Page 9 of 64

1 General

The MTP-1500 series of modular thermal printers is designed specifically for the high performance, size and durability

requirements of cut and drop applications. The compact size and high performance characteristics, coupled with its

rugged design also make it ideal for the kiosk environment.

Four models make up the MTP-1500 Series:

· MTP-1530-SF - 80 mm (3.15 in) paper width , Full Cut . (Part # 901033-0006)

· MTP-1530 -SP - 80 mm (3.15 in) paper width , Partial Cut. (Part # 901034-0006)

· MTP-1532 -SF – 82.5 mm (3.25 in) paper width , Full Cut. (Part # 901033-0010)

· MTP-1532 -SP – 82.5 mm (3.25 in) paper width , Partial Cut. (Part # 901034-0010)

1.1 Definitions

1.1.1 Standard Mode versus Page Mode

Standard mode means printing data as it is received like most serial mode printers. If data is not received fast enough

to keep the printer busy, the printer will print data it has received and then stop and wait for more data to be received

so it can print a little more. This is the most commonly used mode of operation but anytime the printer has to stop and

then restart, there is a possibility of reduced print quality.

· Page mode means that all the data to be printed on a page is received before printing begins so once the

printing process starts, an entire page is printed at full speed.

· Most commands and parameters are the same for both standard mode and page mode but the ESC SP, ESC 2,

and ESC 3 are set independently in standard mode and page mode, See section 4.2 Control Codes and Control

Sequences List .

· Some commands apply only to page mode and some commands are ignored in page mode.

See Table xxx +++ add bookmark to COMMAND LIST table.

· Ladder bar codes can be printed only in page mode.

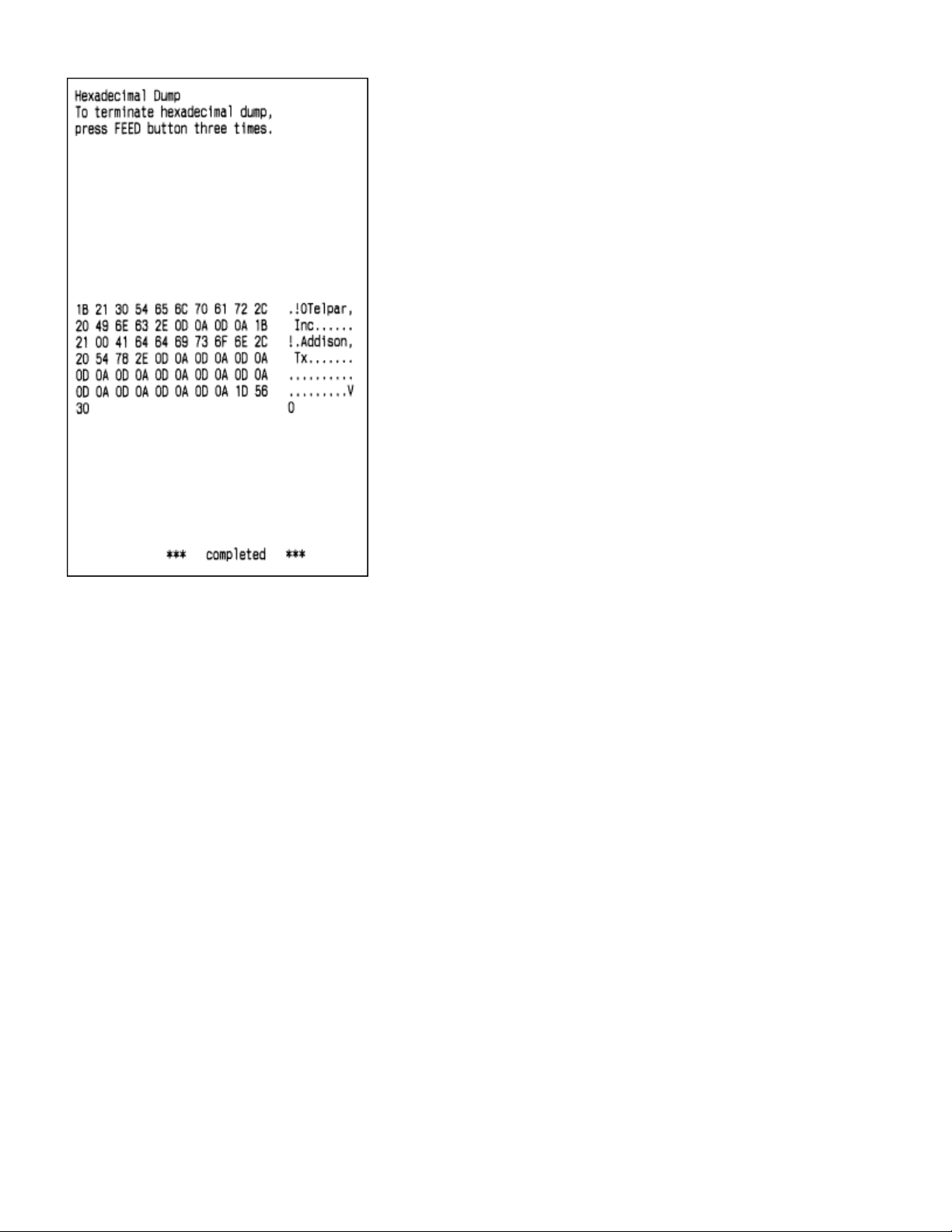

1.1.2 Hex Dump Mode

This function is sometimes useful for diagnosis of application programs when the printer does not perform as

expected. In hex dump mode, the printer prints the hexadecimal code for each character received rather than

processing the data as printable text and as control commands. The exception is that DLE EOT (real time STATUS

request) and DLE ENQ (Real time request to printer) are executed as received even in hex dump mode. The

hexadecimal notation is printed at 10 characters per line on the left side of the page and the printable characters (when

possible) are printed on the right side of the page. Control codes print as periods on the right side section of the

printout to help locate specific areas of the message to see what codes were actually received by the printer. After all

data has been sent to the printer, pressing the paper feed button will flush the buffer and print the last line of data

received.

Hex dump mode is initiated in any of three ways:

1) Open the platen, hold the paper feed button down, turn on power, then close the platen and release the paper

feed button.

2) Set DIP switch DPSW2 position 5 ON and then turn on power.

3) Send the appropriate GS ( A command. On entering hex dump mode, the printer prints a 4 line header

“Hexadecimal Dump”, a blank line, “To terminate hexadecimal dump”, “press FEED three times.”

Hex dump mode is terminated by

1) pressing the paper feed button three times in quick succession or

2) by turning DIP switch DPSW2 position 5 OFF and turning power back on.

Print Sample

Figure 1 Print Sample