DEK 265 horizon User manual

Engineering Specification

DEK Part No. 156935

http://www.dek.com

Copyright (c) 2000 DEK Printing Machines Limited. All Rights Reserved.

Microsoft and MS-DOS are registered trademarks of Microsoft Inc.

Windows and Windows NT are trademarks of Microsoft Inc.

All other brand and product names are trademarks or registered trademarks of their respective holders.

Trademark Acknowledgment

AutoFlex, Form-Flex, Vortex and ProFlow are registered trademarks of DEK Printing Machines Limited.

Copyright Statement

HORIZON ENGINEERING SPECIFICATION

ENGINEERING SPECIFICATION

GENERAL DESCRIPTION .........1

TECHNICAL SPECIFICATION ........2

MACHINE FOOTPRINT..........5

KEY FEATURES ...........6

Camera System ..........6

Windows NT ..........13

Diagnostics ..........14

SCREEN IMAGE POSITIONING ........16

MACHINE OPTIONS ..........17

ProFlow ...........17

2D Inspection ..........19

Under Screen Cleaner .........24

Paste Dispenser ..........26

Board Clamp Options .........27

Tooling ...........30

Networking ..........36

Generic Equipment Model ........36

Special Board Handling Options .......36

Speed Up ...........37

Remote Board Stop .........37

Statistical Process Control ........38

Remote Product Changeover ........38

Long Board ..........38

Off Line Editor ..........39

Remote Event Monitor.........39

Temperature Control Unit ........39

Environmental Control Unit ........40

Chapter Issue 1 May 00 Engineering Specification

CONTENTS

Engineering Specification Chapter Issue 1 May 00

CONTENTS

ENGINEERING SPECIFICATION

GENERAL DESCRIPTION

Using a world wide installed base of thousands of 265 printers, DEK has

engineered the evolution of the industry’s most successful screen printer

platform to create the Horizon – a printing machine focused on improving

flexibility, yield and price/performance.

The Horizon adds more features and greater choice, blending proven technology

options and utilization-based process innovation to deliver unique

manufacturing advantages. It is an engineered evolution precisely optimized for

functionality, flexibility, cost-effectiveness and longevity.

Common features evolved from DEK’s 265 family provide immediate user

confidence. In turn, a minimal learning curve and easy transfer of existing

product files result in faster process improvements. Horizon’s intuitive

Windows NToperating system, is the globally accepted user interface to

achieve better productivity effectively.

Horizon’s precision-engineered mechanical assemblies, advanced electronic

control systems and ISO9001 manufacturing procedures combine to deliver

maximum efficiency and quality through high yields, product flexibility and fast

changeover. The Horizon conforms to the following standards:

• CE: 89/392/EEC, 89/336/EEC and 73/23/EEC

• UL 1950, 3rd Edition 1995

• CAN/CSA C22.2 No950-95

Advanced equipment utilization programs to fine tune the process, together with

DEK’s applications resource, extend the reliability production engineers and

line operators can expect from the Horizon. The Horizon package addresses

future capacity requirements through its range of expansion options, process

enhancements and documented upgrade paths.

Chapter Issue 1 May 00 Engineering Specification 1

ENGINEERING SPECIFICATION

GENERAL DESCRIPTION

TECHNICAL SPECIFICATION

Screen Frames Specification

Type External (w x l x t) Internal (w x l)

Standard DEK 265 736 x 736 x 38/40mm

(29″x29″)

660 x 660mm

(26″x26″)

Optional Chase Adaptors DEK 260 585 x 585 x 38mm

(23″x23″)

508 x 508mm

(20″x20″)

Sanyo 550 x 650 x 38mm

Optional Screen Adaptors All common stencil sizes available:

Sanyo, Ekra, Fuji, Panasonic, MPM etc.

Image Position Centre, Front, Custom

Board Handling Specification

Minimum Size 40 x 50mm

Maximum Size 510 x 508mm (620 x 508mm)*

Thickness 0.2 - 6mm

Warpage Up to 8mm including PCB thickness

Underside Component Clearance Programmable 3 - 42mm

Transport Conveyors Programmable motorized

Transport Direction Left to Right

Right to Left

Left to Left

Right to Right

Interface Protocols All popular interfaces available

Board Location Patented Over the Top Clamps

Edge clamping*

Vacuum*

Foil-less Clamps with vacuum*

Registration Fully Automatic Vision

Process Parameters Specification

Print Speed 2 - 150mm/sec

Print Pressure 0 -20kg Programmable (Closed Loop Feedback)*

Print Gap 0 - 6mm

Stencil Seperation Speed: 0.1 - 20mm/sec

Distance:0-3mm

Print Modes ProFlow

Print Print

Print Flood

Flood Print

Adhesive

Paste Knead Programmable: Number, Period, On Demand

Vision Specification

Vision System Cognex 8100 Vision System

Camera Lighting Software Controlled Programmable Lighting

2Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

TECHNICAL SPECIFICATION

Fiducials 2 or 3

Fiducials Types Synthetic fiducial library or unique pattern recognition

Fiducial Size 0.5 - 3mm

Fiducial Position Anywhere on PCB (see Fiducials, Key Features)

Fiducial Error Recovery Auto Lighting Adjustment

Auto Fiducial Search

Smart Fiducial

Performance Specification

Alignment Stencil to Board Repeatability 6 sigma @ 25µm

Cycle Time 12.5 secs

10.0 secs*

Product Changeover 2 minutes#

New Product Set Up <10 minutes

Operator Interface Specification

Hardware Colour VGA Touch Screen Display, keyboard and mouse

Software Operating System Windows NT

Manuals Electronically on CD-ROM

Hard Copies Available*

Options Specifications

ProFlow Fully enclosed, high speed DirEKt Imaging system

Optional Temperature Control Unit

2D Inspection Full inspection capability of screen and board:

Basic

Advanced

Automatically triggered recovery sequences

Inspection outputs available to Statistical Process Control software

Tooling Magnetic Pillars

Form-Flex

AutoFlex programmable tooling (35mm pitch)

MultiFlex with or without vacuum

Dedicated Vacuum Plates

Under Screen Cleaner Paper - Fully programmable wet, dry and vacuum assisted paper

under screen cleaner

Vortex - Fully programmable wet/dry and vacuum assisted foam

cassette under screen cleaner

Paste Dispenser Fully programmable automatic paste dispensing system. Available

for 1kg and 500g cartridges

Temperature and Humidity Sensor Sensor to measure and display temperature and humidity with in the

printing area. SPC output available

Environmental Control Temperature Control Unit (TCU):

Controls the temperature of the printing area

Temperature and Humidity Control Unit (ECU):

Controls the temperature and humidity of the printing area

Statistical Process Control On board package to collect, manage and display critical process

parameters

Board Clamps Alternatives Edge Clamps

Foil-less Clamps

Chapter Issue 1 May 00 Engineering Specification 3

ENGINEERING SPECIFICATION

TECHNICAL SPECIFICATION

Remote Event Monitoring Desktop application for remote status monitoring and reliability

anaysis of printer

Generic Equipment Model On board package for communications with host using TCP/IP

interface

Selective Print Pass This option enables selective print or pass through of boards

Flexible Board Printing Option enables printing of thin flexible boards

Remote Board Stop Optional alternative to camera board stop for use with large and/or

heavy boards or carriers

Speed Up Option to reduce machine cycle time from 12.5sec to 10sec.

Remote Product Changeover Stand alone database program controlling and monitoring the

product file loaded, matches current board input

Off Line Editor Off line software package to generate and edit product files.

Available on board or via network

Network LAN package to transfer data within the factory network. Package

includes DEK netfile software, which can target product and SPC

files to location on the network

Certification Specification

CE 89/392/EEC

89/336/EEC

73/23/EEC

Subsequent Amendments

ETL UL 1950, 3rd Edition 1995

CAN/CSA C22.2 No 950-95

Services Specification

Power Supply 100, 110, 120, 200, 210, 210, 220, 230, 240 volt Single Phase

50/60Hz

Current:

110V - 16 Amps

120V - 15 Amps

200 - 220V - 8 Amps

230 - 240V - 7 Amps

Air Supply Air to ISO 8573.1 standard quality class 2.3.3

Pressure 5 -8 bar at 5 Litres/min

Shipping Information Specification

Approx Weight 900kg

Approx Dimensions 1314 x 1325 x 1592mm

(51.7″x 52.1″x 62.6″)

* Options

# Timed using AutoFlex

4Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

TECHNICAL SPECIFICATION

MACHINE FOOTPRINT

Chapter Issue 1 May 00 Engineering Specification 5

ENGINEERING SPECIFICATION

MACHINE FOOTPRINT

1314

85 1064 1113

312

1592

1285

1065

1195

1435

1572

1490

980 max

243

302

2230

500

R413

Monitor Omitted

for Clarity

Arc of Monitor Arm

Extremity of Monitor Tray

Follows the Arc of Monitor Arm

Plan View

Front View Side View (Right)

CAUTION

OVER CURRENT PROTECTION. Magnetic/thermal

over current protectors protect the machines’ internal

wiring and components from overheating/fire during

fault conditions. DEK require additional machine

supply protection with the fitment of a wall mounted

circuit breaker rated to 16 Amps and conforming to

national/federal regulations.

NOTE

All dimensions in millimetres

Board Transfer Height 820 - 980 mm

Screen Load Height 905 - 1065 mm

Services Required

Voltage:

100/110/120/200/210/220/230/240V Single Phase

50/60Hz

Current:

110V - 16 Amps

120V - 15 Amps

200 - 220V - 8 Amps

230-240V-7Amps

Air Supply:

Air to ISO 8573.1 standard quality class 2.3.3

Pressure 5 - 8 Bar at 5 Litre/min

Weight 900 Kg

KEY FEATURES

Camera System The camera assembly integrated into the Horizon is a compact assembly of

optics, lighting and a standard CCIR camera. The camera is fitted with a split

optic unit to allow the camera to capture the image from the stencil and board at

the same time. Thereby, eliminating the relative movement between the images

captured. The camera assembly incorporates ‘Telecentric Lenses’ and ‘Flat

Lighting’.

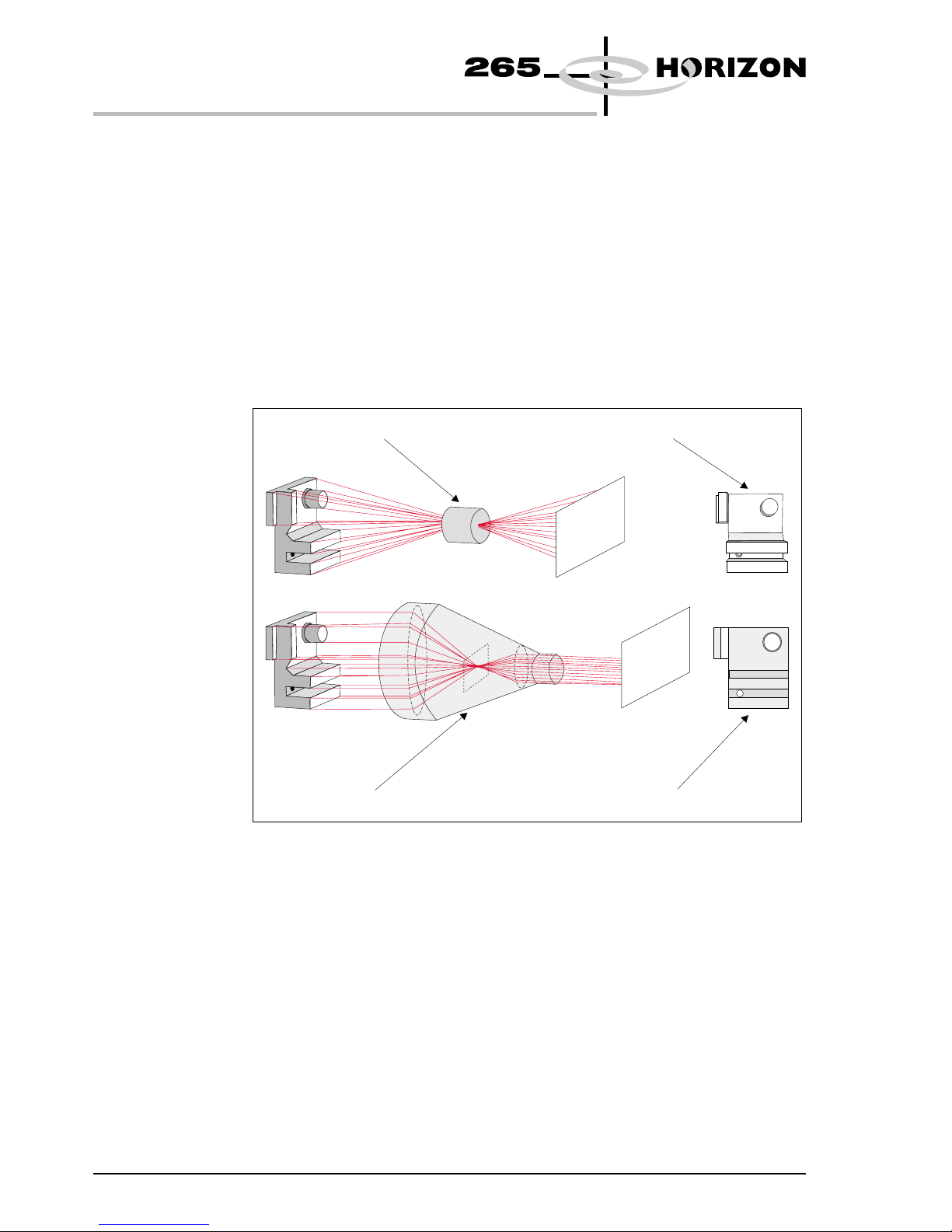

Telecentric Lens The optic unit within the camera assembly uses telecentricity to ensure that

board warping, distance between camera and board and the actual position of the

fiducials within the field of view do not affect the alignment accuracy.

6Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

KEY FEATURES

Conventional Lens Distorted Image

Undistorted Image

Telecentric Lenses Array

Variations in the distance between the optic unit and the board fiducials due to

uneven board surface are transparent when using telecentric lenses. With a

standard lens the diameter, centroid and position of a fiducial varies with this

distance, hence key elements in determining alignment of the board vary

depending on where the fiducials lie in the field of view.

Without DEK’s use of telecentric lenses, a pre-alignment stage would have to be

added to bring the fiducials into the centre of the field of view, before carrying

out a final alignment stage.

Chapter Issue 1 May 00 Engineering Specification 7

ENGINEERING SPECIFICATION

KEY FEATURES

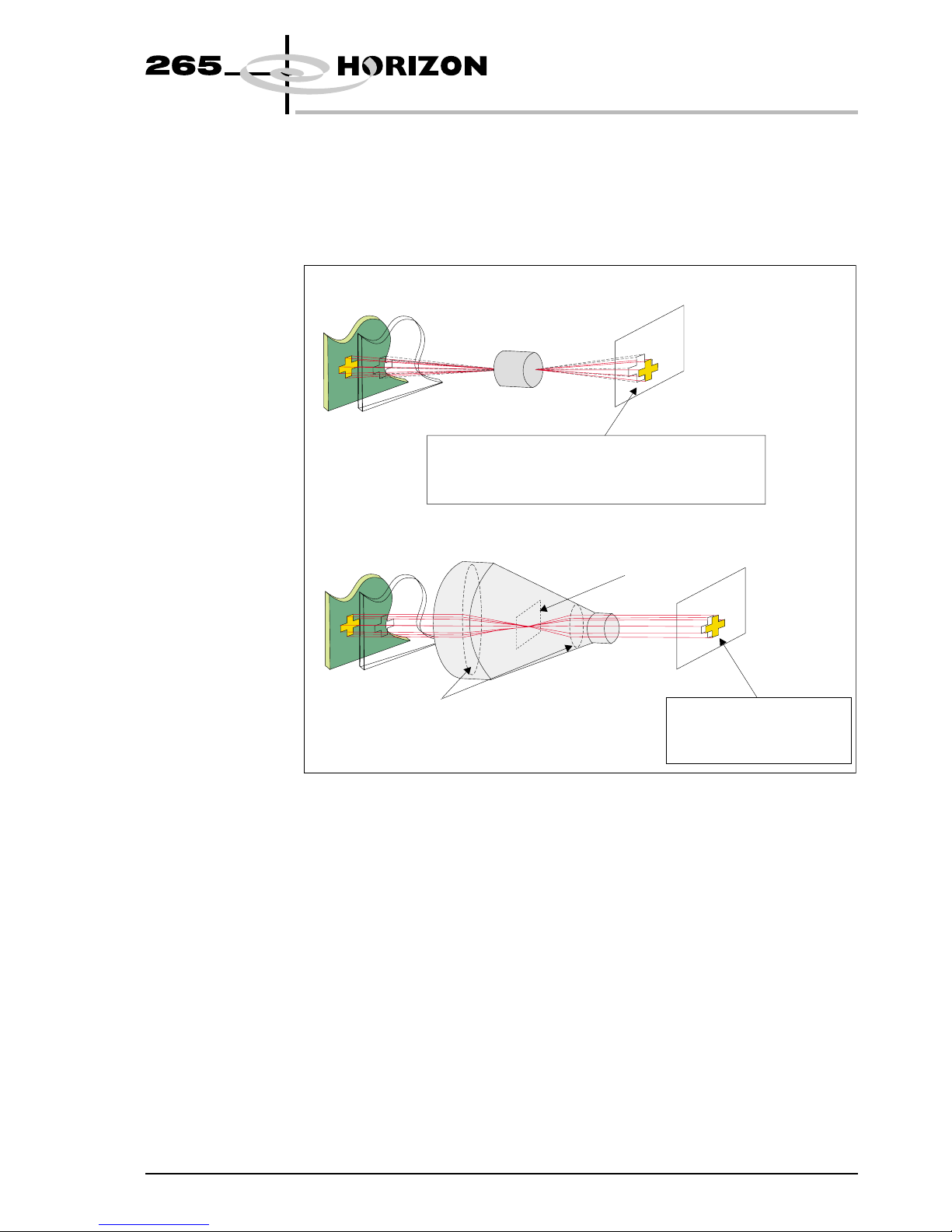

Conventional Lens

If the board to camera distance varies due

to uneven board surface, the position and size

of the fiducial will vary accordingly.

Telecentric Lenses Array

Lens

Telecentric Stop

All fiducials seen as

identical wherever they

appear in the field of view.

Flat Lighting Essential for any vision system is to have the highest quality images with which

to process. Poor quality images may result in a degradation of image processing

leading to less accurate alignment and if inspection is used, misleading results.

DEK’s camera assembly fitted to the Horizon has been specifically designed to

enable low quality boards to be aligned and inspected with equal accuracy as

gold/copper boards. The lower quality boards have uneven Hot Air Solder

Levelled (HASL) pads and features.

The uneven surface texture and irregularities of these features and pads would

cause dead zones, ie areas where there is no light and hot spots of light caused by

reflection of light from solder pads and wet solder paste.

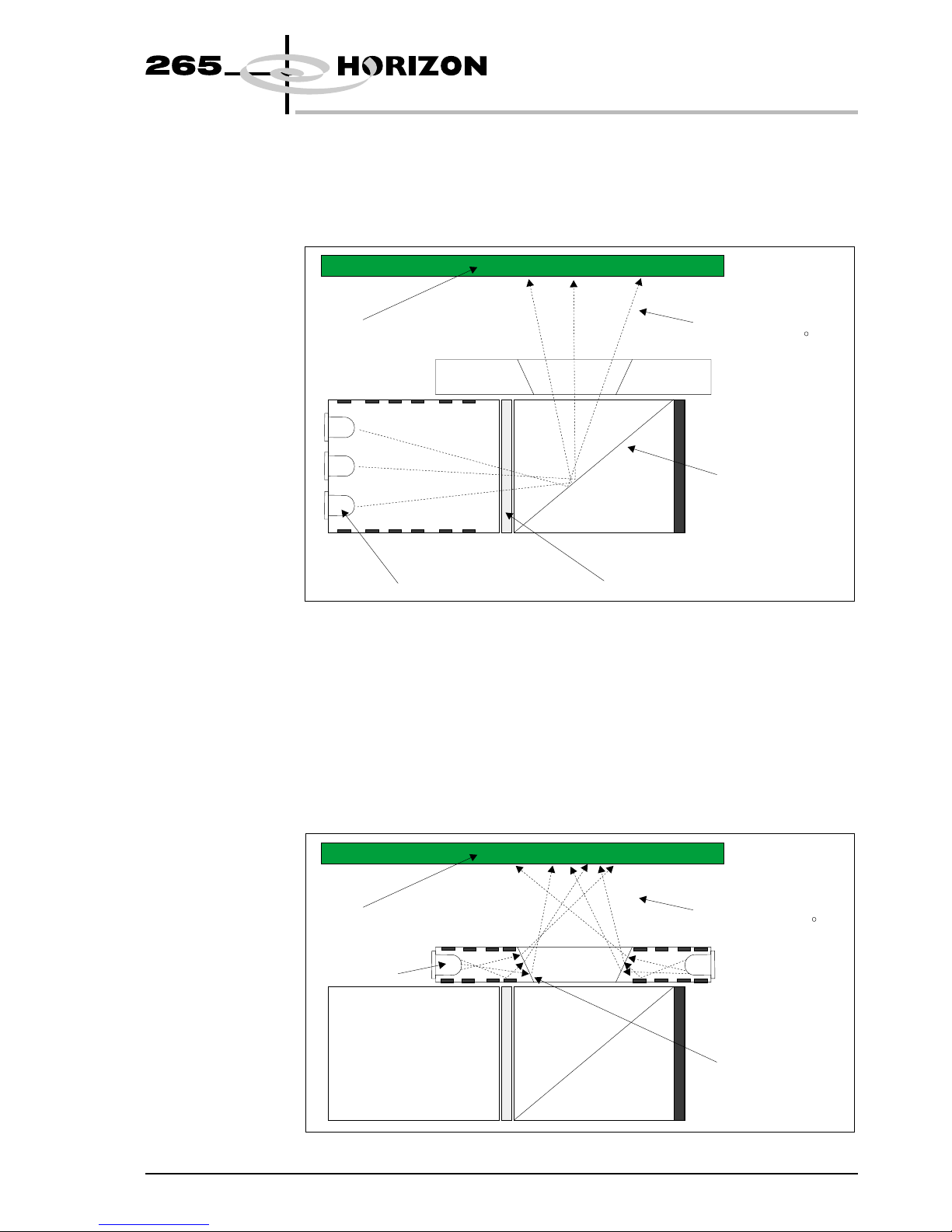

For high accuracy and reliable image processing DEK has incorporated a flat

lighting design within the camera assembly. This is achieved by utilizing two

light sources:

•Direct lighting - producing normal incidence and angles up to 25°

•Indirect/Oblique lighting - producing angles from 25° - 50°

8Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

KEY FEATURES

Light from a normal light source

HASL feature Surfaces not seen

by camera

Surfaces seen

by camera

Direct lighting is achieved by a block of six LEDs shining through a diffuser to

produce a very uniform light source. The light is passed through a cube beam

splitter which increases the illumination and the range of angles reaching the

board.

Indirect /Oblique lighting is used in addition to direct lighting to produce light

paths between 25° and 50° to create uniform illumination, eliminating hot spots

of light.

An array of 12 LEDs sited in a polished ring around the lens aperture produce a

light source which is reflected and scattered by the polished surface and the

white paint of the assembly to the fine ground conical inner ring. This produces

very uniform illumination which is radiated in all directions providing a very

balanced illumination of the board.

Chapter Issue 1 May 00 Engineering Specification 9

ENGINEERING SPECIFICATION

KEY FEATURES

Board

LED Array

Inner Ring

Light paths

between 25 and 50

Board

LED Array Diffuser

50/50 Beam Splitter

Light paths

between 0 and 25

PatMax The Horizon machine uses PatMax® object location software to produce

accurate repeatable stencil to board alignment. PatMax interprets geometric

shapes within objects. A square fiducial is interpreted by PatMax as four

separate line segments. The advantages of the system are greater accuracy at

lower image quality. The object can be a different size, or different orientation to

the object learned. The target can be partly obscured and degraded.

10 Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

KEY FEATURES

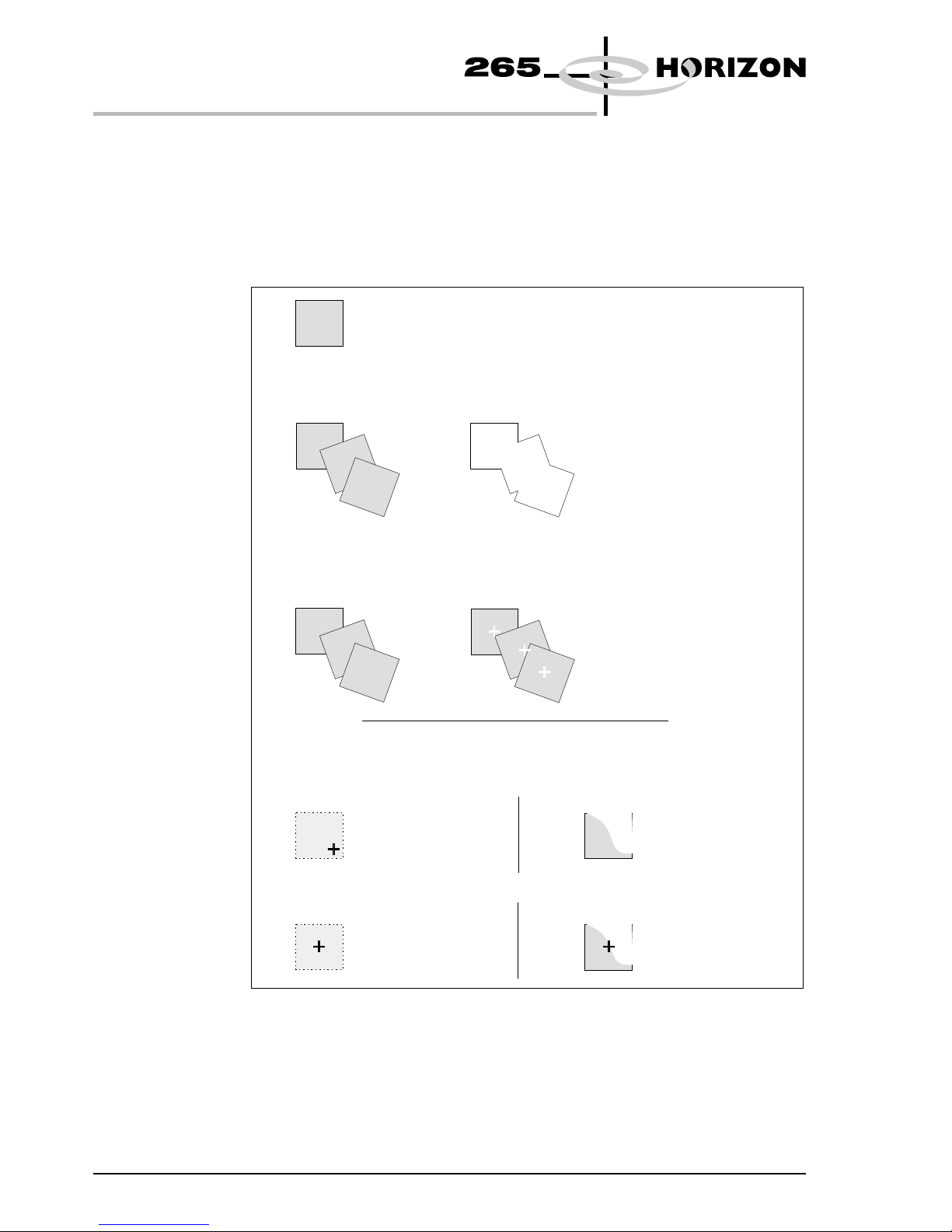

= Learned fiducial

Non PatMax Object Location Software - Confused Objects

PatMax Object Location Software - Confused Objects

Target

Target

Interpretation

Interpretation

Result

Result

Fail to Locate

X

Successful Location

of Three Objects

Non PatMax Object Location Software

PatMax Object Location Software

Degraded Object Partial Object

Result

Fiducial Not Found

Result

Successful Location

of Fiducial

Result

Successful Location

of Fiducial

Result

Fiducial Not Found

Fiducials The Horizon uses the vision system to capture and process alignment marks or

fiducials to align the stencil to each board before it is printed. The alignment

marks or fiducials are produced as part of the artwork of the board and stencil, in

the same relative position. The information processed is used to correct stencil

to board alignment.

The Horizon has a library of synthetic fiducials of the most commonly found

shapes. The dimensions of these fiducials can be tailored by the operator to fit

the fiducials on the board and stencil. The fiducial on the stencil can be can be

different from the fiducial on the board. After the vision system has been taught

these fiducial parameters, it is able to search the field of view of the camera and

recognize any features which resemble fiducials.

After finding a shape it is assigned a score comparing its shape and size to the

shape and size of the fiducial in the vision system library. This score is set

between 1 and 999, the better the fit the higher the score.

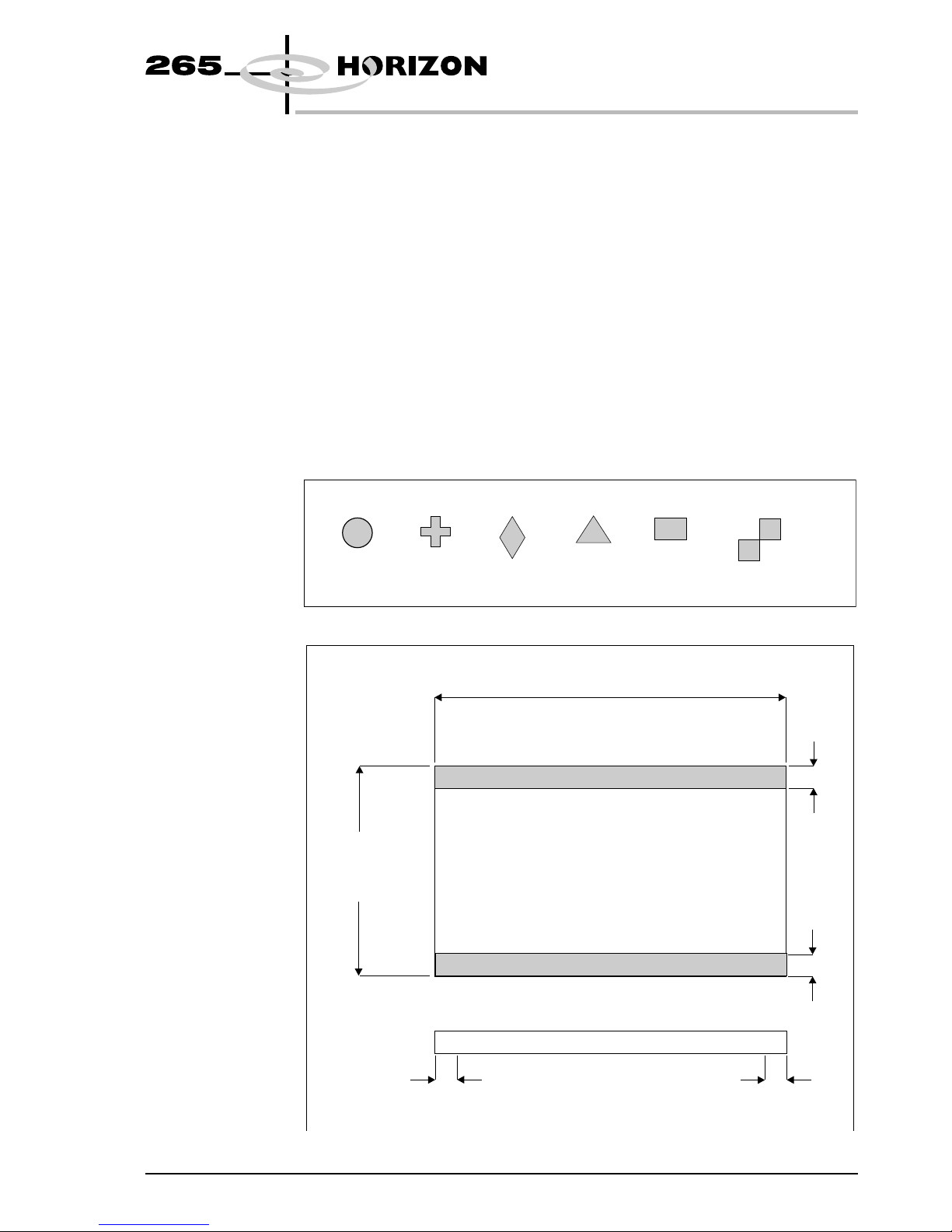

The fiducial shapes available is shown below:

Chapter Issue 1 May 00 Engineering Specification 11

ENGINEERING SPECIFICATION

KEY FEATURES

CIRCLE CROSS DIAMOND TRIANGLE RECTANGLE DOUBLE SQUARE

Board Length

Shaded Areas: No Printing and No Fiducials

Board

Width

3mm

3mm

3mmMustBeFree

of Underside Components

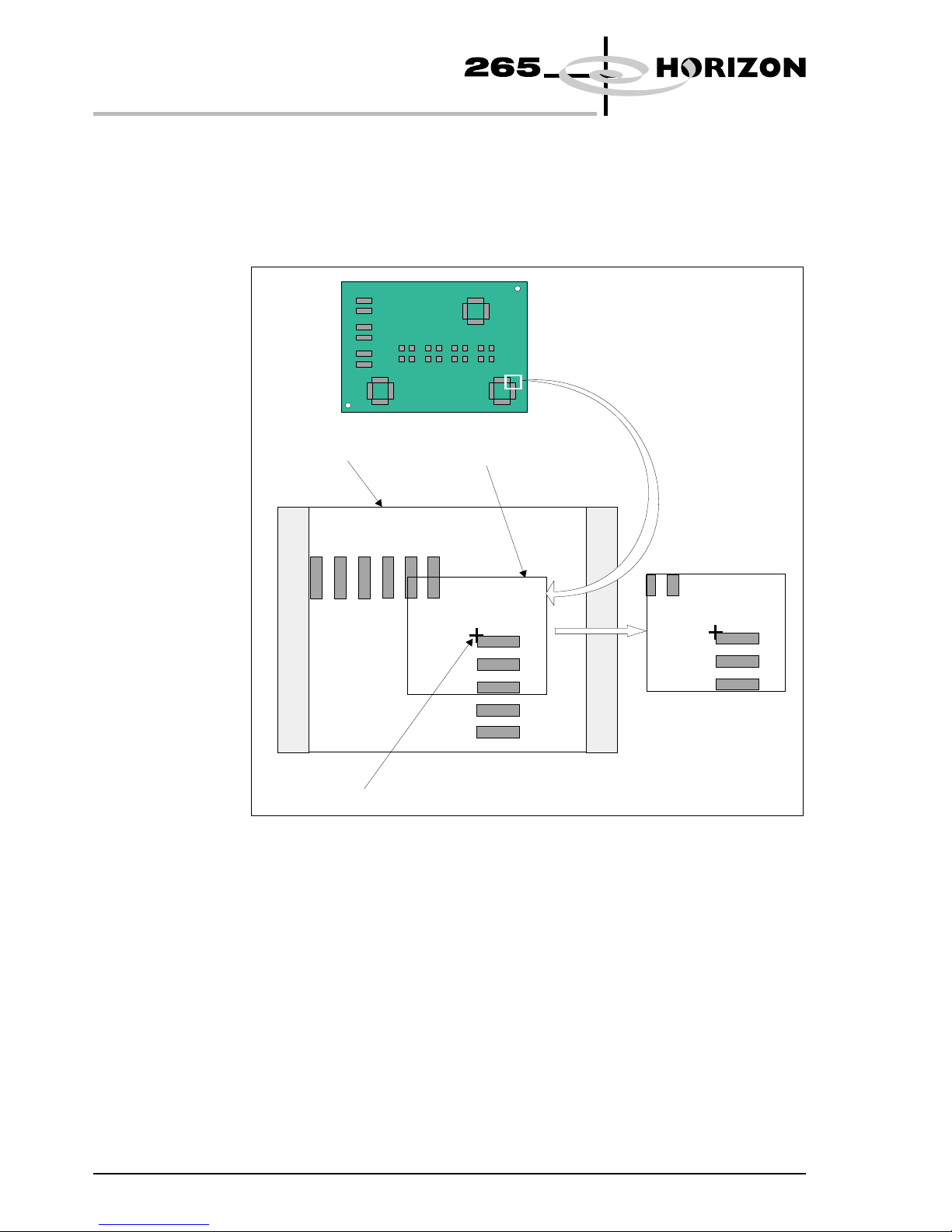

Video Model The video model is an alternative to using fiducials for stencil to board

alignment. Video model uses the correlation between the image of an area of the

stencil and the image of the same area of the board to align the two. This is useful

if the board or stencil has no fiducials or the condition of the fiducials does not

allow satisfactory recognition.

12 Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

KEY FEATURES

Field of View

Alignment Point

Sample Window

Video Model Fiducial

Windows NT The Horizon uses Windows NT operating system due to its inherent robust

nature. It is a globally accepted and industry standard user and programming

interface.

The main printer control, vision and user interface modules run under Windows

NT with the time critical, board handling and axis jogging routines running on

the real time operating system of the Baldor® Optimized Control NextMove

ISA card.

The Windows NT operating system provides built in networking compatible

with all industry standard networks as well as allowing standalone applications

such as QC Calc to be run onboard alongside the printer control system.

Chapter Issue 1 May 00 Engineering Specification 13

ENGINEERING SPECIFICATION

KEY FEATURES

Diagnostics The Horizon machine contains a diagnostic module which enables the following

functions:

•Calibration of the machine

•Aid to machine fault diagnosis by means of

- Individual access and control of modules

- Access to the machine I/Os

This module can be password protected and can be enabled without the need to

initialize the Horizon. It allows the user to control the sequence of the machine

so that a particular module can be exercised.

Initiating the diagnostic module allows the user access to the following menu

options:

Selecting System allows access to the following functions:

•Digital and analogue I/Os

•Functioning of tricoloured beacon

•Facility to change various machine passwords

14 Engineering Specification Chapter Issue 1 May 00

ENGINEERING SPECIFICATION

KEY FEATURES

Table of contents