Carefully read this manual before assembling

the SHUTTLE and follow the instructions.

✓

Check to ensure that the SHUTTLE is the

correct lift solution for the intended operations.

Carry out a thorough risk analysis prior to

assembly and use of the SHUTTLE and act in

accordance with the results thereof.

✓

Check that the SHUTTLE has been assembled

by a person authorised and qualified to do so.

✓

Check that correct marking is present,

especially the stickers warning of the

entrapment hazard and the winch sticker

warning against running the winch at rail

end and prescribing mandatory use of the

slip coupling on the drill/driver driving the

SHUTTLE winch.

✓

As far as the scaffolding is concerned, check

that this (i) is certified scaffolding and that it

complies with the most recent guidelines, (ii)

that it has been put up correctly and in accor-

dance with the guidelines and (iii) that it has

been put up by a qualified person.

✓

Check (i) that the outriggers are in place, (ii)

that the crate with load remains fully within

the outer diameter of the outriggers and (iii)

can move freely along the entire length of the

lift mast.

✓

✓Make sure that unauthorised persons

cannot operate the SHUTTLE. Disassemble

the SHUTTLE completely if the aforesaid

requirements cannot be (sufficiently) met.

✓Always use the slip coupling of the drill/driver

when operating the SHUTTLE winch. Set this

coupling in accordance with the instructions in

this manual.

✓Always use the SHUTTLE winch spring lock to

secure the SHUTTLE carriage at height.

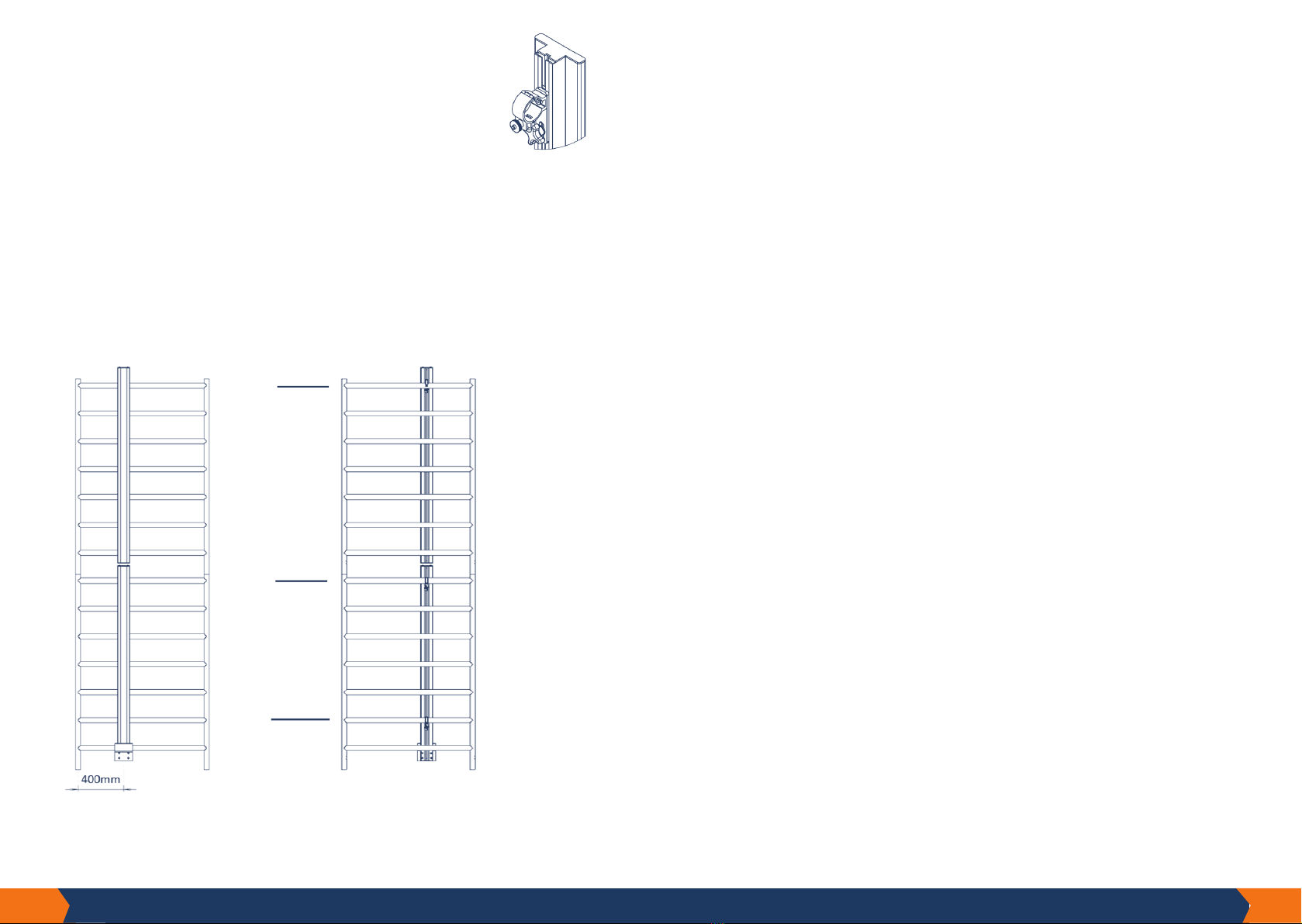

Make sure the lift mast is perfectly straight and

that the winch is completely perpendicular to

it. This is important to prevent folding of the

winch belt.

✓

DO

Do not use the SHUTTLE if there is anything

in the manual that you do not understand.

Contact the supplier for advice.

X

The SHUTTLE must never be assembled, used,

moved or disassembled by unauthorised

persons.

X

Never use the SHUTTLE in poor weather

conditions that could endanger the user (snow,

sleet, heavy rain, lightning).

X

Never use the SHUTTLE near overhead

electrical cables that are within reach of the

user.

X

X

The SHUTTLE is exclusively intended for the

vertical transport of goods and not of persons

and/or animals. Lifting and/or lowering

persons and/or animals with the SHUTTLE is

strictly forbidden.

X

Never load the SHUTTLE crate with a weight

higher than 30 kilos.

X

Never bend over the railing of the platform

to take goods out of the loading crate. The

user’s upper body must at all times remain fully

behind the platform railing.

X

Never use the SHUTTLE if the winch slip

coupling has not been properly adjusted and/

or if it is not working properly.

X

X

Never allow the SHUTTLE winch to run against

the rail end as this can damage the winch.

When using the SHUTTLE, never allow anyone

to stand or move underneath the SHUTTLE.

DON’T

3. SAFETY

DO’S/ DON’TS

Finally

Avoid getting trapped: keep out of the way of the Shuttle.

Persons on the lower platforms of the scaolding should take care not to place their hands/

arms and feet/legs directly next to the Shuttle’s guide rail.

Likewise, make sure no objects are sticking out of the Shuttle’s path.

Warning stickers must be axed to the inside of the guide rail.

These stickers are supplied with the product by the manufacturer and more can be ordered

if desired.

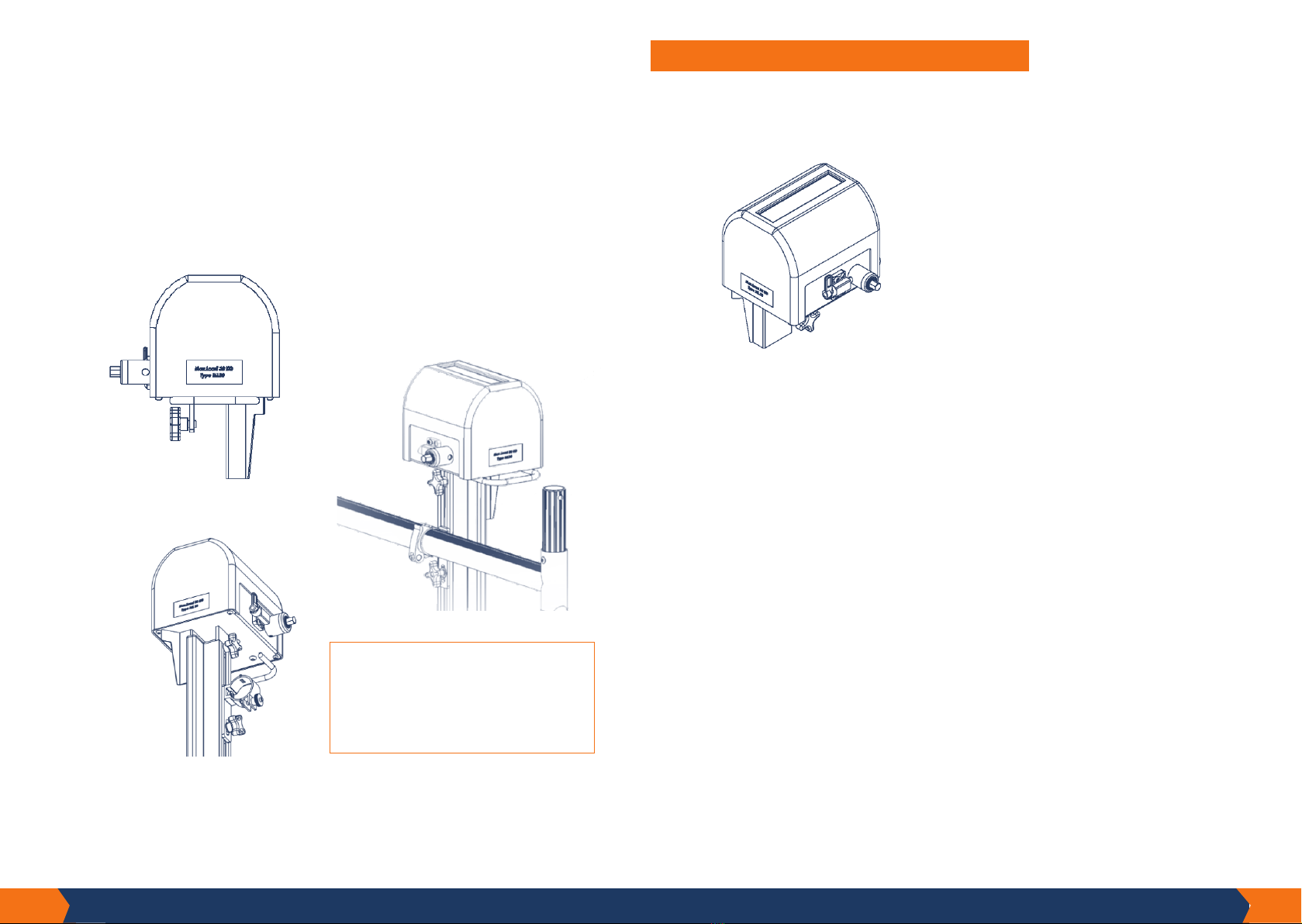

Regularly check your winch belt and make sure that it always runs perfectly flat and

straight when in operation

The most important point to pay attention to when using the winch belt is that it always

enters the winch flat and without folding and twisting. Avoid folds in the winch belt. When

entering the winch drum enters, these folds become worse and the belt no longer rolls up

flat. This will damage and weaken the winch belt.

The winch belt has enormous strength. The belt must nevertheless be checked regularly (at

least once a month) to ensure that no damage has been caused, for example, by contact

with sharp objects.

If you detect any cracks, frays or notches, replace your belt immediately!

The winch belt must be replaced with a new belt five years after its production date, due to

UV rays acting on the belt. This also applies if the belt is still completely intact.

Remember - maximum 30-kilo load and goods only

The Shuttle is designed for loads of up to 30 kilos. Do not exceed that weight. Overloading

can also damage your drill.

The Shuttle must be used to lift goods only. Under no circumstances should it be used to

lift or lower animals or children/adults.

17.

^

16.

^