deconta Quick-Dush ECO-LINE Series User manual

Instruction manual

Personnel lock system

Quick-Dush ECO-LINE

Manufacturer: deconta GmbH

Im Geer 20, D - 46419 Isselburg

Description / Type-No.: Personnel lock system Quick-Dush ECO-LINE

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 2

Table of contents

on page

1 Introduction 3

2 Basic safety advice 4

2.1 Intended use 4

2.2 Operation 4

3 Transport 5

3.1 Delivery 5

3.2 Transport 5

3.3 Storage 5

4 Scope of delivery 5

5 Technical description 6

5.1 Description of unit 6

5.2 Description of personnel lock system 6

6 Technical data 7

7 Initial operation 8

8 Maintenance and care 12

9 Possible disturbances and their repair 12

10 Declaration of conformity 13

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 3

1 Introduction

Dear customer,

Thank you for choosing a deconta product!

With this device you obtain a practical solution with simple operation, which was

completed in a compact and functional way.

The deconta products guarantee:

Stability, long life and servicability on site

Mechanics with „kick“

Pleasing design

The copyright of this instruction manual remains with deconta. This manual is intended

for assembly, operation and maintenance personnel. It contains instructions and drafts of

technical nature which may neither be distributed nor used in any unauthorised way for

competitive purposes or passed on to others.

For more information, please visit our website www.deconta.com.

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 4

2 Basic safety advices

The handling of the appliance technology is only allowed for instructed staff. The exact

knowledge of the instruction manual is an important condition for your staff in regard to

the handling of the machine.

2.1 Intended use

As an operator, you are obliged by deconta to follow the instruction manual and to use

this engineered technology equipment only in accordance with the regulations and not in

an inappropriate way! In the event of non-observance, deconta assumes no liability.

We make an explicit reference to the required safety measures indicated in the TRGS

519 Number 7.3, § 8 and 9, when assembling and disassembling as well as in regard to

maintenance of the equipment.

2.2 Operation

In order to ensure the safety during the operation of the device, the following must be

observed:

Do not place in an explosive area.

Necessary repairs, maintenance and cleaning, in particular in the field of electrical

equipment may only be realized by qualified staff.

The safety and protective equipment has to be treated with care.

the indicated safety advices have to be kept in a readable state and have to be

observed

In order to ensure safety, any changes to the machine are prohibited.

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 5

3 Transport

3.1 Delivery

Unless agreed otherwise, the lock system is packed completely and securely for

transport by deconta.

Transport damages have to be documented at once during the handing over of the

carrier or another supplier. Please note the possible damages additionally on the way bill.

3.2 Transport

A special transport rack for all single parts of the personnel lock system has been

developed for transport and storage.

To avoid damages caused by improper handling or carelessness, it is common practice

to handle the Transport with care.

3.3 Storage

The lock system may only be stored when decontaminated. In order to avoid

damages, the installation has to be kept in a dry area with no access for unauthorized

persons.

4 Scope of delivery

The volume of delivery of a lock system, unless no other agreements have been made,

consists of:

• Personnel lock (number of chambers depending on the model)

• Instruction manual

optional • Water treatment boiler system with integrated filtration system

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 6

5 Technical description

5.1 Description of unit

During asbestos sanitation works within closed rooms, it must be avoided that asbestos

fibres leave the sanitation area and pose a threat to human health or the environment.

Therefore, the sanitation area (also called dirty area) has to be separated from the clean

area and be kept in dynamic negative pressure by Negative Pressure Units.

In order to leave or enter these areas, the personnel lock system Quick-Dush ECO-LINE

has been developed and built. It enables the transfer inward and outward as well as the

cleaning of the persons without endangering the environment.

5.2 Description of Personnel lock system

Following main features characterise the personnel lock system:

Minimal set-up time thanks to a clamping fixture technique, installation without

tools.

Windows on all doors

Roof translucent

Steady connection of the bottom and roof elements thanks to corner profiles

Sealing of the doors thanks to a magnetic stripes passing through

Side walls and doors made out of recycled plastics

Good insulating properties against heat and cold.

Easy cleaning thanks to light coloured and smooth surfaces

Room for the shower with shower head

Grate floor in every chamber

All wall elements with ventilation

Water connections GEKA system

The Lock system is a modular system and can be adapted in almost every situation. Roof

and bottom elements having the same attachment enable to extend the existing system

later on and to continue using existing parts. An enlargement with any number of

chambers is possible at any time.

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 7

6 Technical data

Dimensions per chamber, inside:

Model 750 Model 900

Dimensions per chamber:

interior (LxWxH): 730 x 730 x 1965 880 x 880 x 1965

exterior (LxWxH): 750 x 750 x 2000 900 x 900 x 2000

Weight:

3-chamber lock system 150 kg 161 kg

5-chamber lock system 236 kg 257 kg

Water supply:

Fresh water connection: 1/2“ hose and GEKA-

connection to shower element

of personnel lock system

Sewage water connection: 3/4“ hose and GEKA-

connection to bottom element

of personnel lock system

Options:

Side wall with hose connector flange

Side wall with additional air supply filter

Side wall with window

Additional chambers

technical changes reserved

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 8

7 Initial operation

Preparation:

Previous to the assembly of the personnel lock:

Determine the exact position and the ground plan

The ground has to be flat and clean

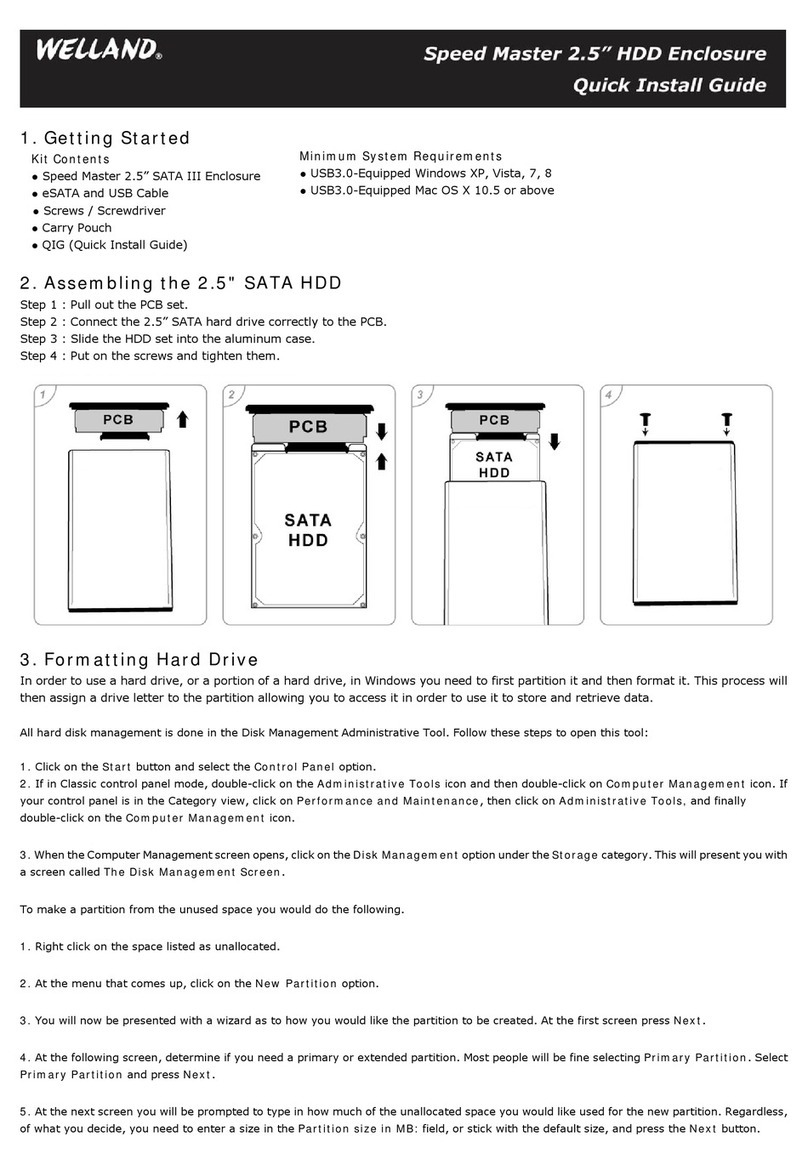

Assembly:

Put the bottom elements straight ahead from each other and place the grates.

In case of unevenness of the space, at least 2 squared timbers of a minimal cross

section of 10 cm x 10 cm should be placed underneath the total length and aligned.

Note:

The sewage water connection of the shower cabin should have the shortest way to the

water treatment device, in order to avoid needless lengths of hoses or cables. The

mounting brackets of the base tube have to be cleaned before the insert of the door and

wall elements!

load capacity of single floor element: max. 150 kg

Insert the corner profile in the connection corner of two bottoms and tense the quick

clamping fixture situated at the end of the corner profile with the bottom.

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 9

Insert one wall element in the mounting bracket of the bottom element and the corner

profile

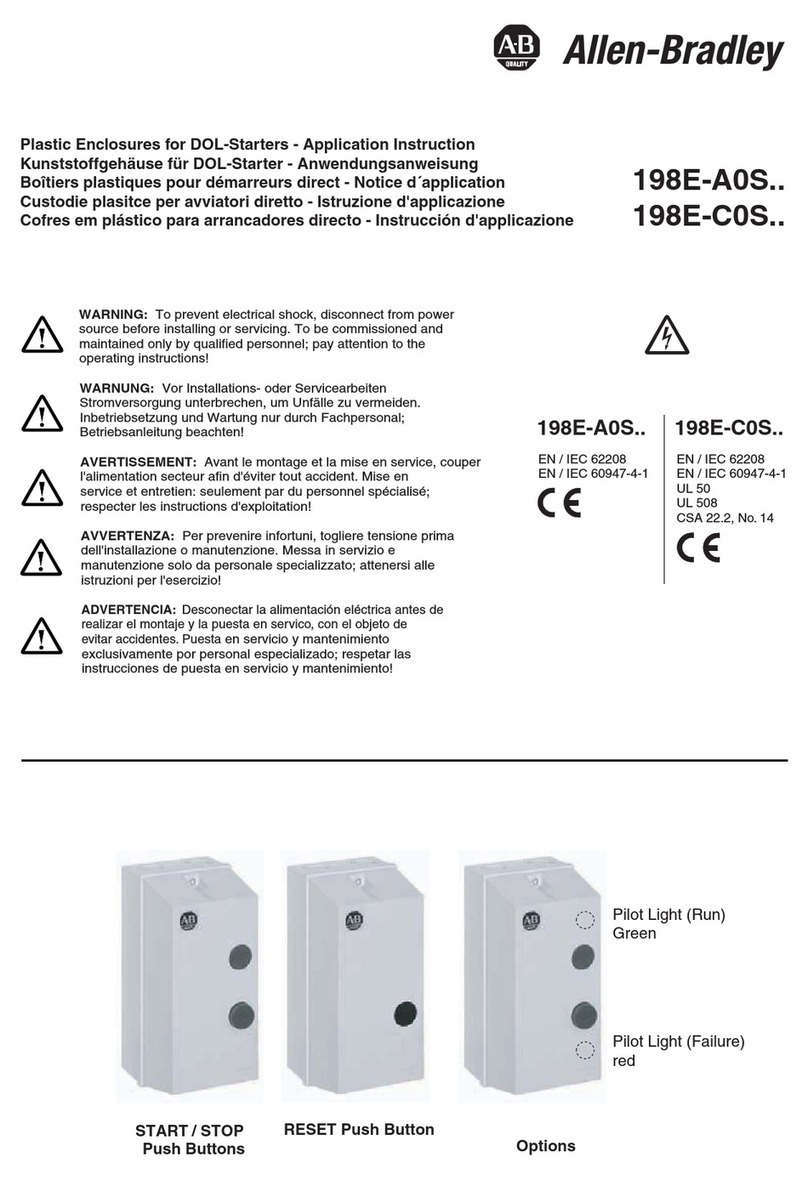

The following pictures show the further assembly:

Important:

To prevent the shower water from overflowing, it must be observed to mount the

door elements toward the shower in the fixing section of the shower bottom!

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 10

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 11

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 12

8 Maintenance and care

Daily maintenance

Check on free flow of the hoses

Clean the chambers daily

Clean the chambers carefully with a moist wiping cloth after each termination of a

shift

Check the grates on free flow

For the cleaning and care of the Quick-Dush, you can use standard cleaning agents.

9 Possible disturbances and their repair

Disturbance Possible causes Repair

Shower water in adjoining

room Shower door (s) mounted in

wrong base tube Rectify the wrong assembly

Difficulty in assembling the

wall and the bottom Mounting bracket is dirty Clean mounting bracket

Difficulty in assembling the

wall and the bottom Mounting bracket is bent Straighten mounting bracket

Clamping fixture too loose Gripping length wrongly

adjusted Adjust

Clamping fixture too tight Gripping length wrongly

adjusted Adjust

Instruction manual

Personnel lock system Quick-Dush ECO-LINE

Seite 13

10 Declaration of conformity

In accordance with the European directives

Machines/Installations (98/37/EG)

Electromagnetic Compatibility (89/336/EWG)

Low Voltage Electrical Equipment (2006/95/EG)

The type of the machine/installation:

Product/ Marking type: Personnel lock system Quick-Dush ECO-LINE

is developed, constructed and manufactured in accordance with the above described directive(s)

and comply with the following applied harmonised standards

DIN EN 292, Safety of machines, devices and installations

DIN EN 60 204.1, Electric equipment for industrial machines

Comply with the following national standards, directives and specifications:

DIN 8586, Bend forming

DIN 8588, fragmentation

Following documentation is fully available:

Overall plan of the machine/Installation with connection scheme

Detailled and entire documents for the control of the machine/installation accordance with the

safety and health requirements

A list of basic requirements of CE directives, standards and specifications, which were

respected during the construction of the machine/installation.

A description of solutions for accident prevention which could emanate from the

machine/installation

One copy of the installation manual of the machine/installation

Isselburg, 22.06.2009

_______________ _____________________

Place, Date legally binding signature

This manual suits for next models

2

Table of contents