30 Protected Height is equal to ESPE total length: no dead zone is present.

In SH4-2/3/4, first beam center is positioned at 130 mm from light curtain bottom, pro-

tected height is defined as the distance between uppermost and lowermost beam

centreline.

Figure 2: Detection zone

Referring to the figure above the protected height is reported in the table here below.

MODEL PROTECTED HEIGHT (mm)

SH4-14/30-0300-X-X

300

SH4-14/30-0450-X-X

450

SH4-14/30-0600-X-X

600

SH4-14/30-0750-X-X

750

SH4-14/30-0900-X-X

900

SH4-14/30-1050-X-X

1050

SH4-14/30-1200-X-X

1200

SH4-14/30-1350-X-X

1350

SH4-14/30-1500-X-X

1500

SH4-14/30-1650-X-X

1650

SH4-14/30-1800-X-X

1800

SH4-14/30-1950-X-X

1950

SH4-14/30-2100-X-X

2100

SH4-14/30-2250-X-X

2250

SH4-2-0500-X(X)-X-(X)

500

SH4-3-0800-X(X)-X-(X)

800

SH4-4-0900-X(X)-X-(X)

900

SH4-4-1200-X(X)-X-(X)

1200

PROTECTED

AREA

Protected height

Operating distance

PROTECTED

AREA

Protected height 130mm

Operating distance

SH4-14/30 SH4-2/3/4

INSTALLATION

10

SH4 BASE-STANDARD

Minimum installation distance

The safety device must be positioned at a specific safety distance (Operating distance).

This distance must ensure that the dangerous area cannot be reached before the dan-

gerous motion of the machine has been stopped by the Safety Control System.

The safety distance depends on 4 factors, according to the EN ISO 13855 Standard:

• Response time of the ESPE (the time between the effective beam interruption and

the opening of the OSSD contacts)

• Machine stopping time including Safety Control System computing and actuating

time if present.

• ESPE resolution

• Approaching speed of the object to be detected

Figure 3: Installation distance (vertical positioning)

The following formula is used for the calculation of the safety distance:

S = K (t1 + t2) + C

where:

• S = Minimum safety distance in mm

• K = Speed of the object, limb or body approaching the dangerous area in mm/s

• t1 = Response time of the ESPE in seconds (see appendix “Technical Data”.)

• t2 = Machine stopping time in seconds (including the Safety Control System)

• C = Additional distance based on the possibility to insert the body or one of the

body parts inside the dangerous area before the protective device trips.

• C = 8 (R - 14) for devices with resolution ≤ 40 mm

• C = 850 mm for devices with resolution > 40 mm

• R = Resolution of the system

When devices with > 40 mm resolution are used, the height of the top beam has to be ≥

900 mm (H2) from machine supporting base while the height of the bottom beam has

to be ≤ 300 mm (H1).

NOTE: K value is:

2000 mm/s if the calculated value of S is ≤ 500 mm

1600 mm/s if the calculated value of S is > 500 mm

HOW TO CHOOSE THE DEVICE

PRODUCT REFERENCE GUIDE

11

If the safety light curtain must be mounted in a horizontal position (see figure below)

the distance between the dangerous area and the most distant optical beam must be

equal to the value calculated using the following formula:

S = 1600 mm/s (t1 + t2) + 1200 - 0.4 H

where:

• S = Minimum safety distance in mm

• t1 = Response time of the ESPE in seconds (see appendix “Technical Data”.)

• t2 = Machine stopping time in seconds (including the Safety Control System)

• H = Beam height from ground; this height must always be less than 1,000 mm

Figure 4: Installation distance (horizontal positioning)

Practical examples

Let's suppose to have a light curtain with height = 600 mm

To calculate the distance of the device from the ESPE, in a vertical position, the follow-

ing formula is used:

S = K*T + C

where:

• S = Minimum safety distance in mm

• t1 = ESPE response time

• t2 = Machine stopping time (including the Safety Control System)

• T = (t1 +t2) Overall system stopping performance

• C = 8 * (R - 14) for devices with resolution ≤ 40 mm

• R = Resolution of the system

In all cases, if K = 2000 mm/s, then S > 500 mm.

Distance will have to be recalculated using K = 1600 mm/s.

NOTE: The reference standard is EN ISO 13855 “Safety of machinery -

Positioning of safeguards with respect to the approach speeds of parts of

the human body”.

The following information is to be considered as indicative and concise.

For correct safety distance please refer to complete standard EN ISO 13855

INSTALLATION

12

SH4 BASE-STANDARD

TYPICAL APPLICATIONS

Example 1: Operating point protection on drilling machines

The operator positions the part and takes it back after machining. The operator must be

protected against possible abrasions while working.

Solution:

SH4 14mm safety light curtain is especially suitable for this kind of applica-

tion, which requires the installation of the device directly on the machine.

Advantages:

Highly reduced profile size guarantees installation flexibility for machine

dimensions.

Example 2: Bending presses

The safety device must protect the operator from being squashed between the top and

bottom tool or the machined part during the fast approach phase.

Solution:

If only one beam of the safety light curtain is darkened while the press is mov-

ing down, the mobile tool bar will stop.

Advantages:

The safety light curtain can be used in most bending operations thanks to

its easy installation and compact dimensions.

As well as offering excellent reliability, SH4 ensures increased plant productivity as it

reduces the dead times necessary for machine accessing, adjustment and maintenance.

This manual suits for next models

10

Table of contents

Other Datasensing Accessories manuals

Popular Accessories manuals by other brands

Proteco

Proteco RF 36 Installation and use manual

NeuLog

NeuLog NUL-216 Guide

Johnson Controls

Johnson Controls 7351J Installation and maintenance instructions

Cedes

Cedes IMS 100 Pro Series Installation and operation manual

Waterpik

Waterpik Water Flosse WP-65 manual

Lightolier

Lightolier Lytecaster 1045 specification

ADInstruments

ADInstruments Lt Series quick start guide

Omron

Omron ZFV-LTF01 instruction sheet

Perry Electric

Perry Electric 1PR6092 quick guide

VuPoint

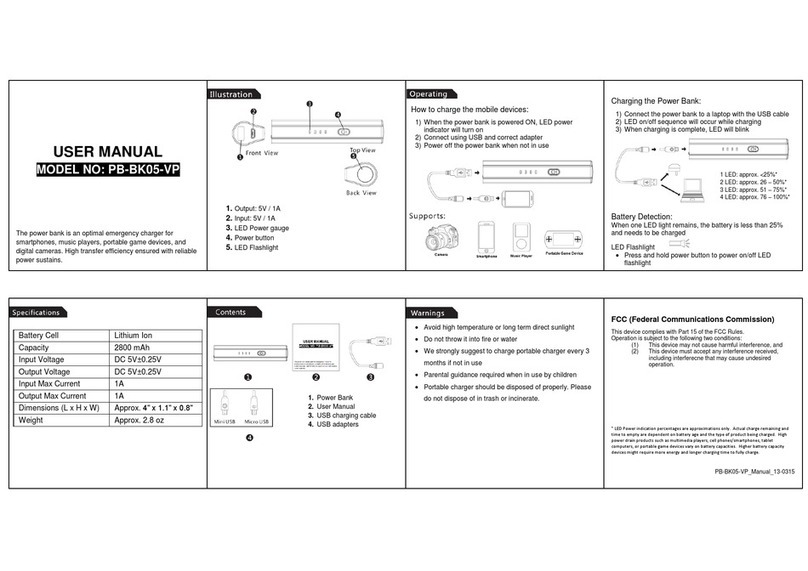

VuPoint PB-BK05-VP user manual

Black & Decker

Black & Decker TC212B instruction manual

Siko

Siko LEC100 Translation of the original installation instructions