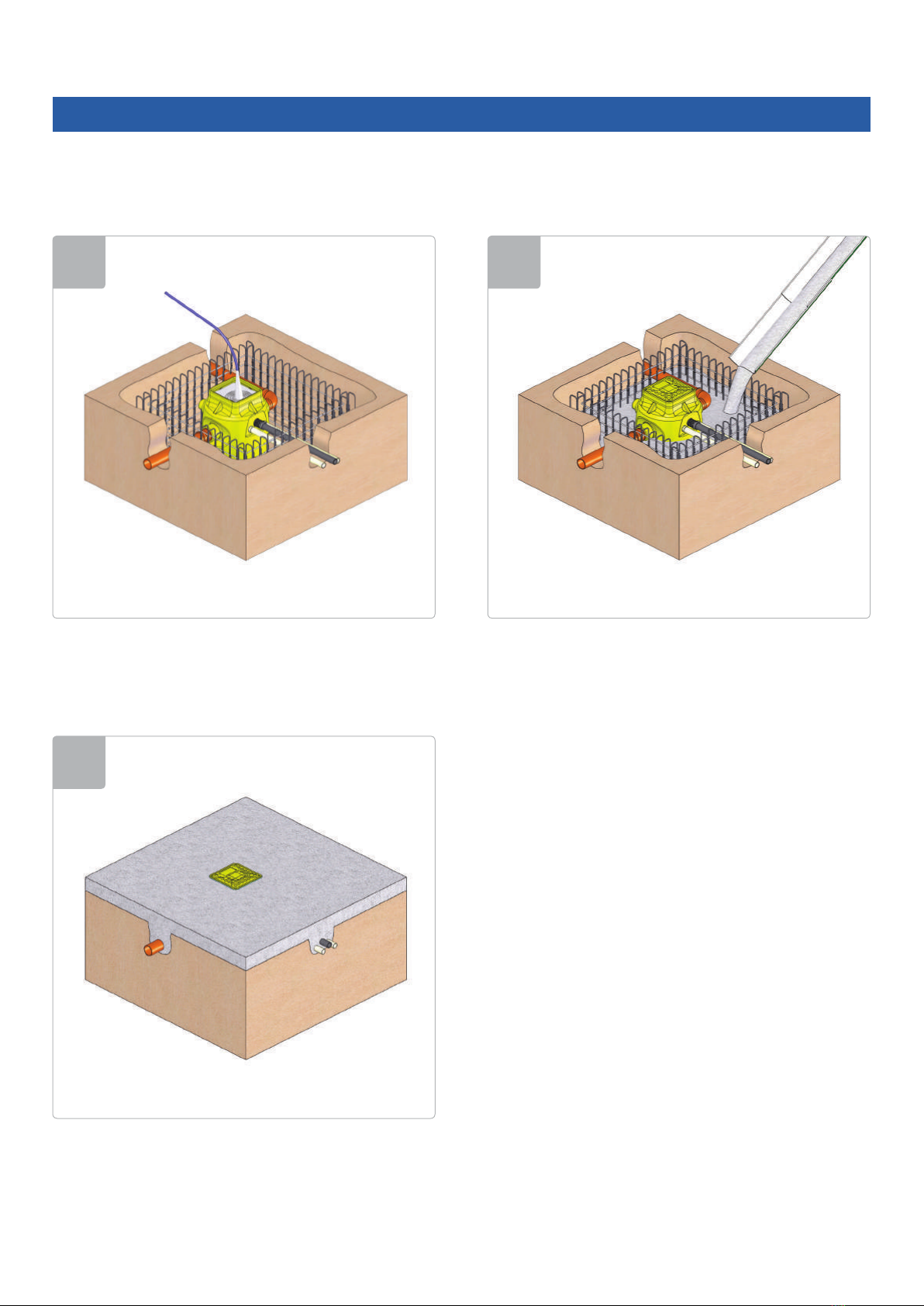

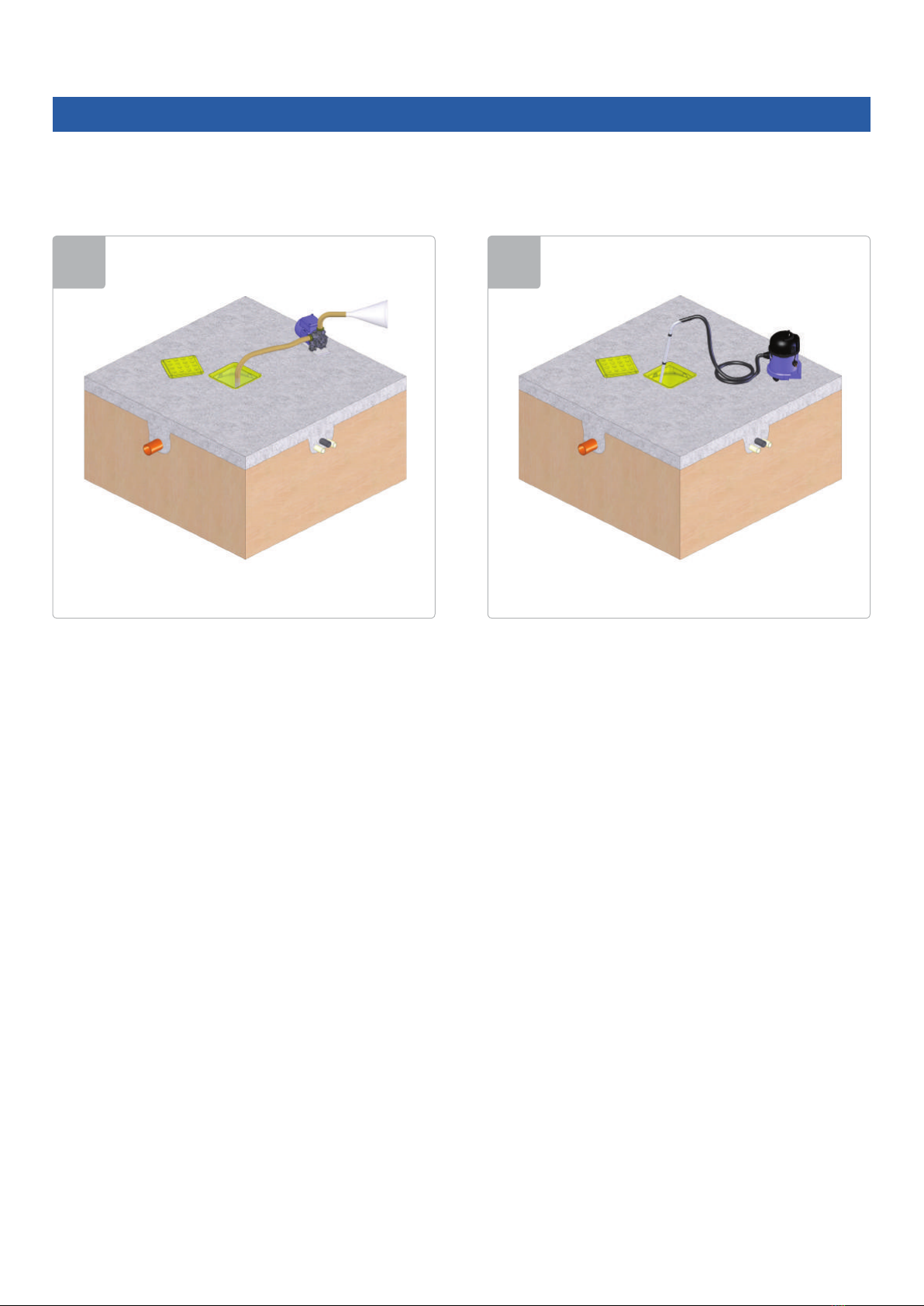

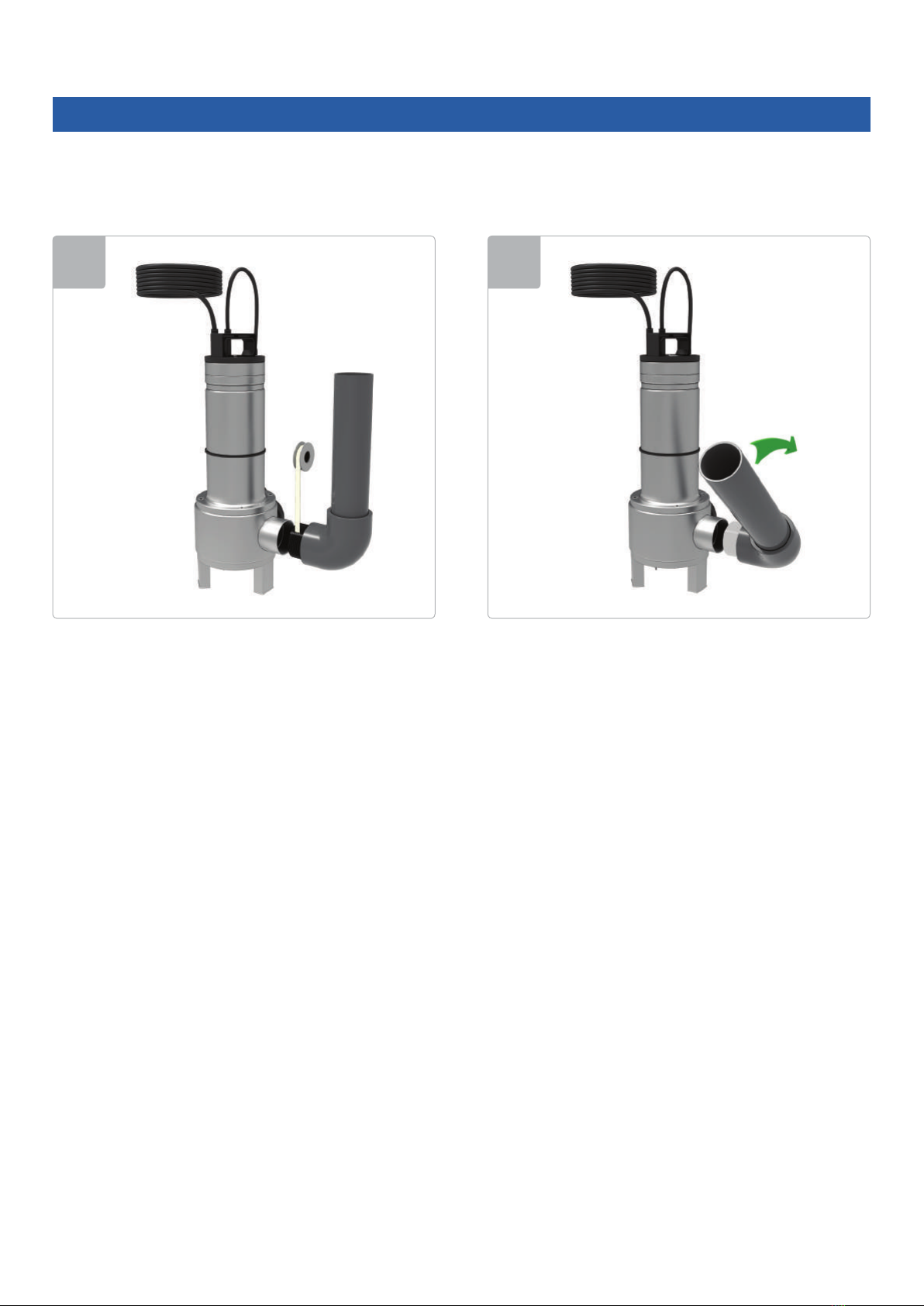

Delta Membranes Delta Foul V3 User manual

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

SKC

SKC AirChek Connect operating instructions

Summit

Summit SNS Installation, operation and maintenance manual

CET

CET PFP-27hp-HV instruction manual

Debem

Debem MB 80 Instructions for use and maintenance

Hoppecke

Hoppecke Electrolyte Circulation System Installation and operating instructions

Pentair

Pentair Jung Pumpen COMPLI 300 E instruction manual

AFRISO

AFRISO PrimoSol 130 Series operating instructions

Gardena

Gardena WSP 7000 operating instructions

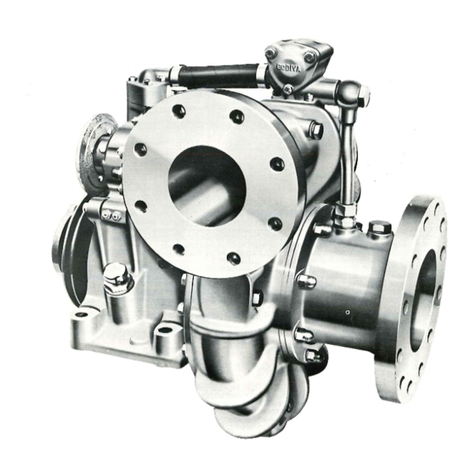

Idex

Idex Godiva GV10000 installation manual

Pentair Flotec

Pentair Flotec FP5200 Series Installation and operation manual

DAE Pumps

DAE Pumps Sonora S330 instruction manual

Flotec

Flotec FP4155 owner's manual

Graco

Graco 225014 Instructions-parts list

Advance acoustic

Advance acoustic 4000 Installation and service manual

T.I.P.

T.I.P. DRAIN 6000/36 operating instructions

Becker

Becker U 4.190 operating instructions

Kessel

Kessel Easy Clean Free Mix & Pump Disposal instructions

Gormann-Rupp Pumps

Gormann-Rupp Pumps AMT 489 Series Specifications information and repair parts manual