Elsys TraNET FE User manual

2021 Elsys AG www.elsys-instruments.com 1

Elsys AG

Elsys AG

Mellingerstrasse 12

CH-5443 Niederrohrdorf

Switzerland

Phone: +41 56 496 01 55

Email: [email protected]

www.elsys-instruments.com

TraNET®FE

User Guide MK3

Elsys AGwww.elsys-instruments.com2

Content

1. Safety Information 4

2. Introduction 5

2.1 Variants of TraNET Models 5

2.2 Requirements of the Client Computer 6

2.3 Basic Mode of Operation of the TraNET device 7

2.4 Network Drive 9

3. TraNET Client PC Connection Guide 10

3.1 IP Address Configuration 10

4. Device Configuration 12

4.1 Time and Synchronization Settings 13

4.2 Measurement Settings 15

5. Hardware Specification 18

5.1 Signal Inputs, Pin Assignments 18

5.2 USB Interface 20

5.3 TPCE Block Diagram 21

5.4 Standard Filter 22

5.5 Trigger Logic 22

5.6 Anti-Aliasing Filter Module 23

5.7 Power 25

5.8 Operating Condition 25

5.9 Dimensions 25

6. Data Acquisition Card Specification 26

6.1 TPCE DAQ Card 26

6.2 TPCE-LE DAQ Card 28

6.3 TPCE-DP DAQ Card 30

7. Software API 31

7.1 LabVIEW 32

TraNET FE User Guide

Elsys AG www.elsys-instruments.com 3

TraNET FE User Guide

Warning

Lethal voltages exist inside the TraNET instrument. Only qualified technicians

of supplier staff are authorized to open the TraNET case. Otherwise warranty

will be lost!

Always ensure that power cord is removed before opening

the case.

Thank you!

Thank you for purchasing Elsys High Precision Data Acquisition Equipment. For more informa-

tion, please visit www.elsys-instruments.com

Notice

The information in this document is subject to change without notice.

ELSYS AG SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS OR OMISSIONS CON-

TAINED HEREIN; NOR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE

FURNISHING, PERFORMANCE, OR USE OF THIS MATERIAL

Elsys AGwww.elsys-instruments.com4

TraNET FE User Guide

1. Safety Information

This instrument is intended for indoor use and should be operated in a clean, dry environ-

ment.

Make sure this product‘s operating environment is kept within the parameters as specified in

the chapter Operating Condition!

The design of the instrument has been verified to conform to the EN 61010-1 safety standard

per the following limits:

• Installation (Overvoltage)

• Category II (Main Supply Connector) and Category I (Measuring Terminals)

• Pollution Degree 2

• Protection Class I

Elsys AG www.elsys-instruments.com 5

TraNET FE User Guide

2. Introduction

2.1 Variants of TraNET Models

Elsys provides several different TraNET device models.

Note: This manual refers to TraNET FE only!

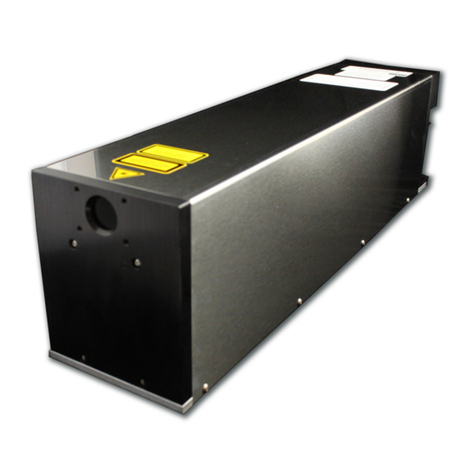

2.1.1 TraNET FE

TraNET FE (Frontend Unit): Depending of the number and type of channels, there exist a couple

of different models. These devices works as a LAN server. It always requires an Ethernet Link to

a client computer (e.g. a Notebook PC) for operation.

TraNET FE 204 TraNET FE 404

TraNET FE 204 with

Dust-Proof option

TraNET FE 408 DP

TraNET FE Rack

Elsys AGwww.elsys-instruments.com6

TraNET FE User Guide

2.2 Requirements of the Client Computer

For using the data acquisition software TranAX, the following minimal client computer config-

uration should be advised:

• PC (Notebook, Desktop PC, IPC etc.)

• Intel i5 or better (at least 2.0 GHz recommended)

• Full HD Graphic display 1920x1080 pixels or higher

• 4 GB RAM minimum, recommended 8 GB

• Hard disk with sufficient free space for programs and possible storage of measuring data (at

least 100 GB recommended)

• GBIT Ethernet port

• Windows 10 Professional, 64 Bit

2.1.2 TraNET EPC

TraNET EPC: IPC based instrument. Individual configu-

rations up to 32 channels per device can be realized.

The device works under Windows operating system.

If only local operation is used, Ethernet link is not re-

quired (data acquisition operating software TranAX

runs on the instrument itself).

2.1.3 TraNET PPC

TraNET PPC: Portable PC with installed monitor and

keyboard. Individual configurations up to 24 channels

per device can be realized. The device works under

Windows operating system. If only local operation is

used, Ethernet link is not required (data acquisition

operating software TranAX runs on the instrument it-

self).

For TraNET EPC and TraNET PPC consult the corresponding PC manuals and the manual of the

TPCE modules.

Elsys AG www.elsys-instruments.com 7

TraNET FE User Guide

2.3 Basic Mode of Operation

TraNET FE devices are based on an embedded microcomputer with a hard disk, a Gigabit Eth-

ernet controller and a PCIe bus interface to control the installed TPCE-Modules. The firmware

runs under a Linux operating system.

TraNET FE operates via Ethernet Link as a TCPI/IP Server. A simple point to point connection to a

client PC (e.g. Notebook PC) allows an easy installation. Otherwise it can be connected to any

existing LAN and allows remote operation. For establish a WIFI connection, an additional WIFI

router must be used.

There are four different operation modes in which the data acquisition instrument can be used.

Any of these operation modes are ready to use in all driver interfaces or in the Application soft-

ware.

2.3.1 Scope

In Scope mode the device runs like an Oscilloscope. Incoming data from the ADC are written

into the on-board memory until a trigger condition occurs. After the trigger condition, the

measurement continuous until the post-trigger time is over and stops. The length of the mea-

surement is limited by the maximum memory available on the board.

2.3.2 Multi-Block

Multi-Block Mode works like the Scope mode but with the addition that the available on-board

memory is splitted up in several blocks. On each trigger, a new part of the memory is used. This

way, the on-board memory can be used more effective than in the Scope mode. The maximum

number of blocks is limited by the block size and the available memory.

2.3.3 Continuous

In the Continuous mode incoming data from the ADC‘s are buffered on the on-board memory

an then transfered immediately to the built-in hard disk of the device. The maximum recording

length is only limited by the hard disk size. The amount of data produced per second depend on

the used sampling rate and the number of activated channels. If the data rate is higher than the

PCIe interface or the hard-disk write throughput, some data from the on-board buffer get lost.

Elsys AGwww.elsys-instruments.com8

TraNET FE User Guide

2.3.4 ECR (Event Controlled Recording)

This mode is optional!

The ECR mode allows targeted acquisition of cyclic or sporadically arising events. This implies

that the registration of measuring data only occurs if certain signal conditions (trigger, time

window, repetitions, etc.) are fulfilled. Thus many unwanted and unneeded signal data will not

be stored.

• The digitalized signal will be stored to the

on-board memory which acts as a ring

buffer.

• As soon as the trigger is released, a block

of samples will be read from the ring buf-

fer and will be saved to the hard disk.

• If a new trigger event within the actual

block occurs, a new overlapping block will

be saved.

• If the ring buffer is full, the oldest mea-

surement data will be overwritten with

new incoming data. Usually, the over-

written data would be transferred to the

hard disk before this happens. If too many

events occur in a period of time, the ring

buffer may overflow.

2.4.2 ECR Dual Mode

An other feature of ECR is the “Dual Mode”. It allows to store a continuous measurement at a

slower sampling rate than the captured blocks. For example fast transient can be captured at 10

MS/s by the triggered blocks while storing slower signals at 100 kHz over a long period of time.

Elsys AG www.elsys-instruments.com 9

TraNET FE User Guide

2.4 Network Drive

The data from the internal SSD or external USB drive can be accessed over a shared network

drive. Just type “\\IPAddress” (ex. \\192.168.0.33) in your address field of the Windows File

Explorer and you will see the shared folder “Measurement Data”. Files generated during the

measurement are named with the extention .tmp and can’t be removed. They will be renamed

after terminating the measurement.

2.4.1 SMB 1.0 Access

TraNET devices of the generation 2 are using the samba file sharing protocol SMB 1.0. This ver-

sion is not longer supported by Windows 10 by default. For accessing Gen. 2 devices, the SMB

1.0/CIFS client support must be activated manually in the Windows Feature Settings:

Elsys AGwww.elsys-instruments.com10

TraNET FE User Guide

3. TraNET Client PC Connection Guide

The TraNET device communicates over an Ethernet connection with the client PC. This section

describes all important points for setting up the connection successfully.

3.1 IP Address Configuration

The factory default adress configuration of a TraNET FE is

Static IP 192.168.0.33

In order to setup up a connection to the TraNET FE device, the client computer must be config-

ured to a static IP address in the same IP range, for example 192.168.0.34.

Once a successful connection is established, the IP configuration can be changed on the device

web page by typing the IP address of your device in your web browser.

3.1.1 DHCP

For using a connected DHCP server, activate “DHCP” on the LAN Configuration page and press

on “Save”. The device will reboot and tries to get a valid IP address from the DHCP server.

If the device does not obtain a valid IP address from a DHCP server, the device will assign an

Auto IP address in the address range from 169.254.0.0 to 169.254.255.255. If device is con-

nected to a Windows client through a 1:1 connection, Windows will assign automatically an IP

address in the same range as the TraNET.

By clicking on the “On” button under “Device Identification” the NET LED on the device will starting

blinking. This can be used for verifying that you are connected to the right device. Click on “Off” for

leaving the blinking mode

Elsys AG www.elsys-instruments.com 11

TraNET FE User Guide

You can’t connect as written above?

Someone has maybe already changed the IP Address already. Set the device to DHCP and AUTO

IP mode:

• Switch off the TraNET FE device, press and hold the button in the hole next to the LED

“Ready”, power-on the device and wait until the LED “Ready” blinks permanently.

Alternatively, the button can also be pressed during runtime for at least 4 seconds. LED

“Ready” will stop flashing (stays green or off). DHCP and Auto-IP will be set, after approx.

10 seconds. The green LED “Ready” starts flashing again. IP Settings now have changed to

DHCP and AUTO IP mode.

• Network settings on the computer now have to be set to DHCP too!

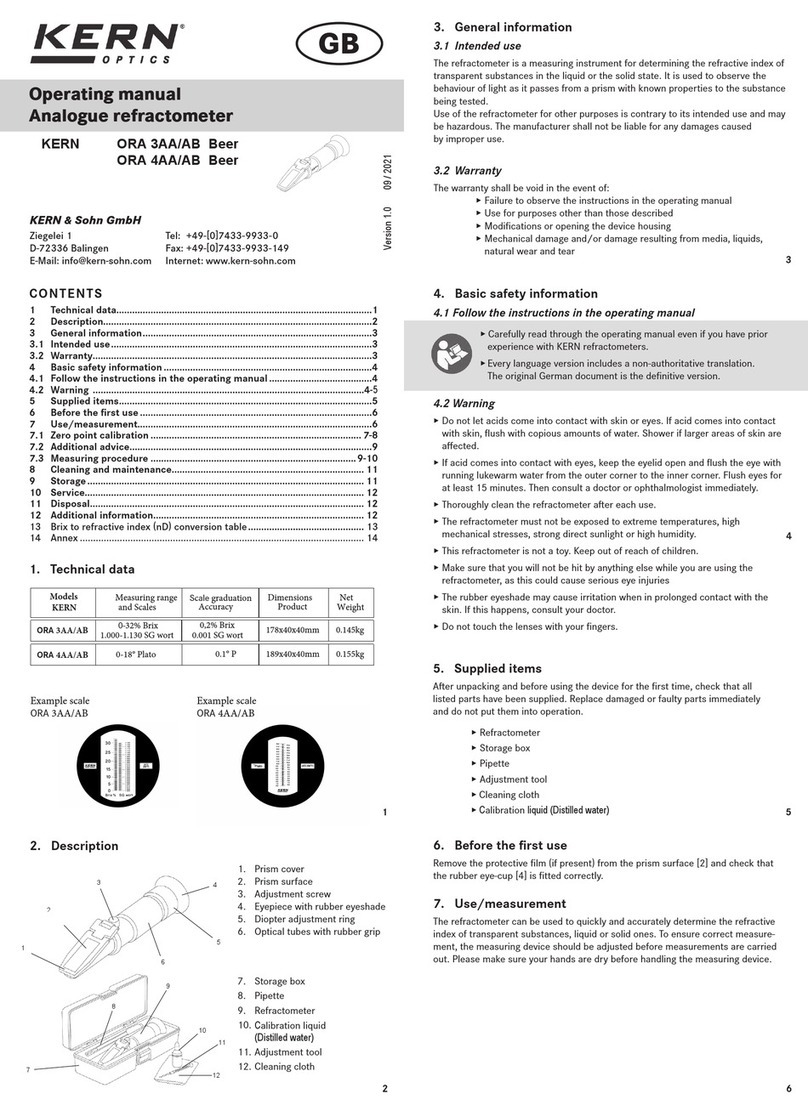

pass

Done

Connect to

Device

Device Found

TranAX search for

devices

UDP Broadcast on port

10020/10021

pass

IP address configuration

successful

Power On

TraNET request a

valid IP address from

the DHCP server

TraNET FE

Connection Flow

fail

TraNET set an Auto IP

in the range

169.254.0.0 -

169.254.255.255

Test if address is unique

in the net

fail

pass

UDP port blocked?

Check Firewall Settings

for Port UDP

10020/10021

no device

found

Check Windows

Settings, Auto IP

address enabled?

NO

Enable Auto IP in

Windows (DHCP)

Check Firewall Settings,

Allow TranAX to communicate

over the Network

fail

TCP IP port 10010

blocked?

TranAX network

communication blocked?

Condition:

1:1 connection or network with DHCP server

Elsys AGwww.elsys-instruments.com12

TraNET FE User Guide

4. Device Configuration

Several device settings can be changed over the built-in web page as mentioned in the IP con-

figuration chapter. The web page can be accessed over

http:\\IPAddress

The welcome page shows device information, LAN configuration status, Firmware version and

general hardware state like CPU temperature.

Elsys AG www.elsys-instruments.com 13

TraNET FE User Guide

4.1 Time and Synchronization Settings

The TraNET FE device is equipped with a real time clock which is battery driven. This time is used

for:

• Generating the “Last calibrated on” time stamp

• Generating timestamps for log entries in the system log file

• Base-time for the measurement start and trigger time if the measurement is started by auto-

start.

By default, the absolute measurement start time is taken from the client computer

from which the measurement is started (normally the computer on which TranAX is

running). See “Use Local Time” on the Server Settings Page for using the TraNET FE real

time clock as reference.

Elsys AGwww.elsys-instruments.com14

TraNET FE User Guide

4.1.1 IEEE 1588 (PTP) Synchronization

With the release of the MK3 of the TraNET FE device, it is possible to synchronize several TraNET

FE or 3rd part devices with the help of the PTP time synchronization protocol.

The TraNET FE can either be the master clock or a client clock. If any master clock is available in

the network, the TraNET FE will automatically sync on that clock, when the clock is running in

the same clock domain.

Settings:

• Enable Master Clock: The TraNET FE device will act as grandmaster clock source

• Clock Domain: Only clocks running in the same clock domain get synchronized

• UTC-TAI Offset: PTP is based on the TAI time. The RTC is UTC. This parameter

compensates the time difference between these two clocks.

In 2021, the offset is 37s.

PTP Status Information:

• Grandmaster Clock Present:

true if a grandmaster clock was detected and synchronized.

• Grandmaster Clock Identity:

The ID of the grandmaster clock or the ID of the own clock if the

clock from the device act as grandmaster.

• Number of Communication Paths:

shows how many connection path exist between the device and

the grandmaster clock.

• Offset from the Master:

Indicated the actual time difference between the device clock and

the master clock.

• Mean Path Delay: Travel delay of any network package between the device and the

master clock.

In order to use the PTP as time reference for a measurement in TranAX, the following

additional settings must be set up:

• Activate “Use Local Time” on the Server Settings Page

• Activate “PPS Sync” in the Control Pannel of TranAX

• Select “Ethernet (PTP)” as Pulse per Second Source on the Server Settings Page.

By activating the “PPS Sync”, the measurement is started precisely on the Pulse per Second

signal from the PTP hardware, for having exact starting times on each connected device.

The precision and stability of the PTP synchronization depends on the used network devices

(switch, routers, cables) and traffic load on the network!

Elsys AG www.elsys-instruments.com 15

TraNET FE User Guide

4.2 Measurement Settings

4.2.1 Device

• Name: Set the device name as visible in TranAX

• Description: Additional information about the device helping to identify the device in

the network.

• Server port: TCP Port, should only be changed if it is in conflict with another

application in the network. Default 10010

4.2.2 Measurement Settings:

• BDF File Path: select if BDF files are stored to the internal or the external USB drive.

• Nr. Of BDF Files: Defines how many old heap files will be preserved when several

consecutive measurements were started. If set to 0, on each new

continuous or ECR measurement the last heap file gets overwritten.

• Auto Start at Power Up:

The device starts the measurement automatically with the last settings

when the device powers up.

• Start Autosequence at Power Up:

If any remote autosequence/MFC are stored on the device, enabling this

option will automatically start the autosequence after power up.

• Use Local Time: if enabled, the absolute measurement time is taken from the device real

time clock (RTC), otherwise the client computer from which the

measurement is started acts as time reference.

For using PTP or GPS synchronization, option must be enabled!

4.2.3 Synchronization Settings

• SyncLink 2 extra Delay:

Additional delays for compensating daisy-chained SyncLink 2 connection.

• Pulse Per Second (PPS) Source:

Selects the source of the PPS signal for timebase synchronization:

- Ethernet (PTP) uses the PPS from the PTP hardware

- GPS (internal) uses the PPS from the integrated GPS receiver

(Optional)

- External Timebase Input for using any external PPS signal

connected to the Ext-IO input “External Timebase”.

Attention: For using the PPS synchronization,”PPS Sync” must be activated on

the TranAX Control Panel.

Elsys AGwww.elsys-instruments.com16

TraNET FE User Guide

Elsys AG www.elsys-instruments.com 17

TraNET FE User Guide

4.2.4 2-in-1 Configuration

2in1 mode allows splitting up the device in 2 independent devices. The device must be built up

with at least two TPCE cards. One card can be separated from the rest of the device. This option

is only available on request.

• Option Code: a valid option code is needed for enabling 2in1

• Enable: activates 2in1

• Board Number: selects which board is split from the main device setup.

• 2in1 Server Port 2: communication port for the second device, default 10011

4.2.5 LXI Trigger Settings

TraNET FE device can be either source or receiver of UDP-based LXI trigger messages. The con-

figuration of the trigger is done in the control panel of TranAX.

• LXI Trigger Broadcast address:

The UDP address at which the trigger message will be sent to.

• LXI Trigger Master address:

not used.

4.2.6 Advanced Settings

The advanced settings configures some low level device parameters for continuous or ECR

measurement.

• Memory Page Size: Defines the chunk size at which measurement data are stored in

the BDF file. Max allowed size is 512k. At slow sampling rates,

this value can be lowered for storing the data more often

to the disk.

• Number of Pages: Number of page reserved by default in the device memory.

• Max Number of Pages: Maximum number of pages allowed to be reserved for the

measurement buffer.

• Save Interval Time in seconds:

time interval at which the buffered memory page are stored to

the disk even if the page size is not reached.

• Enable Hardware ECR Retrigger:

Enables the hardware retrigger block for having lower system

load during fast trigger bursts.

Elsys AGwww.elsys-instruments.com18

TraNET FE User Guide

5. Hardware Specification

5.1 Signal Inputs, Pin Assignments

5.1.1 Analog Inputs

TraNET FE with Single Ended Inputs

Channel 5 (6), 7 (8) are configured by software to differential inputs.

BNC 5, 7 = Positiv, 6,8 = Negativ inputs.

TraNET FE with Differential Inputs

Channel 2 is used as single ended input. The corresponding negative input can be

left open or shorted.

Elsys AG www.elsys-instruments.com 19

TraNET FE User Guide

D-SUB Connector 25 pol. Female

Connector Pin Pin Name Description Spec.

1 Trigger out 5 V TTL

14 Armed out (active low)

Sync Clock out

Functionality set in

TranAX

5 V TTL

2 - Reserved

15 Disarm in (active low) 5 V Pull-Up

3 Start Record in 5 V Pull-Up

neg. Slope

16 Trigger in 5 V Pull-Up

4 Timebase in or PPS source Fmax = ¼ of the

max. sample rate

5 V Pull-Up

17 +5V

5 GND

18 A1

Marker Inputs

3.3 V

Pull-Up

6 A2

19 A3

7 A4

20 A5

8 A6

21 A7

9 A8

22 B1

Marker Inputs

10 B2

23 B3

11 B4

24 B5

12 B6

25 B7

13 B8

Input protection on all digital Inputs and Outputs: Maximum 10 V

5.1.2 Rear View (e.g. TraNET 204x)

5.1.3 Digital In / Out / Marker

Elsys AGwww.elsys-instruments.com20

ADC Clock

External Timebase

Internal Timebase

ADC Data

ADC Data Internal

A B CD EF12 34

56

C3

TraNET FE User Guide

5.1.4 External Timebase

The External Timebase can be used for capturing the measurement data at a specific moment.

The external timebase is not a reference clock but will be synchronized to the internal ADC

sampling clock. Therefor the external timebase must be at least two time slower than the ADC

clock.

If the External Timebase is used as PPS source (see 4.2.2), the timebase functionality is disabled.

5.2 USB Interface

Starting with revision 3 of the TraNET FE, the device provides a USB 3 interface for connecting

any external storage devices like USB sticks or USB SSD drives.

The external drive can be used as backup drive for copy internal BDF files from continuous mea-

surements if no fast Ethernet connection is available. It is also possible to set the external drive

as standard drive for storing the BDF file directly during the measurement.

Maximum data throughput depends on the used external drive. In all

cases, only USB Gen. 3.x devices must be used!

External Drives must be formated in exFAT file format!

Table of contents

Other Elsys Measuring Instrument manuals