DEHAS Quality Mix High Flow User manual

Table of Contents

1. Explanation of the key abbreviations............................................................................ 2

2. Safety information –Warnings, precautions and identification

information.............................................................................................................................. 2

3. Contents of delivery; Inspection upon receipt .......................................................... 4

4. Intended usage...................................................................................................................... 5

5. Before initial usage .............................................................................................................. 5

6. Technical specifications ...................................................................................................... 7

7. Pressure drop in the system............................................................................................. 8

8. Transportation and storage conditions......................................................................... 9

9. Dryness and composition of the supply gases .......................................................... 9

10. Illustrations and identification of components .......................................................... 9

11. Installation ............................................................................................................................ 12

12. Alarm test .............................................................................................................................. 12

13. Initial use ............................................................................................................................... 13

14. Cleaning / disinfection ...................................................................................................... 14

15. Maintenance.......................................................................................................................... 15

16. Product returns.................................................................................................................... 16

17. Disposal .................................................................................................................................. 16

18. Troubleshooting................................................................................................................... 17

19. Warranty conditions........................................................................................................... 18

20. Part numbers........................................................................................................................ 19

Status: 03/2022

2

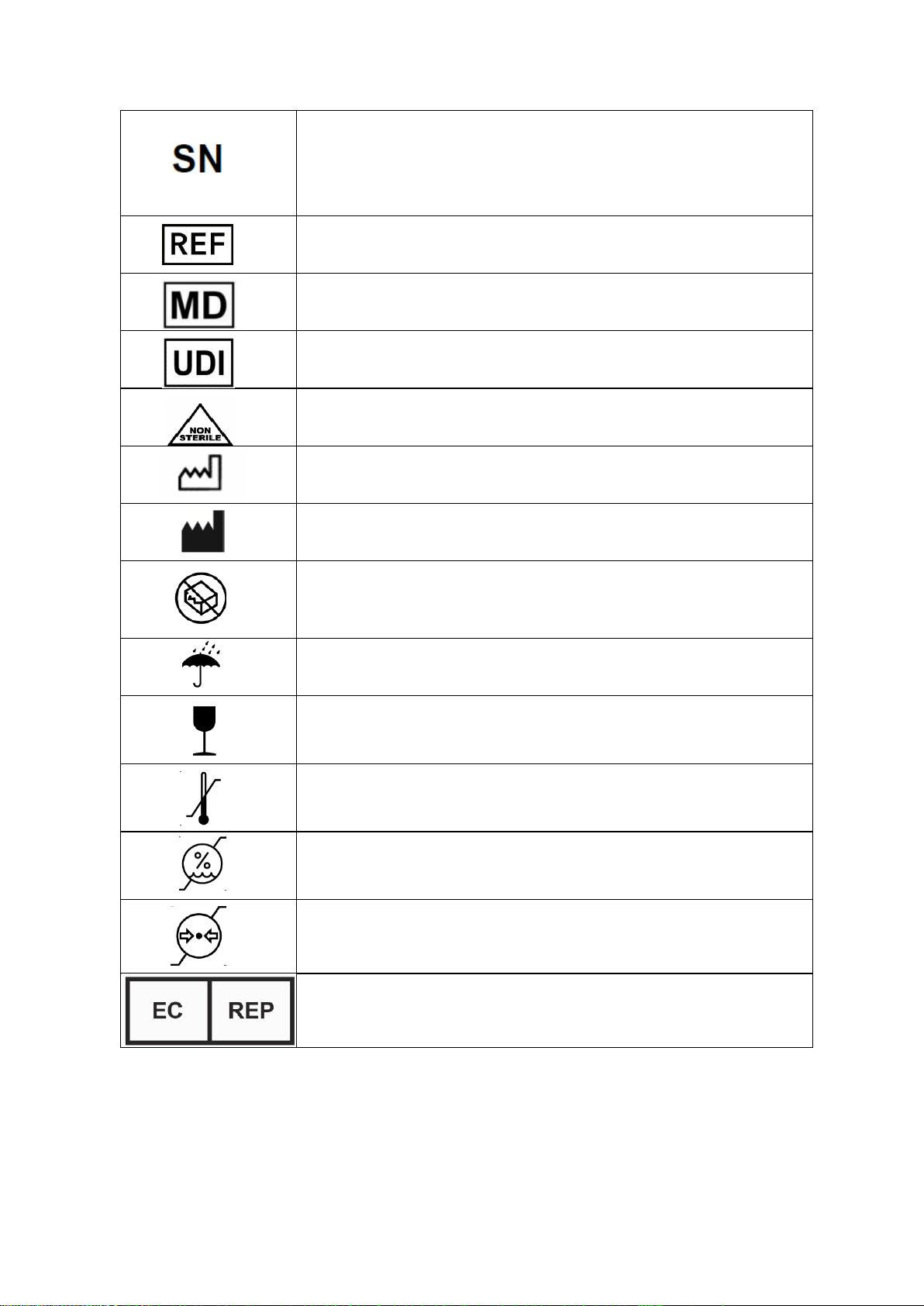

1. Explanation of the key abbreviations

FIO2

Fractional concentration of inspiratory oxygen

DISS

Diameter Index Safety System

NIST

Non-Interchangeable Screw Thread

Bar

Measurement unit for pressure

l/min

litre per minute

2. Safety information –Warnings, precautions and

identification information

Symbol

Description

This symbol indicates that the device complies with the

regulation 93/42/EEC concerning medical devices and all

applicable international standards.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION is used to indicate a potentially hazardous

situation which, if not avoided, may result in property

damage.

or

Refers the user to the necessity of consulting the

operating instructions.

Follow the instructions!

DO NOT USE OIL

3

Shows the serial number of the manufacturer so that a

certain medical product can be identified.

Shows the order number of the manufacturer so that

the medical product can be identified.

Medical device

UDI Barcode

Non-sterile

Date of manufacture

Show the manufacturer of the medical product according

to the EU guidelines 90/385/EEC, 93/42/EEC and

98/79/EC.

Shows a medical product that should not be used if the

packaging is damaged or opened

Describes a medical product that must be protected

against humidity.

Describes a medical product which can break or be

damaged if not handled with care.

Describes the temperature limit values that the medical

product can be safely exposed to.

Describes the humidity range that the medical product

can be safely exposed to.

Describes the atmospheric pressure range that the

medical product can be safely exposed to.

EU Authorised Representative

4

3. Contents of delivery; Inspection upon receipt

Contents of the delivery: 1 Base mixer along with any additional components

specified for your order

1 Operating instructions

Inspection: Take the device out of its packaging and inspect it for

damage. Do NOT use the device if you find any

damage. Contact your retailer.

5

4. Intended usage

The air-oxygen mixer Quality Mix is used to administer a continuous, precise mix

of medical air and medical oxygen –through its outlet ports –to infants, children

and adults. The exact fractional inspiratory oxygen concentration (FIO2)

corresponds to the selected FIO2setting on the control knob (dial).

Indication: This device should be used for patients who find it difficult to get

sufficient oxygen from the ambient air.

Contraindications: This device should not be used for patients who cannot breathe

on their own. Do not use for life support or life saving

procedures.

5. Before initial usage

Read all instructions before use!

These operating instructions are intended to show trained professionals how to

install and operate the Quality Mix. They promote safety and protect your device

from damage. If you do not understand information or instructions in this

document, do not use the device and contact your supplier.

DANGER

This product is not intended for use as a life-sustaining or life-supporting device.

6

WARNING

The air-oxygen mixer should only be operated by trained medical

professionals under the direct supervision of a licensed physician.

Use this air-oxygen mixer only for the purpose described in these

instructions.

Check the prescribed dose before administering to patients. Monitor the

flow frequently.

The air-oxygen mixer may only be serviced by a qualified service

technician.

Always follow the EN and DIN standards pertaining to medical gas

products, flow meters and oxygen handling.

The oxygen concentrations can optionally be confirmed using an oxygen

analyser/monitor.

The accuracy of the oxygen concentration can be affected if the bleed

flow is not activated at flow settings below 15 l/min for High Flow mixers,

and at 3 l/min for Low Flow mixers.

Do NOT interfere with or disable the alarm.

Do not use the mixer when the alarm sounds.

Do NOT use oil in or near the mixer.

Do NOT obstruct or block the bleed port at the auxiliary outlet of the

mixer.

Do NOT use the mixer near flames, flammable/explosive substances,

vapours or gases.

NEVER smoke in an area where oxygen is being used.

The rotary dial for the oxygen concentration cannot be rotated 360

degrees. Turning the dial to less than 21% or more than 100% oxygen

will damage the mixer.

CAUTION

Close the gas supply line whenever the air-oxygen mixer is not being used.

Store the air-oxygen mixer in a clean, dry place when it is not in use.

The air-oxygen mixer contains NO magnetic, ferrous materials; it can be

used with MRIs (max. 3 Tesla). A distance of 2 metres must be adhered to.

The O2 monitor cannot be used with MRIs as an accessory part.

7

CAUTION

Make sure that all connections are secure and tight.

Avoid excessive pressure surges of more than 6.5 bar whenever the

mixer's inlets are pressurized.

Do NOT sterilise.

Do NOT immerse in liquids.

Do NOT sterilise with Ethylene Oxide (EtO).

Do NOT use if dirt or contaminants are found on or near the mixer or its

connectors.

Do NOT clean with aromatic hydrocarbons.

The supply's inlet pressure must correspond to the value specified on the

mixer.

When using bottled gas or a high-pressure gas source, always use a

pressure reducer to maintain the pressure range between 3.2 and 6.5 bar.

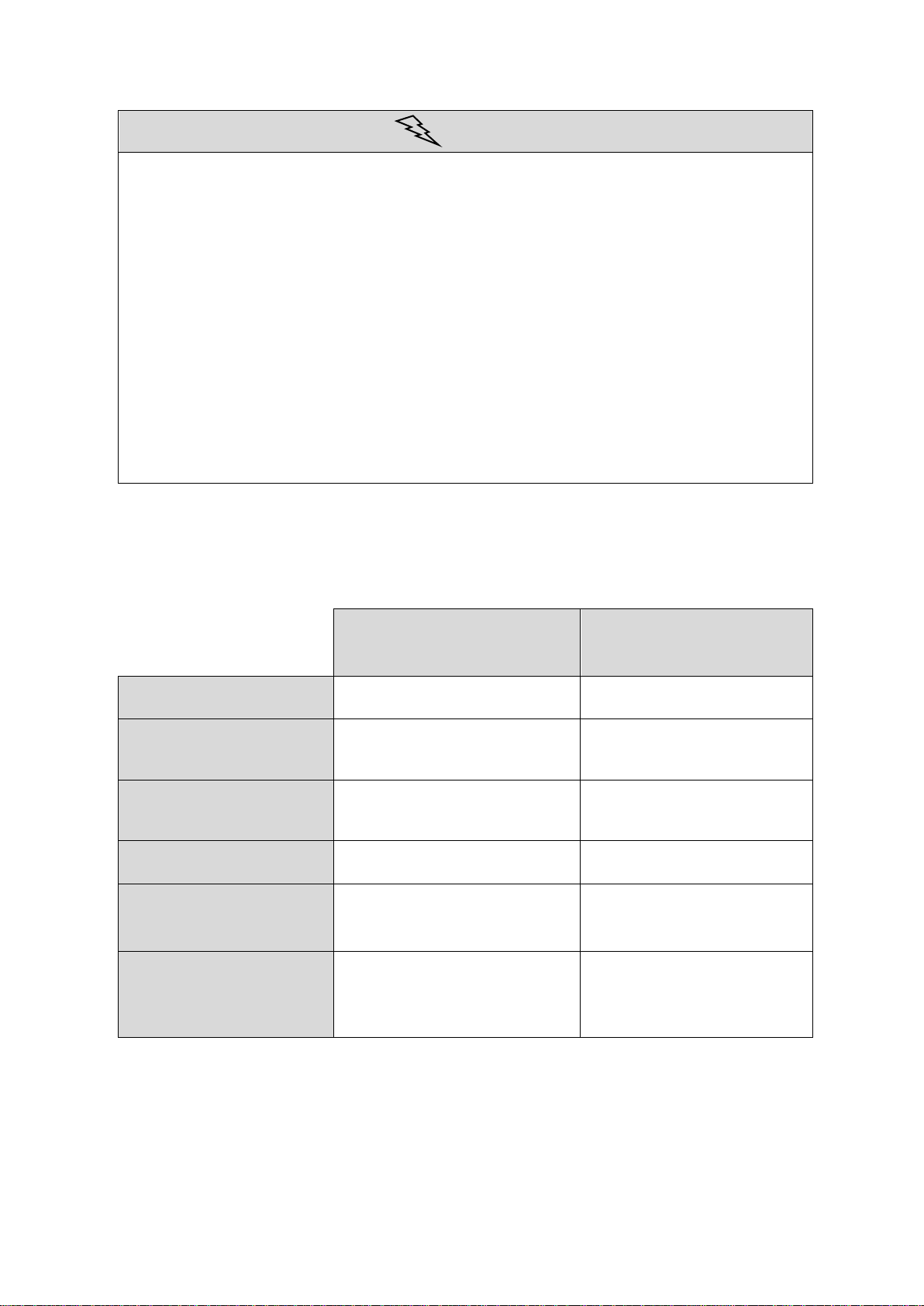

6. Technical specifications

High Flow with high flow

capacity

Low Flow with low flow

capacity

Main outlet of flow

15 –120 l/min

3 –30 l/min

Auxiliary outlet of flow

with bleed

0 –105 l/min

0 –27 l/min

Auxiliary outlet of flow

without bleed

15 –120 l/min

3 –30 l/min

Bleed flow

≤ 13 l/min at 3.4 bar

≤ 3 l/min at 3.4 bar

Maximum combined

flow (of all outlets)

≥ 120 l/min

≥ 30 l/min

Emergency flow

(malfunction of air or

oxygen supply)

> 85 l/min

> 15 l/min

8

Applies to both High Flow and Low Flow

Alarm sounds when

supply pressure drops

Alarm on at a pressure difference between both gasses of

0.9 –1.8 bar.

Alarm off at a pressure difference between both gasses of > 0.3 bar.

E.g.: Inlet pressure 4.2 bar. Alarm on at 3.3 –2.4 bar. Alarm off at

max. 3.9 bar.

Alarm volume

≥ 80 dB at a distance of 30 cm

Setting range of the

oxygen concentration

21 –100%

Gas inlet pressure

3.2 –6.5 bar: air and oxygen pressure differential should be

within max. 0.7 bar

Accuracy of the mixed

gases (FIO2)*

± 3% oxygen

Connection types

DISS outlets for mixed gases and NIST inlets for air and

oxygen

Dimensions (LxWxH)

13 x 16.5 x 12.2 cm

Weight

1600 g

Operating temperature

+5°C to +50°C

* The accuracy of the oxygen concentration can be affected if the bleed is not activated in accordance

with the specifications.

This air-oxygen mixer has been degreased before it was delivered to prepare it for

use with oxygen. The reverse gas flow of the air-oxygen mixer corresponds to

clause 9 of the ISO 11195 standard. The oxygen-analysis device being used must

comply with the ISO 80601-2-55 standard and the CE regulations.

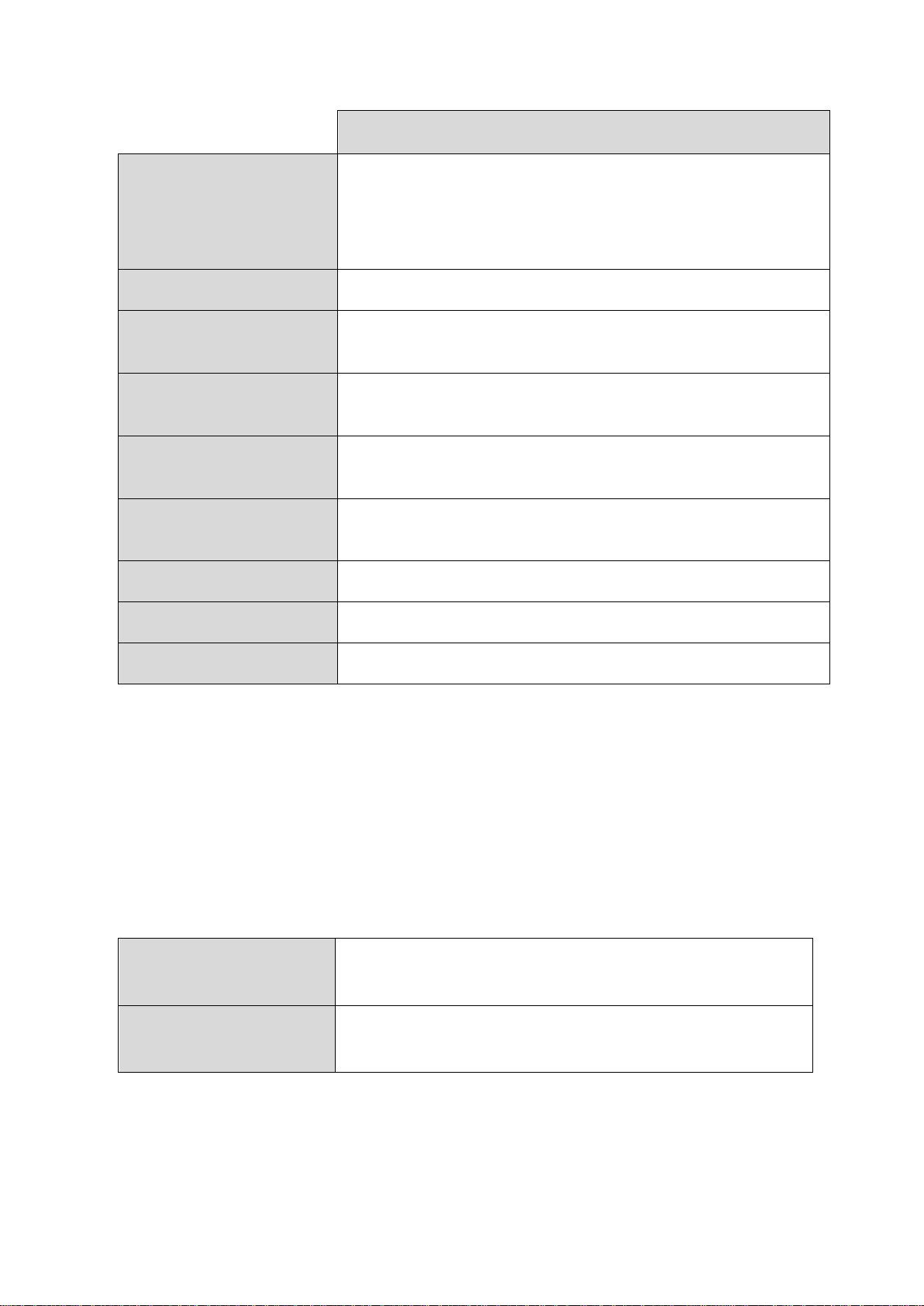

7. Pressure drop in the system

Low Flow

≤ 0.14 bar at inlet pressures from 3.2 to 6.5 bar,

with a flow rate of 10 l/min at 60% FIO2

High Flow

≤ 0.21 bar at inlet pressures from 3.2 to 6.5 bar,

with a flow rate of 30 l/min at 60% FIO2

9

8. Transportation and storage conditions

Temperature range

-20°C to 50°C

Humidity

Max. 95% non-condensing air humidity

9. Dryness and composition of the supply gases

Air:

The medical air supply must meet the requirements of the national standards.

Oxygen:

The oxygen being used must meet all requirements for medical oxygen according

to the European Pharmacopoeia.

10. Illustrations and identification of components

CAUTION

The labelling on the device will not come off if you follow the preparation

instructions properly. Contact the manufacturer or your local representative if

the labelling becomes unreadable.

These images show the Quality Mix Low Flow

10

Left side, without bleed valve Right side

Rear view

11

Components

Description

Rotary dial for oxygen

concentration

A rotary dial for setting oxygen concentration levels

between 21% –100%. The FIO2scale is used for

reference purposes only. This dial cannot be turned

360°. It starts at 21% and can turn to 100%.

Main outlet without

bleed

A DISS fitting with external (male) thread and a

check valve. This provides the gas flow when

connected to a control mechanism such as a flow

meter.

Auxiliary outlet with

bleed valve (optional)

A DISS oxygen fitting with external (male) thread

and a check valve. This provides the gas flow when

connected to a control mechanism such as a flow

meter.

The outlet can be fitted with a bleed valve that allows

the user to activate (ON) or deactivate (OFF) the

bleed function. If the bleed is activated (ON), this

outlet ensures an accurate oxygen concentration at

the following flow rates:

Model Flow range

High Flow 0 –105 l/min

Low Flow 0 –27 l/min

Adjustment collar on the

bleed valve

This collar is used to activate or deactivate the bleed

(venting) function. This bleeding ventilation is

necessary to maintain an accurate FIO2concentration

at flows below 15 l/min (for the HF mixer) or below 3

l/min (for the LF mixer). To activate the bleed

function, turn the knurled collar ring until the ON

position is reached.

Medical oxygen port

A NIST oxygen connection with internal thread and

one-way valve: for connecting an oxygen supply

hose.

Medical air port

A NIST air connection with external thread and one-

way valve: for connecting an air supply hose.

Alarm

An audible alarm that sounds when an excessive

pressure drop or stoppage is detected on the air or

oxygen supply lines.

12

11. Installation

WARNING

Read the operating instructions carefully before you install or use this

device.

CAUTION

Check the Quality Mix for visible damage before use. Do not use it if it is

damaged.

Note: Carry out the following tests before you use the device for the first

time:

Alarm test (see the following section 12)

Preparation for the alarm test

1. Mount the air-oxygen mixer on a rail or support rod in an upright position.

2. Connect the air and oxygen supply lines to the appropriate inlet ports on

the bottom of the mixer.

3. Connect a flow meter or other metering device to one of the outlet ports.

Flow capacity of the main outlets:

HF mixer: 15 –120 l/min

LF mixer: 3 –30 l/min

Bleed outlet:

Some of the air-oxygen mixture is vented at this outlet to maintain an

accurate concentration at a low flow setting.

• HF mixer: 15 l/min or less

• LF mixer: 3 l/min or less

4. Connect a supply line to the outlet port of the flow meter.

12. Alarm test

1. Connect the air-oxygen mixer to the air and oxygen sources. Put the mixer

under pressure and open the flow meter in the direction of the tapered

arrow.

2. Set the oxygen concentration dial to 60% (FIO2).

13

3. Disconnect or turn off the air supply to the air-oxygen mixer. A loud

whistling noise should be emitted from the mixer as an alarm. This

whistling noise indicates that the alarm is working properly.

4. Re-connect the air supply to the mixer and activate; the whistling should

stop.

5. Disconnect or turn off the oxygen supply to the mixer. This whistling noise

indicates that the alarm is working properly.

6. Re-connect the oxygen supply to the mixer and open the line; the whistling

should stop.

7. DO NOT USE the device when the alarm is not functioning properly.

13. Initial use

CAUTION

Check the Quality Mix air-oxygen mixer for visible damage before use. Do not

use it if it is damaged.

1. Mount the mixer to the rail or to a stand holder.

2. Connect the air and oxygen supply lines to the mixer and the supply.

3. Connect the flow meter(s) to each outlet on the mixer.

The flow meter must be connected to the bleed side for flow rates up to

15 l/min for High Flow and 3 l/min for Low Flow!

On mixers with the optional built-in bleed shut-off (optional), this must be

turned on. Turn the knurled collar ring until it engages in the ON position.

For flow rates above 15 l/min for High Flow and 3 l/min for Low Flow mixers,

this can be deactivated if the devices are fitted with bleed shut-off.

Turn the knurled collar ring until it engages in the OFF position.

4. Set the oxygen concentration dial to the prescribed value.

5. Check the flow of air/oxygen mixture to the patient.

6. Use an oxygen analyser/monitor to check the air-oxygen concentration.

7. If the air-oxygen mixer is not used any more, close the gas supply and

disconnect the device from the gas supply.

14

14. Cleaning / disinfection

CAUTION

NOT suitable for sterilisation.

NEVER immerse the air-oxygen mixer in liquids.

Do NOT use strong solvents or abrasives.

Do NOT clean with aromatic hydrocarbons.

The exterior of the device should be disinfected at regular intervals. At a

minimum, it should be disinfected after each patient according to the

applicable hygiene standards.

1. Disconnect all gas connections and equipment before cleaning.

2. Wipe down the outer surfaces using a cloth moistened with a non-oxidizing

disinfectant and water.

3. Wipe dry with a dry cloth.

The manufacturer recommends the use of the disinfectant Dismozon

plus®, from Bode Chemie GmbH & Co.

15

15. Maintenance

The following maintenance and inspection tasks must be carried out:

•The user must test the alarm once per month.

•The safety technical inspection must be carried out each year by a trained

operator or a medical technician.

•Have the device serviced at least once every 2 years by a trained professional.

The test of the reverse gas flow is part of the service and must therefore be

carried out every 2 years.

Test of the reverse gas flow

1. Set the oxygen concentration of the air-oxygen mixer to 60%.

2. Connect the air connecting tube to the mixer and to the gas supply. Then

turn on the gas supply.

Measure the flow at the oxygen inlet using a suitable measuring instrument.

The flow must not exceed 10 ml/h.

If the flow is greater than 10 ml/h, the duckbill valve in the oxygen inlet

must be replaced in accordance with service instructions and the

measurement must be repeated.

3. Connect the connecting tube for oxygen with the mixer and the gas supply

and open the supply.

Measure the flow at the air inlet with a suitable measuring instrument.

The flow must not exceed 10 ml/h.

If the flow is greater than 10 ml/h, the duckbill valve in the air inlet must

be replaced in accordance with service instructions and the measurement

must be repeated.

16

16. Product returns

Please contact your retailer concerning this. They will help to coordinate the

return. It is important that you provide a description of the error or malfunction so

that the return can be processed effectively. All returns must be shipped in sealed

containers to prevent damage. The specialist retailer is not responsible for any

devices that are damaged during transport.

17. Disposal

This device and its packaging contain no hazardous materials. No special

precautions are required when disposing of the device and its packaging.

Please recycle.

17

18. Troubleshooting

Consult the following section in the event that the air-oxygen mixer malfunctions.

If this information does not help to solve the problem, please contact DEHAS or

your nearest retailer.

Problem

Possible cause

Remedy

Discrepancy between

the oxygen

concentration setting at

the mixer and the

concentration at the

analyser/monitor

(of more than 3%)

1.

Flow requirements

for high-flow model:

less than 15 l/min.

Flow requirements

for low-flow model:

less than 3 l/min.

1.

Use the bleed outlet and

activate the vent (bleed)

function

2.

The analyser/monitor

is not registering or

measuring precisely

2.

Re-calibrate the monitor

or check using another

analyser/monitor.

3.

The bleed outlet is

blocked at low flow.

3.

Remove the blockage.

4.

The gas supply line is

contaminated.

4.

Check the gas supply

using a calibrated oxygen

analyser/monitor to

ensure that the oxygen

content is 100% and the

air content is 21%.

5.

Downstream device

causing back flow or

restricted flow

5.

Disconnect the mixer.

Check the oxygen

concentration at the

outlets of the mixer.

No flow at the mixer's

outlets

1.

The gas supply is

switched off.

1.

Switch on the gas supply.

2.

The gas supply is not

connected.

2.

Connect the gas supply.

18

Problem

Possible cause

Remedy

The alarm sounds

1.

The difference

between the oxygen

pressure and air

supply pressure is

greater than

specified.

1.

Adjust this pressure

differential until the

air/oxygen pressures

meet the specifications

19. Warranty conditions

The supplier guarantees that the mixer will be free of material defects or

workmanship errors for the following period:

One (1) year from delivery

If, within the applicable period, a device defect should occur, then the dealer shall

–after written notification thereof and substantiation that the device has been

stored, installed, maintained and operated in accordance with the instructions of

the dealer and in accordance with standard industry practice, and that no

modifications, substitutions or changes were made to the product –correct such a

defect by suitable repair or replacement at its own expense.

ORAL STATEMENTS DO NOT CONSTITUTE A WARRANTY.

The retailer is not authorised to make oral warranties about the merchandise

described in this contract. Any such statements are not binding and not part of the

sales contract. Thus, this written second statement is a final, complete and

exclusive statement of the contractual terms.

The current version of the retailer's Terms and Conditions and German law are

valid.

19

20. Part numbers

Designation

Part number

QualityMix High Flow Blender DISS Connection

D-B-G-HF-DISS

QualityMix High Flow Blender NIST Connection

D-B-G-HF-NIST

QualityMix Low Flow Blender DISS Connection

D-B-G-LF-DISS

QualityMix Low Flow Blender NIST Connection

D-B-G-LF-NIST

QualityMix flow meter 0-3L

D-B-FL-3

QualityMix flow meter 0-6L

D-B-FL-6

QualityMix flow meter 0-15L

D-B-FL-15

QualityMix flow meter 0-16L

D-B-FL-16

QualityMix flow meter 3,2-32L

D-B-FL-32

QualityMix flow meter 8,5-85L

D-B-FL-85

QuylityMix O2 Module –Oxygen monitor for direct mouting on the

blender

D-B-O2-M

QualityMix pressure reducer module DISS

D-B-PR-DISS

QualityMix pressure reducer module NIST

D-B-PR-NIST

QualityMix rail clamp

D-B-SH

QualityMix rail clamp

D-B-SH-MKIII

QualityMix rail clamp version with safety-pin

D-B-SH-SP

Transport bracket for gas blender - consisting of fastening claw and

mounting plate

D-B-G-TH

QualityMix membrane kit, Service

D-EM019294

This manual suits for next models

1

Table of contents

Popular Medical Equipment manuals by other brands

Mangar

Mangar Camel quick start guide

Mediana

Mediana P10 Operator's manual

SCHILLER MEDICAL SAS

SCHILLER MEDICAL SAS FRED easy user guide

St. Croix Sensory

St. Croix Sensory Nasal Ranger Operation manual

Hydas

Hydas LH-885XL instruction manual

Cantel Medical

Cantel Medical MEDIVATORS renatron II 100 Series instruction manual