Dectron DRY-O-TRON Supervisaire DS 010 User manual

FOR MODELS

DS DSV DB RS RB

010 010 010

015 015 015

020 020 020

030 030 030

040 040 040 040 040

042 042 042 042 042

050 050 050 050 050

060 060 060 060 060

062 062 062 062 062

080 080 080 080 080

082 082 082 082 082

100 100 100 100 100

102 102 102 102 102

120 120 120 120 120

122 122 122 122 122

150 150 150 150 150

152 152 152 152 152

162 162 162 162

164 164 164 164

182 182 182 182

184 184 184 184

202 202 202 202

204 204 204 204

242 242 242 242

244 244 244 244

282 282 282 282

284 284 284 284

362 362 362 362

364 364 364 364

368 368 368 368

402 402 402 402

404 404 404 404

408 408 408 408

482 482 482 482

484 484 484 484

488 488 488 488

562 562 562 562

564 564 564 564

568 568 568 568

804 804 804 804

808 808 808 808

Dectron, Inc. March 2012

Data subject to change without notice.

1

®

For future reference,

write your model number* here ______________

write your serial number* here ______________

write your ref number* here ______________

*See Product Description - Unit Nameplate.

Design, Installation, Start-Up, and Operation Manual

Arranged by Trades and Tasks

(Attach pages as addenda to contracts & work-orders.)

Contents: Section

Product Description 1

Building Design and Construction 2

Receiving, Unloading, Lifting, & Locating 3

Installation 4

Pre-Assembly 4a

Air Distribution, Ventilation, & Ducts 4b

Piping 4c

Wiring 4d

Testing, Adjusting, and Balancing 5

Startup 6

Operation and Maintenance 7

Service 8

Prg

Esc

Esc

Prg

Supervisaire®CONTROLLER

1

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

2

USER AGREEMENT:

Where any differences exist between the named electronic file obtained directly from Dectron,

Inc. and other versions, the named electronic file shall have precedence. Electronic versions

are subject to validation by Dectron, Inc.

CANADA

DECTRON INC.

4300 Poirier Boulevard

Montreal, QC.

H4R 2C5

Tel.: 514-334-9609 or

1-800-667-6338 or

1-888-DECTRON

U.S.A

DECTRON INC.

10898 Crabapple Road

Suite 103

Roswell, GA 30075

Tel.: 770-649-0102 or

1-800-676-2566

Fax: 770-649-0243

Corresponding Electronic File Name:

DS_SPVR_OM_2012-Mar-27.pdf

NOTE:

For your convenience this manual is organized into tasks arranged in a workable order. Most

material relevant to a single task is on one page or a group of sequential pages.

Please attach copies of the appropriate pages to the task contract or work-order. License is

hereby granted to copy and distribute as appropriate any pages contained herein for the sole

purpose of assisting in the proper application, installation, operation, maintenance, and/or

service of Dectron products only. All other rights are retained by Dectron.

To the Owner:

This manual contains important instructions on designing for, installing, starting, operating, and

maintaining your DRY-O-TRON® and system. Please read the entire manual carefully and if you

have any questions contact your local Dectron representative.

Your warranty is valid only if conditions explained in this manual are met.

To the Installer:

This manual contains vital instructions for installing and starting up the DRY-O-TRON® and

system. Please read the entire manual carefully and if you have any questions contact your local

Dectron representative. Your customer’s satisfaction is at stake and the DRY-O-TRON® warranty

may be void if conditions explained in this manual are not met.

Heating, Cooling, or Dehumidifying Construction Sites

The DRY-O-TRON®unit is not a convenience air conditioner. Its capacity is carefully

matched to the expected load. Errors of installation, damage to the unit, and other

performance reductions will be obvious once the building begins normal use.

Never use the unit to heat, cool, or dehumidify a construction site. The air coils must be

protected against construction dusts until all construction dusts have been removed from the

space, and from the outdoor-air intake (if any). Construction dusts bind to the cooling coil

permanently and cannot be removed. Once bound, the dusts reduce heat transfer and airflow

rate. Filters will not prevent this.

The resulting performance reduction and possible component damage are not covered by

the Dectron warranty.

2

Page

Safety 4

Product Description 1.1

Major Airflow Options 1.5

Unit Nameplate Information 1.11

Building Construction 2.1

Safety 2.2

Moisture Migration & Required Vapor Retarder 2.4

Door and Window Design 2.5

Component Overview 2.6

Space Heating and Cooling Availability 2.8

Outdoor-Air Intake 2.9

Air-Handler Location 2.10

Condenser or DryCooler Location 2.12

Maximum Refrigerant-Tube Length 2.13

Ducts 2.14

Fire / Smoke Detectors 2.21

Air Distribution 2.22

Supply Diffuser Proximity and Aiming 2.29

Fabric Duct 2.30

Pool-Chemical Storage Facility 2.31

Pool-water Chemistry 2.32

Receiving, Unloading, Lifting, and Locating

Safety 3.2

Air Handler

Select Air Handler Location 3.4

Nameplate Information 3.4

O/A Intake Clearances 3.5

Flue and Exhaust Clearances 3.5

Minimum Service Clearances 3.6

Door Clearances 3.7

Unit Support 3.9

Vibration Isolation 3.9

Underside Piping 3.10

Overhead Installation 3.11

Lifting Air Handler 3.12

Remote Condenser or DryCooler

Select Location 3.14

Vibration Isolation 3.16

Lifting 3.17

Installation 4.1

Safety 4.2

Component Overview 4.4

Air Distribution 4b.1

Ducts 4b.11

Standard Practice 4b.12

Determine Allowable O/A Flow 4b.14

Standard Supply-Air Flows 4b.15

Ducting Parallel Units 4b.16

Return-Duct Requirements 4b.17

Return Grille Location 4b.19

Construction Dust 4b.20

Supply-Duct Requirements 4b.21

Supply-Duct Heater 4b.21

Outdoor-Air Duct 4b.23

Ventilation Systems 4b.24

Exhaust Duct 4b.28

Checklist 4b.29

Page

Piping

Safety 4c.1

Refrigerant Piping 4c.4

General Piping 4c.16

Cooling Water 4c.18

Heating Water 4c.21

Condensate Drain 4c.22

Pool Water 4c.23

Checklist 4c.27

Wiring

Safety 4d.1

Power 4d.4

Control Signals 4d.11

Checklist 4d.33

Test, Adjust, and Balance

Safety 5.2

Determine Damper Types 5.11

Apply Electric Power 5.13

Controller Interface 5.14

(NO LINK) Interface Addressing 5.15

Set Air Dampers 5.16

Enable Blower(s) 5.19

Determine Allowable Outdoor-Air Intake Rate 5.27

Test, Adjust, and Balance Airflows 5.28

Test Adjust, and Balance Water Flows 5.30

Checklist 5.38

Startup 6.1

Safety 6.2

Pre-Startup Adjustments 6.4

Pre-Startup Checklist 6.8

Controller Interface 6.13

Enable Operation 6.22

Adjustments 6.26

Instructions for Warranty Registration 6.36

Warranty Registration 6.37

Operation 7.1

Safety 7.2

Maintenance 7.4

Maintenance Record 7.5

Air Filters 7.7

Pool Chemistry 7.19

Heating and Cooling Availability 7.20

Logical Flow Charts 7.21

Controller Interface 7.25

User Interface Map 7.26

Read Status Messages 7.28

Set-Point Adjustments 7.30

Warranty 7.32

Service 8.1

Safety 8.2

Alarms 8.4

Sensor Curves 8.22

Other Possible Problems 8.23

Closing Manual Valves 8.33

Display Contrast 8.34

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Contents

Data subject to change without notice.

3

3

WARNING

Dectron, Inc. March 2012

DECTRON

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Safety Warnings

Data subject to change without notice.

4

Save this manual and refer to it whenever a question arises. This manual contains important safety information.

Read the entire manual first, then follow the instructions for designing for, installing, starting, and/or operating this

product.

Follow any safety, warning,operating, or instructional labels on and inside the product.

Do not attempt to move, install, or service this product unless you are qualified to do so.

Risk of electric shock. Can cause injury or death.

Some installation and service procedures could expose personnel to the risk of

electric shock. Electric shock can cause injury or death.

The unit controller does not disconnect electrical energy from the unit, even in the

OFF condition. Use only approved devices (e.g. locking safety switch), to disconnect,

lockout, and tagout all sources of electrical energy before working inside the unit

cabinet. Follow all applicable safety regulations.

Risk of explosive pressure release. Can cause injury or death.

This product contains refrigerant liquid and vapor under high pressure. Some

installation and service procedures could expose personnel to the risk of explosive

discharge. Some installation and service procedures could expose personnel to the

risk of frostbite from release of refrigerant.

Reclaim refrigerant to reduce the pressure to atmospheric before working on pipes,

valves, heat exchangers, compressors, pressure switches, etc.

Once opened, do not close any manual refrigerant valves that might isolate

refrigerant from the relief valve. If necessary, install relief valves (by others).

Risk of contact with moving parts. Can cause injury or death.

This product contains rotating parts and V-belt drives. Some installation, service,

and maintenance procedures could expose personnel to the risk of injury or death

from contact with these parts.

Using only approved devices (e.g. locking safety switch), disconnect, lockout, and

tagout all sources of electrical energy before working inside the unit cabinet. Allow

adequate time for rotating parts to stop. Follow all applicable safety regulations.

Do not operate the unit until ductwork or a screen is installed at each blower

outlet.

Risk of top-heavy units tipping over. Can cause property damage, injury, or death.

Some units and some ancillary equipment may be shipped in crates that are top

heavy. Follow the instructions in the Lifting and Locating section, along with all

appropriate codes and procedures.

Vertical units may be top-heavy even after removal from shipping materials. Follow

the instructions in the Lifting and Locating section, along with all appropriate codes

and procedures.

WARNING

Risk of flying liquids, gases, particles. Can cause eye injury.

Many tasks involve risk of exposure to flying materials which can cause eye injury.

Always wear protective safety glasses or goggles, as appropriate.

WARNING

WARNING

WARNING

DESCRIPTION

4

Dectron, Inc. March 2012

DECTRON

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Warnings

Data subject to change without notice.

5

Risk of falling. Can cause injury or death.

Depending on the size and location of this product, some installation, service, and

maintenance procedures could expose personnel to the risk of injury or death by falling.

Designs should include adequate service and maintenance access. Use fall-

protection equipment as appropriate.

Risk of contact with hot surfaces. Can cause injury.

This product contains surfaces which can cause burn injury.

The compressor, refrigerant-discharge tubes, and heat exchangers can become

extremely hot during operation.

Compressor crankcase heaters can be extremely hot at any time.

Turn off the unit and allow time for these parts to cool before working inside the unit

cabinet. Wear protective clothing (gloves, sleeves, etc.) while working on these parts.

Risk of leaking water. Can cause property damage.

This product may use circulating water under pressure.

This product requires a free-flowing drain.

Freezing or other abnormal conditions could cause leakage or overflow.

Uncontrolled water can cause expensive damage to buildings and other equipment.

Do not locate this product above any equipment that could be damaged by water.

Risk of contamination of breathing air. Can cause injury or death.

Application of this product may involve the intake of outdoor air. The point of intake

must be carefully chosen to prevent intake of contaminants.

Application of this product may involve air-handling equipment, e.g. ducts, cabinets,

plenums, etc., which operate below atmospheric pressure. Such equipment must be

carefully located and installed to prevent the intake of contaminants.

Follow the instructions in this manual and all applicable codes.

NOTICE

NOTICE Risk of uncontrolled condensation. Can cause property damage.

This product is intended to control relative humidity and temperatures. Improper

design, installation, and/or operation can lead to uncontrolled condensation of water,

with associated property damage.

Read and follow the instructions in this manual. Optional material will be noted as

being optional. All other material should be considered as important to the proper

function of the product.

WARNING

WARNING

CAUTION

DESCRIPTION

5

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

6

Product Description

DESCRIPTION

DRY-O-TRON®is the original energy recycling

dehumidifier. Tens of thousands of units have

been installed throughout the world, and DRY-

O-TRON®has become synonymous with qual-

ity, reliability and energy savings.

Dectron Inc., the inventor of DRY-O-TRON®, is

a company committed to being the absolute

best at what they do - providing leading expert-

ise and quality products to customers who

need to control high humidity efficiently.

Today’s DRY-O-TRON®represents years of

intensive research and development by a team

of highly qualified experts. Dectron has the

only large-scale dehumidifier testing and envi-

ronmental simulation laboratory in the industry.

Every DRY-O-TRON®model line has been

developed in this laboratory, and every cus-

tomer’s unit is factory tested before shipment.

The DRY-O-TRON®is available in a broad

range of standard products for industrial and

commercial applications. We also have a team

of highly skilled engineering and manufacturing

professionals who are dedicated to custom

design projects.

DRY-O-TRON®DS Series

Energy-Recycling

Dehumidifiers and

Water Heaters for

Indoor Pools,

Whirlpools and Spas

1.1

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Data subject to change without notice.

Product Description

Your DRY-O-TRON®energy

recycling dehumidifier and water

heater is a precision engineered

product, finely tuned to the condi-

tions in your natatorium to

achieve maximum performance

and energy savings.

Your DRY-O-TRON®has been

tested at our factory by skilled

personnel. The installation of this

state-of-the-art equipment must

be performed by an experienced

heating, ventilation and air condi-

tioning (HVAC) technician, who

has been trained by Dectron.

IMPORTANT!

The DRY-O-TRON®is one of

several key components in

your natatorium environment

control system. In order for

your natatorium to be comfort-

able and condensation free the

following areas must be

addressed by you and your

contractor, engineer and archi-

tect design team:

ΔΔHumidity control

ΔΔAir distribution

ΔΔDuct design

ΔΔVentilation requirements

ΔΔMoisture migration

ΔΔPool water chemistry

A humidity control system will

not provide the expected com-

fort level and building protec-

tion if any of these are over-

looked.

Dectron provides guidelines

(included in this manual) for each

of these critical areas. These

guidelines have been devel-

oped from years of field experi-

ence and should be strictly

adhered to or there is a good

chance that your system will

not work as expected. It is the

responsibility of the owner and

his design team (contractor, engi-

neer and architect) to ensure that

careful consideration has been

given to all of the aspects of

natatorium environment control.

At Dectron, we care about how

you protect your investment.

The DS Series

ΔRecycles energy

ΔSaves up to 80% of the energy

costs associated with indoor

pools and spas

ΔHelps protect against building

damage resulting from uncon-

trolled humidity

ΔHeats the pool water (See

ventilation limitations under

Major Airflow Options and

under Building Construction-

Outdoor-Air Intake.)

ΔMaintains relative humidity

levels between 50 and 60% -

Guaranteed!

ΔCan provide year round

comfort with optional air

conditioning

ΔContributes to space heating in

cold weather

The DRY-O-TRON®DS Series

When properly installed accord-

ing to Dectron’s instructions, the

DRY-O-TRON®will give years of

trouble-free comfort, energy sav-

ings and building protection.

The DRY-O-TRON®features a

unique patented simultaneous

energy recycling system. Only

DRY-O-TRON®can heat air and

water continuously and at the

same time with recycled energy

to provide ultra-smooth control

over space conditions. This

means a more comfortable envi-

ronment for the bather. Water and

air temperatures are always

maintained close to their set

point, while relative humidity lev-

els are kept to a comfortable 50-

60%. DRY-O-TRON®can also be

equipped with optional air condi-

tioning for year round space tem-

perature control.

Dectron is the only manufacturer

of energy recycling dehumidifiers

that will guarantee pool water

temperature and space relative

humidity conditions, in writing.

Dectron stands behind their

product!

DRY-O-TRON®dehumidifiers

features standard microprocessor

control. For the owner this

means precise automatic control,

high reliability, and ease-of-use.

For the installer and service

person this means simpler

installation and start-up with

built-in diagnostics and

troubleshooting in the unlikely

event that service is required.

Dectron uses state-of-the-art

computer design and model

selection programs which incor-

porate ASHRAE ventilation

requirements to design the right

DRY-O-TRON®system for every

application.

DESCRIPTION 7

1.2

How the DRY-O-TRON®Works

In the natatorium, there is a

vapor pressure difference

between the pool water and the

enclosure air. This produces

continuous evaporation of pool

water, resulting in high humidity

conditions and a steady drop in

pool water temperature if left

uncontrolled. The high humidity

can result in serious building

decay, and the pool water

requires virtually continuous

heating.

An earlier practice called for

exhausting the humid air, replac-

ing it with outdoor air which had to

be heated to room temperature.

In addition, a full size pool heater

was required to maintain pool

water temperature. This

procedure was costly and wasted

energy as well.

The heat lost by the pool when

evaporation takes place is

actually “trapped” by the moisture

in the air. A DRY-O-TRON®unit is

engineered to capture this

trapped energy, and to recycle it

back to the pool where it came

from! This energy recycling can

save up to 80% of the cost of

heating your pool by earlier

methods. Now you can protect

your investment from humidity

damage, provide a comfortable

environment for bathing, and

save money at the same time!

You can also feel good about

making your contribution to the

environment by using recycled

energy.

The DRY-O-TRON®

dehumidifiers have been

specifically designed to offer a

complete solution for natatorium

environment control. In

DRY-O-TRON®units, cooling is

used to produce from moist air:

ΔΔComfortable, dry supply air

ΔΔTotal heating requirement for

pool water

ΔΔCondensate (returned to the

pool if desired, reducing make-

up water requirements.)

The energy cycle of this process

has an efficiency of 100% since

all moisture or latent heat is con-

verted into sensible heat for

recycling. The electrical energy

required to operate the system is

also converted into sensible heat

and contributes to space heating.

In the DRY-O-TRON®, warm

humid air passes through the

dehumidifying coil and is cooled

below its dew point, thereby con-

densing moisture. The heat cap-

tured by this process is combined

with the heat generated from the

compressor power consumption.

This recovered heat is then avail-

able for recycling. The DRY-O-

TRON®is the only system on the

market which can simultaneously

and continuously recycle this

recovered energy into:

ΔΔHeating the supply air. The

leaving supply air dry bulb

temperature is always the

same or higher than the

entering return air (except

during cold pool water start-up

and when the air-conditioning

option is in use).

A built-in automatic compen-

sation system permits unit startup

regardless of water temperatures.

During initial start-up with low

pool water temperature, all avail-

able heat is directed to the pool

water. Once the desired tempera-

ture is reached, the water heating

system adjusts its output auto-

matically.

The DRY-O-TRON®’s capability

of simultaneously and continu-

ously recycling heat to air and

water ensures a more stable

natatorium environment.

DRY-O-TRON®units are avail-

able in a number of configura-

tions which will easily accept the

introduction of controlled quanti-

ties of outdoor air. DRY-O-TRON®

models DS 40 and larger are

equipped with a standard make-

up air intake which will allow up to

15% outdoor air.

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Product Description

Data subject to change without notice.

8DESCRIPTION

1.3

Dectron, Inc. March 2012

DECTRON

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Data subject to change without notice.

9

Features

ΔΔStandard operator panel

ΔΔEnergy efficiency

ΔΔLittle maintenance required

ΔΔSimple operation

ΔΔSimple installation

ΔΔThe basic Dectron DS series DRY-O-TRON®units

offer dehumidification of natatorium air as well as pool

water heating. The optional Cooling mode offers space

cooling.

ΔΔThe DS series DRY-O-TRON®unit controls an aux-

iliary pool water heater as necessary to maintain pool

water temperature.

ΔΔAn optional hot-water heating system is available to

make use of a building boiler system for heating. This

factory modification must be ordered at time of pur-

chase.

ΔΔDS series DRY-O-TRON®units are supplied with

heat exchangers, air filter(s), and all controls.

ΔΔAn optional outdoor air intake system includes an

automatic damper to stop the outdoor airflow during

unoccupied periods.

ΔΔA microprocessor control system automatically

determines the proper operating mode, based on con-

ditions and occupation. A simple connection to building

management systems is available.

ΔΔEnergy consumption

The DS DRY-O-TRON®series offers a temperature

and humidity monitoring system that insures the unit is

working only as necessary. Automatic refrigeration

staging in the remote condenser matches the system

capacity to the load. Energy consumption is always

minimized.

Horizontal Configuration

Vertical Configuration

DESCRIPTION

Product Description

Sample

Appearance may vary.

Sample

Appearance may vary.

1.4

Product Description Major Airflow Options

DECTRON

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

10

Basic DRY-O-TRON®

The basic DRY-O-TRON®controls the humidity in

the space and returns to the pool the heat it has lost

to evaporation.

The same amount of return air passes through the

evaporator and the evaporator bypass.

The outdoor-air intake flow rate can be up to 15%

of the total supply airflow rate, or up to 35% if the

unit has the air-conditioning option, depending on

outdoor temperature. The incoming outdoor air

must be heated (by others) to not less than 32°F

(0°C). There may be limitations on maximum flow

rates. See subsequent page in this manual.

Any unit with more than 15% outdoor air must have an auxiliary pool heater, which may be by others.

A built-in clock may limit the intake of outdoor air and/or the exhaust of room air to occupied periods only.

DRY-O-TRON®with Economizer

The economizer reduces the amount of energy

required for cooling by using a full flow of outdoor

air when possible.

The same amount of return air passes through

the evaporator and the evaporator bypass.

Under normal (not economizer) mode the

outdoor-air intake flow rate can be up to 15%

(or up to 35% with air-conditioning option) of the

total supply airflow rate, depending on outdoor

temperature.

Except in economizer mode, the incoming

outdoor air must be heated (by others) to not less

than 32°F (0°C). There may be limitations on

maximum flow rates. See subsequent page in

this manual.

In order to maintain a negative pressure on the

natatorium, the exhaust airflow rate should be 110% of the outdoor air intake flow rate.

When outdoor air conditions permit, the refrigeration system is automatically stopped and the room exhaust

air and outdoor air intake flow rates are varied to control temperature.

The outdoor-air intake damper(s) must be adjusted mechanically to limit the intake flow to maintain a slight

negative pressure on the room.

Natatoriums with DRY-O-TRON®units having the Economizer option must also have auxiliary pool heaters,

which may be by others.

Some units with the economizer option may also be equipped with the Intelligent Energy Saver option.

The Intelligent Energy Saver®economizer reduces the amount of energy required for cooling and for

dehumidification by using an increased flow of outdoor air when possible. A preset amount of outdoor air is

brought in during occupied periods, and is increased only as necessary for dehumidification or cooling.

For more information on the Economizer option, refer to Appendix M5 - Economizer.

RETURN AIR

COOLING COIL REHEAT COIL

SUPPLY BLOWER

RETURN-AIR

FILTERS

BYPASS DAMPER

OUTDOOR-AIR

FILTERS OUTDOOR-AIR DAMPER

SUPPLY AIR

OUTDOOR AIR

RETURN AIR

COOLING COIL REHEAT COIL

SUPPLY BLOWER

RETURN-AIR BLOWER MIXING DAMPER

RETURN-AIR

FILTERS

BYPASS DAMPER SUPPLY-AIR FILTERS

OUTDOOR-AIR DAMPER

EXHAUST-AIR DAMPER

SUPPLY AIR

OUTDOOR AIR

EXHAUST AIR

DESCRIPTION

1.5

DECTRON

DRY-O-TRON®with SmartSaver®

The SmartSaver®exchanges heat from the

exhaust air to the incoming outdoor air to save

heating energy. A heat pipe or a thermo-siphon

system is installed between the exhaust air and

the outdoor air intake. When the outdoor air is

colder than the room exhaust air, the

SmartSaver®recovers heat from the exhaust

stream and delivers it to the outdoor air intake.

The same amount of air passes through the

bypass and the evaporator.

The normal occupied-period outdoor-air intake

flow rate can be up to 15% of the total supply

airflow rate, or up to 35% if the unit has the

air-conditioning option. Units with the

SmartSaver option do not require incoming

outdoor air to be heated, as long as the incoming

outdoor air is above -20°F (-29°C).

Any unit with more than 15% outdoor air

must have auxiliary pool heat, which may be by others.

The exhaust airflow rate should be 110% of the outdoor air intake flow rate.

For more information, refer to Appendix M3 - SmartSaver.

SUPPLY AIR

EXHAUST AIR

OUTDOOR AIR

OUTDOOR AIR

COOLING COIL REHEAT COIL

SUPPLY

BLOWER

RETURN-AIR

FILTERS

EXHAUST-AIR

FILTERS

SMARTSAVER

EVAPORATOR

MINIMUM EXHAUST BLOWER

MINIMUM EXHAUST DAMPER

BYPASS DAMPER

SMARTSAVER FILTERS

MINIMUM O/A DAMPER

SMARTSAVER CONDENSER

RETURN

AIR

DRY-O-TRON

®

Glycol SmartSaver®

The SmartSaver®exchanges heat between the

exhaust air and the incoming outdoor air to save

energy. A pumped-glycol heat-exchange system is

installed between the exhaust air and the outdoor

air intake. When the outdoor air is colder than the

room exhaust air, the SmartSaver®recovers heat

from the exhaust stream and delivers it to the

outdoor air intake stream. When the outdoor air

is warmer than the room exhaust air, the

SmartSaver®removes heat from the outdoor air

intake stream and delivers it to the exhaust

air stream.

The same amount of air passes through the

bypass and the evaporator.

The normal occupied-period outdoor-air intake flow

rate can be up to 15% of the total supply airflow rate,

or up to 35% if the unit has the air-conditioning option. Units with the SmartSaver option do not

require incoming outdoor air to be heated, as long as the incoming outdoor air is above -20°F (-29°C).

Any unit with more than 15% outdoor air must have auxiliary pool heat, which may be by others.

For more information, refer to Appendix M3 - SmartSaver.

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Major Airflow Options Product Description

Data subject to change without notice.

11

SUPPLY AIR

EXHAUST AIR

OUTDOOR AIR

OUTDOOR AIR

COOLING COIL REHEAT COIL

SUPPLY

BLOWER

RETURN-AIR

FILTERS

EXHAUST-AIR

FILTERS

SMARTSAVER

EVAPORATOR

GLYCOL PUMP

MINIMUM EXHAUST BLOWER

MINIMUM EXHAUST DAMPER

BYPASS DAMPER

SMARTSAVER FILTERS

MINIMUM O/A DAMPER

SMARTSAVER CONDENSER

RETURN

AIR

DESCRIPTION

1.6

EconoPurge Option

Units equipped with the Purge option may also be

equipped to maximize energy conservation with a

variation of economizer or Intelligent Energy Saver

options.

If the unit is equipped with an outdoor-air temperature

sensor, the Purge mode described above may also

operate automatically during periods when the outdoor

air is cool enough to control room temperature by

ventilation alone. This mode is one of the

economizer options.

If the unit is equipped with both outdoor-air

temperature sensor and an outdoor-air humidity

sensor, then the Purge mode described above may

also operate automatically when the outdoor air is cool

and dry enough to control room temperature and/or rel-

ative humidity by ventilation alone. This mode is one of

the the Intelligent Energy Saver options.

The outdoor-air intake damper(s) must be adjusted

mechanically to limit the intake flow to maintain a slight

negative pressure on the room.

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Product Description Major Airflow Options

Data subject to change without notice.

12

DECTRON

SUPPLY AIR

OUTDOOR AIR

OUTDOOR AIR

COOLING COIL

FACE DAMPER REHEAT COIL

SPACE HEATER

SUPPLY

BLOWER

RETURN-AIR

FILTERS

MINIMUM EXHAUST BLOWER

MAXIMUM EXHAUST DAMPER

MINIMUM EXHAUST DAMPER

MAXIMUM EXHAUST BLOWER

BYPASS DAMPER

MINIMUM O/A DAMPER

PURGE DAMPER

SUPPLY FILTERS

RETURN

AIR

EXHAUST AIR

SUPPLY AIR

OUTDOOR AIR

OUTDOOR AIR

COOLING COIL

FACE DAMPER

SUPPLY

BLOWER

RETURN-AIR

FILTERS

MINIMUM EXHAUST BLOWER

MAXIMUM EXHAUST DAMPER

MINIMUM EXHAUST DAMPER

MAXIMUM EXHAUST BLOWER

BYPASS DAMPER

MINIMUM O/A DAMPER

PURGE DAMPER

SUPPLY FILTERS

RETURN

AIR

REHEAT COIL

SPACE HEATER

EXHAUST AIR

EXHAUST AIR

Normal operation

Purge Mode

DRY-O-TRON®with

Purge Option

Superchlorination of a pool may produce

gases and odors that preclude the presence

of swimmers in the natatorium. Purge mode

may be controlled manually to minimize the

time in which people must be out of the

natatorium during superchlorination.

On receipt of a manual input from the

operator,

1. the refrigeration system is stopped,

2. the supply blower continues to run,

3. the evaporator face dampers close,

4. the evaporator bypass damper closes,

5.

the outdoor-air damper opens completely,

6. the dampers for blower EF2 open, and

7. EF2 (the larger exhaust blower) runs.

Under normal conditions, half the return

air passes through the evaporator while the

other half passes through the bypass.

Under normal (not Purge) mode the

outdoor-air intake flow rate can be up to

15% (or up to 35% with air-conditioning

option) of the total supply airflow rate,

depending on outdoor temperature.

Except in Purge mode, the incoming outdoor

air must be heated to not less than

32°F (0°C). Theremay be limitations on

maximum flow rates. See subsequent page

in this manual.

Natatoriums with DRY-O-TRON®units

having the Economizer option must also

have auxiliary pool heaters, which may be

by others.

For more information, refer to

Appendix M6 - Purge.

DESCRIPTION

1.7

DECTRON

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Major Airflow Options Product Description

Data subject to change without notice.

13

RETURN AIR

COOLING COIL

REHEAT COIL

SUPPLY BLOWER

RETURN-AIR

FILTERS

BYPASS DAMPER

OUTDOOR-AIR DAMPER

SUMMER

EXHAUST-AIR

DAMPER

WINTER

EXHAUST-AIR

DAMPER

SUPPLY AIR

OUTDOOR AIR

EXHAUST AIR

RETURN

AIR

RETURN AIR

COOLING COIL

REHEAT COIL

SUPPLY BLOWER

RETURN-AIR

FILTERS

BYPASS DAMPER

OUTDOOR-AIR DAMPER

SUMMER

EXHAUST-AIR

DAMPER

WINTER

EXHAUST-AIR

DAMPER

SUPPLY AIR

OUTDOOR AIR

EXHAUST AIR

RETURN

AIR

DRY-O-TRON®with

EconoSaver®

The EconoSaver®reduces the amount of

energy needed for heating by recovering heat

with the refrigeration system.

In the summer, room air is exhausted

directly. In winter mode, cold air from the

evaporator is exhausted. The heat removed

from the exhaust air is returned to the

incoming outdoor air in the reheat heat

exchanger. This reduces the energy needed

for heating.

The same amount of return air passes

through the evaporator and the evaporator

bypass.

The outdoor-air intake flow rate can be up

to 15% (or up to 35% with air-conditioning

option) of the total supply airflow rate,

depending on outdoor temperature. The

incoming outdoor air must be heated (by

others) to not less than 32°F (0°C). There

may be limitations on maximum flow rates.

See subsequent page in this manual.

DESCRIPTION

1.8

DECTRON

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

There are many options for duct connections. In many cases, these options can simplify duct work and lead to

better airflow and better performance.

Some options are illustrated here. Other options are available. Contact your Dectron representative.

For outdoor units, suitable hoods are provided for outdoor air and exhaust air (if any).

Horizontal Units, Return-Air Connections,

Optional at Time of Sale Horizontal Units, Supply-Air Connections

Optional at Time of Sale

Horizontal Units, Outdoor-Air Connections

Optional at Time of Sale (May be linked to other options.) Horizontal Units, Exhaust-Air Connections

Optional at Time of Sale (May be linked to other options.)

DESCRIPTION

Samples

Appearance may vary.

NOTICE Optional Equipment - Some vertical units may have selectable supply-air discharge ports.

Product Description Available Air Connections

14

1.9

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Available Air Connections Product Description

Data subject to change without notice.

DESCRIPTION

Samples

Appearance may vary.

Samples

Appearance may vary.

DECTRON

The standard supply-air discharge for vertical units (model DSV-

xxx) is vertically upward.

Some vertical units may have field-selectable ports allowing

supply air to exit through the top or right side. Where this is the

case, select the best port for the installation. It may be possible

to eliminate an otherwise-required duct elbow near the unit.

Cover the unused port with the blank cover.

Other adjustments, including adjustments to the blower, may be

necessary. Open the front-middle access panel and/or the rear-

top access panel to view the blower arrangements. Be sure air

will flow in the proper direction.

Some vertical units with plenum blowers may be equipped with a plenum.

In this case, there may be several field-selectable ports for supply air.

Choose the port (or ports) that allows the best duct routing. Close the other

ports with the included covers.

The plenum of some vertical units may be removable. This may

facilitate moving the unit through tight clearances.

To remove the plenum, open the access panel and disconnect the motor or

the variable-frequency drive (if so equipped). Remove and retain the

mounting screws. Carefully remove the plenum, setting it aside in a

protected area.

When the unit is in its final position, re-assemble the plenum, fastening it in

place with the mounting screws. Re-connect and torque the wires to the

blower or drive.

It may be possible to re-locate the plenum of some vertical units for more

choices of supply-air direction. In this case, remove the plenum as

described above. Remove the side panel and use it to close the top of the

unit. Mount the plenum where the side panel was. (See the illustrations

below.) Re-route the blower wires and re-connect them.

NOTICE Optional Equipment - Some vertical units may have selectable supply-air discharge ports.

Return Air

Outdoor

Air

Supply Air

Supply Air

Return Air

OutdoorAir

Return Air

OutdoorAir

Return Air

OutdoorAir

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

Supply Air

15

1.10

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

16

Product Description Unit Nameplate

DESCRIPTION

Model Nomenclature:

ixxx-sss-v

nominal voltage

2 = 208V, 1Φ, 60 Hz

3 = 230V, 1Φ, 60 Hz

4 = 208-230V, 1Φ, 60 Hz

5 = 208-230V, 3Φ, 60 Hz

6 = 230V, 3Φ, 60 Hz

7 = 460V, 3Φ, 60 Hz

8 = 575V, 3Φ, 60 Hz

9 = 208V, 3Φ, 60 Hz

Configuration

BH = natatorium dehumidifier, economizer, horizontal

SA = natatorium dehumidifier, skid only, no blower

SB = natatorium dehumidifier, skid only, with blower

SF = natatorium dehumidifier, field-assembled

SH = natatorium dehumidifier, horizontal

SPA = natatorium dehumidifier, field-assembled, no blower

SPB = natatorium dehumidifier, field-assembled, with blower

SV = natatorium dehumidifier, vertical

nominal moisture

removal capacity in

lbs./hr.

D = indoor cabinet

R = outdoor cabinet

DRY-O-TRON ®

MODEL #:

SERIAL #:

I.D. D

ELECTRICAL RATING 460 V ac, 3 ph, 60 Hz

COMPRESSOR

LRA RLA

COMPRESSOR

LRA RLA

COMPRESSOR

LRA RLA

COMPRESSOR

LRA RLA

BLOWER MOTOR HP FLA

BLOWER MOTOR HP FLA

BLOWER MOTOR HP FLA

COND. FAN MOTOR HP FLA

COND. FAN MOTOR HP FLA

PUMP MOTOR HP FLA

ENTHALPY MOTOR HP FLA

ELECTRIC HEATER kW A

Max. L.A.T. (°F)

SERVICE POWER

SPACE HEATING COIL

PSIG Max.

MCA A MAX. FUSE/CKT. BKR.* 15 A

*(HACR type per NEC)

R-22 FACTORY CHARGE lbs

AIR VOLUME CFM

BELT SIZE

WIRING DIAGRAM

REFRIGERANT DESIGN PRESSURES: HIGH/LOW 300/150 PSIG

COMFORMS TO ANSI/UL STD 1995

CERTIFIED TO STD CAN/CSA-

C22.2 NO. 236

LR 45671

FABRIQUÉ AU CANADA / MADE IN CANADA

REF.:

POOL # 1: ft² POOL # 3: ft²

E.W.T.: °F E.W.T.: °F

POOL # 2: ft² POOL # 4: ft²

E.W.T.: °F E.W.T.: °F

AIR TEMP.: °F R.H.: %

R-22 TOTAL SYSTEMCHARGE: lbs

OIL TO BE ADDED AT START-UP: oz

OIL TYPE:

MAX. LENGTH OF REF. LINES (ONE WAY) ft

BETWEEN D.O.T. & REMOTE CONDENSER:

LINE SIZE:

AIR COOLED COND. MODEL #: HOT GAS: in

LIQUID: in

50379

CSA and ETL Label

Operating conditions: Make sure

unit is operating within these con-

ditions. Unit has been selected

and sized accordingly.

Nameplate specifications supersede any other specifications

or statements found in this manual.

For units with air-cooled air-conditioning, the tubes connecting

the DRY-O-TRON®to the remote condenser must be exactly

as shown here. Consult Dectron before exceeding the maxi-

mum length of tube or changing the tube diameters.

At installation, add type and amount of refrigeration oil as shown.

If assistance is needed, have

model, serial number, and Ref.

number (below) before calling.

Important branch circuit information

Component specifications.

Replace with belt of

same type and size

when necessary.

Adjust supply-airflow to

this value ±10%.

Ref number

For units with air-cooled air

conditioning, subtract the amount of

refrigerant given by “Factory Charge”

from the amount given by “Total

System Charge”. The difference must

be added to the DRY-O-TRON®at

installation. See Installation - Piping -

Refrigerant.

This amount of refrigerant is supplied

by others.

Name plate

on corner

Horizontal Indoor Unit

Outdoor Unit

Vertical

Indoor Unit

Name plate on

corner spar or inside

weather door

Name plate

on corner

1.11

Dectron, Inc. March 2012

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Contents Building Construction

Data subject to change without notice.

17

Page

Safety 2.2

Moisture Migration & Required Vapor Retarder 2.4

Door and Window Design 2.5

Component Overview 2.6

Space Heating and Cooling Availability 2.8

Outdoor-Air Intake 2.9

Requirements for Air-Handler Location 2.10

Minimum Service Clearances 2.10

Overhead Installation 2.11

Requirements for Location of Remote

Condenser or DryCooler 2.12

Maximum Refrigerant-Tube Length 2.13

Ducts

Minimum Straight Duct Lengths 2.14

Spa / Return Grille Separation 2.15

Outdoor-Air Intake 2.16

Standard Practice for Ducts 2.18

Traversing Plane 2.19

Duct Insulation 2.20

Fire / Smoke Detectors 2.21

Air Distribution 2.22

Tall Windows 2.27

Very Tall Windows 2.28

Windows with Cross-Members 2.28

Supply Diffuser Proximity and Aiming 2.29

Fabric Duct 2.30

Pool-Chemical Storage Facility 2.31

Pool-water Chemistry 2.32

Manual Appendices 2.33

Building Construction Checklist 2.34

BUILDING

CONSTRUCTION

NOTICE Risk of uncontrolled condensation. Can cause property damage.

The information presented in this section represents Dectron’s best effort as of the time of

issue. This information should be considered in all building designs incorporating a pool.

Where any steps are not clear, Dectron offers technical assistance at 1-800-667-6338 or

1-800-676-2566.

Dectron does not warrant that this information is complete for any particular application.

Follow all applicable codes and regulations. Where any recommendations in this manual

conflict with such legal requirements, the legal requirements take precedence.

Dectron, Inc. does not engage in architectural or building-engineering services. All

responsibility for proper and functional building design and construction is borne by others.

Product Description 1

Building Design and Construction 2

Receiving, Unloading, Lifting, & Locating 3

Installation 4

Pre-Assembly 4a

Air Distribution, Ventilation, & Ducts 4b

Piping 4c

Wiring 4d

Testing, Adjusting, and Balancing 5

Startup 6

Operation and Maintenance 7

Service 8

2.1

Dectron, Inc. March 2012

DECTRON

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Building Construction Safety Warnings

Data subject to change without notice.

18

Risk of uncontrolled condensation. Can cause property damage.

This product is intended to control relative humidity and temperatures. Improper

design, installation, and/or operation can lead to uncontrolled condensation of water,

with associated property damage.

Read and follow the instructions in this manual. Optional material will be noted as

being optional. All other material should be considered as important to the proper

function of the product.

Risk of contamination of breathing air. Can cause injury or death.

Application of this product may involve the intake of outdoor air. The point of intake

must be carefully chosen to prevent intake of contaminants.

Application of this product may involve air-handling equipment, e.g. ducts, cabinets,

plenums, etc., which operate below atmospheric pressure. Such equipment must be

carefully located and installed to prevent the intake of contaminants.

Follow the instructions in this manual and in all applicable codes.

WARNING

NOTICE

Risk of falling. Can cause injury or death.

Depending on the size and location of this product, some installation, service, and

maintenance procedures could expose personnel to the risk of injury or death by

falling.

Designs should include adequate service access, maintenance access, and fall

protection.

WARNING

Risk of fire/smoke alarm failure. Can cause property damage, injury, or death.

Placement of fire/smoke detectors is critical for reliability. Read and follow the

instructions in this manual, the alarm manual (by others), and all applicable codes.

WARNING

BUILDING

CONSTRUCTION

2.2

Dectron, Inc. March 2012

DECTRON

Owner’s Manual DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Building Construction

Data subject to change without notice.

19

This page intentionally left blank.

BUILDING

CONSTRUCTION

2.3

Dectron, Inc. March 2012

DECTRON

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Building Construction Moisture Migration

Data subject to change without notice.

20

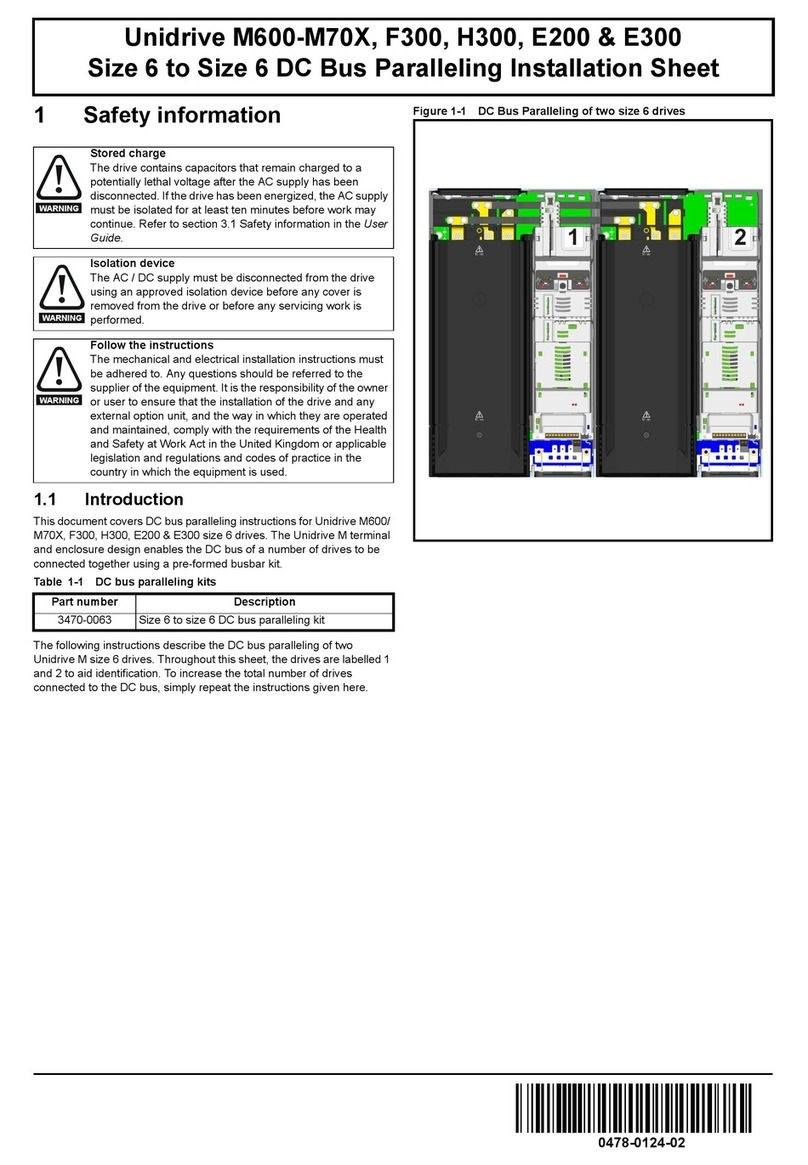

The pool enclosure should be built to the latest

building codes and must be suitable for year-

round operation at 50% to 60% relative humidity.

Vapor Retarder

Before the design of the roof and walls is

finalized, the enclosure temperature and relative

humidity must be known; thus determining the

dew point (the temperature at which condensa-

tion will occur). For common dew points, see the

graph below.

If the room air goes below this dew point

temperature, water will condense from the air.

IMPORTANT!

Check the pool enclosure design (exterior

walls AND ceilings) for proper vapor retarder

location.

When the outdoor air temperature is sufficiently

low, parts of the exterior wall and ceiling will be

at or below the dew point temperature. These

parts MUST be on the outdoor (or cold side) of

the vapor retarder.

The vapor retarder should be adequate for the

purpose and should be continuous. All seams

should be completely sealed. Penetrations, as

for conduit, etc., should be sealed.

NOTE: Where the inside building finish includes

a perforated material, a continuous vapor

retarder must be installed behind it.

Failure to install the vapor retarder properly will

result in condensation forming in

the structure,

with all the consequent damages.

See Water Vapor Retarders in ASHRAE

Handbook of Fundamentals.

CONDENSATION

RESULTS IN

SOGGY

INSULATION

OUTDOOR 32°F

DRY

INSULATION

OUTDOOR 32°F

NO VAPOR

RETARDER

MOISTURE-LADEN

WARM AIR

INDOOR 84°F (29°C),

50% RH

VAPOR

RETARDER

MOISTURE-LADEN

WARM AIR

INDOOR 84°F (29°C),

50% RH

For this example, the dew point of

the room air is 63.4°F (17.4°C).

This temperature will occur some-

where in the wall.

BUILDING

CONSTRUCTION

75°F

24°C 80°F

27°C 85°F

29°C 90°F

32°C

80°F

27°C

70°F

21°C

60°F

16°C

50°F

10°C

DEW POINT

Dry-Bulb Temperature

40% RH

50% RH

60% RH

DEWPOINTS vs. DRY-BULB TEMPERATURES Example:

An indoor pool enclosure has air

at 85°F and 60% relative humidity.

What is the dew point?

On the chart at left, start at 85°F

dry-bulb temperature. Go up to

the blue 60% RH line, then left to

70°F dew point.

The dew point of this air is 70°F.

Surfaces allowed to go below this

temperature will sweat.

2.4

This manual suits for next models

135

Table of contents

Popular Controllers manuals by other brands

brennenstuhl

brennenstuhl BrematicPRO UPWS 868 01 W1000 3726 Instructions for use

Denso

Denso SMT7 instruction manual

UTC Fire and Security

UTC Fire and Security DET-TRONICS 95-8533 instructions

NEC

NEC NEC Express5800 Series user guide

Hunter

Hunter Hydrawise Pro-HC Connecting

LOVATO ELECTRIC

LOVATO ELECTRIC DCRL8 instruction manual