Davis & Shirtliff DAYLIFF DX Series Installation instructions

DX Filter

Installation &

Operating Manual

INDEX

© Davis & Shirtliff Ltd 2022

Contents herein are not warranted

SPECIFICATIONS

1.

1

2.

INSTALLATION 3

3.

OPERATION 6

4.

TROUBLE SHOOTING 8

5.

TERMS OF WARRANTY 9

1

1. FILTER SPECIFICATIONS

The DAYLIFF 'DX' filter range is a comprehensive selection of swimming pool

filters suitable for both domestic and light institutional pool applications.

Combining the latest filtration technology with nearly twenty years of production

experience the range offers outstanding reliability, longevity, performance and

value. Five models in different sizes are available, all providing the following

features:-

l Elegant moulded filter bodies of non-corroding GRP construction for

strength and longetivity.

l Simple to use flange connected six-position multiport valves with union

connections. The flange arrangement greatly simplifies installation and

media replacement as well as providing a secure watertight seal.

l Specially designed internal collector laterals providing maximum

filtration and backwashing efficiency and minimal media loss.

l High-grade silica sand and glass media for exceptional filtration

performance.

Congratulations on selecting a Dayliff DX Filters. They are

manufactured to the highest standards and if installed and operated

correctly will give many years of efcient and trouble free service.

Careful reading of this Installation Manual is therefore important,

though should there be any queries they should be referred to the

equipment supplier.

2

It must be remembered that the most important aspect of a pool's appearance is

the quality of its water. The key to this is efficient filtration and a pool's filter is the

one piece of equipment where compromise does not pay. DAYLIFF 'DX' filters

are quality products which have been carefully designed to combine the highest

standards of performance with outstanding reliability and ease of operation.

With a DAYLIFF filter clean, sparkling water is assured at all times.

OPERATING PARAMETERS

H

From pool

To pool

Multiport valve

To waste

D

* Includes media and water

Dayliff DAB Power,

kW

SPP50M

SPP50M

DPL550

4

0.07

DPL550

SPP75MDPL750

SPP150MDPX1100

SPP200MDPX1100

SPP300MDPX1500

0.55

0.75

1.5

0.5

2.2

1.5

0.33

0.33 40,000

0.55

Light

Use

Normal

Use

Heavy

Use Suction Delivery

Recommended

Piping Size

Pool Capacity (Litres)Pump Options

Rated

Flow

3

(m /hr)

Model

DX300

DX300

Model Dimensions (mm)

H

Filter

Area

2

(m )

10

0.20

14

0.3

22

0.43

25

0.43

32

0.67

1.1

1.1

Power,

kW

1.1

100,000

140,000

220,000

250,000

300,000

30,000

80,000

115,000

180,000

200,000

240,000

25,000

60,000

85,000

130,000

150,000

180,000

1.5”

1.5”

2”

2.5”

2.5”

3”

1.5”

1.5”

1.5”

2”

2”

2.5”

DX500

DX500

DX600

DX600

DX750

DX750

DX800

DX800

DX900

DX900

830

830

980

1060

1280

1400

D

300

520

620

770

770

925

MPV

Valve Size Test

4.5

4.5

4.5

4.5

4.5

4.5

Working

3

3

3

3

3

3

Pressure (Bar) Weight (kgs)

Nett

11

13

15

21

25

32

Working*

115

170

250

420

525

820

3

2. INSTALLATION

2.1 Pipe Connections

The recommended piping layouts for “freeboard” and “decklevel” pools are

shown below. Piping should be uPVC Class C or D. Alternatively G.I. Piping

can be used if there is a risk of fracture.

Pipelines should be laid with as few bends as possible and either level or at

an even rising slope to the pump as changes in slope can lead to air pockets

and consequent operational problems. The backwash pipe must fall evenly

to a suitable discharge point below the level of the filter.

It is recommended that isolating valves be installed on the pool suction

adjacent to the pool wall and on the main drain, skimmer and vacuum

connections at the pump suction. A valve should also be fitted on the pool

return pipe if the inlets are below water level. The filter is supplied complete

with union connections to facilitate equipment removal if ever necessary.

Connections to the Multiport Valve are indicated on the appropriate outlets.

DECK LEVEL LAYOUT

4

FREE BOARD LAYOUT

2.2 Filter Positioning

When the Multiport Valve is clamped, the handle of the valve in the ‘FILTER’

position should line up with the manufacturer’s name plate. The filter should

therefore be positioned to take account of this BEFORE it is charged with

media.

2.3 Media Charging

The filter is provided with suitably graded media which should be gently

poured into the filter as per the details given below.

5

LAYER 1

LAYER 2

MODEL

LAYER 1 LAYER 2 LAYER 3

GRADE DEPTH

(MM)

DEPTH

(MM)

DEPTH

(MM)

GRADE GRADE

BAGS

(No.)

BAGS

(NO.)

BAGS

(NO.)

DX 500 C 175 0.6 A 200 1.5 NONE - -

DX 600 C 200 1.0 A 200 2.3 NONE - -

DX 750 C 200 2.0 A 200 4.5 NONE - -

DX 800 C 175 2.0 A 200 4.0 B 160 2.0

DX 900 C 200 4.0 A 200 6.0 B 110 2.0

MEDIA CHART

Sand Media

3 3

*Each standard DAYLIFF media bag is 1ft (0.03m ) & weighs appox. 50 kgs

C

DX300 - 0.3 A - 0.6 NONE - -

30% Freeboard for expansion

during backwash

When charging proceed as follows:-

! Disconnect the inlet, outlet and backwash pipes from the Multiport Valve at

the union connectors.

! Unscrew and remove the Multiport Valve clamp and lift out the valve, which

is sleeved on to an extension from the bottom collector pipes. This pipe

should now be blocked with paper or a cloth to prevent the ingress of media

during charging.

! Charge with media as per the instructions given above.

! Replace the Multiport Valve ensuring that both the valve neck and collector

O-rings have first been smeared with petroleum jelly. Note this should be

done whenever the Multiport Valve is removed.

! It is also important to ensure beforehand that all sand has been removed

from the filter O-ring seat and the O-ring itself to prevent leakage.

Rotate the Multiport Valve to align the outlet ports with the piping and ensure

proper seating. When properly seated the clamp should be secured ensuring

uniform torque but not over tightening of the clamp bolts. If the joint weeps under

pressure, reseat the MPV in a different position ensuring it is properly seated on

the filter neck. Over tightening will damage the filter.

6

2.4 Commissioning

When commissioning, the following procedure must be followed ensuring

the the MPV is properly :-

! Open all suction valves and ensure that the pump strainer is filled with

water.

! Open any valve on the return side of the filter.

! Set Multiport Valve to 'BACKWASH' and start pump.

! Check flow at the backwash pipe and allow the pump to run until the

backwash water is observed as reasonably clean, a minimum of five

minutes being recommended. This step is essential as the filter media is

not fully pre-washed and this procedure rinses the new sand clean.

Note that as the filter is initially empty it will take time to fill and there will

be a delay of a minute or two from when the pump is switched on to

when flow is observed.

! Stop pump and turn MPV to 'RINSE'.

! Start pump and allow media bed to rinse until waste water is observed

as clean. Stop pump and turn MPV to 'FILTER'.

! Start pump and allow system to operate until a steady flow is noticed at

the pool inlets. As the system is not primed it will take time for all air to

be expelled, so be prepared for a delay of up to ten minutes before a

steady flow is apparent.

Under no circumstances should the position of the

Multiport Valve be changed when the pump is running.

Always switch off the pump first or serious equipment

damage may result.

WARNING

3. OPERATION

3.1 Use of Multiport Valve

DAYLIFF filters are fitted with a Multiport Valve to control filter operation.

There are six positions on the valve and the various operations possible with

the different settings are described below.

7

FILTER

RINSE

BACKWASH During normal operation the filter will accumulate dirt in

the media bed. This is cleaned by a process of

backwashing when the filter flow is reversed and water is

pumped from the bottom to the top of the filter and then

to waste. It should be carried out whenever the filter

pressure exceeds the clean running pressure by 0.3Bar,

there is a noticeable reduction in inlet flow or weekly,

whichever is sooner. The backwashing process normally

takes 2-3 minutes and should be continued until the

waste water in the sight glass is observed as clear.

The normal operating position. Water from the pump is

fed into the top of the filter and after passing through the

media is collected at the bottom. It is then returned to the

pool through the inlet pipes.

After backwashing the filter media needs to be rinsed.

Water is pumped into the top and out of the bottom of

the filter as for normal filtering, but is then discharged to

waste. This removes any residual dirt in the media

instead of returning it to the pool. Rinsing should not

take more than one minute and again the sight glass on

the side of the valve can be used to see when the water is

clear.

WASTE

FILTER

PUMP

TO POOL

FROM POOL

WASTE

FILTER

TO POOL

FROM POOL

PUMP

PUMP

WASTE

FILTER

TO POOL

FROM POOL

3. OPERATION

TO POOL

FROM POOL

WASTE

FILTER

PUMP

RECIRCULATE

WASTE

In this position the filter is by-passed and the water is

pumped straight back into the pool. It will normally only

be necessary to use this position if there is a problem

with the filter itself (e.g. a leak or major blockage). It can

also be used if the filter is on a spa bath to increase the

pressure at the hydro-jet inlets.

The waste position is used for emptying the pool. The

filter is by-passed and water is taken straight from the

pool to waste. If it becomes necessary to empty the pool

make sure that the pump is not switched off once the

operation begins as there may be problems with priming

when the water level is below the pump. This position

can also be used for vacuuming to waste. This may be

necessary if there is a large amount of sediment on the

floor of the pool which would rapidly clog the filter in

TO POOL

FROM POOL

WASTE

FILTER

PUMP

8

WARNING

3. OPERATION

This shuts off all flow to the filter. In pool applications it is

most frequently used to isolate the filter when removing

the line strainer lid to clean the basket.

CLOSED

WASTE

FILTER

PUMP

FROM POOL

TO POOL

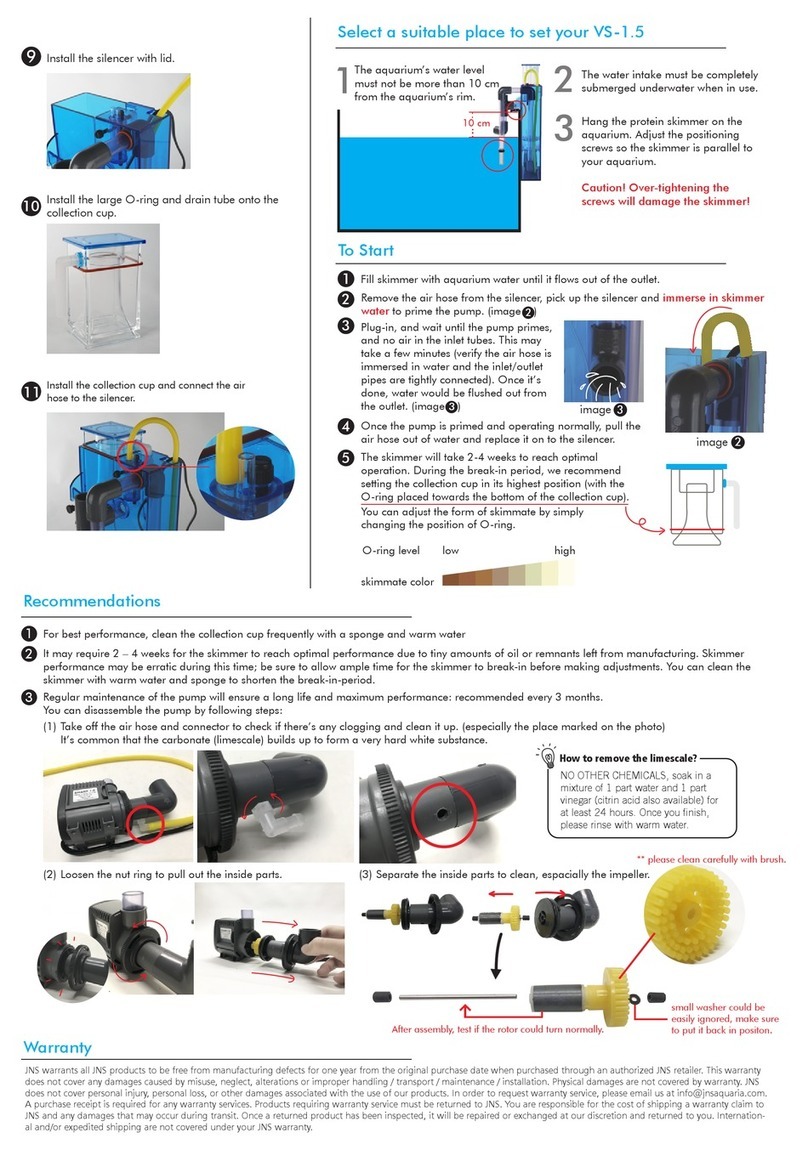

3.2 Maintenance of Filters

DAYLIFF filters need no routine maintenance other than regular

backwashing. However, over time the media will progressively clog and

become less effective. The period will depend upon the pool installation and

usage, though is normally some years. Ineffective media becomes apparent

through reduced filter efficiency and when this occurs re-charging with new

media will be necessary.

Important Note:-

The pipe connections must be correctly done as shown above. Hand tightening is

adequate for the MPV unions and under no circumstances should a pipe wrench

be used. If the union weeps, add more thread tape on the union threads and

make sure to check that the union O-Ring is in place.

PROBLEM

FILTER

POSSIBLE CAUSE SOLUTION

Flow rate very high

Water coming

out not clear

4. TROUBLE SHOOTING

Regulate flow rate to optimal levels

to ensure adequate filtration time

Filter not working well Check that the filter is in good

condition

Clogged sand filter Back wash the filter

Feed pump not working well

Low clean water

flow

Check that the pump performance

has not dropped drastically

Filter clogged Back wash the filter

System’s pipeline clogged Check that the pipeline is not

clogged and clean pipe if it's the case

Feed pump failed Repair or replace the pump

No water supply

at all

Check the right valves have been

closed or opened for the right

process operation

Filter clogged Backwash the filter

Valve arrangement control

Feed pump failed Repair or replace the pump

5. TERMS OF WARRANTY

i) General Liability

ii) Standard Warranty

• In lieu of any warranty, condition or liability implied by law, the liability of

Dayliff (hereafter called the Distributor) in respect of any defect or failure

of equipment supplied is limited to making good by replacement or

repair (at the Distributor’s discretion) defects which under proper use

appear therein and arise solely from faulty design, materials or

workmanship within a specified period. This period commences

immediately after the equipment has been delivered to the

customer and at its termination all liability ceases. Also the warranty

period will be assessed on the basis of the date that the Distributor is

informed of the failure.

ŸThis warranty applies solely to equipment supplied and no claim for

consequential damages, however arising, will be entertained. Also the

warranty specifically excludes defects caused by fair wear and tear, the

effects of careless handling, lack of maintenance, faulty installation,

incompetence on the part of the equipment user, Acts of God or any other

cause beyond the Distributors's reasonable control. Also, any repair or

attempt at repair carried out by any other party invalidates all

warranties.

General Terms

If equipment failure occurs in the normal course of service having been

competently installed and when operating within its specified duty limits

warranty will be provided as follows:-

• Up to three years - The item will be replaced or repaired at no

charge.

• Over three years, less than ve years - The item will be replaced or

repaired at a cost to the customer of 50% of the Davis & Shirtliff

market price.

The warranty on equipment supplied or installed by others is conditional

upon the defective unit being promptly returned free to a Davis &

Shirtliff ofce and collected thereafter when repaired. No element of site

repair is included in the warranty and any site attendance costs will be

payable in full at standard chargeout rates.

9

INS503A-12/22

This manual suits for next models

6

Table of contents

Popular Swimming Pool Filter manuals by other brands

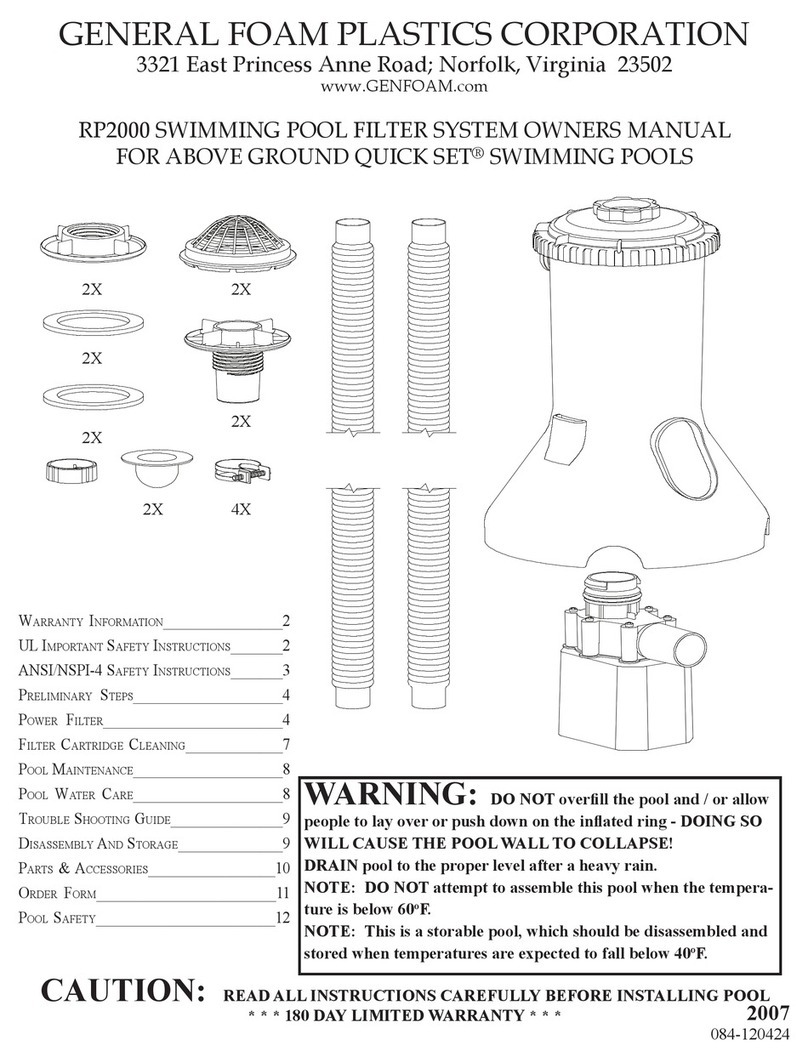

General Foam Plastics

General Foam Plastics RP2000 owner's manual

ubbink

ubbink Pool Filter 300 manual

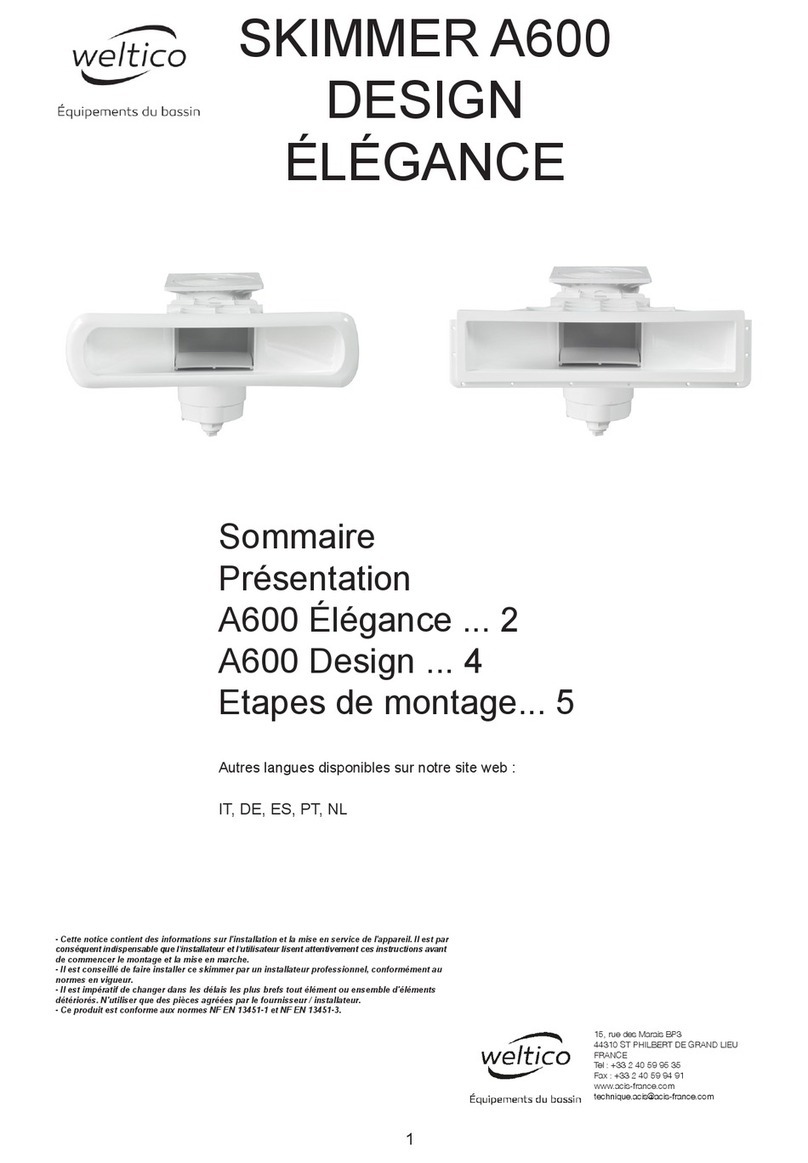

ACIS

ACIS weltico A600 ELEGANCE Assembly instructions

Pentair

Pentair FNS Plus FNSP 24 owner's manual

ChlorKing

ChlorKing NEXGEN10 Installation, operation and maintenance manual

Evolution

Evolution A15TS Installation and operation manual