Deer Fence Access Gate User manual

Access Gate Instructions

Tools needed: battery powered driver with Phillips bit attachment, US wrenches/socket set, small hammer

and pair of snips to cut through excess tension cable and ties

Gate Hardware Kit Contents:

QTY

ITEM DESCRIPTION

PART

1

Small bundle of 8" 120

lb strength self locking

fence

ties

(attach fence to gate)

1

4

1 3/8 black

steel

gate corners

2

1

16ft black PVC coated braided steel cable

(hinge side top to latch side bottom)

3

2

Sets of access gate hinges (male 1 5/8

support, female 1 3/8 gate)

4

2

1 5/8 band to 1 3/8 end cap assemblies for “L” or “L2”

5

1

Printed instructions

(not pictured)

6

2

Latch assemblies for access gate

7

1

Bag:

20 self tapping screws, 1

turnbuckle, 2 caps for posts +

2

black

wire

clamps

8

Note: Gate schematics are size specific and are included separately as an attachment

1) Unpack gate tubing bundle and gate hardware kit on a clean level surface.

2) Lay out materials and dry fit the tubing material you received into the various fittings according to your

gate schematic. You won’t need parts “M” and “L or L2” (if applicable) right now. Also, save the larger

sized male 1 5/8 hinge from part #4 to use later on “M”. Slide the female hinges and fork latches over

each part “A” before putting on the corners, part #2.

3) Next, screw together all four corners with 4 self tapping screws in each corner. Be sure to tap in each

corner with a small hammer before fastening, making sure the tubing material is seated all the way in

each corner. The self tapping screws go through the holes in each corner into the steel tubing below

with light pressure. Hold the spinning screw in place until it drills itself through. Some customers prefer

to pilot a small hole with a drill bit, which will work well too.

4) Next, attach part #4 (female hinge side) to the gate frame and tighten fully about 12” from the bottom

and top of the gate

5) Attach both part #7 fork latches to the gate frame spaced 12” apart centered on the other part “A”

that the hinges aren’t on. Be sure to tighten both nuts on either side in sequence so the fork is able to

move up and down freely

6) The final step in the gate assembly is to attach the adjustable tension cable. There is one cable per

gate, hinge side top to latch side bottom. The tension cable assembly has three parts: 1 black coated

steel cable, 2 black coated wire clamps and 1 black coated turnbuckle . A) Put the turnbuckle hook end

into the latch side bottom corner hole of part 2 B) run the cable through the wire clamp into

turnbuckle eye end and back into the wire clamp and tighten. The turnbuckle should be open fully

before tightening. The turnbuckle is used to adjust tension on the cable once you hang the access gate.

Latch side bottom to hinge side top corner assembly photo:

Connect the cable through the other corner in the same way, only without a turnbuckle (cable through clamp,

then through corner and back into clamp then tighten)

Gate Frame Instructions

1) Assemble part “L” by attaching #5 to each end using self tapping screws. The pieces should be aligned

the same on either side as pictured above. Screw through the pre drilled holes part #5 into the steel

tubing. If you have to adjust the tube later you can slide the steel tube in or out for slight adjustment.

This assembled piece makes up the top spreader pole which gives structure to the hinge side post and

the latch side post. NOTE: in short access gates, in place of part “L” you have two part “L2” which are

side braces. These braces support the hinge side post and latch side post in place of a top spreader

pole, as pictured in your schematic.

2) Gather your last two parts, part “M” and male hinges part #4 and the assembled spreader bar needed

to make up the gate frame. Gate frames can be either installed in concrete or in ground sleeves. Note:

when installing in ground sleeves, be sure to space out each sleeve appropriately or the gate will not fit

properly in the frame. For ground sleeve/gate installation we suggest using a digging bar to pilot the

hole for each sleeve first.

3) Install hinge side post first. Loosely attach the male hinges to post and tighten temporarily to be

adjusted later. Either A) dig a hole, fill with one bag of concrete mix and set post in concrete and let

the concrete cure or B) drive a ground sleeve in to the ground for your post. Screw locking set screw or

sleeve spike (between post and sleeve) into sleeve to prevent the post from spinning around and to

lock it in. If using concrete, make sure the proper amount of post is left above ground to hang your

gate and the top spreader bar, measure with assembled gate if necessary.

4) Once the hinge side post is set in concrete or installed into a ground sleeve and leveled, it’s time to

measure for the latch side post. The easiest and most accurate way to do this is to use the mounted

access gate with extended out fork latches to gauge where the other latch side post will go. This is

important because if you are off an inch the gate will not latch properly. Prop up the bottom of the

latch side gate with a brick or piece of wood so it doesn’t bend the post. Once measured, install the

latch side post.

5) Hang the top bar between both part “M” (if applicable). The top bar is measured for a gate frame that

has been installed with the proper spacing. If for some reason the top bar pulls the posts in or pushes

them outward, there is some adjustment that can be done. To push farther apart, unscrew the self

tapping screws and move the end pieces farther apart, then screw back in. You can gain a few inches

maximum this way. If the top bar needs to come closer together, the 1 3/8 tube will need to be cut

with a reciprocating saw, pipe cutter or hacksaw and re-attached.

6) Attach the braces (if applicable – gates 5 1/2ft or less). Braces get installed by sliding the bands over

the posts and digging the other end into the ground on an angle. As the gate posts get pulled, the

brace in the ground lends support. See photo below for brace examples on short gate:

7) Test swing and latch of installed gate. If the bottom latch side of the gate is too close to the ground, it

can be adjusted upwards by tightening the turnbuckle

8) Attach fence material to gate (not provided). The easiest and most effective way (without space

around gate) to install fencing on the gate is to unroll fencing across the entire gate, including the gate

frame and attach fully with fence ties, part #1. Use fence ties every 4” or so to connect the fence

material to the access gate and the gate frame. Once fully attached, use snips to cut the fence material

around the gate so it can open and close. You can also stake a piece of fence under the gate to prevent

animals from digging down under the gate for entry.

Table of contents

Popular Fencing & Gate manuals by other brands

Costway

Costway GT3987 manual

Weka Holzbau

Weka Holzbau 670.0627.00.00 manual

PF

PF FF9000 Installation, operation & maintenance manual

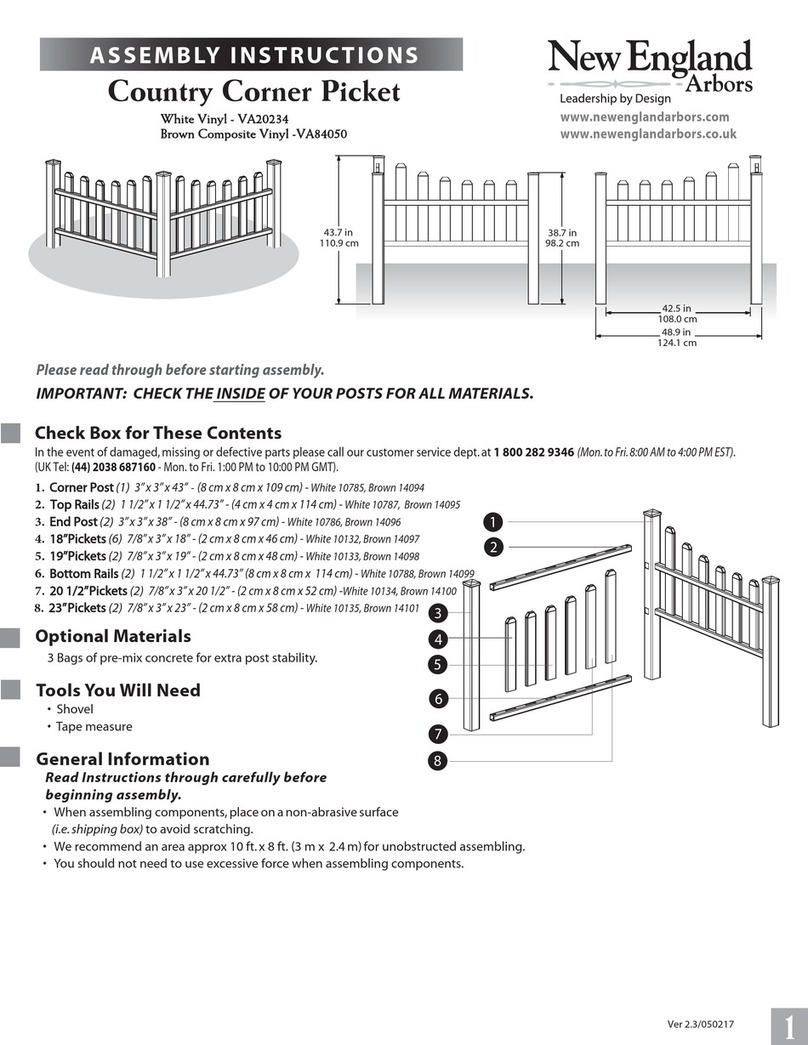

New England Arbors

New England Arbors Country Corner Picket VA20234 Assembly instructions

Pet Stop

Pet Stop OT-100 owner's guide

helo sports

helo sports M-00011 Mounting instruction