DEHACO DTS-100 User manual

User Manual

Floor stripper DTS100 EU

2020-04_v3.2_EN

Floor stripper

DTS100 EU (230V)

2Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

EC DECLARATION OF CONFORMITY

Translation of original user manual according to annex 1,

section 1.7.4. of Machinery Directive 2006/42/EC.

We, Dehaco B.V., hereby declare that the products listed below comply with the essential requirements

of the above-mentioned European Directive and the following harmonised standards:

Product: Floor stripper

Brand: Dehaco

Type designation: DTS100 (230V)

Manufacturer: Dehaco B.V.

Kruisbaak 25

2165 AJ Lisserbroek - NL

Directives: Machinery Directive, 2006/42/EG

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

Standard(s) NEN-EN-ISO 12100 Risk Reduction

Place and date: Lisserbroek, 01-02-2020

Managing director: Jeroen Korporaal

3© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

Index

INDEX

EG-Declaration of conformity 2

1. Introduction 3

2. General description 4

3. Machine overview 5

4. Intended use 6

5. Specications 7

5.1 General 7

5.2 Wear parts 7

5.3 Noise emission 7

5.4 ibration hand arm system 8

6. Safety 9

7. Transport & Storage 11

8. Get started! 12

8.1 Setting up 12

8.2 Start working 13

8.3 Completing the work 14

8.4 Preparing for transport 14

8.5 Replacing a blade 14

9. Maintenance 15

9.1 Daily maintenance 15

9.2 Torques 15

10. Malfunctions 16

10.1 Green led does not light up 16

10.2 The driving components do not

function properly 16

10.3 Stripper does not function properly 17

10.4 Error code in the frequency controller 17

11. Warranty conditions 19

12. Repair 19

13. End of life span 20

14. Parts 20

© Copyright 2021, Dehaco B.V.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise, without express written permission from Dehaco B.V. This also applies to any

accompanying drawings and diagrams. Dehaco B.V. reserves the right to revise sections of this document at any time and without prior or direct

notice to the customer. The contents of this manual can also be changed without prior notice. For information regarding setting, maintenance

or repairs not included in this user manual, please contact your supplier’s technical department. This user manual has been prepared with the

utmost care, however Dehaco B.V. cannot accept responsibility for any errors in this user manual or the consequences thereof.

Dehaco B.V.

Kruisbaak 25

2165 AJ Lisserbroek - NL

T +31 (0) 88 20 20 800

I www.dehaco.nl

Dealer

4Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

1. Introduction | 2. General description

1. INTRODUCTION

Thank you for purchasing the DTS100 Floor stripper.

You are now in the possession of a machine that, if

used correctly, can be used without any malfunctions

for many years to come.

The objective of this user manual is to make you

familiar with the machine’s operation, give instructions

for working safely and provide guidelines for periodic

maintenance.

The manual was drawn up for all persons involved with

the machine’s use, operation and maintenance.

These persons must:

Ø

required for their task.

ØHave read and understood this user manual.

ØObserve all indicated safety instructions.

Ø

their disposal, if necessary.

This user manual, the type plate and the safety stickers

applied to the machine contain important safety

information and as such are an integral part of the

delivery.

Keep this manual in a safe place and pass it on to the

new owner when the machine is sold on.

When this user manual, the type plate or the safety

stickers are damaged, these should be applied or

made available again.

These components can also be provided by your

supplier afterwards.

WARNING!

Make sure you are familiar with the content of this

user manual before you start working with the

machine, so you are able to use all its possibilities

in an optimal and safe way!

At delivery, the DTS100 has been fully assembled

and tested and is ready for use.

The delivery comprises:

ØFloor stripper DTS100

ØCase with accessories:

§This manual,

§Hearing protection, safety goggles,

gloves

§Strip blades

§6 and 8 mm socket head wrench

§Extension cord

Immediately at delivery, check that the machine

is complete and undamaged. In case of missing

components or damage during transport, please

immediately contact your supplier.

2. GENERAL DESCRIPTION

The DTS100 Floor stripper was developed by Dehaco

for optimum use, great capacity and a long life span.

This was achieved by applying available technical

know-how to meet practical requirements.

A simple but constructively high quality Floor

stripper was designed, extensively tested in practice

and taken in production.

An -easily exchangeable- hard steel blade

suspended in vibration rubbers is made to vibrate

by means of a driven eccentric. By inserting this

blade under the carpet, the glue layer is “cut

through” by means of vibration. Depending on the

carpet’s weight and the glue used, the driving speed

can be variably adjusted, so that the maximum

capacity can be achieved for any situation.

In order to be able to turn around quickly, two

freewheels have been mounted that are pressed

Characteristic features:

- Very easy to operate

- Quickly exchangeable hard steel blade Drive

with maintenance free geared motor

- No lubrication points

- Removable extra counter-weight plates

- Low required power (220V – 16A)

- Extra freewheel set for quick turning,

positioning and transporting.

5© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

3. Machine overview

Blade holder

OF/OFF Strip motor

ON/RESET Press button

Drive motor

Hoisting point

Strip motor

Driven wheel

Clamping plate

Control panel

Thumb button for operating drive motor

Drive speed controller

Emergency stop button

Handle

Extension cord holder

Tiller

Side plate (counter-weight)

Front plate (counter-weight plate)

Plug tiller head

Plug power cord

Clamp screw tiller

Freewheel

3. MACHINE OVERVIEW

6

4. Intended use | 5. Specications

✆

4. INTENDED USE

The DTS100 Floor stripper is intended for:

- easy removal of carpet tiles, carpet and glue

residues,

- use with an accompanying hard steel blade,

-

- use by one person who is capable of doing this

type of work.

WARNING!

Any other use than described above shall exclude

Dehaco from any responsibility!

Use for other purposes has not (yet) been investigated.

For any other possible applications, please contact

your supplier IN ADVANCE to consult whether the

machine is suitable for such purpose.

WARNING!

The DTS100 Floor stripper does NOT comply with the

ATEX Directive and should therefore NOT be used on

locations with an increased re/explosion hazard!

5. SPECIFICATIONS

5.1 General

Weight: 100 kg

Supply voltage: 230V / 50 Hz

(check the type plate!)

Plug: CEE 3-pole, 16A

Frequency: 50 Hz

Strip blade motor: 0.55 kW

Drive motor: 0.25 kW

IP class: IP 54

V blade: 29 cm

5.2 Wear parts

SWear parts are components in the machine that

do not fall under the warranty conditions, due to

additional contact with the product.

The wear parts of this machine include:

- The strip blade.

- The clamping plate.

- The blade holder.

5.3 Noise emission

The noise level in the direct vicinity of the DTS100

at a test setup is approx. 76 dB. Due to additional

room in which the work is performed, wearing hearing

protection is expressly recommended. This is to

prevent hearing damage when used for a long period

of time!

THEM!

5.4 Vibration hand arm system

The measured value of the vibrations: 4,6 m/s2.

The deviation on this measurement is: 0.5 m/s2.

Usage time per day:

Limit value 2.5m/s2.5 hours

Limit value 5.0 m/s29 hours

These are values measured with a new machine and

depend on factors such as accessories, maintenance,

the surface to be treated and ambient temperature.

Measures in case of values above 2.5 m/s2:

-

- Use anti-vibration work gloves

- Take breaks, switch between jobs

- Ensure warm hands

- Keep the blade sharp!

- Ensure proper maintenance

- Periodically replace the vibration rubbers.

7© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

6. Safety

6. SAFETY

WARNING!

Almost all accidents are the result of:

lower concentration, negligence, inattentiveness

or incorrect assessments! Work steadily and stay

concentrated: You have been warned!

if necessary place additional (building) lighting to

All persons involved with assembly, commissioning,

operation, maintenance and repair must:

§Have the level of know-how and

§Have read and understood this user

manual.

§Observe all indicated safety instructions.

§

tools at their disposal, if necessary.

WARNING!

There is an immediate hazard of physical injury,

damage to machines and the environment in case of

inexperienced and inexpert use: Keep bystanders at

a safe distance from the work !

- Keep children and other persons at a distance

when using the machine. If you are distracted,

you could lose control of the tool.

- Stay alert, know what you are doing and use

common sense when using the machine. Do

not work with machines when you are tired

medication. A moment of inattentiveness when

using the tool could lead to serious injuries and

damage to the machine and the surrounding

- Remove all loose tools before switching on the

machine.

- Prevent an unbalanced body posture. Make

maintain your balance. In this way you are

better able to control the machine during

unexpected situations.

Carefully read the user manual prior to

starting the machine!

- Wear suitable clothes. Do not wear loose-

hanging clothes or jewellery. Keep hairs,

clothes and gloves away from moving parts.

Loose-hanging clothes, long hair and jewellery

could be taken along by moving parts.

-

power cord when adjusting the machine,

This precaution will prevent the machine from

being started unintentionally.

- Repair damaged parts prior to use or have

them repaired. Many accidents are caused by

poor maintenance.

- Keep cutting tool inserts sharp and clean.

Carefully maintained cutting tool inserts with

sharp cutting edges are less prone to getting

stuck and are easier to guide.

- In addition to the above-mentioned rules,

you should also familiarise yourself with local

working conditions and health and safety

rules.

CAUTION:

Structural preventive maintenance reduces the risk

of malfunctions during work!

WARNING!

Use personal protective equipment as obliged

nationally, locally and/or at the building site, but at

least use the following: safety helmet,

hearing protection, safety goggles, gloves, safety

shoes.

8Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

7. Transport & Storage | 8. Get started!

7. TRANSPORT & STORAGE

7.1 Transport

CAUTION!

ØRemove the blade from the stripper prior to

transport! Think of your safety.

- Due to the compact dimensions and low own

weight, it is possible to use a car trailer or van

to supply and remove the Floor stripper.

- Loading and unloading can be performed with

a ramp and the machine’s own drive.

- A crane hook has been provided for using

lifting tools.

- In order to save space, it is possible to remove

the handle (tiller head). Use the provided 8mm

socket head wrench for this.

7.2 Opslag

When decommissioning the DTS100 Floor stripper for

a longer period of time, it is recommended to perform

the following actions:

STORAGE!

ØDo NOT clean the Floor stripper with a high-

pressure cleaner! Cleaning with compressed air!

- Neatly clean the machine.

- Perform maintenance, see section 9.

- Store the machine in a dry, preferably

frost-free room.

- Cover the machine, if possible.

8. GET STARTED!

CAUTION!

Check in advance that there are NO bolts, screws or

threaded ends protruding from the oor. This could

damage the strip mechanism.

8.1 Get started

CAUTION!

ØBefore you connect a power cord, you must rst

check it for damages!

CAUTION!

ØThe Floor stripper can be moved manually by

tilting the machine backwards, so that it is

supported by the transport wheels.

CAUTION!

ØThe hard steel blades are very sharp!!

ØProceed carefully when installing and removing

the blade!

CAUTION!

ØCheck that the power supply and converter are

suitable for the machine!

- Check that the tiller and the plug of the tiller

head cord are properly fastened.

- Mount the counter-weight plates and fasten

them properly. The bolt heads should go in the

blind holes, so they do not protrude! Use the

provided 8 mm socket head wrench for this.

- Carefully select a strip blade type: see box to

the left. The correct strip blade that is suitable

for the work will save you a lot of time and

ensure a better end result!!

- Place a blade in the blade holder and properly

fasten the clamping plate using the 6 mm

socket head wrench.

- Insert the power cord in the counter plug on

the stripper.

The Floor stripper is now ready for use.

Guidelines for selecting the

correct strip blade:

-

the bevelled side of the blade at the

top.

- In case of a wooden (soft)

the blade around, due to the

adapted cutting angle.

-

15° angle

- In case of hard material, select a narrower

blade

- In case of carpet, for instance, select a U blade

to cut loose strips of material

- Use your experience and/or consult with your

supplier to determine which blade model is

most suitable for your application.

9© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

8. Get started!

8.2 Start working

CAUTION!

ØPrior to pressing the “on/reset” button, ALWAYS

due to the starting current!

- First set the strip motor to “0/OFF”.

- Set the rotary button for drive speed fully to

the left, to the zero position.

- Check that the emergency stop button is not

pressed in.

- Press the green “ON” button: the led in the

button should light now.

- Set the strip motor to “I / ON”.

- Operate the drive motor forwards or

backwards using the green thumb buttons on

the handle.

- Use the potentiometer on the tiller head to set

the forward drive speed, the reverse speed is

always maximum.

- Work in long lanes, do not repeatedly reverse.

- Turning around is easy by tilting the stripper

backwards and using the freewheels for

turning around.

CAUTION!

ØDo NOT stand on the stripper for extra weight!

- Also during the work, regularly check that all

bolts are still properly fastened.

-

Make sure there are no bolts, screws or

could damage the strip mechanism.

- Regularly remove stripped carpet from the

front of the machine.

- Do watch out for the power cords, to prevent

accidents.

8.3 Completing the work

- Set the strip motor switch to “0/OFF”.

- Remove the plug from the socket.

8.4 Preparing for transport

- Remove the plug from the socket.

- ALWAYS remove the blade prior to transport!

- Before departure, check that all tools,

components and PPE have been returned to

the provided case.

- Insert the plug in the socket again.

- Drive the DTS100 to the transport device by

means of its own power, or manually by means

of the freewheels.

- Store the power cords.

8.5 Replacing a blade

WARNING!

The strip blades are hardened and very sharp,

ALWAYS wear gloves when placing and replacing a

strip blade!

- Place a block under the blade holder, so

that the Floor stripper is somewhat tilted

backwards.

- Loosen the four bolts of the blade holder by a

few turns.

- Take the blunt blade from the blade holder,

store it so that no-one can injure themselves

with it.

- Slide the required strip blade between the

lower and upper piece of the blade holder,

making sure the recesses fall over the bolts.

- Properly tighten the blade holder bolts again,

replace the screws when they show signs of

wear!

- The Floor stripper is now ready for use again!

10 Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

9. Maintenance | 10. Malfunctions

9. MAINTENANCE

WARNING!

Always rst remove the plug from the socket before

performing inspection, maintenance or repairs!

The DTS100 Floor stripper is a simple, reliable

machine. Regularly maintenance is needed however,

to keep the machine in a good condition for optimum

results.

The indicated intervals are a guideline for normal use,

in case of more or less intensive use, these actions can

be performed more or less frequently!

The geared motor of the travel drive is maintenance

free!

9.1 Daily maintenance

- Regularly check the machine -visually- for leaks

and damages, this certainly also applies to the

power cord(s)!

- Repair damages immediately or have them

repaired. This also applies to minor damages.

span of your machine.

- Remove all loose material from the stripper

mechanism.

- Keep the machine clean! This reduces the

risk of accidents and makes your work easier.

convenient!

- Check that all bolts are properly fastened.

- Replace the bolts of the blade holder when the

heads show signs of wear.

CAUTION!

ØClean carefully! Do not spray clean with a

high-pressure cleaner!

9.2 Aanhaalmomenten

For 8.8 hexagon bolts, the following torques can be

observed. (Wurth):

M6x1,0-8.8 10 Nm.

M8x1,25-8.8 25 Nm.

M10x 1,5-8.8 50 Nm.

10. MALFUNCTIONS

This section provides general guidelines for

troubleshooting at the machine, it is not a step-by-step

search diagram.

The Floor stripper DTS100 is solidly built and will

function free from failures for a long period of time, if

used carefully within the stated standards of use.

WARNING!

Only have electrical failures repaired by qualied

and skilled personnel and only use original

replacement parts.

FIRST:

- Disconnect all other machines from the same

power group.

- Try the machine without extension cords, near

the power supply.

10.1 Green led does not light up

Error in the power supply, check the following:

- Is the emergency stop button not pressed

down?

- Are the plugs inserted properly?

- Have any fuses blown? No fuse has been

included in the DTS100 itself.

- Is the extension cord not damaged / broken?

10.2 The driving components do not

function properly

- Has the cord for the tiller head been connected

(properly)?

- Check the power cord, does the led in the reset

button light up??

- Check the tiller head cord for damages.

- Check that the wheel motor is working.

§Reset the frequency controller:

§Pull the power cord out of the stripper.

§Wait 30 seconds (=reset controller )

§Place the power cord back in the counter

plug.

§Restart the machine.

11© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

10. Malfunctions

10.3 Stripper does not function properly

-

- Has the driving speed been adjusted to the

blade load?

- Check the power cord, does the led in the reset

button light up?

- Is the blade still properly fastened in the blade

holder?

- Has a vibration rubber been torn?

- Is there a defective bearing (house)?

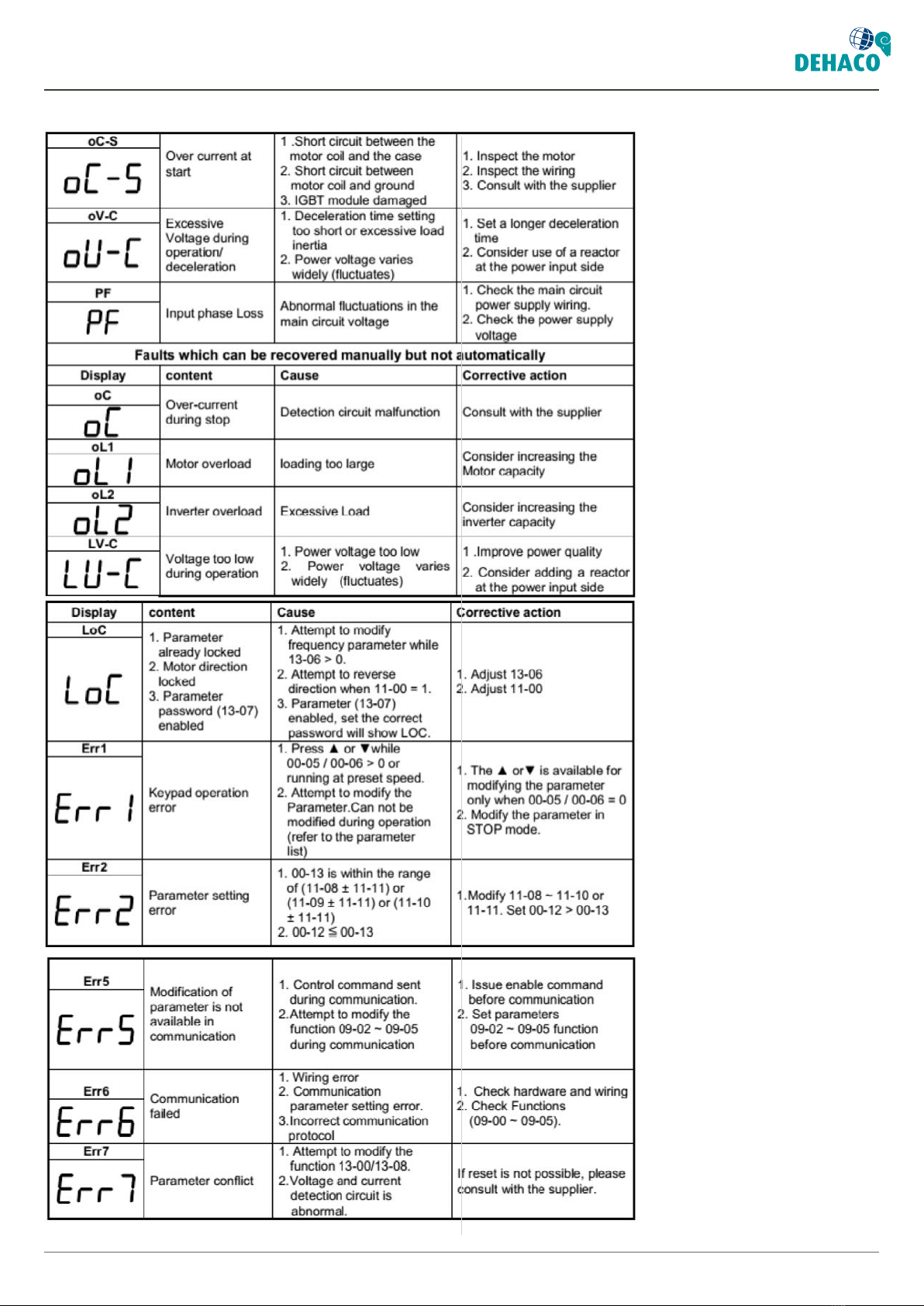

10.4 Error code in the frequency

controller

The DTS100 stripper has been provided with a

In case of a frequency controller error, a code is shown

in the display. These codes can be seen in the next

pages and have been taken from the English S2U

manual:

12 Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

10. Malfunctions

13© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

10. Malfunctions

14 Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

11. Warranty conditions - 14. Parts

11. WARRANTY CONDITIONS

A six month warranty period applies to this machine,

after delivery in accordance with the Metaalunie

conditions.

This means that within this period, only material and

manufacturing defects are repaired free from costs,

AFTER ASSESSMENT BY DEHACO. Transport and/or

travelling expenses must be paid by the customer.

NO WARRANTY is provided for defects that have been

caused when:

Øit can be proven that the machine has been

overloaded.

Øthe machine has been used for purposes for which

it has not been built.

Øit can be proven that maintenance performed has

been poor.

Øthe information in this manual has not been

observed properly.

Øthe machine has been used by unauthorised

persons.

Øthe machine has been repaired with non-original

parts.

Øthe machine has been adapted without written

permission from Dehaco.

NO WARRANTY is provided for wear parts, as stated in

section 5.

12. REPAIR

Dehaco expressly recommends that repairs are only

performed by skilled and experienced personnel.

No extensive repair descriptions have been included in

the manual, but you can always contact Dehaco if you

have any questions.

13. END OF LIFE SPAN

You must always meet the currently and locally

applicable requirements and directives for working

safely and responsible disposal!

If after being used for a long period of time, the

machine has reached its technical end, please proceed

as follows for responsible processing:

ØClean the machine.

ØDisassemble the electronic components. These

can be disposed of separately.

ØDisassemble the plastic parts, these can be

disposed of separately.

ØThe remaining components are made of steel and

can be scrapped.

14. PARTS

The parts list is provided as a separate document.

The machine is developed and built using partly

custom-made parts and partly standard components.

The standard components can be delivered in a short

period of time.

Please contact your supplier to place your order and

ask for the delivery time!!

15© 2021 Dehaco B.V. • User Manuak • Floor stripper DTS 100 UK (115V)_2021-06_v3.2_EN

cmd + shift + klik

16 Dehaco B.V. • Kruisbaak 25 • 2165 AJ Lisserbroek (NL) • ✆ +31 (0)88 - 20 20 600 • [email protected] • www.dehaco.nl

Dehaco B.V

Dehaco Lisserbroek

Kruisbaak 25, 2165 AJ

Lisserbroek, The Netherlands

Dehaco Raamsdonksveer

Steurweg 1, 4941 VP

Raamsdonksveer, The Netherlands

Phone

E-mail

www.dehaco.nl

+31 (0)88 20 20 600

Other manuals for DTS-100

1

Table of contents

Other DEHACO Floor Machine manuals

Popular Floor Machine manuals by other brands

Windsor

Windsor CVC24 operating instructions

Windsor

Windsor MB2000 Operator instructions

Hoover

Hoover FloorMate SpinScrub H3040RM owner's manual

Tennant

Tennant 5200 Operator and parts manual

American-Lincoln

American-Lincoln 4366XP 56516751 Instructions for use

Isoplam

Isoplam L010001 Use and maintenance manual