CARE AND MAINTENANCE

CAREOF THE UNiT

A. Avoid leaning on the unit's door. You may bend the door hinge or tip the unit.

B. Exercise caution when sweeping, vacuuming or mopping near the front of the unit. Damage to the grill and/or switch

can occur.

C. Periodically clean the inside of the ice maker components and inside of the unit. Unplug the maker prior to doing so.

D. Periodically check and/or clean the front grille and condenser coils as needed.

E. Your ice maker has a stainless steel door and cabinet.To keep it looking at its best, we recommend periodically applying a

stainless steel cleaner and a non-abrasive stainless steel polish. This is especially important for outdoor applications and

locations near salt-water environments.

CLEANING YOUR UNIT

Some impurities will remain and build up in the ice maker and stick to the ice maker's parts over time. This build-up must

be removed for proper ice production, ice quality, and ice maker life. Your ice maker isequipped with a cleaning mode that

will help in cleaning out these impurities. This build-up of impurities will need to be cleaned regularly (at the very least,

annually), depending on use and water hardness. You can use an acid such as one specified for ice maker cleaning oryou

can use citric acid to remove the build-up. To clean the ice maker:

A. Switch the selector switch to the"OFF" position.

B. Remove the drain plug at the bottom of the reservoir to drain any remaining water and then reinstall.

C. Add the recommended cleaning solution to the reservoir of the ice maker. Access to the reservoir can be obtained

by removing the front panel screws and the front panel. Determine the proper amount of cleaner from the ice maker

cleaner manufacturer's mixture ratio based on three (3) quarts of water (refer to the manufacturer's directions).

D. Replace the front cover panel and close the door.

E. Switch the selector switch on the grille of the ice maker to the"CLEAN" position. Three (3) quarts of water will automati-

cally be added to the cleaning solution.

F. The total cleaning time will end in 49 minutes. The cleaning cycle will automatically rinse the evaporator plate and also

drain the cleaning solution and rinse with water.

G. After the cleaning cycle has ended, remove the front panel again and check that the build-up has been removed. The

evaporator plate should be clean, shiny, and smooth to the touch. If build-up is still visible, repeat the cleaning cycle

above. If build-up is removed, continue below.

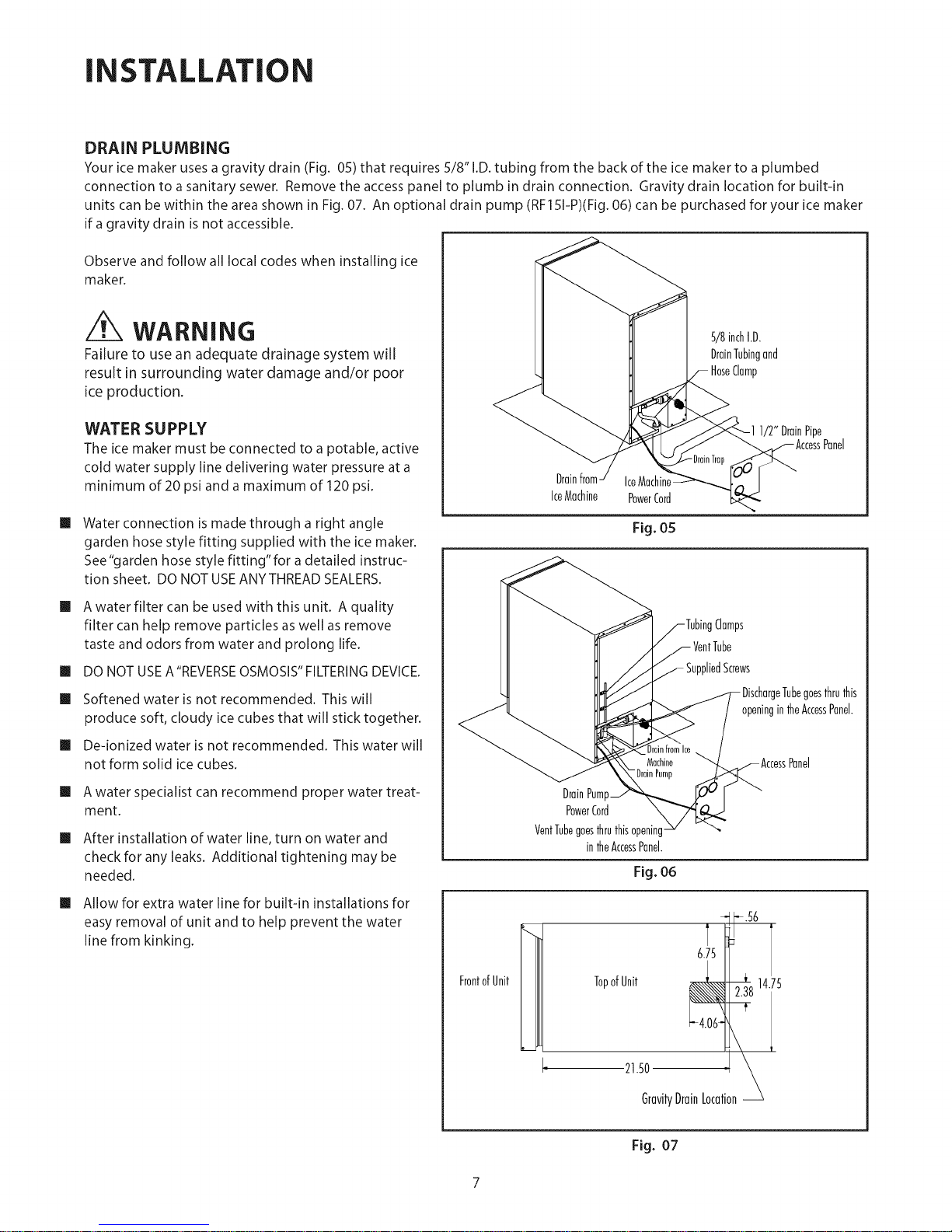

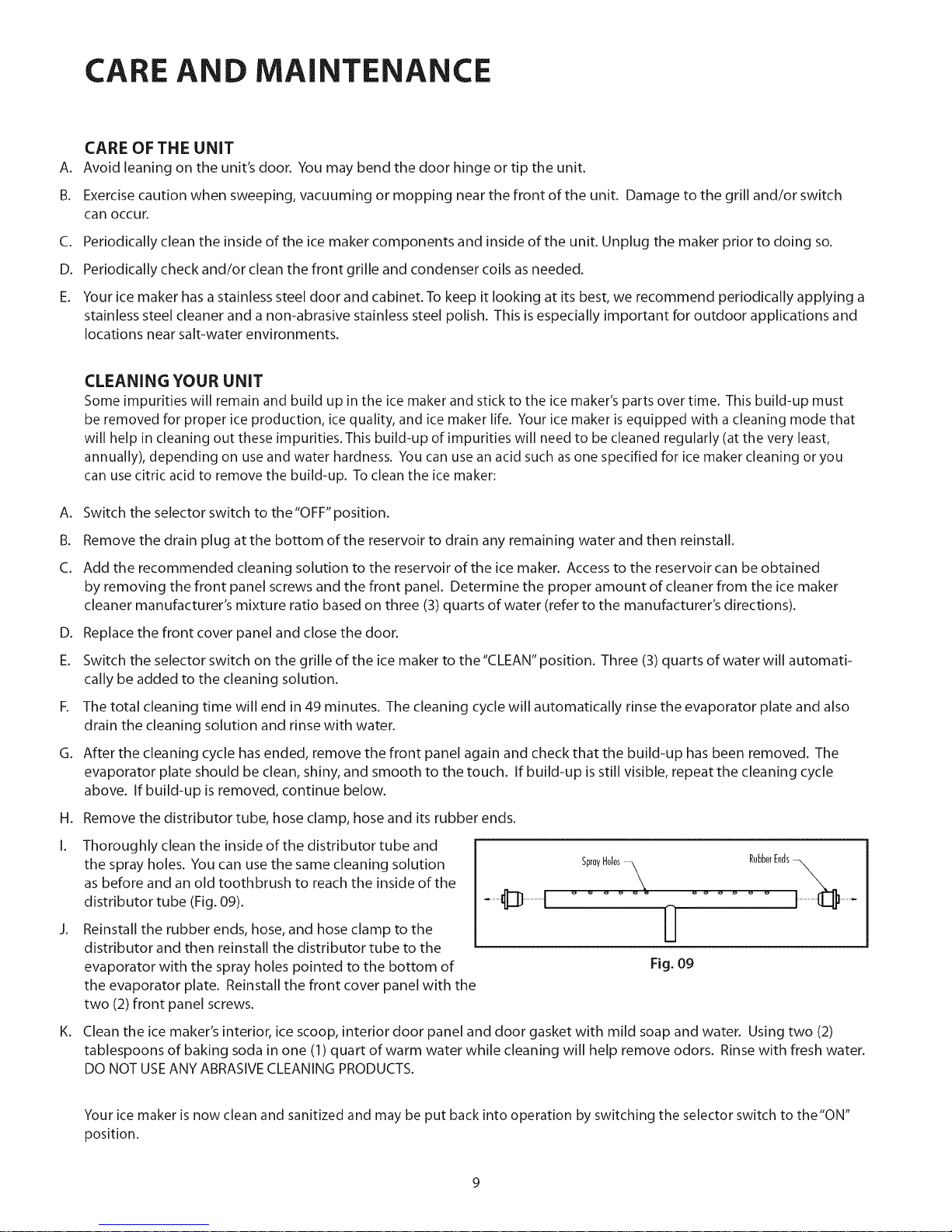

H. Remove the distributor tube, hose clamp, hose and its rubber ends.

J.

Thoroughly clean the inside of the distributor tube and

the spray holes. You can use the same cleaning solution

as before and an old toothbrush to reach the inside of the

distributor tube (Fig. 09).

Reinstall the rubber ends, hose, and hose clamp to the

distributor and then reinstall the distributor tube to the

evaporator with the spray holes pointed to the bottom of

the evaporator plate. Reinstall the front cover panel with the

two (2) front panel screws.

SprayHoles X RubberEnds_

Fig. 09

K. Clean the ice maker's interior, ice scoop, interior door panel and door gasket with mild soap and water. Using two (2)

tablespoons of baking soda in one (1) quart of warm water while cleaning will help remove odors. Rinse with fresh water.

DO NOT USE ANY ABRASIVE CLEANING PRODUCTS.

Your ice maker is now clean and sanitized and may be put back into operation by switching the selector switch to the"ON"

position.