DEHAS QualityMix N2O Series User manual

1

Contents

1. Explanation of the most important abbreviations......................................................... 2

2. Safety information - warnings, safety precautions and labelling information................ 2

3. Package contents and inspection upon receipt........................................................... 3

4. Intended application.................................................................................................... 4

5. Before first use............................................................................................................ 4

6. Technical Data............................................................................................................ 6

7. Pressure drop in the system ....................................................................................... 7

8. Transport and storage requirements........................................................................... 7

9. Dryness and composition of gas supplies................................................................... 7

10. Illustrations and naming of components...................................................................... 8

11. Installation .................................................................................................................10

12. Alarm test ..................................................................................................................10

13. Initial operation ..........................................................................................................11

14. Cleaning and disinfection...........................................................................................12

15. Maintenance..............................................................................................................12

16. Return of Goods ........................................................................................................13

17. Disposal.....................................................................................................................13

18. Troubleshooting.........................................................................................................14

19. Warranty conditions...................................................................................................15

Status: 11/2019

2

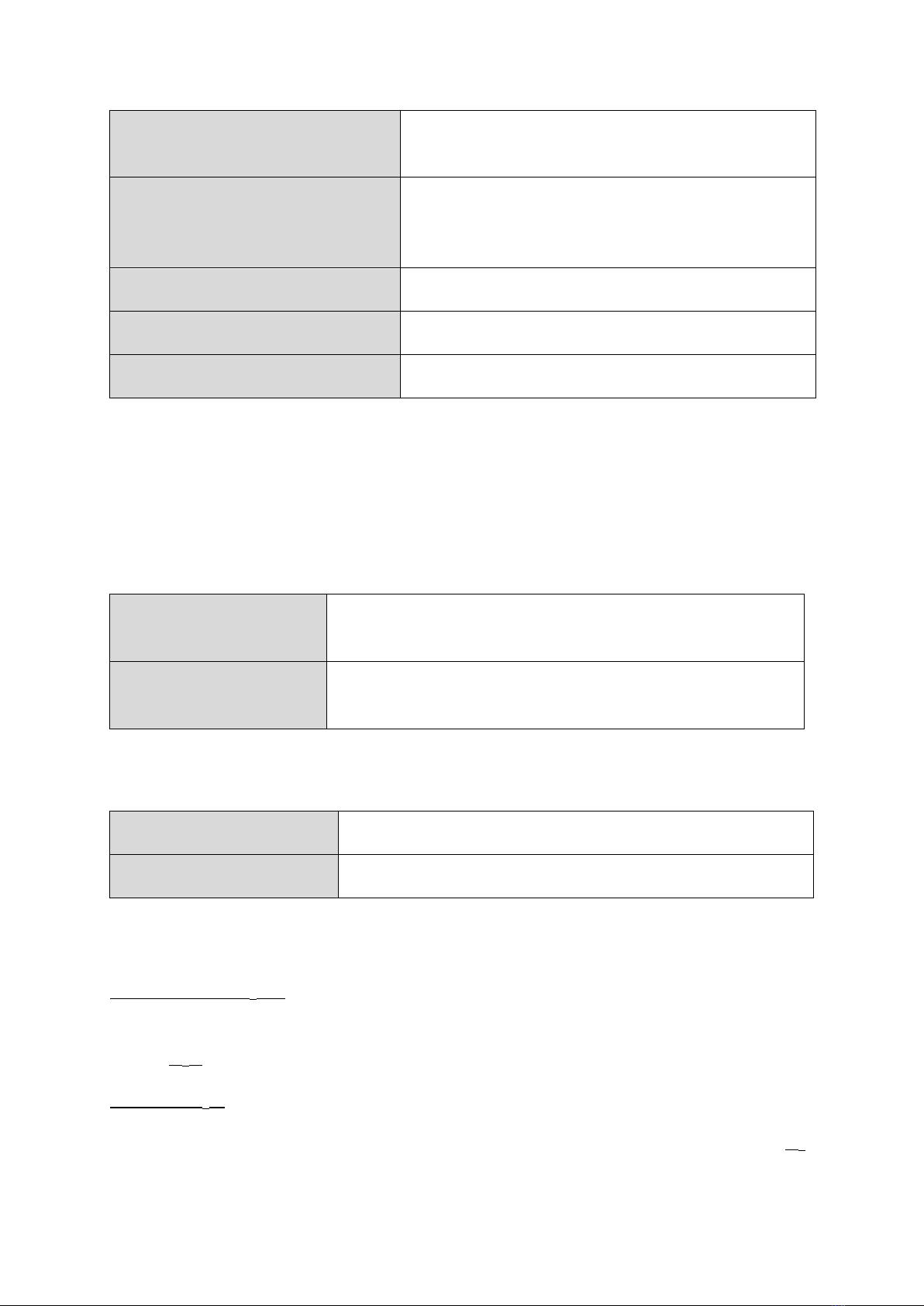

1. Explanation of the most important abbreviations

FIO2

Fractional concentration of inspiratory oxygen

DISS

Diameter Index Safety System

NIST

Non-interchangeable Screw Thread System

Bar

Unit of measurement for pressure

l/min

Litres per minute

2. Safety information - warnings, safety precautions and

labelling information

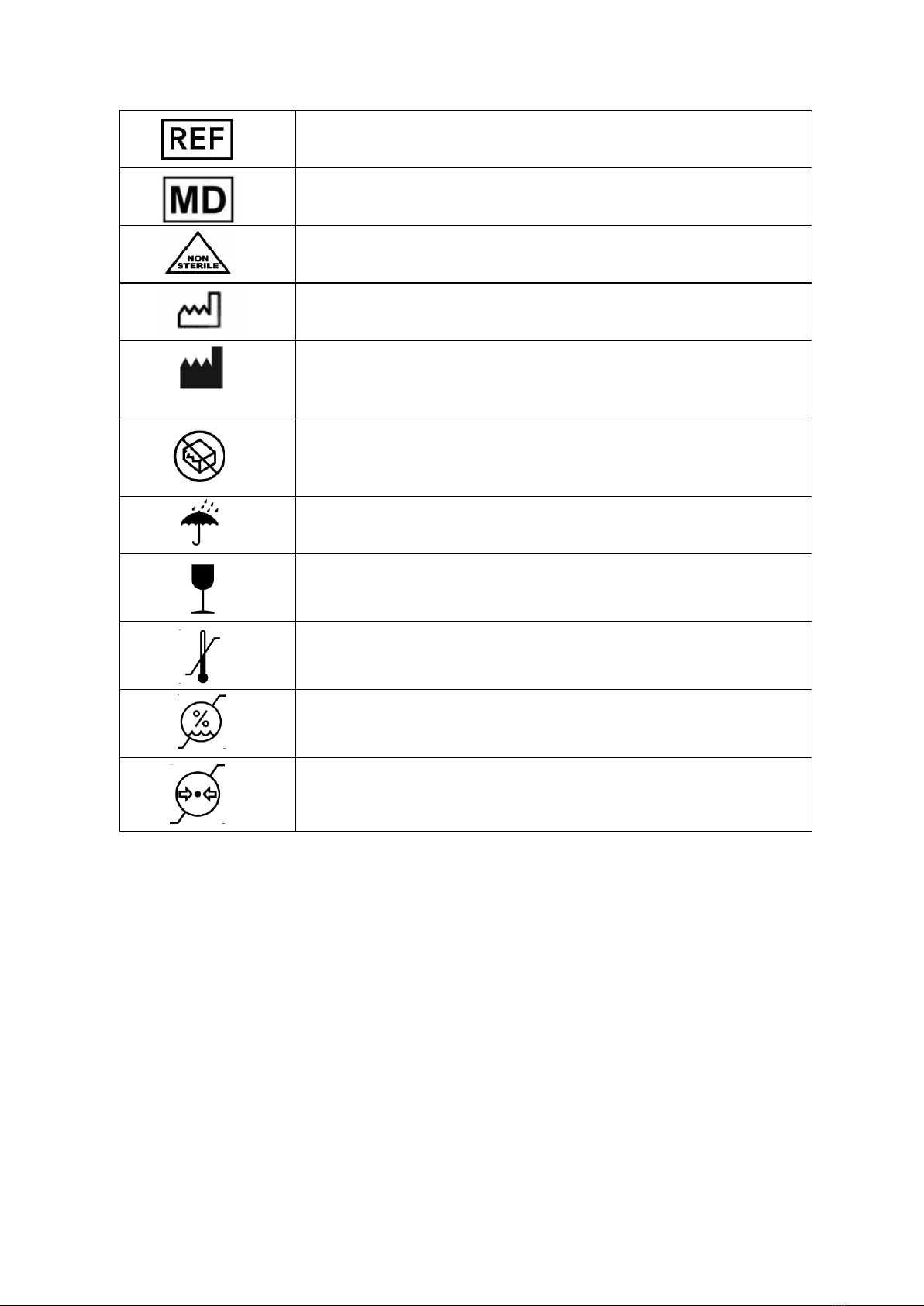

Symbol

Description

This symbol indicates that the device complies with the

requirements of Regulation 93/42/EEC regarding medical

devices and all applicable international standards.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

ATTENTION

Use of this symbol indicates a potentially hazardous

situation which, if not avoided, could result in equipment

damage.

or

Indicates the need for the user to consult the user

manual.

DO NOT USE OIL

Indicates the serial number of the manufacturer so that a

specific medical device can be identified.

3

Indicates the manufacturer's order number so that the

medical device can be identified.

Medical device

Non-sterile

Date of manufacture

Indicates the manufacturer of the medical device

according to EU Directives 90/385/EEC, 93/42/EEC and

98/79/EC.

Indicates a medical device that should not be used if the

packaging is damaged or opened.

Designates a medical device that must be protected

against moisture.

Designates a medical device that may break or be

damaged if handled carelessly.

Describes the temperature limits to which the medical

device can be safely exposed.

Indicates the humidity range to which the medical device

can be safely exposed.

Indicates the range of atmospheric pressure to which the

medical device can be safely exposed.

3. Package contents and inspection upon receipt

Package contents: 1 Basic unit consisting of:

11 mixer with adjustment unit

1Nitrous oxide module with flush function

2Connection hoses (O2 & N2O)

2 Pressure reducer 3.8 Bar (O2& N2O)

1User manual

According to order option

1Demand System N2O with connection hose

4

Or

1Flow meter with connection block and reservoir bag

Inspection: Remove the device from its packaging and inspect it for

damage. If you notice any damage, DO NOT use the device

and contact your distributor.

4. Intended application

The QualityMix N2O oxygen/nitrous oxide mixer is designed for the administration

of a continuous and accurate mixture of medical nitrous oxide and medical

oxygen to infants, children and adults via the exit port. The exact fractionated

inspiratory oxygen nitrous oxide concentration (FIO2/FIN2O) corresponds to the

selected FIO2/FIN2O setting on the control knob (rotary selector).

Indication:

This device is to be used by patients under the supervision of trained specialist

personnel for pain therapy.

Contraindication:

Do not use with patients who cannot breathe independently. Do not use for life

support or life saving.

5. Before first use

Read all instructions before use!

These instructions for use provide qualified personnel with instructions for

installing and operating the QualityMix N2O. The instructions are intended for

your safety and to protect the device from damage. If you do not understand any

information or instructions in this instruction manual, do not use the device and

contact your supplier.

DANGER

This product is not intended for use as a life-saving or life-supporting device.

WARNING

The QualityMix N2O oxygen/nitrous oxide mixer should only be operated

by medical personnel under the direct supervision of a licensed

physician

5

The QualityMix N2O oxygen/nitrous oxide mixer should be used only for

the purposes described in these operating instructions.

Review the prescribed dose before administration to the patient and

monitor the administration frequently

The QualityMix N2O oxygen/nitrous oxide mixer may only be serviced

by a qualified technician

Always comply with EN and DIN standards for the handling of medical

gas products, flow meters and oxygen

The oxygen/nitrous oxide concentration must be confirmed with an

oxygen analysis/monitoring device

DO NOT interfere with the alarm

DO NOT use the mixer when the alarm sounds

DO NOT use oil in or near the mixer

DO NOT use the mixer near flames, combustible/explosive materials,

vapours or gases

NEVER smoke in an area where oxygen is administered

When administering O2/N2O, personnel may be exposed to N2O. The

applicable national laws specifying exposure limits and safety

regulations for handling medical gases in the workplace must be

complied with. Possible exposure can be prevented by continuous,

effective control of the system, ventilation and working practices

The oxygen concentration rotary switch cannot be rotated 360 degrees.

Turning the switch to less than 30% or more than 100% oxygen will

damage the mixer

WARNING

Close the gas supply when the QualityMix N2O oxygen/ nitrous oxide

mixer is not being used

Always ensure an adequate supply of the gases used. After each use,

check the level of the gas source before reuse

Store the QualityMix N2O oxygen/nitrous oxide mixer in a clean, dry place

when not in use

The QualityMix N2O oxygen/nitrous oxide mixer does NOT contain

magnetic materials containing iron and is MRI compatible (max 3 Tesla). A

clearance of 2 meters must be maintained

The O2monitor is not suitable as an accessory for MRT

ATTENTION

Always ensure that all connections are secure and tight

NOT suitable for sterilization

DO NOT immerse in liquids

DO NOT sterilize with ethylene trioxide (EtO)

DO NOT use if dirt or impurities are present on or near the mixer or

connectors

6

DO NOT clean with aromatic hydrocarbons

The inlet pressure of the supply source must correspond with the

specifications of the mixer.

When using any gas source, always use a pressure reducer

within a pressure range of 3.2 to 3.8 bar

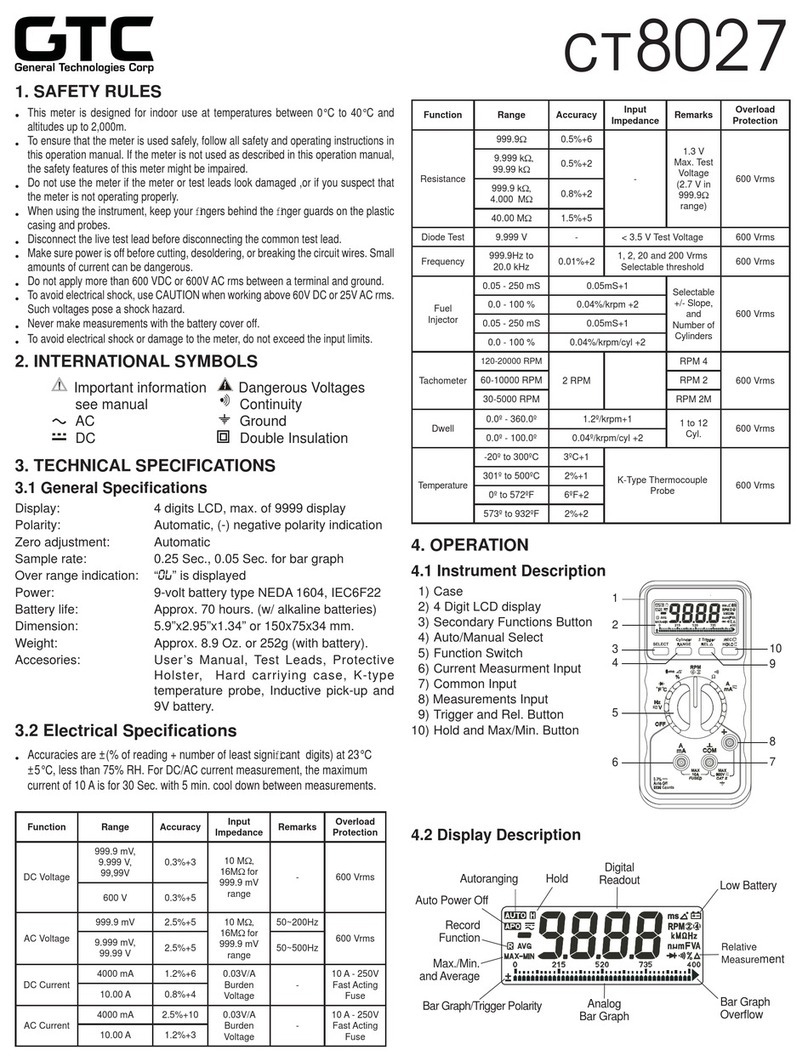

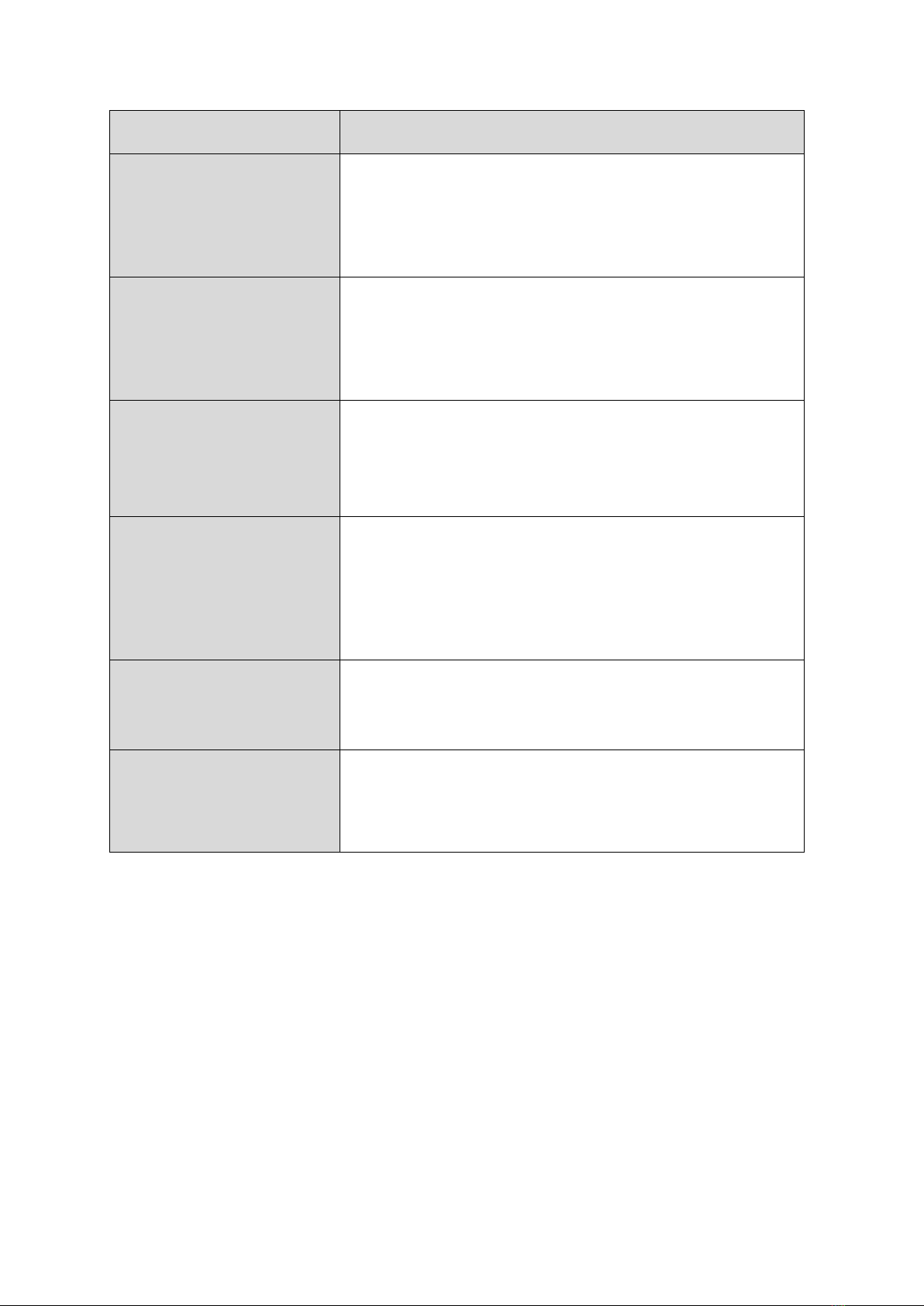

6. Technical Data

Model:

QualityMix N2O Variants:

QualityMix N2O 50 FIX

QualityMix N2O 50

QualityMix N2O 70 (Mechanical stop at

50% N2O)

Main output flow

1-120 l/min

Emergency flow (failure of

nitrous oxide or oxygen supply)

>50 l/min

FLUSH Button

100% O2 ca. 50 Litre/Minute

Alarm activation when supply

pressure drops

Alarm on - at a pressure difference between

the two gases of approx. 0.9 bar.

Alarm off - if the pressure difference between

the two gases is > 0.3 bar.

Example: Input pressure 3.8 bar.

Alarm on at 2.7-2.4 bar. Alarm off at a

maximum of 3.5 bar

Alarm volume

≥80 dB at a distance of 1 m.

Adjustment range of

N2O concentration

0 - 70 % N2O

With a mechanical barrier at 50% nitrous

oxide concentration.

Results in an N2O value equivalent to an O2

concentration of between 100% and 30%

Gas inlet pressure with

required pressure reducer

3.2 - 3.8 bar nitrous oxide and oxygen within

max. 0.7 bar pressure differential

7

Accuracy of the mixed gas

(FIO2)*

± 3 % oxygen

Connection types

1 x DISS output for mixed gas and 1 x NIST

input for nitrous oxide N2O and oxygen O2

respectively

Dimensions LxBxH

13 x 16.5 x 18.2 cm

Weight

2100 g

Operating temperature

+5°C to +50°C

The QualityMix N2O oxygen/nitrous oxide mixer has been degreased for oxygen

utilization prior to delivery. The reversed gas flow of the oxygen nitrous oxide

mixer complies with Clause 9 of ISO 11195:2018. The oxygen analyser used

must comply with ISO 80601-2-55 and CE regulations.

7. Pressure drop in the system

Low flow

≤0.14 bar with inlet pressures of 3.2-3.8 bar and a

flow rate of 10 l/min at >50% FIN2O

High flow

≤0.21 bar at inlet pressures of 3.2-3.8 bar and a

flow rate of 30 l/min at 50% FIN2O

8. Transport and storage requirements

Temperature range

-20 °C to 50 °C

Humidity

max. 95% non-condensing humidity

9. Dryness and composition of gas supplies

Nitrous oxide (N2O):

The medical nitrous oxide must meet all of the requirements for medical nitrous

oxide (N2O) according to the European Pharmacopoeia.

Oxygen (O2):

The oxygen used must meet all of the requirements for medical oxygen (O2)

according to the European Pharmacopoeia..

8

10. Illustrations and naming of components

ATTENTION

If you follow the instructions regarding processing, the labelling on the devices

will remain intact. If the labelling should nevertheless become illegible or

missing, please contact the manufacturer or your local contact person.

This illustration depicts the QualityMix N2O

Main output

DISS connection

For Flowmeter

or N2O demand

valve

NIST connector for

medical oxygen O2

Alarm

Flush O2

Button

NIST connector for

medical nitrous

oxide N2O

Rear - standard rail

bracket connection

Flowmeter

Rotary switch

concentration O2and

N2O with scaling

Supplementary

module N2O

Flowmeter

adjustment knob

(Flow)

9

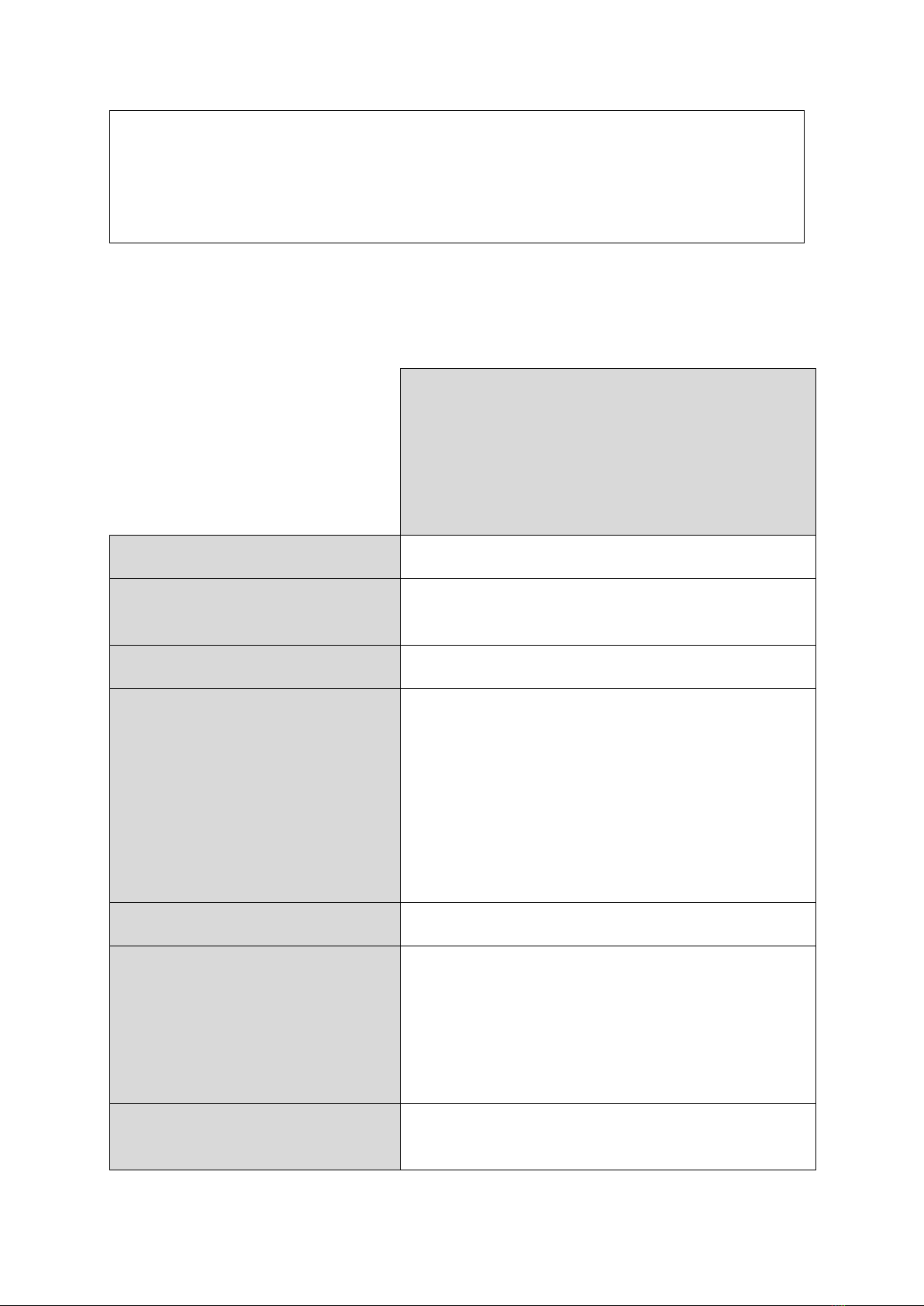

Component

Description

Rotary switch for

oxygen and nitrous

oxide concentrations

A rotary switch for setting the oxygen

concentration to between 21 % - 100 %. The FIO2

scale is for reference purposes only. This rotary

switch cannot be rotated 360°. The rotary switch

starts at 21% and extends to 100%.

Main outlet

A male threaded DISS connector with shut-off

valve that provides gas flow when connected to a

control device such as a flow meter with reservoir

bag or an N2O demand system.

Connection for medical

oxygen

A NIST oxygen connection with female thread and

one-way valve for connecting an oxygen supply

hose.

Connection for medical

nitrous oxide

A male threaded NIST connector and a one-way

valve to connect a nitrous oxide supply hose.

Alarm

An audible alarm that sounds in the event of

excessive pressure drop or failure of oxygen and/or

nitrous oxide supply.

Flush O2button

For administration of 100% O2, independent of the

concentration setting on the rotary switch of the

QualityMix N2O mixer.

10

11. Installation

Warning

Read the user manual before installing or using the unit.

Monitor the oxygen and nitrous oxide concentration with an oxygen

analyzer/monitoring device.

Attention

Check the QualityMix N2O mixer for visible damage before use and do not use

if it is damaged.

Note: Perform the following test before operating the device for the first

time

Alarm test (see section 12)

Preparation for the alarm test

1. Attach the QualityMix N2O oxygen/nitrous oxide mixer to a rail or support

rod in an upright position.

2. Connect the nitrous oxide and oxygen supply lines to the appropriate

inlet ports at the bottom of the mixer.

3. Connect a flow meter or N2O demand valve to one of the output ports.

Flow capacity of the output:

N2O mixer, all variants: 0 –120 l/min

4. Connect an exhaust line to the outlet port of the flow meter or to the

intended connection of the N2O demand valve.

12. Alarm test

1. Connect the QualityMix N2O mixer to the nitrous oxide and oxygen

sources, pressurize the mixer and turn the flow meter anti-clockwise.

2. Set the rotary switch for nitrous oxide concentration to 50% (FIN2O).

3. Disconnect or switch off the nitrous oxide supply to the QualityMix N2O

oxygen/nitrous oxide mixer. The mixer should make a loud beeping

11

sound as an alarm. This sound indicates that the alarm is working

properly.

4. Reconnect and activate the nitrous oxide supply to the mixer; the

beeping should stop.

5. Disconnect or switch off the oxygen supply to the mixer. The beeping

sound indicates that the alarm is functioning properly.

6. Reconnect and activate the oxygen supply to the mixer; the beeping

sound should stop.

7. If the alarm does not function correctly, DO NOT USE the unit.

13. Initial operation

Attention

Before use, check the QualityMix N2O oxygen/nitrous oxide mixer for visible

damage and do not use if it is damaged.

1. Attach the mixer to the rail or stand bracket.

2. Connect the nitrous oxide and oxygen supply lines to the mixer and

supply.

3. Connect the flow meter or the N2O demand system to the output of the

mixer.

4. Set the nitrous oxide concentration rotary switch to the prescribed value.

5. Check the flow of the oxygen/nitrous oxide mixture to the patient.

6. Check the oxygen/nitrous oxide concentration with an oxygen

analysis/monitoring device.

7. When the oxygen/nitrous oxide mixer is not in use, shut off the gas supply

or disconnect the appliance from the gas supply.

12

14. Cleaning and disinfection

Attention

NOT suitable for sterilization.

NEVER immerse the QualityMix N2O oxygen nitrous oxide mixer in any

liquid

DO NOT use strong solvents or abrasives

DO NOT clean with aromatic hydrocarbons

The outside of the device must be disinfected at regular intervals or at

least after each patient in accordance with the applicable hygiene

standard.

1. Disconnect all gas connections and equipment before cleaning.

2. Wipe the outside with a cloth moistened with non-oxidizing disinfectant

and water.

3. Wipe dry with a dry cloth.

The manufacturer recommends the use of Dismozon plus® disinfectant,

manufactured by Bode Chemie GmbH & Co.

15. Maintenance

The following maintenance and inspection tasks must be carried out:

•Monthly check of the alarm by the user

•A safety inspection (SI) must be carried out every year by a trained

operator or medical technician.

•Maintenance should be carried out at least every 2 years by trained

specialist personnel. Inspection of the reversed gas flow is part of the

maintenance and is therefore carried out every 2 years.

13

Reverse gas flow test

1. Set the nitrous oxide concentration of the mixer to 50%.

2. Connect the nitrous oxide supply hose to the mixer and the gas supply and

open the supply.

Measure the flow rate at the oxygen inlet using a suitable measuring

instrument.

The flow rate should not exceed 10 ml/h.

If the flow rate is greater than 10 ml/h, the duckbill valve in the oxygen

inlet must be replaced in accordance with the service instructions and the

measurement repeated.

3. Connect the oxygen supply hose to the mixer and the gas supply, and

open the supply.

Measure the flow rate at the nitrous oxide inlet using a suitable measuring

instrument.

The flow rate should not exceed 10 ml/h.

If the flow rate is greater than 10 ml/h, the duckbill valve in the nitrous

oxide inlet must be replaced in accordance with the service instructions

and the measurement repeated.

16. Return of Goods

Please contact your distributor regarding this matter. They will coordinate the

return for you. It is important that you provide a description of the problem so

that the return can be processed in a targeted manner. All returns must be sent

in sealed containers to avoid damage. The distributor is not responsible for

equipment that is damaged during transport.

17. Disposal

This device and its packaging do not contain any hazardous substances. No

special precautions are required when disposing of the device and/or its

packaging.

Please recycle

14

18. Troubleshooting

If the oxygen/nitrous oxide mixer fails, refer to the troubleshooting section

below. If this does not solve the problem, please contact your local distributor.

Problem

Possible cause

Remedy

Discrepancy between

the setting of the

oxygen concentration

on the mixer and on

the

analysis/monitoring

device (more than 3

%)

1. Pre-pressure too

unequal/too low

Pre-pressure

inspection: optimum

pre-pressure 3.9 to 6.5

Bar

2. Analysis/monitoring

device does not

accurately register

Recalibrate the

monitoring device or

use a different

analysis/calibration

monitoring device

3. Gas supply

contaminated

Check gas supply with

calibrated oxygen

analyser/monitoring

device to ensure

oxygen content is

100% and nitrous

oxide content is 0%

4. The Flow of

downward mounted

device causes

backflow or

restricted flow

Disconnect the mixer.

Check the oxygen

concentration at the

mixer outlet

No flow at the mixer

output

1. Gas supply turned

off

Turn on gas supply

2. Gas supply not

connected

Connect gas supply

Problem

Possible cause

Remedy

Alarm sounds

Difference between

oxygen and nitrous

oxide inlet pressures

higher than prescribed

Correct pressure

difference until oxygen

and nitrous oxide

pressures meet

specifications

15

19. Warranty conditions

The distributor guarantees that the mixer is free from defects in workmanship

and/or materials for the following period of time:

One (1) year after delivery

The distributor will, with written notice and with evidence that the device has

been stored, installed, serviced and operated in accordance with instructions and

standard industry practices and that no modifications, substitutions or

modifications have been made to the product, will correct such defect by

appropriate repair or replacement at the distributor’s expense.

VERBAL STATEMENTS DO NOT CONSTITUTE A GUARANTEE.

The distributor is not authorized to provide oral guarantees about the product

described in this agreement, and such statements are not binding and are not

part of the purchase agreement. Therefore, this second statement is the final,

complete and exclusive representation of the terms of this agreement.

The current version of the General Terms and Conditions of the distributor and

German law shall apply.

16

0482

Declaration of Compliance

DEHAS Medizintechnik GmbH

Wesloer Straße 112, Gebäude M

23568 Lübeck

GERMANY

QualityMix N2O 50 FIX

QualityMix N2O 50

QualityMix N2O 70

And the relevant accessories

Classification:

IIb

Classification Criteria:

Clause 3.2 Rule 11 of Annex IX of the MDD

We hereby declare under our sole responsibility that the products mentioned above comply

with the provisions of the following directives and standards of the EC Council. All

documents are retained on the premises of the manufacturer and the notified body.

Guidelines:

General application guidelines: Medical Device Directive (MDD),

Council Directive 93/42/EEC of 14 June 1993 Annex II.3 on medical

devices of the European Parliament.

Applied standards:

DIN EN 1041

EN ISO 14971

DIN EN ISO 15001

DIN EN ISO 15002

DIN EN ISO 15223-1

DIN EN 62366-1

ISO 11195

ISO 18562-1

ISO 18562-2

ISO 18562-3

ISO 10993-1

Notified Body:

Medcert GmbH / 0482

Address:

Pilatuspool 2, 20355 Hamburg; GERMANY

Certificate number:

4153FR410180612 Expiry date: 11/2021

Already manufactured devices:

Valid from/to:

Traceability via serial number

06/ 2018 to expiry date

Manufacturer representative:

Jens Mittendorf

Position:

CEO /Head of Development

Date of issue:

27 November 2019

Your contact person for sales and service:

This manual suits for next models

3

Table of contents

Other DEHAS Measuring Instrument manuals