DEHAS D-B-FL-3 User manual

1

Contents

1. Foreword:...................................................................................................................................... 2

2. Intended usage:............................................................................................................................. 2

3. Safety information –Warnings, precautions and identification information:.............................. 3

4. Before intial usage: ....................................................................................................................... 4

5. Technical Data:.............................................................................................................................. 6

6. Functional Description: ................................................................................................................. 7

7. General Technical Description: ..................................................................................................... 8

8. Operation Instructions: ................................................................................................................. 9

9. Cleaning and Disinfection: .......................................................................................................... 10

10. Maintenance: .............................................................................................................................. 11

11. Troubleshooting:......................................................................................................................... 12

12. Parts and Spares:......................................................................................................................... 13

13. Customer service / warranty:...................................................................................................... 14

a. Warranty conditions ................................................................................................................... 14

b. Product returns ........................................................................................................................... 14

c. Disposal ....................................................................................................................................... 14

10. Manufacturer Information: ............................................................................................................. 15

Rev. 1.1 Version 08.05.2020

2

1. Foreword:

These operating instructions are intended to help the user to handling the device. Please

keep this information in a safe place!

2. Intended usage:

The flowmeter is intended for use for the precise control of the flow of oxygen or air for

medical purpose in low –pressure range connection (depending on the model).

This product is designed for use in homecare applications, in hospitals, other managed clinical

environments and by the emergency services.

3

3. Safety information –Warnings, precautions and identification

information:

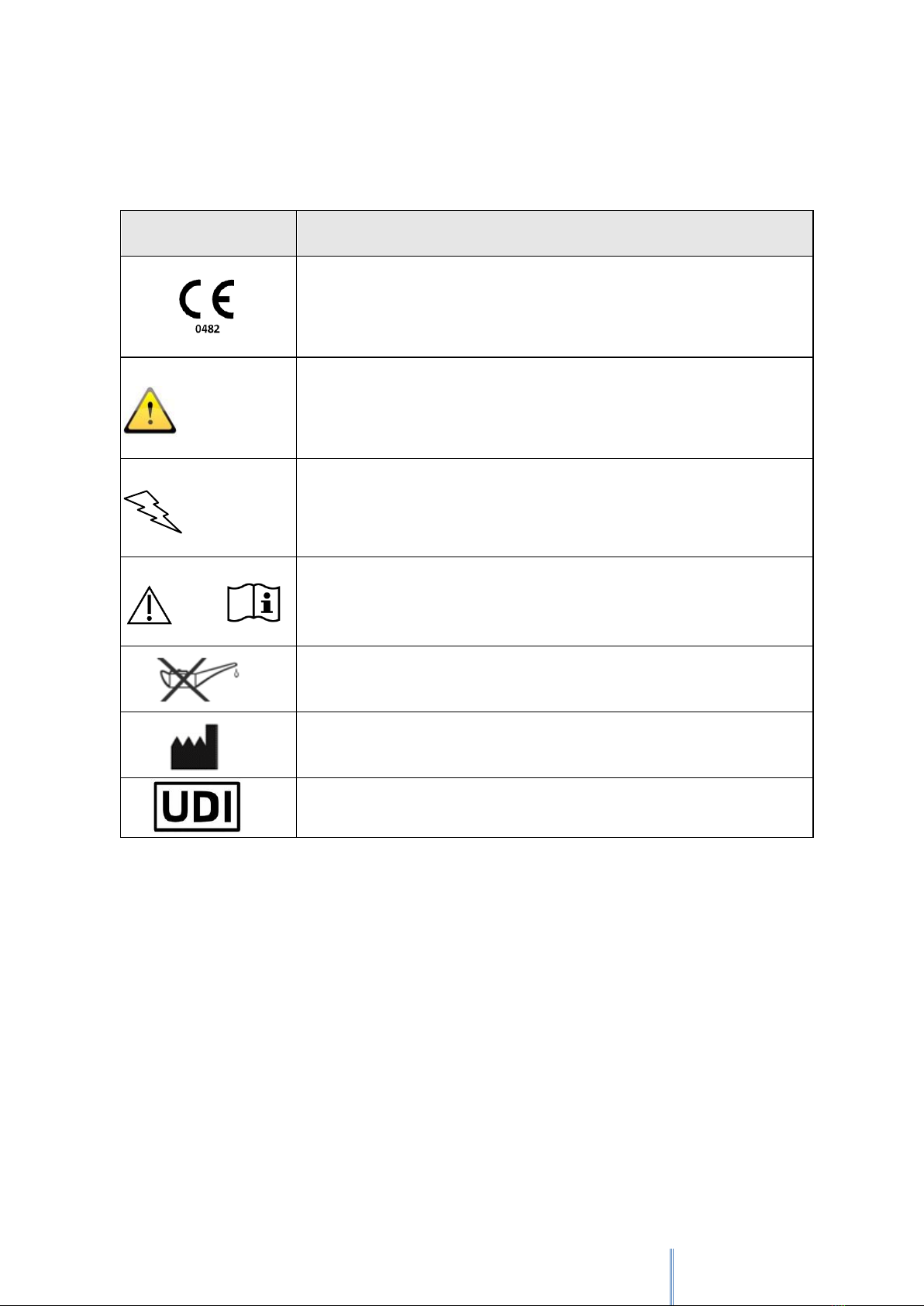

Symbol

Description

This symbol indicates that the device complies with the regulation

93/42/EEC concerning medical devices and all applicable

international standards.

WARNING

Indicates a potentially dangerous situation that, if not prevented,

could result in death or serious injury.

CAUTION

CAUTION is used to indicate a potentially hazardous situation

which, if not prevented, may result in property damage.

or

Refers the user to the necessity of consulting the operating

instructions.

DO NOT USE OIL

Identifies the manufacturer of the medical device according to the

EU directives 90/385 / EEC, 93/42 / EEC and 98/79 / EC

Unique Device Identification

4

4. Before intial usage:

Read all instructions before use!

These operating instructions are intended to show trained professionals how to install and

operate the device. It serves your safety and protects your device from damage. If you do

not understand information or instructions in this document, do not use the device and

contact your supplier.

WARNING

This product is not intended for use as a life-sustaining or life-supporting device.

WARNING

Read through this entire instruction manual before using or showing others how to use

this flowmeter. As with all medical equipment, attempting to use this device without a

thorough understanding of its operation may result in patient or user injury.

Medical gases are, or should be considered a drug and should only be used for

medical purposes as prescribed by a physician or authorized clinician and in

accordance with their instructions.

The flowmeter may only be operated by medical specialists under the direct

supervision of an approved doctor.

The flowmeter is not MRI compatible.

The flowmeter may only be used for the purpose described in these instructions

for use.

The flowmeter may only be serviced by a qualified service technician.

Ensure that the medical gas supply is sufficient for the proposed therapy and is

supplied within the pressure range given in the Device Specification. If the supply

is a gas cylinder, check the cylinder contents gauge regularly.

This flowmeter is only for use with the medical gas indicated on the device label.

Before use, check that the gas cylinder or supply line contains the correct medical

gas. Always check that the flowmeter is connected to the correct gas-specific

terminal unit.

Gas specific connectors are fitted to the flowmeter. Do not attempt to modify the

fittings to suit other gases or fitting systems.

Always observe the EN and DIN standards for medical gas products, flowmeters

and handling of oxygen.

Do not disassemble the flowmeter whilst under pressure.

Secure cylinders to a wall, stand or cart in accordance with local safety regulations.

5

Do not stand in front of a flowmeter or regulator outlet when opening a cylinder

valve.

Do not allow any fluid to enter this device.

The accuracy of the flowmeter can be affected significantly if the input pressure is

other than stated in the technical specification and the device label.

Do not directly connect the flowmeter output to another pressurised gas source as

this may lead to corruption of one or other of the gas supplies (e.g. connecting an

oxygen flowmeter to an air flowmeter via a Y-piece in an attempt to blend their

outputs).

Only use this flowmeter with the flow tube in a vertical position. Failure to do so

may result in incorrect flow rates being displayed.

Make sure that the flow control valve is not clogged or obstructed and that there

is no unwanted pressure. In such cases, there may be temporary changes in the gas

flow.

Arrange the oxygen tubing and gas hose carefully to avoid damage to the hose and

the potential for causing a trip hazard. Never pull or apply excessive force to the

gas hose. A leaking hose may result in high local oxygen and nitrous oxide

concentrations and an increased risk of fire.

Oxygen is not flammable; however the presence of it will drastically increase the rate and

severity of combustion. Oil and/or grease in the presence of an oxygen enriched

atmosphere will become highly combustible. Oxygen must never be allowed to come into

contact with oil, grease or other petroleum-based substances.

Do not use oil or grease on this flowmeter

Do not smoke around oxygen equipment

NOT suitable for sterilization / autoclaving

DO NOT use if there is contamination

DO NOT clean with aromatic hydrocarbons

Caution:

The flowmeter performance may be affected if it is stored or transported at temperatures

outside the range of -20 ° C to +50 ° C.

The performance of the flowmeter may be affected if the flow control valve is over-

tightened when the flow is turned off. Apply the minimum force required to turn off the

gas flow.

6

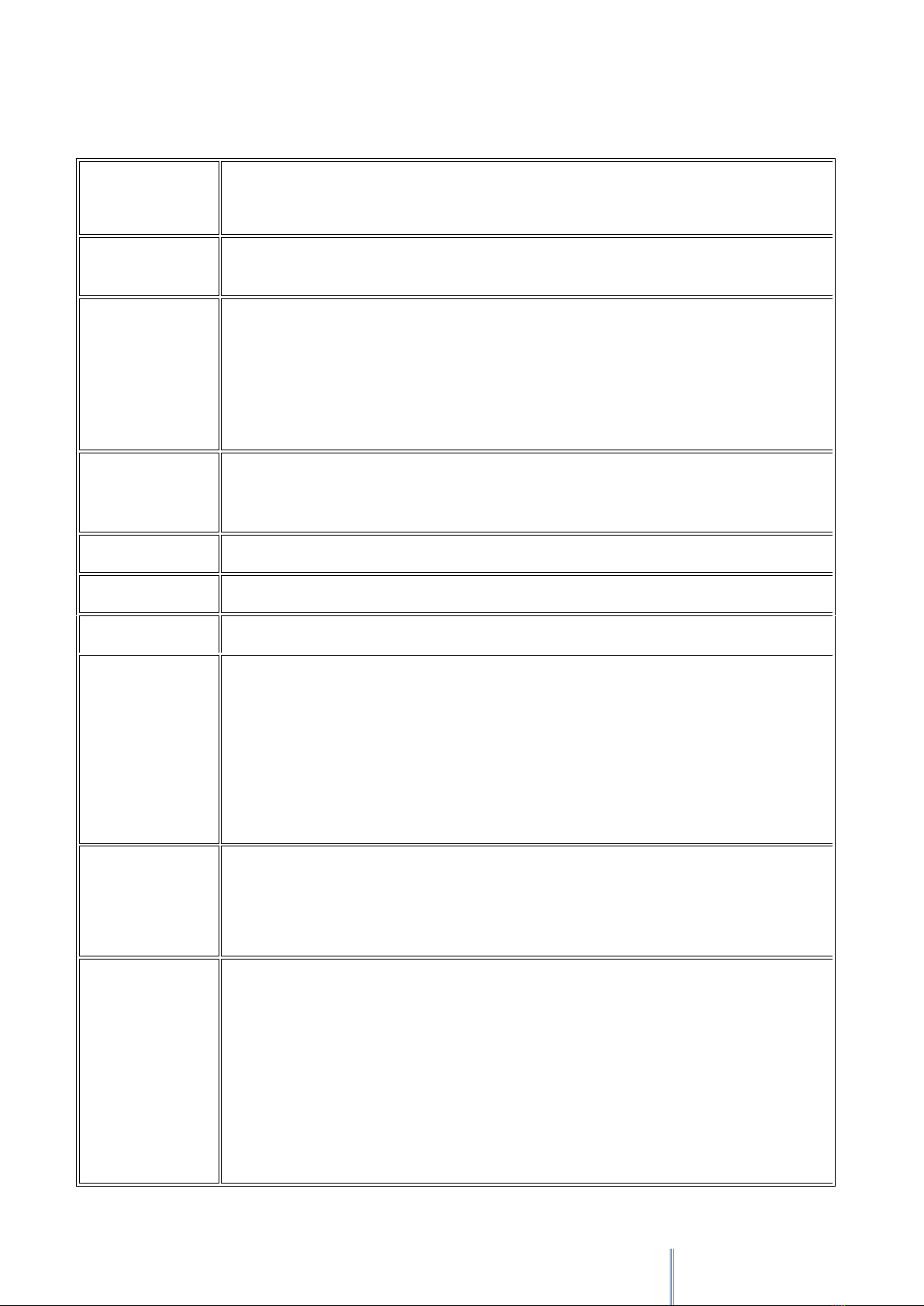

5. Technical Data:

Model:

Pressure compensated flowmeter for medical gases.

Display according to the float principle.

Material:

Body: Stainless steel, aluminum

Flow tube: Polycarbonat (PC)

Accuracy:

Nominal Pressure: ±10% or 0,5l/min (the higher level counts) of indicated reading.

Temperature: 3% increase or decrease in flow rate for every 5 °C increase or decrease

in temperature

Inlet pressure: 4% increase or decrease per 10 kPa increase or decrease in pressure

compared to the nominal pressure

Inlet Pressure

Range/ Suppy

Pressure Range:

450 kPa ± 50 kPa

Gas Compatibility:

Medical Oxygen and/ or Medical Air (Depending on the model)

Inlet:

G1/4”, DIN, NF, AGA, BS, Uni probe, NIST

Outlet:

9/16“-18 UNF, Hose nippel, external thread G1/4”, G 3/8 “, 9/16 “ UNF

Performance /

Flow scale:

Depending on the model:

0 –3 l/min

0 –6 l/min

0 –15 l/min

0 –32 l/min

0 –85 l/min

Environmental

conditions:

Transport and Storage Temperature: -20°C to +50°C

Operating Temperature: 0 °C to +50 °C

Humidity: 0-95% RH non-condensing

Standards:

ISO 15002 Flow-metering devices for connection to terminal units of medical gas

pipeline systems

ISO 15001 Anaesthetic and respiratory equipment. Compatibility with oxygen

ISO 5359 Low pressure hose assemblies for use with medical gases

EN ISO 14971 Medical devices. Application of risk management to medical devices

EN ISO 15223-1 Medical devices. Symbols to be used with medical device labels,

labelling and information to be supplied. General requirements

7

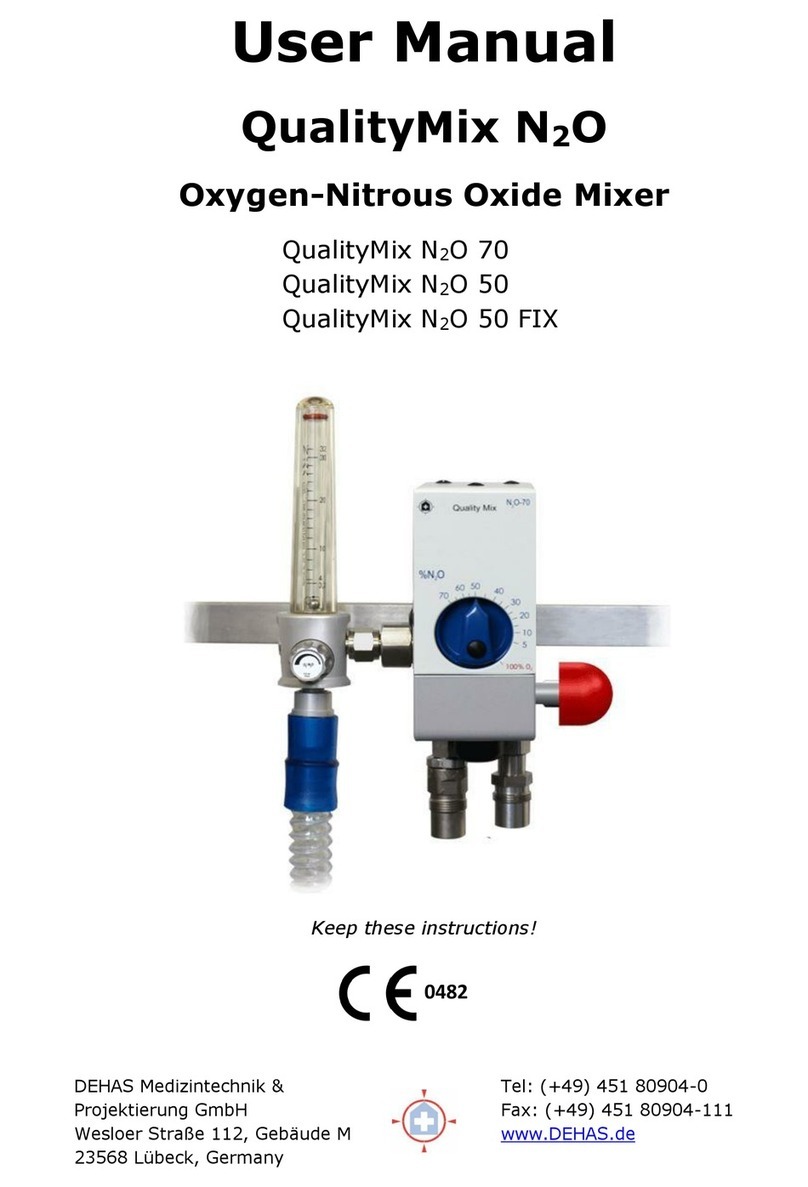

6. Functional Description:

Scale (depending on the

model)

Precision

Rotating Ball

Flow Tube

Gas Specific

Connector

Flow Control

Valve

Gas Specific Connector

(Blind plug, if not in use)

Outlet

8

7. General Technical Description:

The flowmeter provides accurate control of the flow of oxygen or air for medical purposes in

the range of 0 to 85 l / min (depending on the model). A precision-made rotating ball rises

inside a transparent measuring tube. A scale is printed on the measuring tube, on which the

speed of the gas flow is displayed in liters per minute (l / min). The gas flow through the

measuring tube is regulated by a valve arranged downstream of it.

The flowmeter has been designed for connection for example to an Oxygen –Air Blender.

However, it can also be operated as a "stand alone" device for directly connection to the

medical gas supplies.

Gas Specific Connector

The gas-specific quick connection probe has characteristics to prevent connections between

different gas services.

Connection to the patient

Connect the other end of the oxygen hose system to the patient or the surrounding area with

the appropriate connector.

Setting the gas flow

The flow control valve is turned counterclockwise to turn on and increase the gas flow. If the

flowmeter is not working properly, it should not be used. For troubleshooting instructions, see

section 11 of this brochure.

During use

During therapy or treatment, continuously monitor the gas flow and filling level of the gas

bottle (if applicable) and make sure that the supply and supply hose (if applicable) cannot pose

a risk of tripping.

After use

If the supply is from a gas cylinder, close the cylinder valve and disconnect the flowmeter when

therapy is no longer required.

9

8. Operation Instructions:

WARNING

Safety instructions for avoiding accidents while using an oxygen sampling device:

It is the responsibility of the user to avoid the enrichment of the room or ambient air

with a volume fraction> 21% O2.

Connection to the gas supply

Before use, visually check both the flowmeter and hose (if fitted) for any damage or

contamination. Do not connect or use the device if there are any doubts about its condition.

The flowmeter is supplied with a gas specific connector that is designed to connect to a mating

gas specific outlet. Gas specific outlets might be a terminal unit in a medical gas pipeline

system or part of a pressure regulator outlet on a gas cylinder.

If you are using a cylinder supply, ensure that the cylinder contents are adequate for the

planned therapy and turn on the supply at the cylinder.

Connect the gas specific quick connection to the appropriate gas specific outlet.

Align device to the final vertical position and fully hand tighten the connection before turning

on the supply pressure.

For quick connector probes (e.g. BS 5682, DIN, AFNOR), ensure that the connection is correctly

made by gently pulling the flowmeter body or hose (as applicable) before turning on the

supply pressure.

Setting the gas flow

The flow control valve is turned counterclockwise to turn on and increase the gas flow. If the

flowmeter is not working properly, it should not be used. For troubleshooting instructions, see

section 11 of this brochure.

Reading the Flowmeter

The correct reading level of the set flow is on the marking on the scale for the floating ball (top

of the floating ball).

Connection to the Patient

Connect the other end of the oxygen hose system to the patient or the surrounding area with

the appropriate connector (not supplied).

10

During Use

Continue to monitor the level of gas flow and the contents level of the cylinder (if applicable)

during the procedure or therapy and be aware that the supply tubing and hose (if applicable)

may be a trip hazard.

After Use

If the supply is from a gas cylinder, close the cylinder valve and disconnect the flowmeter when

therapy is no longer required.

9. Cleaning and Disinfection:

Ensure the flowmeter is disconnected from the gas supply before attempting to clean it.

ATTENTION

NOT suitable for sterilization / autoclaving

DO NOT disassemble the flowmeter

NEVER immerse the device in liquids.

DO NOT use strong solvents or abrasives.

DO NOT clean with aromatic hydrocarbons.

The outside of the device must be disinfected at regular intervals or at the latest after each

patient in accordance with the applicable hygiene standards.

If you suspect that the flowmeter is contaminated, take it out of operation and refer the

device to the appropriate department.

Never immerse the flowmeter in any fluid or attempt to clean internal parts.

Cleaning and disinfection steps:

1. Disconnect all gas connections and devices before cleaning.

2. Wipe the outside of the flowmeter and the gas supply hose with a cloth soaked in

alcohol or disinfectant.

3. Wipe the device with a dry cloth.

The manufacturer recommends the use of the disinfectant Dismozon plus®, Bode Chemie

GmbH & Co.

11

10. Maintenance:

Interim Inspection

The flowmeter should be regularly cleaned, inspected for damage and checked for

performance. The frequency of inspection and performance checks depends upon usage. As

a guideline, if the flowmeter is used daily this may need to be performed every six months; if

used infrequently an annual check may be sufficient.

Leak Test

Cponnect the flowmeter to a low pressure medical gas supply with a nominal supply pressure

as specified on the label of the device and close the flow control valve. Connect the supply

hose to the flowmeter outlet and immerse the other end of the hose in water. The presence

of gas bubbles in the water indicates a leak. A flowmeter that fails these tests should no longer

be used.

Flow Test

Verify the flow rates for all flow settings against specification i.e. within ±10% or 0,5 l/min (the

higher value counts) at 1 l/min and above.

Service and Repair

The implementation of the maintenance measures and inspections depends on the type of

use, the conditions of use and the intensity of use. The intervals are to be determined by the

user. However, the flowmeter should be cleaned regularly, checked for signs of damage and

its performance checked. In addition, all silicone seals used in the device must be checked

regularly for perfect condition and correct function and replaced if necessary. A period of 2

years is recommended.

Flowmeters with an indirect connection should have the hose assembly replaced according to

the date specified by the manufacturer. The date of manufacture can be found on the device

label of the hose.

12

11.Troubleshooting:

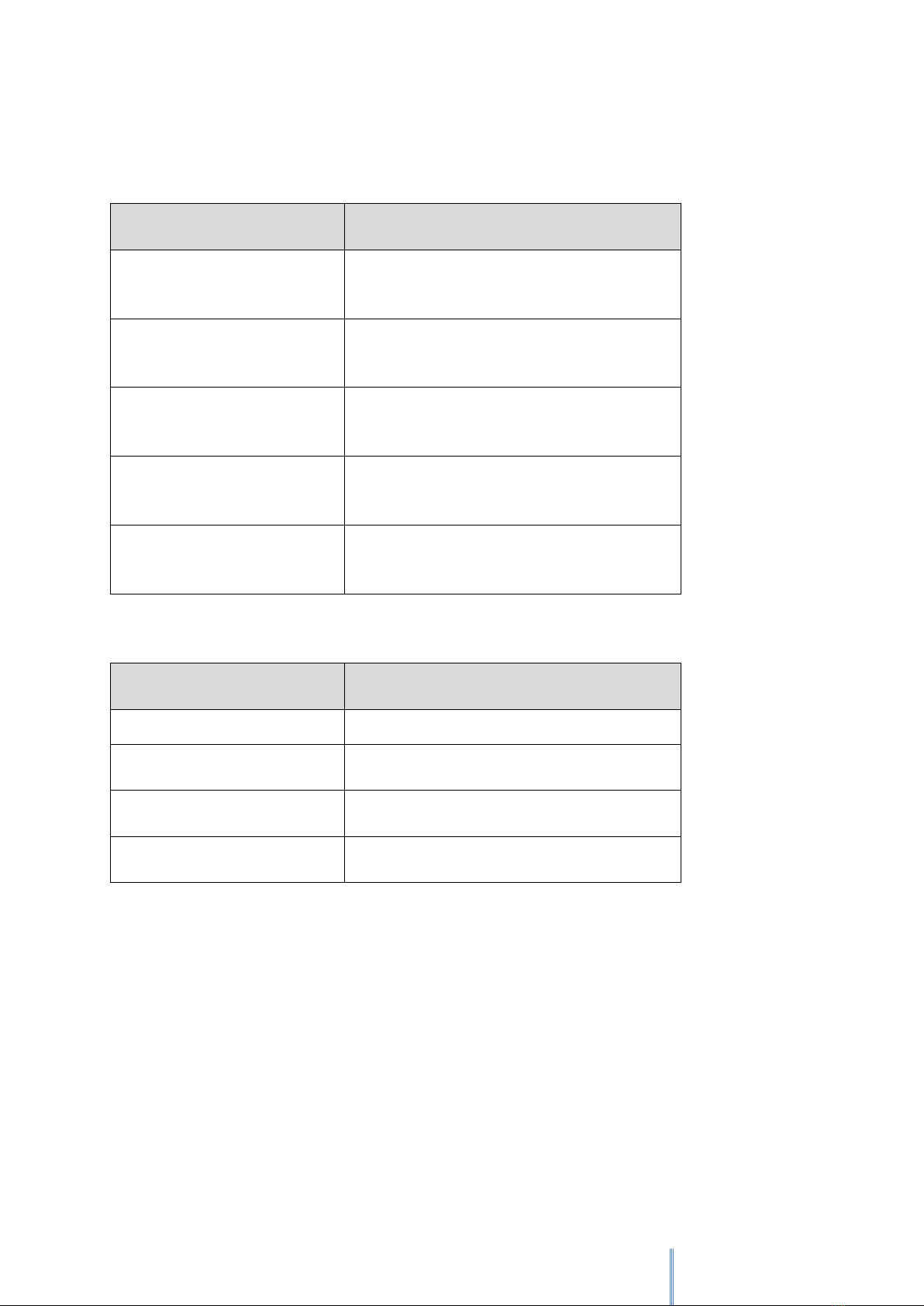

Failure

Possible Cause

Solution of the Problem

No gas flow

Flowmeter is not

connected properly

Check gas supply; check that the gas-specific probe is

correctly connected

Gas cylinder empty

Replace gas cylinder

Medical gas terminal unit

of a pipeline system is not

connected / active

Seek advice from someone authorised to operate the

isolation valves of the medical gas pipeline system

Inlet filter is blocked

Repair required

Audible gas

leak

Seal is worn or damaged

Repair required

Pressure relief valve leaks

because the inlet pressure

is too high

Check whether the gas supply pressure is within

specification of the device.

Top tube is cracked or

damaged

Repair required

Connection is worn or

damaged

Repair required; Exchange necessary

Medical gas hose damaged

Replacement required

Constant gas

flow

Valve or valve seat

damaged

Repair required

13

12. Articles and Spare parts:

Articles:

Part numbers

Description / Version / Performance

D-B-FL-3

Quality Flowmeter

0 –3 l/min

D-B-FL-6

Quality Flowmeter

0 –6 l/min

D-B-FL-15

Quality Flowmeter

0 –15 l/min

D-B-FL32

Quality Flowmeter

0 –32 l/min

D-B-FL-85

Quality Flowmeter

0 –85 l/min

Spare parts:

Part numbers

Description

D - EM019681

Plug Base Body

D - EM016583

Adapter 9/16“

D - EM017999

O –Ring for base body

D –0232900

Top Tube

14

13. Customer service / Warranty:

a. Warranty conditions

The supplier guarantees that the mixer will be free of material defects or workmanship errors

for the following period:

One (1) year from delivery

If, within the applicable period, a device defect should occur, then the dealer shall –after

written notification thereof and substantiation that the device has been stored, installed,

maintained and operated in accordance with the instructions of the dealer and in accordance

with standard industry practice, and that no modifications, substitutions or changes were

made to the product –correct such a defect by suitable repair or replacement at its own

expense.

ORAL STATEMENTS DO NOT CONSTITUTE A WARRANTY.

The retailer is not authorized to make oral warranties about the merchandise described in this

contract. Any such statements are not binding and not part of the sales contract. Thus, this

written second statement is a final, complete and exclusive statement of the contractual

terms.

The current version of the retailer's Terms and Conditions and German law are valid.

b. Product returns

Please contact your retailer concerning this. They will help to coordinate the return. It is

important that you provide a description of the error or malfunction so that the return can be

processed effectively. All returns must be shipped in sealed containers to prevent damage.

The specialist retailer is not responsible for any devices that are damaged during transport.

c. Disposal

This device and its packaging contain no hazardous materials. No special precautions are

required when disposing of the device and its packaging.

Please disinfect and recycle!

15

10. Manufacturer Information:

Manufacturer:

DEHAS Medizintechnik & Projektierungs GmbH

Wesloer Straße 112

23568 Lübeck

Germany

Phone: +49 451 80 90 4 - 112

Fax: +49 451 80 90 4 - 111

Email: [email protected]

Homepage: www.dehas.de

Distribution

DEHAS Medizintechnik & Projektierungs GmbH

Wesloer Straße 112

23568 Lübeck

Germany

Phone: +49 451 80 90 4 - 112

Fax: +49 451 80 90 4 - 111

Email: [email protected]

Homepage: www.dehas.de

Rev. 1.1 Version 08.05.2020

This manual suits for next models

4

Table of contents

Other DEHAS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Conrad Electronic

Conrad Electronic 100515 operating instructions

Alpes Lasers

Alpes Lasers Cascade Laser Starter Kit instruction manual

AFRISO

AFRISO Unitel operating instructions

Cincinnati

Cincinnati CL-900 Series Operation, safety and maintenance manual

C-LOGIC

C-LOGIC 8730 instruction manual

Kessel

Kessel SonicControl Installation, operation and maintenance instructions