Catalogue

Catalogue ..................................................................................................................................................................4

1. About this manual ..................................................................................................................................................5

1.1 Using this manual.........................................................................................................................................5

1.2 Applicable areas...........................................................................................................................................5

1.3 Applicable group...........................................................................................................................................5

1.4 Illustration .....................................................................................................................................................5

1.5 How to use this manual................................................................................................................................5

1.6 General Introduction.....................................................................................................................................5

1.7 Abbreviations and term ................................................................................................................................6

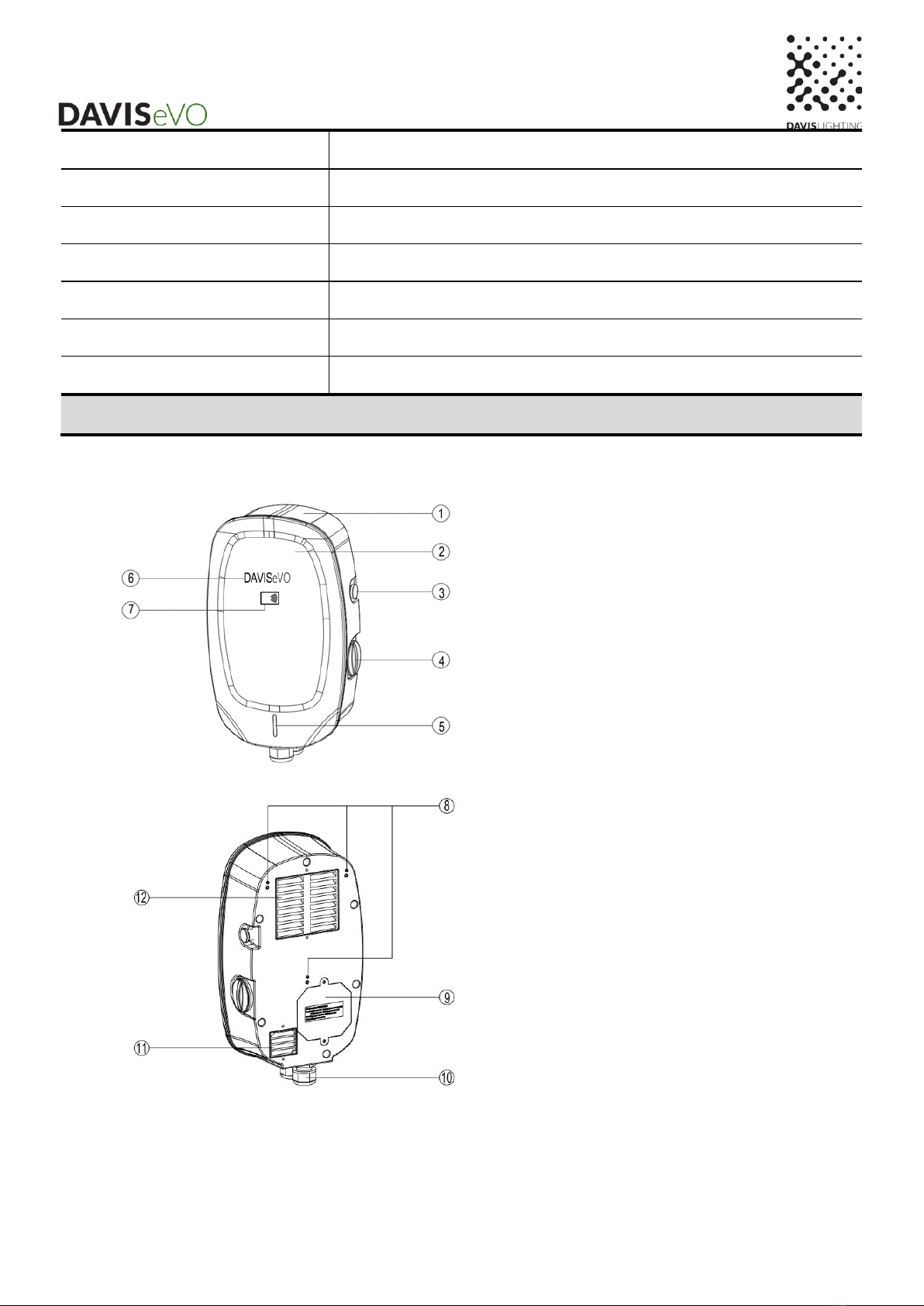

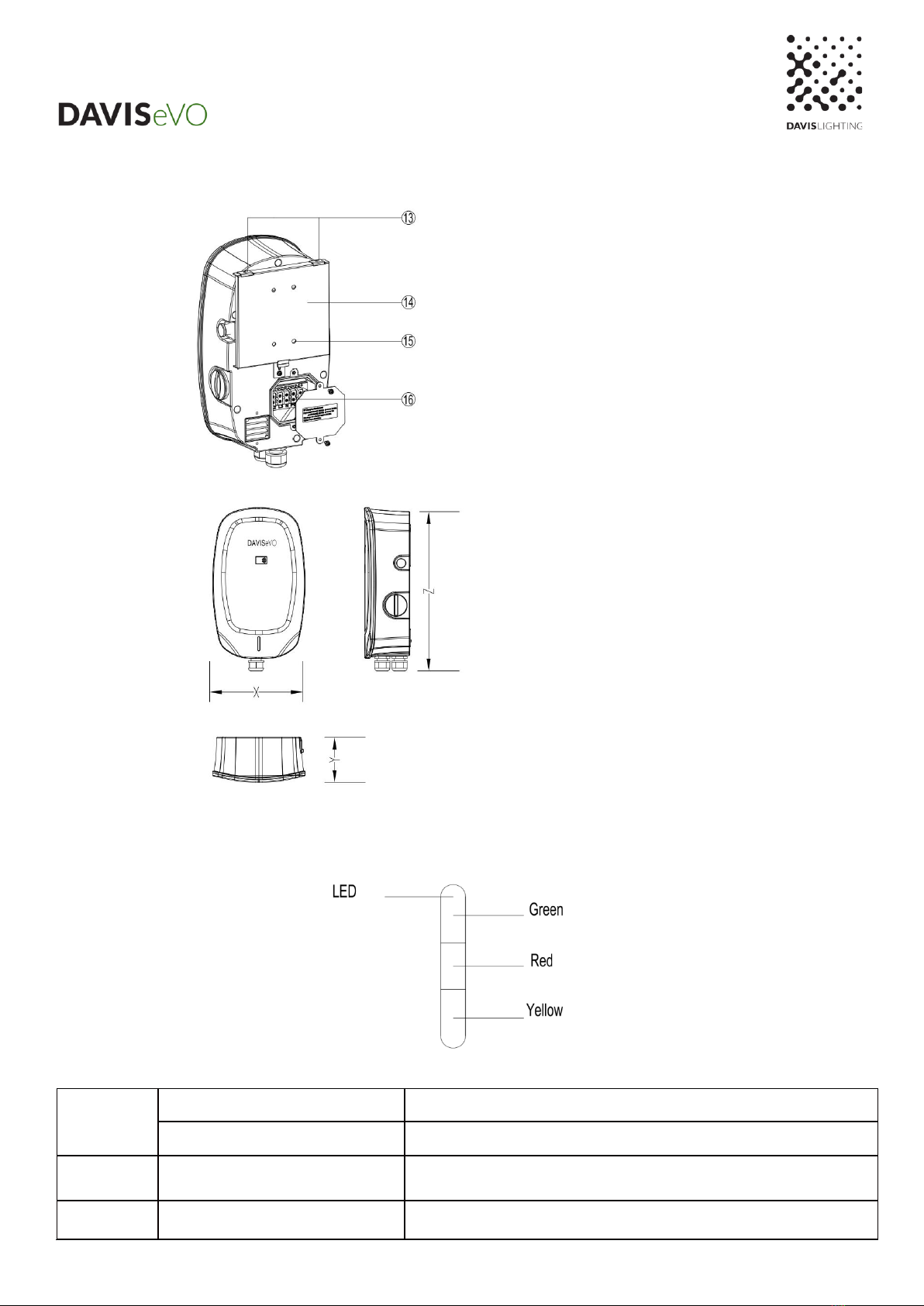

1.8 Product Overview..................................................................................................................................... 6,7

1.9 LED indicator................................................................................................................................................7

2. Specifications ........................................................................................................................................................8

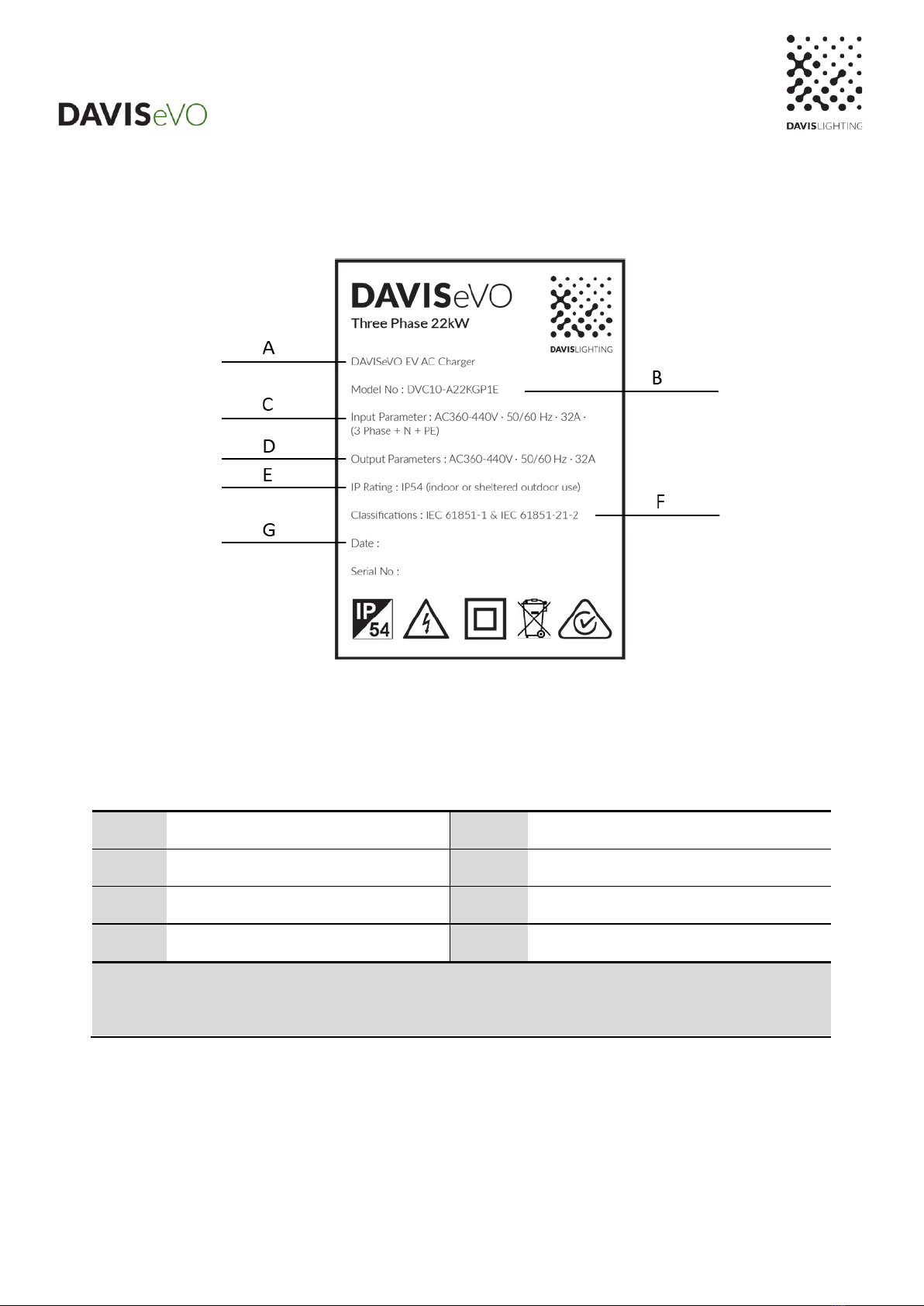

2.1 Product name plate......................................................................................................................................8

2.2 Product technical parameters ................................................................................................................ 9,10

3. Preparation for charger installation...................................................................................................................111

3.1 General requirements ..............................................................................................................................111

3.2 Environment and tool requirements.........................................................................................................111

3.3 Unpack the charger..................................................................................................................................111

4. Electrical installation of charger ..........................................................................................................................12

4.1 General Specification .................................................................................................................................12

4.2 Electrical installation procedure .................................................................................................................13

5. Mechanical installation of the Charger................................................................................................................15

5.1 Installation procedure of power distribution module (Optional) .................................................................15

(1) Cable hole pre-treatment.....................................................................................................................15

(2) Power distribution module cable connection.......................................................................................15

(3) Power distribution module installation.................................................................................................15

5.2 General Specification .................................................................................................................................16

5.3 Support rear plate mounting ......................................................................................................................17

5.4 Mounting bracket installation .....................................................................................................................17

5.5 Installation the whole Charger ...................................................................................................................18

5.6 End and check............................................................................................................................................18

6. Charger power supply operation.........................................................................................................................18

6.1 Power on operation....................................................................................................................................18

6.2 Close the Charger power switch................................................................................................................19

6.3 Power-off operation....................................................................................................................................19

7. Maintenance and fault diagnosis.........................................................................................................................20

7.1 Maintenance...............................................................................................................................................20

7.2 Fault diagnosis ...........................................................................................................................................20

8. DAVIS LIGHTING Service...................................................................................................................................22