DDK CM10-SP Series User manual

CM10-SP××S-×(D6)

Plug Connector

(Weight Saving Type・

・・

・Soldering Type)

Ca le Assem ly Manual(Standard Type)

Date of Issue:Feb 16, 2009

Manual No. TC-605

DDK Ltd.

roduction Engineering Department.

14 Matsuyama-cho, Moka-shi, Tochigi, 321-4393, Japan

改版

年 月 日 改版 No.

A ’08.3.26 新規発行

B ’08.5.13 変更通知 No.T-2205

Revision

Date Revision No.

A 2009/2/16 New Issue

B 2013/10/23 T-3671

Material No. age

TC-605 1/11

Contents

age

1.

Outline .......................................................................................................................................... 2

2.

Specifications ................................................................................................................................ 2

2-1.

Applicable connector ............................................................................................................. 2

3.

Cable Assembly rocess ............................................................................................................... 3

3-1.

Cutting a cable ...................................................................................................................... 3

3-2.

Inserting parts........................................................................................................................ 3

3-3.

Stripping a cable .................................................................................................................... 3

3-4.

Soldering a contact ................................................................................................................ 4

3-5.

Inserting a contact ................................................................................................................. 5

3-6.

Tightening a back shell .......................................................................................................... 6

3-7.

Inserting a bushing and a cable clamp ................................................................................... 8

3-8.

Tightening a clamp nut .......................................................................................................... 9

Material No. age

TC-605 2/11

1. Outline

This Cable Assembly Manual explains how to assemble the wire to the CM 10 angle plug connector.

(Solder type)

2. Specifications

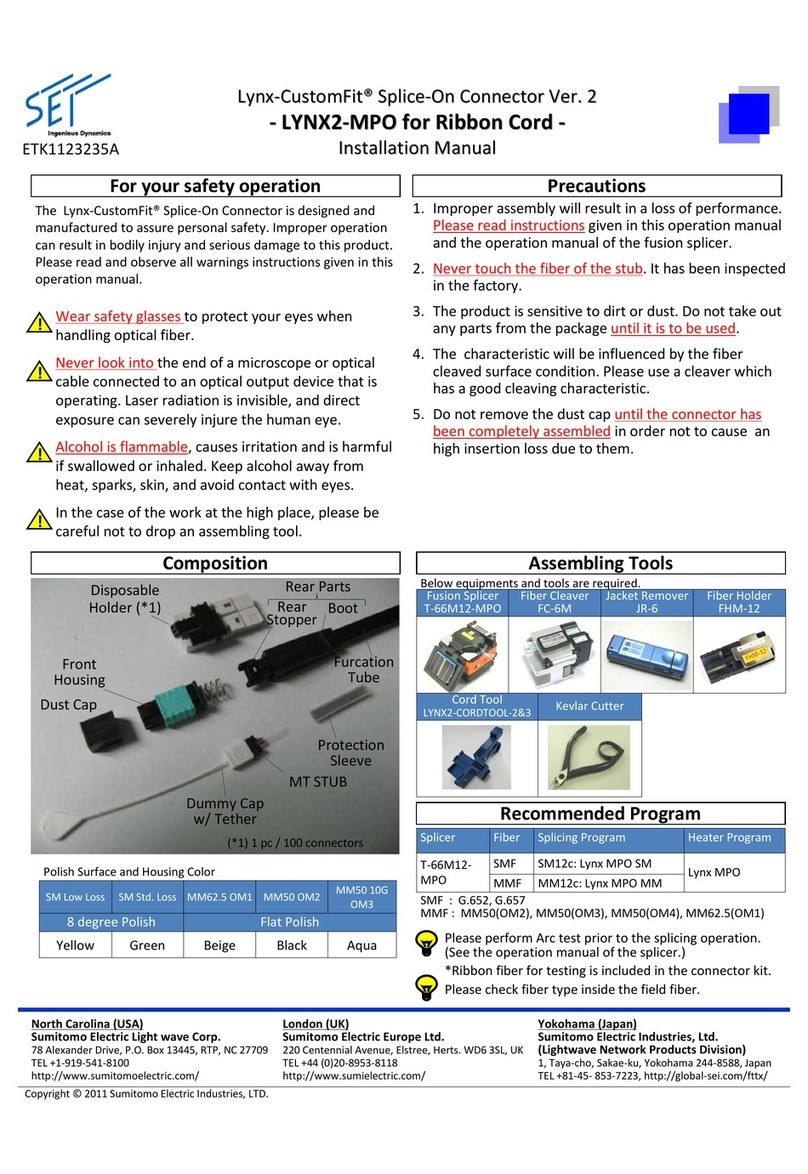

2-1. Applicable connector

Connector name Drawing number

CM10-S 2S-S(D6) 115J-A 12161-1

CM10-S 2S-M(D6) 115J-A 12161-2

CM10-S 2S-L(D6) 115J-A 12161-3

CM10-S 10S-S(D6) 115J-A 12159-1

CM10-S 10S-M(D6) 115J-A 12159-2

CM10-S 10S-L(D6) 115J-A 12159-3

Material No. age

TC-605 3/11

3. Cable Assembly rocess

3-1. Cutting a cable

Cut the cable to the following dimensions:

Note! Not to change ca le length.

3-2. Inserting parts

Insert the clamp nut, the cable clamp, the bushing and the back shell to the cable.

Note! Pay attention to the direction each part is inserted.

Make sure that every part is inserted.

3-3. Stripping a cable

Strip the cable’s sheath to the A length, cut the wire set at its root and strip the core wire to the B length.

Note! Make sure to strip the ca le to the correct length.

Do not leave cutting or scratch to the ca le core.

* When making CM10-SP10S(D6), strip the ca le for No. 10 terminal in a way that the A length

ecomes 1mm longer than that of other ca les.

(This is to prevent excessive tension of the ca le when inserting the contact to the housing

in the next process.)

* Ca le cut length = 35±

±±

±0.5mm for CM10-SPxxS(D6) + Ca le length

= 35±

±±

±0.5mm + Ca le length

Cable length

Bushing Cable clamp

Back shell

Cable

Clamp nut

roduct name A B

CM10-S 10S-×(D6)

18.5 to 19.5

4.5 to 5.0

CM10-S 2S-×(D6)

17.5 to 18.5

Amm

Bmm

Sheath

Core wire

Cable core

(A+1mm for No. 10 terminal only)

Material No. age

TC-605 4/11

Soldering

Enlargement of A area

3-4. Soldering a contact

Apply preliminary soldering to each contact and to the cable’s core wire, then solder the core wire to the

contacts.

Contact name Applicable contact

Applicable cable

CM10-S 10S-X(D6) CM10-#22SC(S1)(D8)

AWG20 or below

CM10-S 2S-X(D6) CM10-#22SC(S2)(D8)

AWG16 or below

Note! Make sure that the core wire does not come out of the contact.

When soldering, make sure that the solder does not stick to the circumference of the solder

cup.

When using a drain wire, attach a heat shrink tu e to the drain ca le after soldering.

* When making CM10-SP10S(D6), the ca le for No. 10 terminal is 1mm longer than other

ca les.

(To avoid

the ca le tension when inserting a contact to the housing in a later

process.)

* The difference in the total A length of the ca les for other than No. 10 terminal must e 1mm

or less.

If a drain wire is soldered

Drain wire

Heat shrink tube

Contact Core wire

Cable

A

29 to 32mm

Difference in total length: 1 mm or less

(for other than No. 10 terminal)

Material No. age

TC-605 5/11

Terminal No.

Contact

Lance

CM10-S 10S(D6)

3-5. Inserting a contact

Insert the contact into the specified terminal number point in the housing.

(Insert grounding wire or drain wire into terminal No. 10).

* When the contact catches the housing, you will hear a snap.

* Pulling the wire for confirming the correct position.

Note! Before inserting the contact, check that the clamp nut, ca le clamp, ushing and angle ack

shell is inserted.

Take care not to insert the contact upside down as shown elow.

* Insert the contact so that the terminal

num er face the same direction.

However, in case of CM10-SP2S(D6), insert the

contact so that the lance and the terminal

num er face the opposite direction.

* Using a pull out tool for pulling up inserted contact.

Tool No.: 357J-50548T

Refer to the instruction manual in case of using

pull up tool.

* As Lance falls down easily after pulling up,

set up to original position efore re-insert.

Terminal No. 10 only

(Grounding wire or drain wire)

Housing

Contact Cable

Insert

CM10-S 2S(D6)

Lance

Terminal No.

Contact

Material No. age

TC-605 6/11

3-6.

Tightening a back shell

(1) To prevent the straight back shell from loosening, coat 2 threads of the circumference of the straight back

shell with adhesive.

●

Recommended adhesive: 1401B (Three Bond Co., Ltd.)

(2) Rotate the back shell coupling of the connector and temporarily tighten the straight back shell.

* When tightening temporarily, match the concavity and convexity of the plug shell with those of the

angle ack shell.

(You can confirm the correct connection of concavity and convexity waving lightly ack shell just

efore inserting to BS coupling.)

Temporarily

tighten

Adhesive (to be coated to 2

threads of the circumference)

Straight back shell

Back shell coupling

Back shell coupling

Straight back shell

Back shell coupling

lug shell concavity and

convexity

Back shell concavity and

convexity

OK

OKOK

OK

NG

NGNG

NG

プラグシェル

バックシェル

lug shell Back shell

Material No. age

TC-605 7/11

Fix the back shell

(3) Fix the 2 surface width of the angle back shell on the tightening guide.

(4) Set the tightening wrench adjusting to the back shell coupling.

(5) With the wrench, tighten the back shell coupling to the angle back shell.

Recommended tightening torque: 4to5Nm

Note! When setting the work to the wrench, adjust it to the 2 surface width.

To remove, take the reverse steps.

Recommended jigs and tools : BS coupling tightening tool (wrench) (357J-51333T)

Bit (357J-51344T)

Torque wrench (CL6N x 8D), Tonichi Mfg.)

* Recommended tightening guide: (357J-50494T)

* Reference dimension for fixing the

back shell

17

20

Board

thickness: 10

(Back shell 2

surface width)

Back shell coupling

Fix the back shell

Back shell

Set

Tightening

wrench

Tighten

19

Torque wrench

* Recommendation:

Tightening guide

(357J-50494T)

Material No. age

TC-605 8/11

3-7.

Inserting a bushing and a cable clamp

Insert the bushing and the cable clamp in the back shell.

Note! After the Bushing insert, confirm that ca le position should e inside of Bushing.

Insert

Cable clamp

Bushing

Cable

Back shell

Material No. age

TC-605 9/11

3-8.

Tightening a clamp nut

(1) Temporarily tighten the clamp nut on the angle back shell.

* To prevent the loosening, it is recommended to coat the straight ack shell with adhesive.

Recommended adhesive: 1401B (Three Bond Co., Ltd.)

(2) Fix the 2 surface width of the angle back shell on the tightening guide.

(3) Set the tightening wrench adjusting the 2 surface width of the clamp nut.

(4) With the wrench, tighten the clamp nut on the angle back shell.

Recommended tightening torque: 4to5 Nm

Note! When setting the work to the wrench, adjust the 2 surface width.

In case of squeezing the clamp nut with excessed torque provided as a ove, the clamp nut

may e roken.

Please use the torque wrench.

To remove, take the reverse steps.

Recommended jigs and tools : Clamp nut tightening tool (wrench) (357J-51334T)

Bit (357J-51345T)

Torque wrench (CL6N×8D, Tonichi Mfg.)

* Recommended tightening guide :(357J-50494T)

Torque wrench

Tightening

wrench

19

Tighten

Tighten temporarily

Fix the back shell

Back shell

Fix the back shell

Clamp nut

Set

*Recommended adhesive

(to be coated on 2 threads of the

circumference)

*Reference dimension for fixing the back shell

17

20

Board

thickness: 10

(Back shell 2

sruface width)

* Recommendation:

Tightening guide

(357J-50494T)

Material No. age

TC-605 10/11

*To connection

(1) Set the mark of each other’s connectors.

(2) Each other’s key (concavity and convexity) are fit in. ush it straight, take care not to tilt.

*To remove , rotate the coupling and pull out to straight.

Receptacle connector key

(Convexity)

lug connector key

(Concavity)

ush it straight

(2)

Pull out to straight

Receptacle connector

mark

lug connector

mark

(1)

Rotate the coupling

Coupling

Material No. age

TC-605 11/11

*When using a conduit

(1) Tighten the nipple of conduit connector on the plug connector (CM10).

(2) Set the conduit on the nipple of conduit connector.

(3) Fix the conduit to the plug connector (CM10). If the conduit is used in a moving part, fix the conduit with a

saddle, etc. so that no load is applied to the plug connector (CM10) and to the conduit connector. If the

conduit is fixed with a saddle, etc., make sure that no load is applied to the fixing area. Set the protective

cover (rubber etc.,) on the conduit to avoid cable damage.

Recommended conduit & connector : NI ON FLEX CO.LTD

Conduit

Tipe:VF Tipe:SR Tipe:FBN Tipe:EM

Tipe:VFS Tipe:SRK etc.,

Connector

Tipe:RCM

* NI ON FLEX CO., LTD home page → http://www.nipolex.co.jp

lug connector

Conduit

Conduit

connector

rotective cover

(Rubber etc.)

Saddle

(2)

lug connector

Conduit

connector

Conduit

(1)

lug

connector

Conduit

Connector

(nipple)

Cable

(3)

This manual suits for next models

6

Table of contents

Other DDK Cables And Connectors manuals

Popular Cables And Connectors manuals by other brands

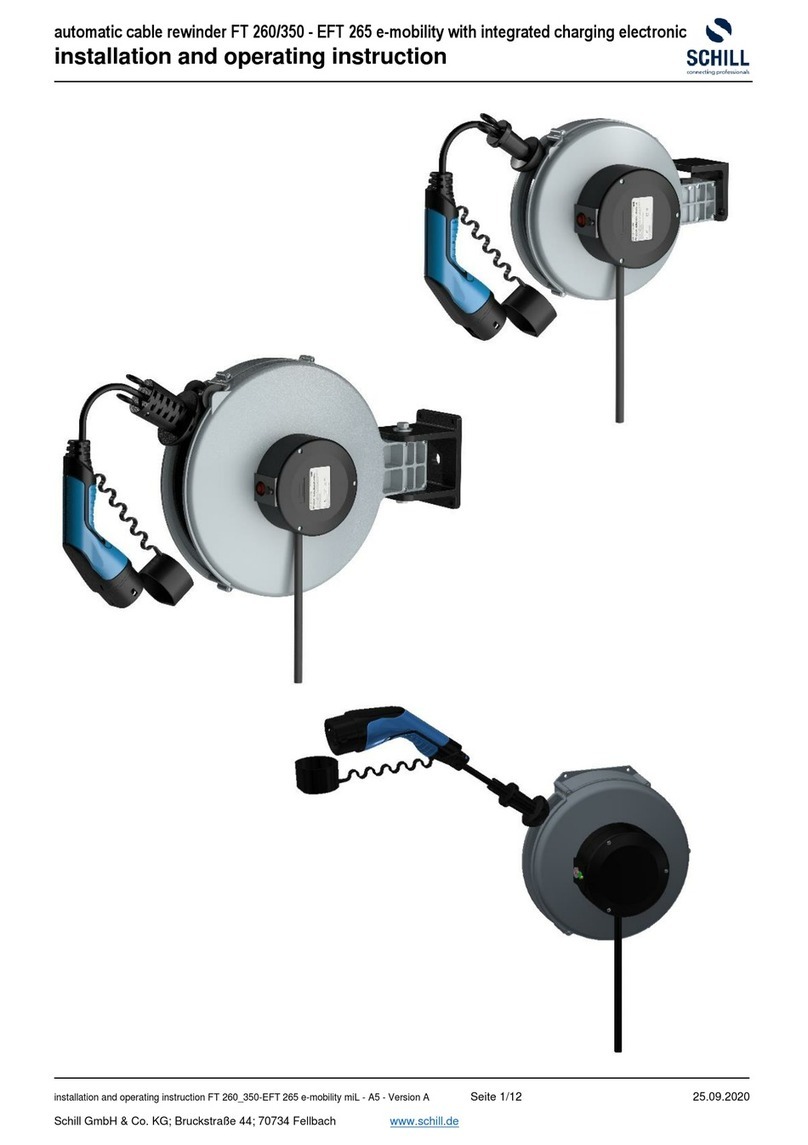

Schill

Schill FT 260 Installation and operating instruction

Parkside

Parkside 280209 Translation of the original instructions

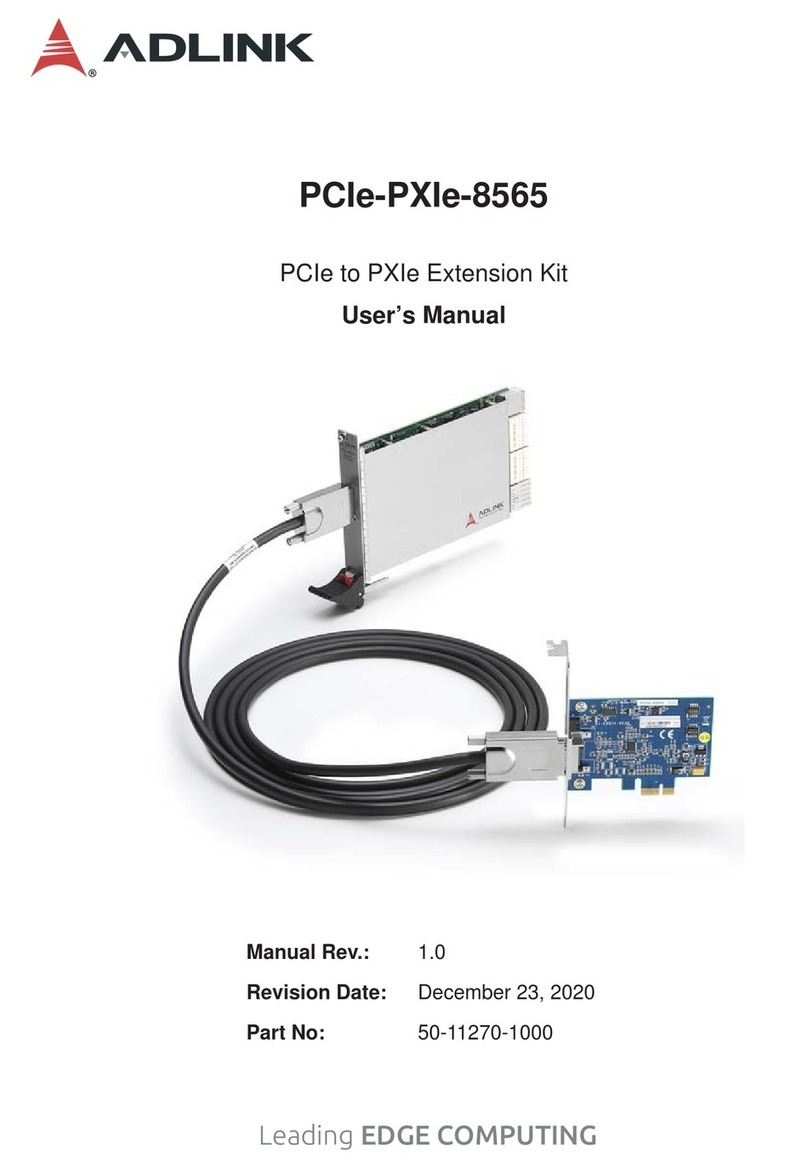

ADLINK Technology

ADLINK Technology PCIe-PXIe-8565 user manual

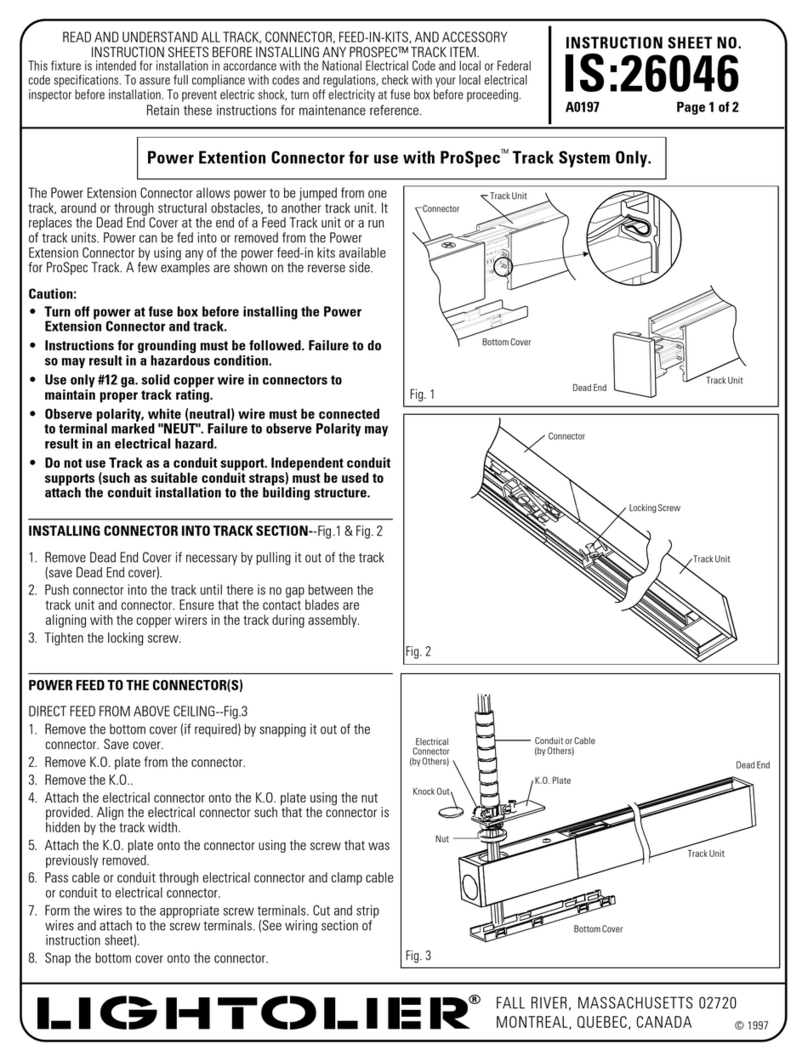

Lightolier

Lightolier ProSpec TRACK ITEM instruction sheet

Amphenol

Amphenol MS Series manual

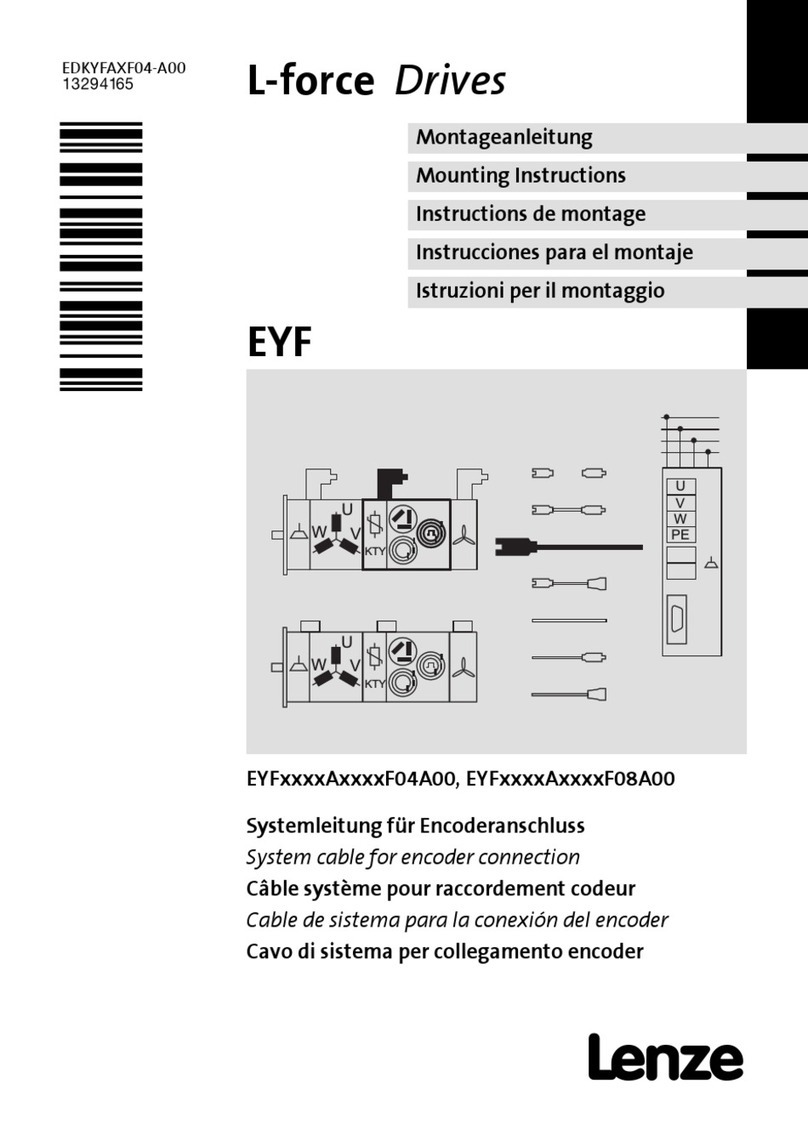

Lenze

Lenze L-force EYF A F04A00 Series Mounting instructions