DEHACO DTS-100 User manual

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floor stripper DTS-170 v1.0 -october 2011 -blz 1-

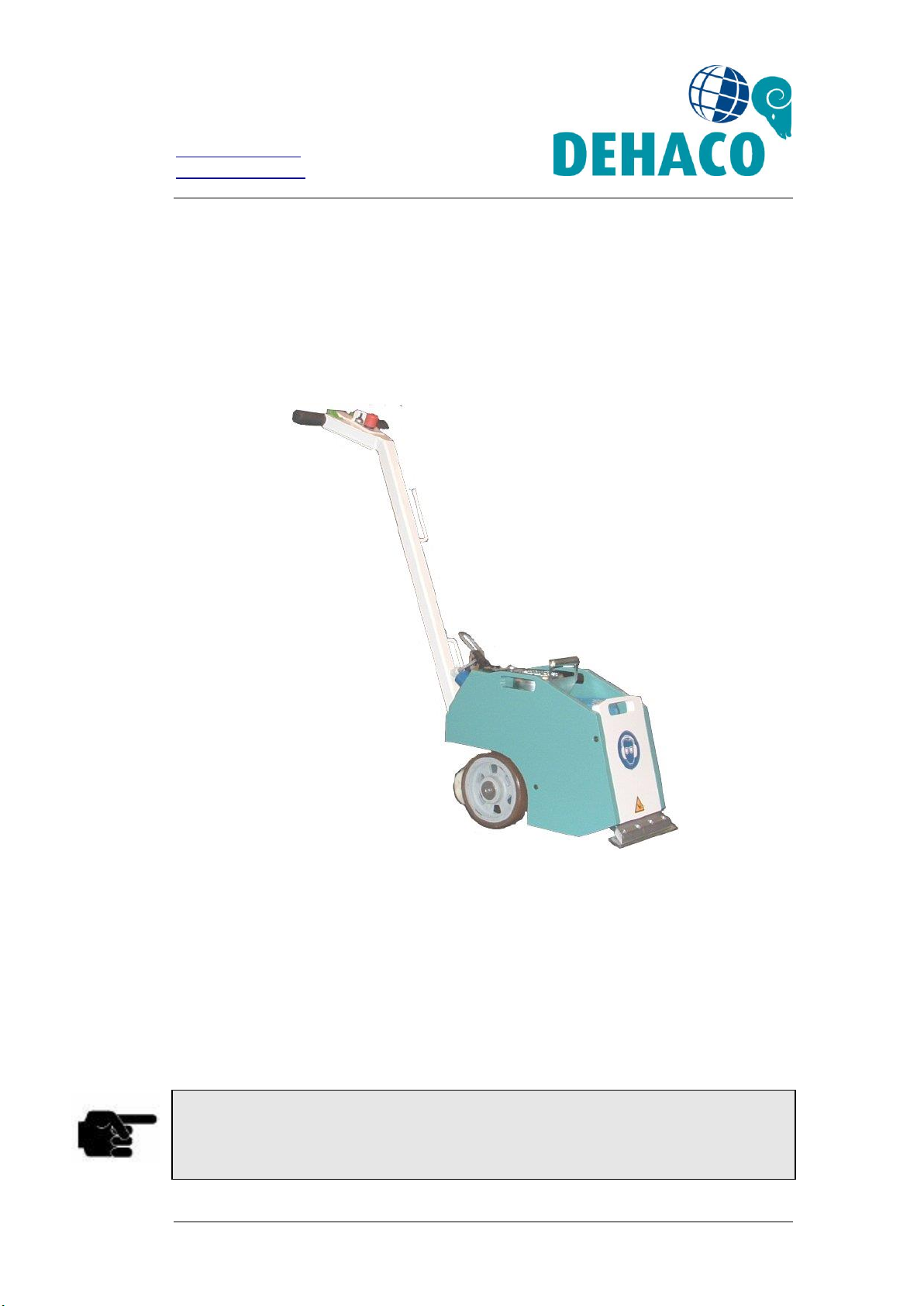

User Manual

FLOORSTRIPPER

DEHACO DTS-100

Specs - Safety –Use - Maintenance

CAUTION!

All persons involved in the installation, commissioning, operation,

maintenance and repair of this product, should have been given these

instructions!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 2-

Contents

1. Introduction............................................................................................ 3

2. Delivery scope ....................................................................................... 3

3. General description................................................................................ 4

4. Intended use.......................................................................................... 6

5. Technical specs...................................................................................... 6

6. Safetey................................................................................................... 7

7.Transport and Storage ............................................................................ 9

7.1 Transport..................................................................................................................9

7.2 Storage.....................................................................................................................9

8. Operation............................................................................................. 10

9. Maintenance ........................................................................................ 12

10. Failures.............................................................................................. 13

11. End of lifespan ................................................................................... 14

12. Warranty ............................................................................................ 14

13. Declaration of Conformity................................................................... 15

14. Spare Parts........................................................................................ 15

15. Attachments ....................................................................................... 15

16. Electrical schedule............................................................................. 16

EG Declaration of Conformity .................................................................. 17

Attachment 1: Parts.................................................................................. 18

©Copyright 2008, Dehaco B.V.

All rights reserved. No part of this publication may be reproduced or transmitted in a

retrieval system, or transmitted in any form or means, electronical, mechanical, by

photocopying, recording or any other kind of way, without the prior written permission of

Dehaco B.V. This also applies to any associated drawings and diagrams. Dehaco B.V.

reserves the right to change the components at any time, without prior or direct notice to

the customer. The contents of this manual can also be changed without notice. For

infromation on setting, maintenance and repair which this manual does not provide, we

ask you to contact the technical department of your supplier. This manual has been

compiled with all possible care, but Dehaco B.V. is not responsible for any errors in this

manual of the consequences thereof.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 3-

1. Introduction

Thank you for purchasing a Dehaco floor stripper. This gives you a

machine available according to the latest state of the art, which you can

use for many years trouble-free when used correctly

This manual aims to familiarize you with the operation, to give you to work

safely, and guidelines for periodic maintenance.

CAUTION!

Make sure that you are aware of the contents of this manual before

starting to work with the floor stripper. This way, you can make optimal use

of the machine.

This manual, the nameplate and safety stickers on the floor stripper

contain important information and are part of the delivery.

In case of damage or loss the plate and stickers must be reapplied or

supplied. Everything will be supplied by Dehaco B.V.

2. Delivery scope

The Dehaco floor stripper is completely

assembled and tested, ready for use!

The delivery includes:

De Floor Stripper

Tool Set (Allen key 6 + 8 mm and a

pitch/ring key 13)

This manual

With delivery of the machines immediately

check if the machine is complete and

undamaged!

If any items are missing or if there is

transport damage, please contact your

supplier!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 4-

3. General Description

The Dehaco floor stripper is designed for optimal use, high capacity and

long life.

We designed a simple but constructive high quality floor stripper, tested in

practice and put into production .

A quickly removable, tempered steel blade hung in rubber shocks is being

vibrated by a driven eccentric. With stabbing this blade under the carpet,

the adhesive will be cut by the vibration. Depending on the thickness and

the adhesive bonding of the carpet, the driving speed can be continuously

adjusted so the maximum capacity is reached in every situation.

To turn quickly, two freewheels are mounted, which will be pushed on the

ground with tipping the stripper. The drive wheels will then be lifted off the

ground.

Characteristics of the Dehaco floor stripper:

Easy interchangeable tempered steel blade, in various designs.

Drive with a maintenance-free motor.

Only 1 lubrication point.

Removable extra ballast plates.

Low power consumption (220V –16A)

Additional wheels for quick turning and positioning

Very easy to operate

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 5-

Part names:

1 8

2 9

3

4 10

5

6 11

12

7 15

16 13

17 14

15

17 16

18

19

18

1 traction motor switch on / off 11 clamp screw drawbar

2 traction motor 12 freewheel

3 integrated lifting eye 13 (emergency) stopbutton

4 stripmotor 14 handle drawbar

5 baseplate blade holder 15 speed control

6 exchangeable tempered blade 16 direction control button

7 driving wheel 17 drawbar

8 RESET / ON button 18 half side plate (ballast)

9 power connection 19 front plate (ballast)

10 plug for drawbar

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 6-

4. Intended use

Thee Dehaco floorstripper type DTS-170:

Is designed to remove carpet and adhesive residue in a simple manner

Is intended for use with the associated Dehaco tempered steel blade

Is intended for use on paved ground (inside)

Is intended for use by an authorized person who is capable to use the

machine

WARNING

Any other use than described above

can lead to life-threatening situations, falls under “improper use” and

shuts Dehaco B.V. out from any liability!!

5. Technical specifications

The machine provided to you meets the following specifications:

DTS-100

Capacity to................ 80 m2/hr

Weight....................... 100 kg

Blade width ............... 25 cm

Power

Strip motor........... 1,1 kW

Traction motor...... 0,55 kW

Connection................ 220V-16A-3P

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 7-

6. Safety

WARNING!

Almost all accidents are a result of:

- Concentration reduction,

- Inattention,

- Negligence,

- Misjudgments!

Work calmly and focussed!

You have been warned!

CAUTION!!

You should, under any circumstances, follow the safety instructions from

the user manual and follow the local regulations.

WARNING!!

There is immediate chance of danger on personal injury, damage to

the machine and the environment during inexperienced and

incompetent use!

Keep bystanders at a safe distance from work!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 8-

Safety on the working environment

a) Keep your working area clean and well lit. Messy, cluttered or dark

working areas invite accidents.

b) Don’t work with this machine in explosive atmospheres, like flammable

liquids, flammable gasses or combustible dust. Power tools create

sparks which can ignite the fumes or dust.

c) Keep children and bystanders away while operating the machine. When

you get distracted it might cause you to lose control of the tool.

d) Stay alert, watch what you are doing and use your sense when using

the machine. Do not operate the machine while under the influence of

drugs, alcohol or medication. One moment of inattention may result in

serious injuries and damage to you and your surroundings.

e) Wear personal protective equipment. Always wear safety glasses,

safety shoes, gloves, ear protection and dust masks. Wearing personal

protective equipment reduces the risk of injuries.

f) Remove all loose tools before turning on the machine.

g)Avoid an unbalanced body position. Be sure you stand properly and

balanced at all times. This allows you to keep the machine under control

in unexpected situations.

h) Wear suitable clothing. Do not wear loose clothing or jewellery. Keep

your hear, clothing and gloves away from moving parts. Loose clothes,

jewellery or long hair can be pulled into moving parts.

i) Stop the machine and disconnect the power before setting the machine,

changing accessories or when you finished working.

This precaution prevents unintentional starting of the machine.

j) Have damaged parts be repaired before use. Many accidents are

caused by poor maintenance.

k) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

l) Consider (besides the above mentioned rules) the local conditions and

regulations as well!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 9-

WARNING!!

Always use personal protective equipment such as nationaly,

loccally and/or reguired at the construction side, but at least:

- Safety glasses

- Gloves

- Safety shoes

- Hearing protection

7. Transport and Storage

7.1 Transport ATTENTION!!

During transportation the steel blade must not be installed in the machine!

Think about your safety!!

For transportation of the floor stripper you can use a car with trailer, due to

its compact size and low own weight.

Loading and unloading can be done with a ramp and the machines own

drive system.

Without ballast plates it’s possible to load and unload the floor stripper with

two men.

For the possible use of lifting equipment a lifting point has been made.

to safe space the handle (drawbar) is easy to remove using the supplied

8mm Allen Key.

7.2 Storage

Is the floor stripper not going to be used for a long time, proceed as

follows:

Clean the machine.

Lubricate the machine according to maintenance schedule (chpt.9)

Store the machine in a dry place and cover it.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 10-

8. Bediening

ATTENTION!!

Check the power cable for damage before connection!

ATTENTION!!

The floor stripper is to move by hand by tilting back the machine so that it

rests on the transport wheels.

ATTENTION!!

The tempered steel blades are very sharp!

Be careful with mounting and removing the blade!

Make sure that the drawbar and the drawbar cable plug are tight

Mount the ballast weight plates and fix them. Use the supplied 6

and 8 mm Allen Keys.

Mount a blade into the blade holder and tighten the base plate

holder with the 6 mmAllen Key. If a nut gets loosened at the back:

use the supplied spanner 13.

Plug the power cable into the socket on the stripper.

THE FLOOR STRIPPER IS NOW READY TO BE USED!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 11-

Startprocedure

Set the stripmotor to “0/OFF”

Check if the emergency button is

not pressed.

Press “RESET / AAN”

the light in the button turns on.

Set the stripmotor to “1/ON”

Operate the traction motor

forward and backworths by using

the green thumb buttons on the

handle.

Adjust the speed with the

speedcontrol on the drawbar.

The reverse speed is always

max.

Stopprocedure

Turn off the machine by pushing

the emergency stop button

Set the stripmotor to “0/OFF”

Remove the blade before

transport!

CAUTION!!

Before pressing the “on / reset” button ALWAYS put the strip motor on “0”

to avoid overload power!

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 12-

9. Maintenance

WARNING!!

Always remove the plug from the socket before inspection,

maintenance or repair is performed!

The DTS-170 stripper is a simple, decent machine. However, regular

maintenance is required to keep the machine in good condition and for

optimal results.

The indicated intervals are a directive under normal use, with more or less

intensive use this work can be carried out more or less often!

The gear of the drive system is maintenance free!

Dagelijks

Check the machine for damage.

Recover also small damages directly or have them be serviced.

This is for your safety and the lifetime of the machine.

Certainly check the electro cables and the blade.

In case of damage: immediately disconnect and have it repaired

first!

Keep the machine clean! This reduces the risk of accidents and

works pleasantly! Don’t spray clean the floor stripper! Dry cleaning!

lubricate the eccentric bearing

on the front. A stroke with a

grease gun with standard EP2

grease is sufficient.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 13-

10. Failures

This chapter provides general guidelines for troubleshooting the machine,

not a step-by-step search diagram.

The Dehaco floor stripper is solid built and will operate trouble-free for a

long time when used within the implicated standards.

WARNING!

Let electrical defaults be repaired only by a qualified person using

only original spare parts. This will ensure that the safety of the

machines is maintained!

1) Driving does not function (properly)

Has the power cable from the drawbar been properly connected?

Check the power supply, is the lamp in the reset button burning?

Check the cable from the drawbar for damage.

Check if the motor is working.

ATTENTION!! Procedure resetting machine:

Unplug the power cable from the floor stripper

Wait 30 seconds (= reset speed control)

Plug the power cable back into the socket

Restart the floor stripper according to CHAPTER 8

2) Stripper does not work (properly)

Has the speed been adjusted according to the load on the blade?

Check the power supply, is the lamp in the reset button burning?

Is the blade sharp enough?

Is the blade still firmly mounted into the blade holder?

Are the rubber shocks ripped?

Is there a failure with the bearing(housing)?

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 14-

11. End of lifespan

If, after a long use, the stripper is at its technical end, proceed as follows

for the responsible processing:

ATTENTION!

You should always meet the requirements and guidelines for working

safely and responsible!

Power tools, accessories and packaging should be recycled on a

environmentally responsible manner.

Proceed as follow:

..........Clean the machine and remove the oil.

..........Disassemble the machine in groups: steel parts / electrical

components.

..........These can be handed separately for recycling.

12. Warranty

For the Dehaco floor stripper a warranty period of 6 months applies. This

warranty means that within this period metal- and manufacturing faults will

be repaired free of charge, AFTER REVIEW OF DEHACO B.V.

Transport- and/or travel expenses shall be paid by the customer. Collateral

damage caused by the machine’s downtime is not covered by this

warranty.

No warranty is given for defects like when:

The machine has been proven overloaded.

The machine has been used for purposes for which it has not been

manufactured.

Maintenance is proven to be performed badly.

The information in this manual is not followed up properly.

The machine is used by unauthorized persons.

The machine is repaired with non-original parts.

The machine has been modified without the written permission of

Dehaco B.V.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 15-

13. Declaration of Conformity

The fixed CE nameplate and the Declaration of Conformity

on page 17 mean that the manufacturer fulfilled the

‘principles of safety integration’ according to the Machinery

Directive.

This means:

a) exclude or reduce risks as far as possible in the design.

b) Make the necessary protective measures in relation to risks that cannot

be excluded (shielding etc.).

c) Inform the user about the residual risks (stickers, manual).

14. Spare Parts

All parts required for maintenance or repair of the machine are available

from your dealer or Dehaco B.V.

15. Attachments

Overview drawing

This is including as the last page(s) in this manual.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 16-

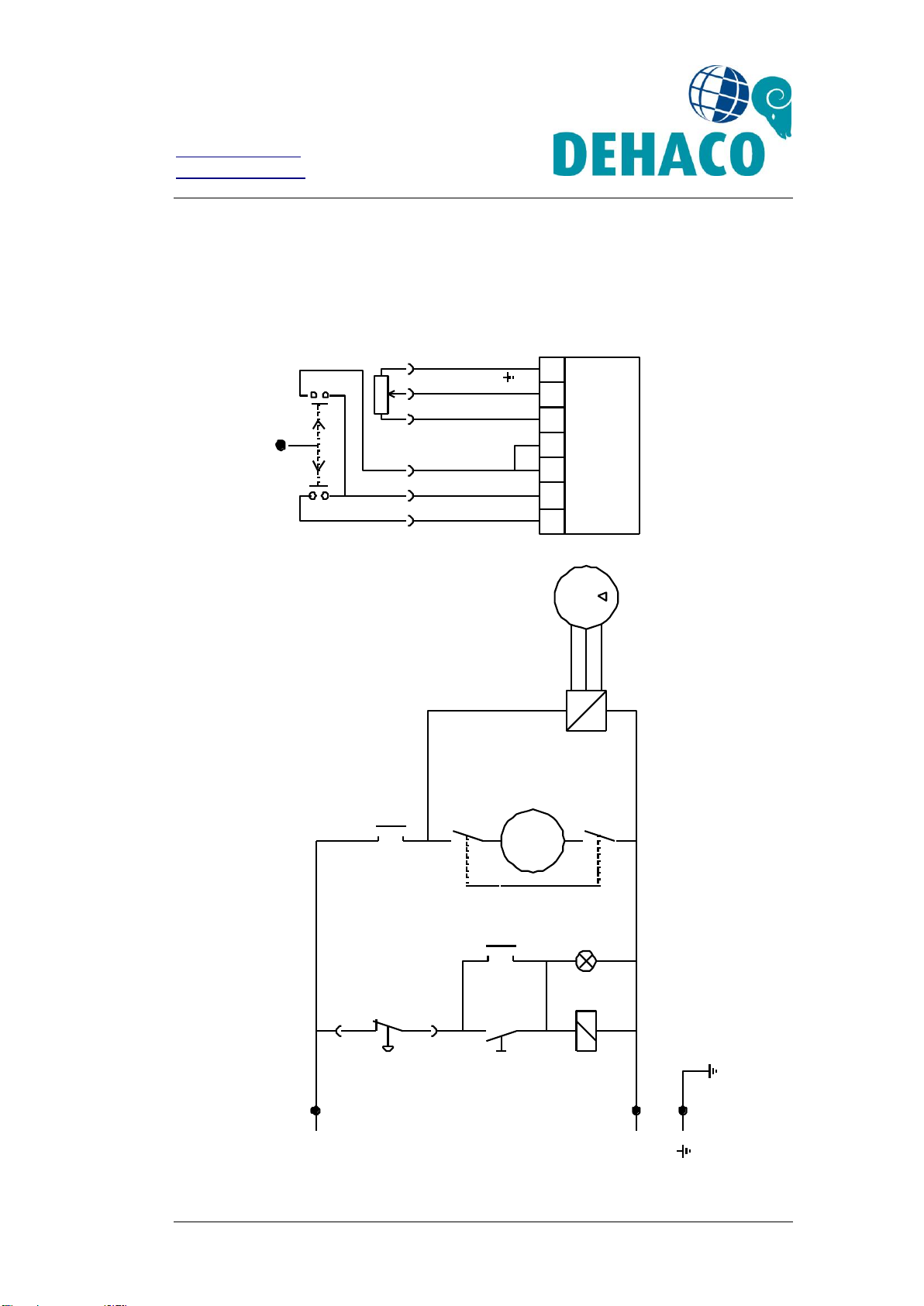

16. Electrical schedule

N

L

NS K1.2

IN/UIT

K1 LA

K1.1 M

1F 220V

M

3F 220V

U

F

1

2

1

2

3

4

11

14

STRIPMOTOR

RIJMOTOR

A1

A2

RESET

Freq. Inverter

Rijmotor

45 8 93

3 4 5 76

FWD

10

REV

SNELHEID

T1

T2

T3

L1

L2

3 4 5 6 7 8

X1

X2

L1

T1

T2

L2

6

21

24

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 17-

EG Declaration of Conformity

ACCORDING TO THE IIAATTACHMENT OF THE MACHINE GUIDELINES

WE,Demto B.V..

Calandstraat 27

4251 NZ Werkendam, the Netherlands

DECLARE UNDER SOLE RESPONSIBILITYTHATTHE PRODUCT:

Brand: Dehaco

Model: FLOOR STRIPPER

Type: DTS-170

WHICH TO THIS DECLARATION RELATES, IS INACCORDANCE WITH

THE PROVISIONS OFTHE FOLLOWING DIRECTIVE:

Machine directive 98/37/EG

Directive SAFETY power tools 2006/95/EG

EMC Directive 2004/108/EG

WEEE Directive 2002/96/EG

AND IS INACCORDANCE WITHTHE FOLLOWING STANDARDS

AND/OR OTHER NORMATIVE DOCUMENTS:

NEN-EN 292-1 NEN-EN 292-2

NEN-EN 414 NEN-EN 5509

NEN-EN 60204-1

MADE IN :

Werkendam, datum: 01-10-2011

Demto B.V.

A.K.J.R. Horden.

DEHACO B.V.

Kruisbaak 25, 2165 AJ Lisserbroek (NL)

Postbus 189, 2160 AD Lisse (NL)

Tel.:+31(0)252 417 950, fax: 418 531

www.dehaco.nl

User Manual Floorstripper DTS-100 v1.0 -October 2011 -blz 19-

Benaming Aantal

10 Dissel 1

DTS170-4710

11 2

DTS170-4711

12 1

DTS170-4712

13 1

DTS170-4713

14 Afdekplaat dissel 1

DTS170-4714

15 1

DTS170-4715

20 1

DTS170-4720

21 Reset/aan drukknop 1

DTS170-4721

22 Stekkerdoos dissel 1

DTS170-4722

23 Wandcontactdoos 1

DTS170-4723

24 1

DTS170-4724

25 1

DTS170-4725

26 Contrastekker dissel 1

DTS170-4726

27 Frequentieregelaar 1

DTS170-4727

28 1

DTS170-4728

29 Relais 1

DTS170-4729

30 1

DTS170-4730

31 1

DTS170-4731

32 Spie 8x7x70 1

DTS170-4732

33 Spie 8x7x35 2

DTS170-4733

34 Aandrijfas 1

DTS170-4734

35 1

DTS170-4735

36 2

DTS170-4736

37 2

DTS170-4737

38 Aandrijfwiel 2

DTS170-4738

39 1

DTS170-4739

40 1

DTS170-4740

41 1

DTS170-4741

42 1

DTS170-4742

43 1

DTS170-4743

50 1

DTS170-4750

51 Frame 1

DTS170-4751

52 1

DTS170-4752

53 1

DTS170-4753

54 Krukas 1

DTS170-4754

55 4

DTS170-4755

56 1

DTS170-4756

57 1

DTS170-4757

58 1

DTS170-4758

59 1

DTS170-4759

60 1

DTS170-4760

61 1

DTS170-4761

Tek no. Bestelno.

Duimknop signaalgever

Potmeter

Noodstopknop

Signaalgever rijrichting

Deksel elektrakast

Schakelaar stripmotor

Elektrakast

Relaishouder

Rijmotor

Wormwielreductor

Zijplaat frame L

Vrijloopwiel

Stelring 25x40x16

Disselhouder

Zijplaat frame R

Ballastplaat R

Ballastplaat L

Ballastplaat voor

Stripmotor

Steunring

Lagerblok frame

Trillingdemper 40x30

Trillingdemper 30x30

Meshouder

Kikkerplaat alu.

Lagerblok meshouder

Lagerblok onderframe

Onderframe lagerplaat

Other manuals for DTS-100

1

This manual suits for next models

1

Table of contents

Other DEHACO Floor Machine manuals

Popular Floor Machine manuals by other brands

Triple S

Triple S panther 26T owner's manual

Sebo

Sebo duo instruction manual

Sanitaire

Sanitaire SC6085 Series owner's guide

Eureka

Eureka MAGNUM EB BASIC OPERATION, MAINTENANCE & TROUBLESHOOTING MANUAL

Nilfisk-Advance

Nilfisk-Advance PBU Operator's manual

Kärcher

Kärcher KM 85 W B Classic operating instructions