Contents

M 300 S 11/2010 - 300003201-001 - F

Security Measures..................................................................................................................................................4

Important information ............................................................................................................................................4

Burner description..................................................................................................................................................5

1 Brief description......................................................................................................................................................................................5

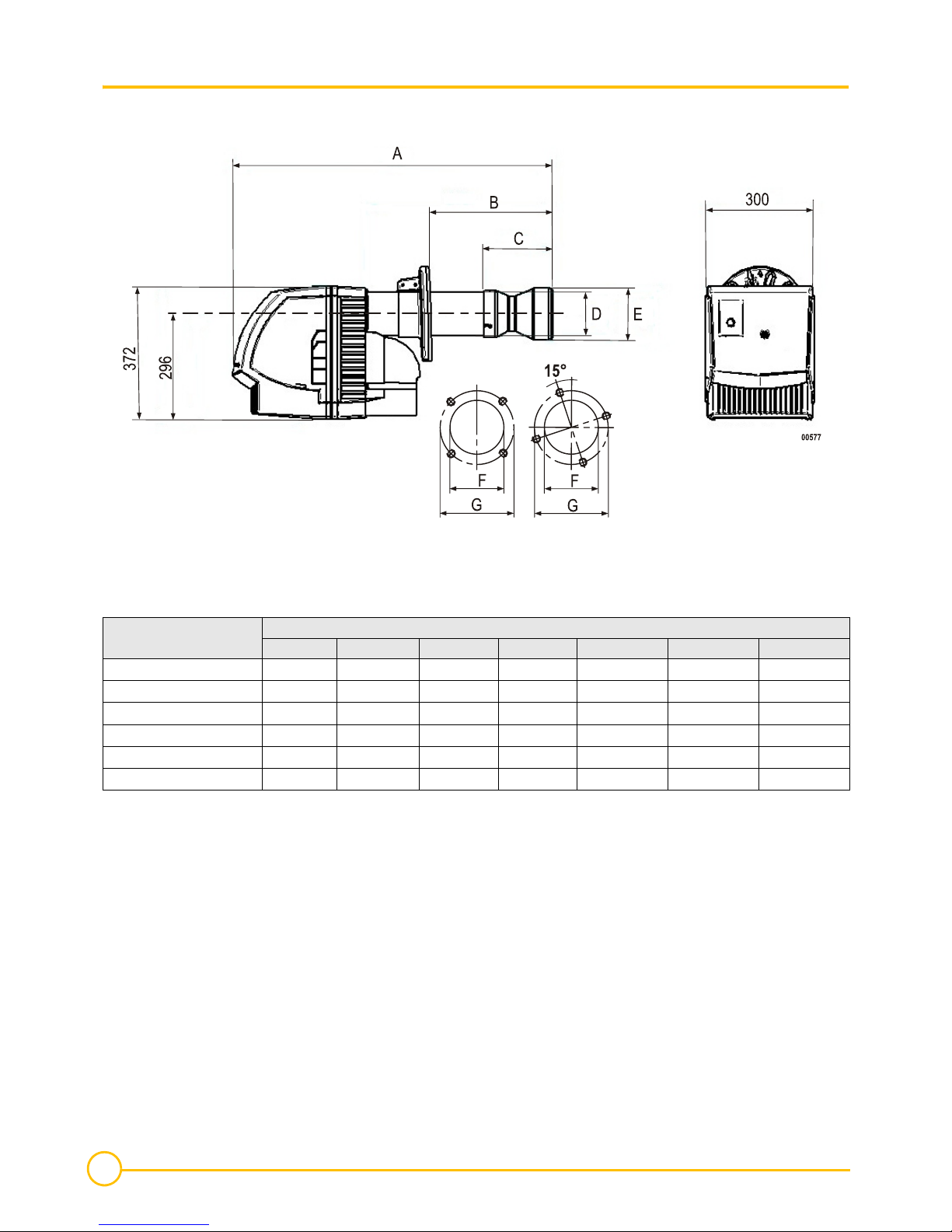

2 Dimensions.............................................................................................................................................................................................6

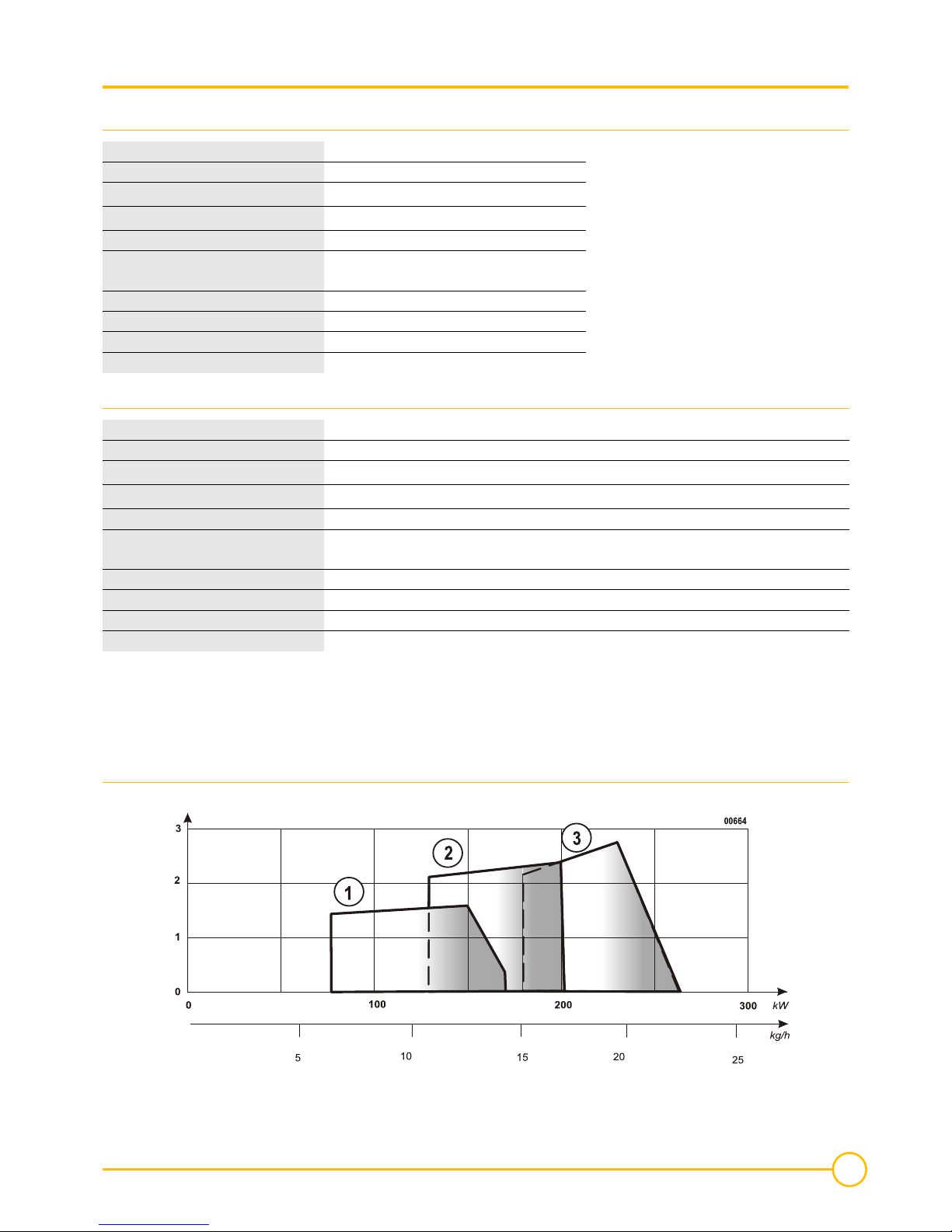

3 Technical data........................................................................................................................................................................................7

4 Main parts...............................................................................................................................................................................................9

5 Base with cables - Command and safety box ......................................................................................................................................13

Command and safety box ....................................................................................................................................14

1 Operating cycle ....................................................................................................................................................................................14

2 Safety (For DKO 976 only)...................................................................................................................................................................14

3 Diagnosing breakdowns (For DKO 976 only).......................................................................................................................................14

Installation.............................................................................................................................................................15

1 Assembly of the sliding flange..............................................................................................................................................................15

3 Maintenance.........................................................................................................................................................................................16

4 Fuel oil nozzle assembly ......................................................................................................................................................................17

5 Positioning the turbulator and ignition electrodes.................................................................................................................................17

6 Positioning the mechanism ..................................................................................................................................................................18

7 Fuel and electrical connections............................................................................................................................................................18

Adjustment............................................................................................................................................................19

1 Recommended Settings M 301 S.........................................................................................................................................................20

2 Recommended Settings M 302 S.........................................................................................................................................................22

Checking the operation........................................................................................................................................24

Final checks ..........................................................................................................................................................24

Maintenance procedure .......................................................................................................................................24

Electrical diagram.................................................................................................................................................25

Operating incidents..............................................................................................................................................27

Spare parts - M 300 S - 300003201-002-F............................................................................................................28