Dehutech DT-3500 User manual

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 2

EC-declaration of conformity

Dehutech AB

Mätslingan 22

SE-187 66 TÄBY

Sweden

declare under own responsibility that the product:

Dehumidifier DehuTech 3500 (type DA-3500 in Swedish market) from unit no 141 1601

which is detailed in this declaration complies to the following harmonized European standards and

technical specifications:

SS-EN 60335-1/A13 Electrical domestic appliances - general requirements

SS-EN 60335-2-40 issue 4.2 Specified requirements for electrical heat pumps, air

conditioning units and dehumidifiers.

SS-EN 60335-2-40 C1 Specified requirements for electrical heat pumps, air

conditioning units and dehumidifiers.

amendments SS-EN 60335-1 T1:2, T2, T3, T4, T5

according to conditions in directive:

2006/95/EC Low voltage directive

2004/108/EC EMC Directive (Standard units)

Täby 2016-01-04

________________________

Ulf Rahle, Managing Director

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 3

Table of contents

GENERAL SAFETY INFORMATION......................................................................................................................................4

APPLICATIONS ..................................................................................................................................................................5

METHOD OF OPERATION ..................................................................................................................................................5

PRODUCT DESCRIPTION....................................................................................................................................................6

CASING ...................................................................................................................................................................................6

ROTOR ....................................................................................................................................................................................6

FILTERS ...................................................................................................................................................................................6

FANS FOR PROCESS-AND REACTIVATION AIR ...................................................................................................................................6

HEATER FOR REACTIVATION AIR....................................................................................................................................................6

ELECTRICAL PANEL .....................................................................................................................................................................6

OPERATION OPTIONS .................................................................................................................................................................6

INSTALLATION ..................................................................................................................................................................7

INSTALLATION AND SERVICE ACCESS...............................................................................................................................................7

DUCT CONNECTION FOR PERMANENT INSTALLATION.........................................................................................................................7

ELECTRICAL INSTALLATION...........................................................................................................................................................7

COMMISSIONING .............................................................................................................................................................8

MAINTENANCE .................................................................................................................................................................9

FILTERS ...................................................................................................................................................................................9

ROTOR ....................................................................................................................................................................................9

ELECTRICAL MOTORS..................................................................................................................................................................9

HEATER ...................................................................................................................................................................................9

ROTOR DRIVE BELT.....................................................................................................................................................................9

ROTOR SEALINGS.......................................................................................................................................................................9

GENERAL SUMMARY OF MAINTENANCE INTERVALS.........................................................................................................................10

TRANSPORTATION.......................................................................................................................................................... 10

FAULT FINDING...............................................................................................................................................................11

TECHNICAL DATA............................................................................................................................................................ 12

DIMENSIONS ..........................................................................................................................................................................12

TECHNICAL DATA.....................................................................................................................................................................12

PERFORMANCE CHART &DRY AIR FLOW DIAGRAM .........................................................................................................................13

SPARE PARTS LIST...........................................................................................................................................................13

COMPONENT DATA ........................................................................................................................................................15

MISCELLANEOUS / NOTES...............................................................................................................................................17

APPENDIX 1 – ELECTRICAL WIRING ................................................................................................................................. 18

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 4

General safety information

•Anyone operating the DehuTech

dehumidifier should have access to this

manual, and should be aware of the safety

information.

•Only personnel with adequate knowledge

of the dehumidifier should be allowed to

operate and service it.

•Only personnel with authorization for

electrical installations are allowed to make

repair of electrical components.

•Repair of electrical components should be

carried out by suitable qualified

personnel.

•The dehumidifier must not be installed in

areas where explosion proof equipment is

required.

•Disconnect the dehumidifier from the

mains prior to opening any service panel.

•Prior to servicing the dehumidifier must

be left to cool down for at least 15

minutes after operation.

•The service panel should remain closed

except when servicing is carried out.

•The dehumidifier can only be used for

dehumidification of air at atmospheric

pressure.

•Never use the dehumidifier without the

filters as the desiccant rotor can become

contaminated and lose capacity.

•Signs and instructions on the dehumidifier

should not be removed or altered.

•This manual should always be accessible

and kept close to the dehumidifier.

•All maintenance and control of the

dehumidifier should be as per the

specified schedule.

•Use only genuine spare parts.

•Written permission must be obtained from

DehuTech AB prior to making any alteration

or modification.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 5

Applications

The DehuTech Dehumidifier is of the solid

desiccant wheel type designed to dry air of

atmospheric pressure. The dehumidifier can be

used for drying air of up to 100 % relative

humidity (RH) with temperatures from -30°C to

+40°C.

The applications are numerous and wide

spread. Below are some examples:

•Controlling humidity levels in production

processes.

•Drying of temperature sensitive products.

•Maintaining correct humidity in storage

areas.

•Protection of equipment sensitive to

corrosion.

•Controlling humidity levels in museums

and archives.

•Drying after water damage and drying of

buildings during construction.

•Climatic improvements in damp areas.

Method of operation

The dehumidifier operates with two air

streams. A larger air stream to be dehumidified,

and a smaller air stream to exhaust the

moisture out of the desiccant rotor.

Two fans inside the dehumidifier create air

streams which travel through the desiccant

rotor in opposite directions.

The larger air volume, the process air, passes

through the slowly rotating silica gel rotor.

Silica gel is a hygroscopic material adsorbing

water vapour direct from the air. When passing

through the rotor the humidity of the air is

reduced, whilst the moisture content of the

rotor material increases. On exiting the rotor

the dried air is introduced into the area, or the

process to be dehumidified. The adsorption

process works in temperatures from -30°C to

+40°C.

The smaller air volume, the reactivation air,

adsorbs the moisture from the silica gel rotor.

This reactivation air is heated by an internal

heater to a temperature of approximately

+120°C. As the reactivation air passes through

the rotor, in an opposite direction to the dry air,

it will decrease the moisture content of the

rotor material. The reactivation air will leave

the dehumidifier as warm, moist air, which is

then exhausted out from the building.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 6

Product description

The dehumidifier is designed to meet the

requirements of IEC protective class IP 44.

Casing

The casing is fabricated from stainless steel and

is insulated including inner panels. The top of

the dehumidifier has a panel that can be

removed for service access. All duct

connections to the dehumidifier are designed

for connections to standard size spiral ducts.

Rotor

The dehumidifier has a drying rotor fabricated

from a desiccant material. The rotor has a

matrix of corrugated and flat heat resistant

sheets which houses the Silica Gel desiccant

agent. This matrix creates a large number of

axial flutes through the rotor, which together

builds up an immense surface area for moisture

adsorption in a small volume. The rotor is

manufactured and processed to be able to

withstand moisture saturated air without being

damaged. This means the rotor can be used in

conjunction with a pre- cooling coil.

Furthermore the rotor will not be damaged

even if the fan or the heater for reactivation

should fail during operation. The rotor is

incombustible and non-flammable.

Rotor sealings

The rotor has two pheriperical sealings.

Rotor drive system

The slow rotation of the rotor is achieved by an

electrical gear motor and a belt drive. The belt

sits on the outer rim of the rotor and is driven

by a pulley on the drive motor. A belt tension

device keeps the belt in place and maintains

tension to prevent belt slip. Correct operation

of the drive system, and direction of rotation

can be checked by opening the front panel.

The centre hub of the rotor is equipped with

ball bearings. The rotor shaft is made from

stainless steel.

Filters

The dehumidifier has two separate filters. One

in the process air inlet and one in the

reactivation air inlet.

Fans for process- and reactivation air

The fans are direct driven radial fans with a

three phase EC motor for the process air fan

and a single phase EC motor for the

reactivation air fan, class IP 54, ISO F. The fans

are accessible for service behind the panels.

Heater for reactivation air

The reactivation heater is of the PTC-type

(Positive Temperature Control), which cannot

be overheated, and gives the possibility of a

stepless control for 50 - 100 % of the

dehumidification capacity. This is achieved by

controlling the reactivation air volume.

Electrical panel

The electrical panel is located in a separate

compartment at the top of the dehumidifier.

Switches and indications for operation are

mounted at the front of the dehumidifier.

Operation options

Using the operation switch on the dehumidifier,

different running options can be selected:

0 Dehumidifier not in operation.

MAN Dehumidifier in continuous

operation.

AUTO Automatic operation by remote

humidistat, or other external

start/stop signal.

In the electrical compartment, there is a switch

marked S3, which allows continuous operation

of the dry air fan.

For dehumidifiers with PLC, the operation

is described in the PLC controller manual.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 7

Installation

Installation and service access

The DehuTech Dehumidifier is designed for

indoor installation, and must be installed in an

upright position, preferably bolted to the floor.

Ensure a space of 1000 mm above the

dehumidifier for inspection and service.

Duct connection for permanent installation

The dehumidifier can be installed in the room

that should to be dehumidified or in a separate

room.

To obtain the best performance the outlets from

the fans should be equipped with diffusors.

Wet air duct out from dehumidifier

The wet air from the dehumidifier should be

exhausted to the outside. The duct should be as

short as possible to minimize the chance of

condensation of the wet air. This duct should

slope down slightly to stop any condensed water

from flowing back into the dehumidifier.

If the wet air duct is extremely long, or must be

installed sloping upwards from the dehumidifier,

it should be insulated and have a drainage point

(2-4 mm) drilled at its lowest position.

The exhaust opening should have a coarse wire

net.

Reactivation air into the dehumidifier

The reactivation air duct into the dehumidifier

should be as short as possible. The intake

opening of the duct should have a coarse wire

net, to stop foreign objects from entering the

dehumidifier. No insulation is needed and the

duct can slope up- or downwards. In some

installations, as an alternative, the reactivation

air can be taken from the installation room. For

this alternative no duct connection is needed.

A damper should be installed in the reactivation

air duct to enable correct setting of the

reactivation air volume during commissioning.

Process- and dry air with the dehumidifier

installed in the dehumidified room

When the dehumidifier is installed in the

dehumidified room space it would normally

take the process air direct from the room

without any duct system, with only a protection

net for the inlet required. The dry air outlet

would normally have a duct system designed

for distribution of the dry air in the building.

Process- and dry air with the dehumidifier

installed outside the dehumidified room

When the dehumidifier is installed in a separate

plant room all inlet and outlet openings are

usually ducted.

The dehumidifier takes the process air as

ambient air, or as pre-treated air

(cooled/heated), or alternatively as return air

from the dehumidified room. The dry air from

the dehumidifier can be connected for post

treatment or ducted back to the dehumidified

room.

A damper can be installed in the process air duct,

enabling correct commissioning of the dry air

volume.

Electrical installation

See the electrical wiring diagram in appendix 1.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 8

Commissioning

On initial start-up, the following steps should be

taken in this order:

1. Ensure that the external isolation switch

is isolating the unit from the mains, and

that the main switch on the

dehumidifier is set in the OFF position.

2. Open the service panel of the

dehumidifier and ensure that no foreign

objects are left inside the unit or in the

electrical compartment

3. Ensure that the process and reactivation

air dampers are open, and that ducts are

clean and free of blockages.

4. Check that air filters are installed and

clean.

5. Rotate the fan impellers by hand and

make sure they can move freely.

6. Ensure that the mains supply fuse is

suitably rated.

7. Compare set values for motor circuit

breakers with correct values in electrical

wiring diagram in appendix 1.

8. Connect the dehumidifier to the main

electrical supply by turning the isolation

switch to ON, and check all three phases

are live. Terminal L1, L2, L3 in the

dehumidifier.

9. Check to see that the lamp called STAND

BY is lighting up, but that the machine

doesn’t start.

10. Start the dehumidifier for a short

moment (3-4 seconds) by turning the

main switch to the MAN position. While

in operation, check that the rotor is

slowly turning in the right direction, and

the green operation lamp lights up.

Stop the dehumidifier by turning the

main switch to 0, and check the

direction of rotation for the fans.

11. Mount the service panels and ensure

they seal properly to the casing.

12. The dehumidifier is now ready for

operation.

13. Start the dehumidifier and check that

the unit is operating at the correct air

volumes by taking measurements in the

ducts. Always check the airflows on the

overpressure side of the dehumidifier

(dry air duct and wet air duct).

14. If requested check the dehumidification

performance by measuring humidity in

the dry air outlet from the dehumidifier.

Compare the result with the

performance chart on page 13.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 9

Maintenance

NOTE! With all maintenance and service of the

dehumidifier:

•Switch off the dehumidifier

approximately 15 minutes prior to

opening any service panel, allowing the

heater to cool down.

•Disconnect the dehumidifier from main

electrical supply by turning the external

switch to the off position.

The maintenance intervals for the dehumidifier

depend on the surrounding environment and

installation site. Recommended maintenance

intervals could therefore differ from one

installation to another. Incorrect maintenance

and service may result in reduced

dehumidification capacity.

Filters

The dehumidifier is equipped with two separate

filter banks, one for the process air and the other

for the reactivation air. The filters are positioned

at the respective inlets and will clean the air prior

to entering the dehumidifier.

Intervals for cleaning or replacement of the

filters will be determined by the amount of dust

and particles in the air at the installation site.

We recommend that the filters are checked at

least once a month.

The unit can be equipped with differential

pressure measurement for checking the

pressure drop over the filters.

Never operate the dehumidifier without the

filters, as the rotor can be damaged by dust.

Rotor

The rotor is maintenance free. However should

it be necessary to clean the rotor the first choice

should be careful use of compressed air. With

severe contamination the rotor can be washed

with water.

Cleaning with water is no routine matter, please

contact DehuTech AB or local distributor prior to

this procedure.

Check the rotor bearing and the rotor surface

once a year.

Electrical motors

The electrical motors are equipped with ball

bearings. The bearings are designed to last

the life of the motor and therefore no

maintenance is required.

Check the motors once a year for any

abnormal sound.

Heater

The reactivation electric heater does not need

maintenance, but should be checked twice a

year for any mechanical damage to the heating

elements.

Rotor drive belt

Check the belt tensioning at regular

intervals. The tensioning is maintained

constantly by the belt tension device, and

should not need to be adjusted during

normal operation.

Rotor sealings

Check that the sealings are in the right

position and not damage.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 10

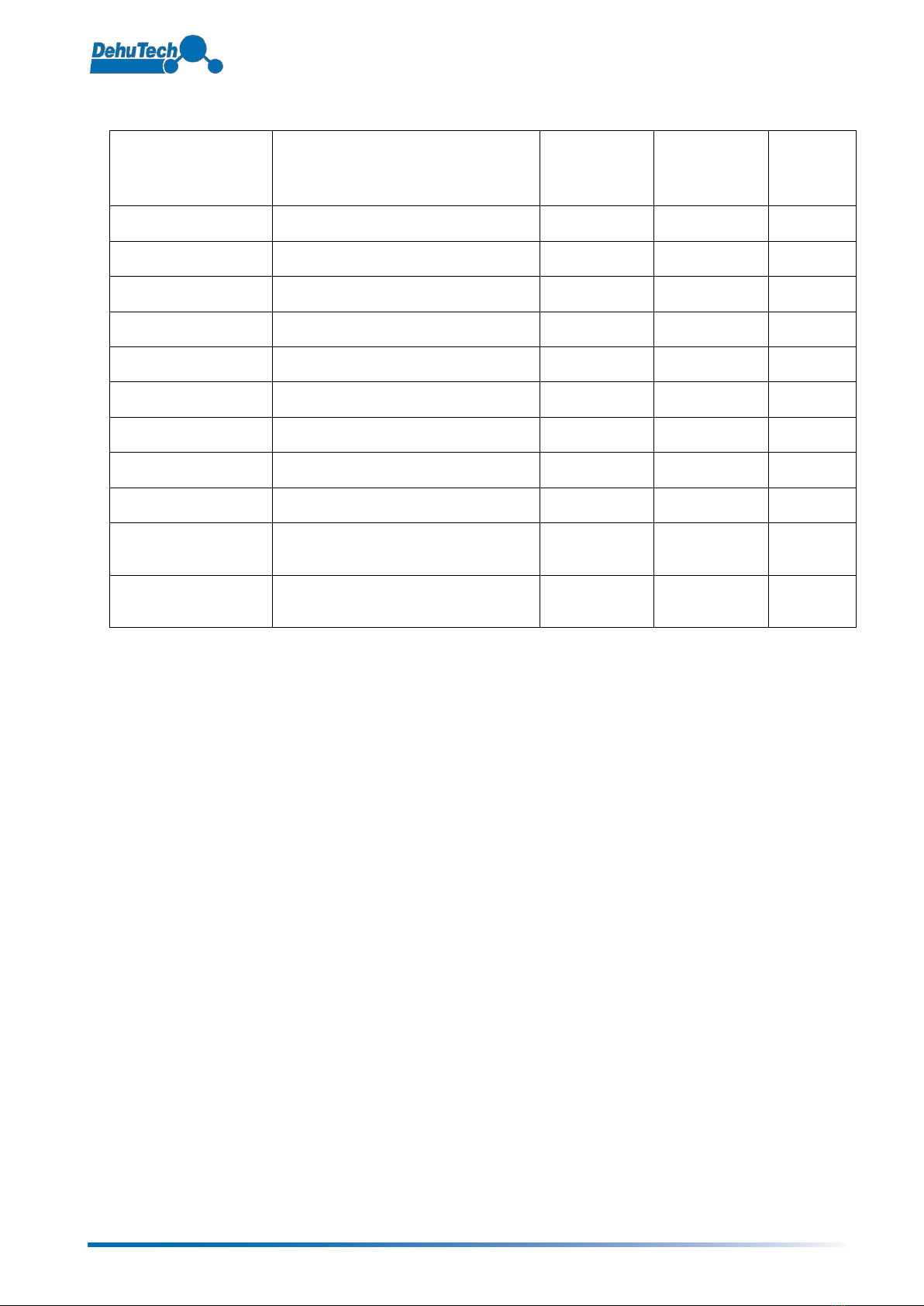

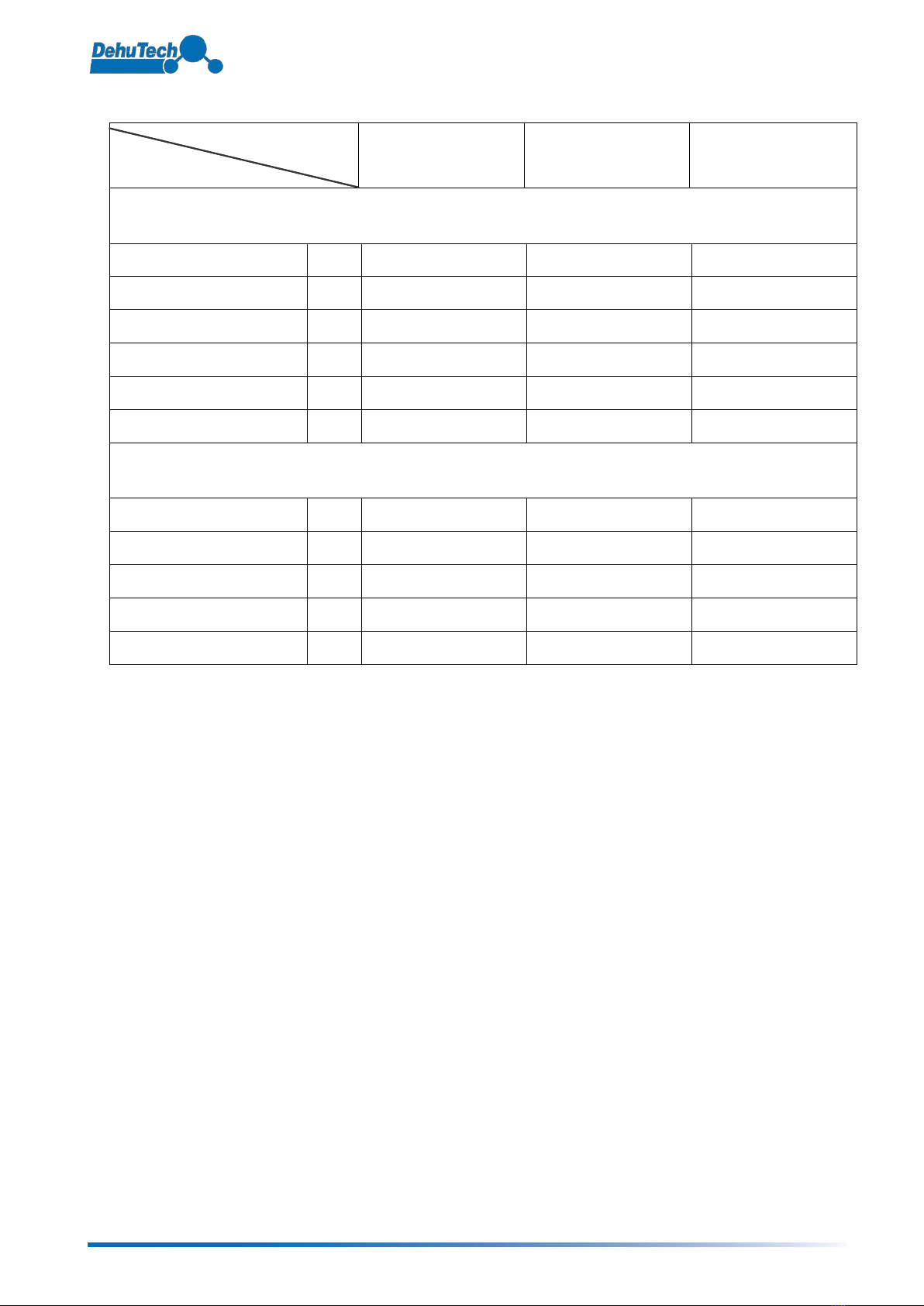

General summary of maintenance intervals

Filter

Rotor bearing

Motors

Rotor drive

Heater

Sealings

On demand

√

Every 6th month

√

√

√

Every 12

th

month

√

√

Transportation

Observe the following for transport or

handling of the dehumidifier:

•Check the dehumidifier on

delivery for any transport damage.

•The dehumidifier should be

protected from rain and snow.

•The dehumidifier should always

stand upright on its feet.

•Never put other goods on top of

the dehumidifier.

•Transport and lift the dehumidifier

by fork lift. Ensure that the forks

go all the way to the back of the

dehumidifier before lifting.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 11

Fault finding

Malfunction

Possible cause of trouble

Corrective action

None, or reduced

dehumidification capacity

Filter clogged

Electrical heater faulty

Airflow reduced

No rotation of rotor

Internal leakage in unit

Altered air volumes

Altered reactivation temperature

Air leakage

Clean or replace filters

Check fuses

Check openings and dampers

Check belt tensioning

Check sealings and springs

Measure and check air volumes

Check reactivation heater

Check panels and check seals

Circuit breaker or fuse faulty

Fan faulty

Too large air volume

Rotor does not rotate

Reactivation heater faulty

Check fans and motors

Check air volumes and dampers

Check drive motor and drive belt

Check reactivation heater

Dehumidifier does not start

No control circuit

Faulty control signal

Phase fault

Fuse for controls faulty

Check control fuses

Check external start/stop signal

Check main fuses and phase sequence

Check electrical components

Rotor does not rotate

Drive belt is slipping

Drive belt broken or worn

Rotor jammed

Drive motor faulty

Check belt tensioning

Replace drive belt

Check centre shaft, rim of rotor

Replace complete gear motor

No dry- or wet air volume

Filter clogged

Fan faulty

Phase fault

Ducts blocked

Clean or replace filters

Check fan, motor and impeller

Check main fuses and phase sequence

Check dampers and ducts

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 12

Technical data

Dimensions

Technical data

Dehumidification capacity 19,2 kg/h (at +20°C and 60 % RH

See performance chart for other data)

Process air flow 3 500 m3/h (at 170 Pa available pressure)

Wet air flow 850 m3/h (at 260 Pa available pressure)

Power supply 28,7 kW (3 x 400 V, 50 Hz)

Weight 210 kg

Noise level 71 dB(A)

Note: Valid only for standard units, with standard air-flows.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 13

Performance chart & dry air flow diagram

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 14

Spare parts list

Part

Technical specification

No installed

No of

recommended

spare parts

Comment

Drive motor

SMG65/30-4, 230-240V 50Hz 3 rpm

1

1

Capacitor

0,5 µF 700 V

1

Belt pulley

12 L 050-6F

1

Drive belt

855 L ( width 12 mm)

1

Belt tensioner

Rosta SE11 + R11

1

Process air fan

GR31C-ZID.DC.1K (400V)

1

React. air fan

K3G 250-RR01-H2 (230V)

1

Heater PTC

HRKK 42/22 - 400V

1

1

Rotor

Rotor 3500

1

Process air filter

Panel filter

715 x 494 x 45 mm

1

2

Reactivation air filter

Panel filter

310 x 450 x 25 mm

1

2

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 15

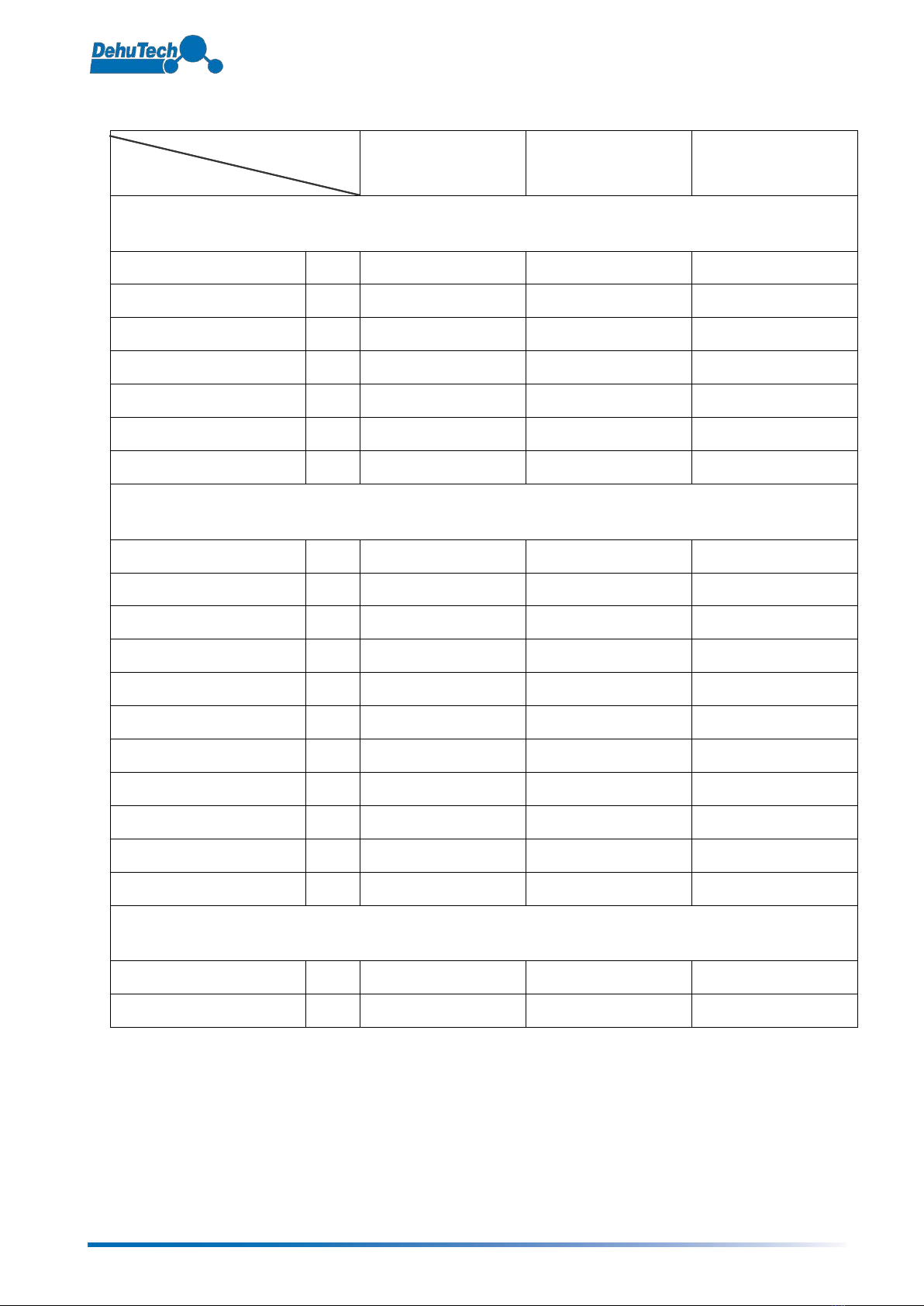

Component data

Unit part:

Components:

Process air side

(Dry air side)

Reactivation air side

(Wet air side)

Rotor

FANS

Manufacturer

ZIEHL-ABEGG

ebmpapst

Fan type

GR31C-ZID-DC.1K

K3G 250-RR01-H2

Speed

rpm

3 550

3 740

Model

RH31C-ZID.DC.1R

R3G 250-RR01-H1

Air flow

m3/h

3 500

850

Head pressure

Pa

External pressure available

Pa

170

260

MOTORS

Manufacturer

ZIEHL-ABEGG

ebmpapst

Rotek

Model

-

M3G 084-DF

SGM65/30-4

Speed

rpm

3 550

3 740

3,0

Power

kW

2,2

0,5

7,8 W

Voltage

V

3 x 400

230

230

Frequency

Hz

50/60

50/60

50/60

Amps

A

3,6

2,2

60 mA

Power factor

cos

ϕ

-

-

Protection class

IP

54

54

Insulation class

ISO

F

F

Specialties

ROTOR

Type

Rotor 3500

Rotor speed

rph

11

Continued on next page.

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 16

Continued from previous page.

Unit part:

Components:

Process air side

(Dry air side)

Reactivation air

(Wet air side)

Rotor

FILTERS

Type

Panel filter

Panel filter

Filter class

EU-4

EU-4

Filter media

Glass fibre

Glass fibre

Dimensions

mm

1p. 715 x 494 x 45

1p. 310 x 450 x 25

Pressure drop, clean filter

Pa

40

40

Pressure drop, dirty filter

Pa

140

140

HEATER, REACTIVATION AIR

Power

kW

24

Type

PTC

Voltage

V

400

Number of elements

Type of elements

Resistance PTC

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 17

Miscellaneous / Notes

DehuTech AB

Mätslingan 22

SE-187 66 TÄBY

Sweden

Tel: +46 8 792 04 08

Fax: +46 8 792 55 59

E-mail: info@dehutech.com

Website: www.dehutech.com

© 2016 DehuTech AB - Subject to change without notice DT-3500 - 18

Appendix 1 – Electrical wiring

Table of contents

Other Dehutech Dehumidifier manuals

Popular Dehumidifier manuals by other brands

Seaira Global

Seaira Global WatchDog NXT60 How to Change the Control Board

KUL

KUL KU34393 user manual

Ingersoll-Rand

Ingersoll-Rand HRD Series Operator's instruction manual

Breville

Breville All Climate LAD250 Instruction book

Sinclair

Sinclair CFO-20N Service manual

Meritor Wabco

Meritor Wabco System Saver Series Maintenance manual