Delavan SONAC 120 User manual

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

1

An L&J Technologies Co.

5911 Buttereld Road

Hillside, IL 60162

Phone: 708-236-6000

Fax: 708-236-6006

INSTALLATION & OPERATION

MANUAL

SONAC 120

2

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

was started in 1976 to offer new and innovative

electronic designs in tank gauging. L&J’s new products always used the

latest electronics and therefore the company quickly grew.

Ten years later L&J bought GPE. Along with GPE, L&J bought

, a GPE afliate that manufactures ttings and valves for

the same type of tanks that used the gauging equipment.

A short time later, all 3 companies were reorganized under one corporate

entity called . In 1994, a brand new, state-of-the-art

manufacturing facility was built to bring all of the L&J Technologies

manufacturing efforts under one roof.

In 1996, L&J bought , a manufacturer of liquid level controls

and Hi/Low level switches for the boiler, process, and liquid storage

industries.

On February 28, 2000, L&J purchased Durlam Associates, (now Durlam

Inc.). is located in Houston, Texas and is the leading

manufacturer of berglass reinforced plastic (FRP) Derakane 470

conservation vents and ttings.

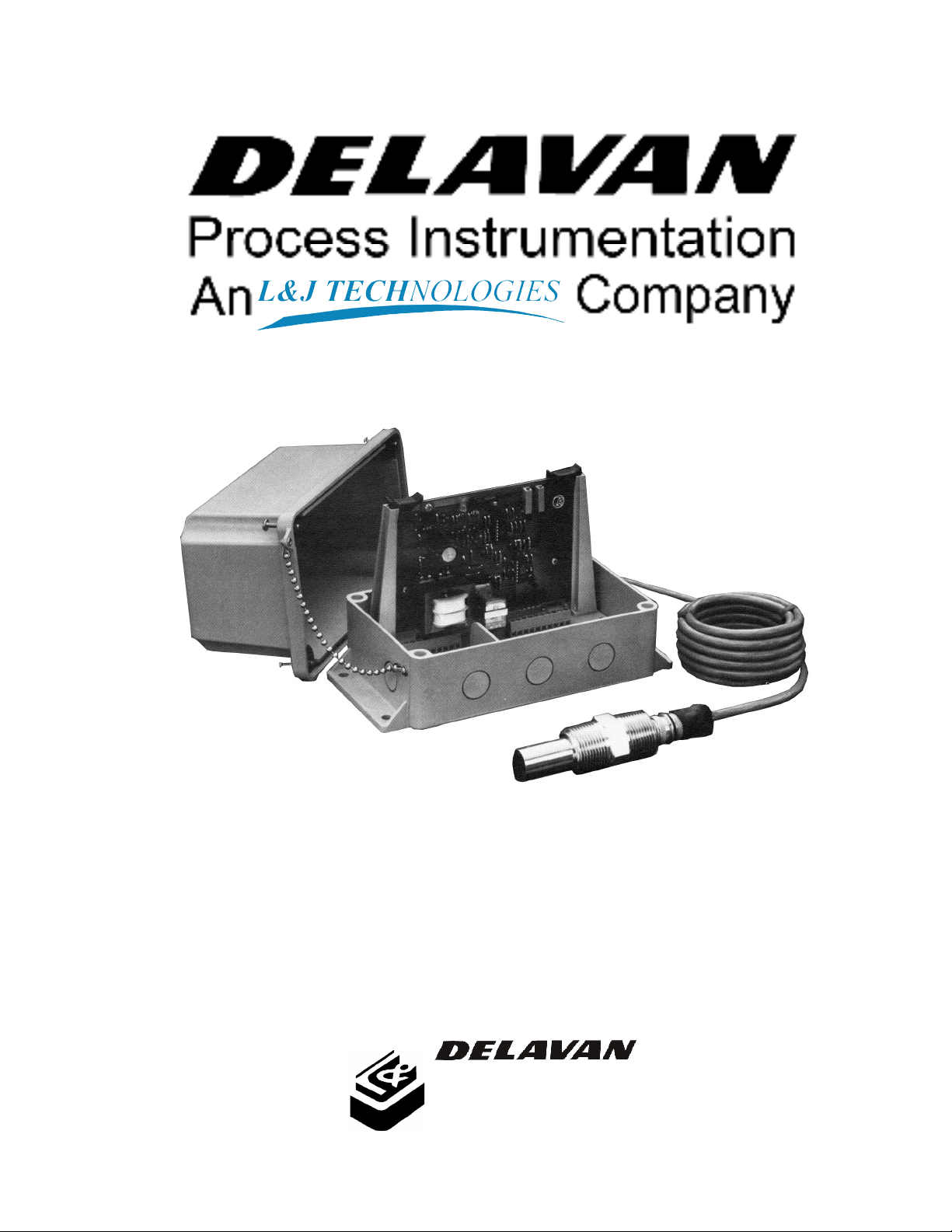

On March 31, 2000, L&J purchased Delavan Process Instrumentation

in Naugatuck, CT. is a well-established name in

ultrasonic, capacitance and microwave point level and continuous level

measurement for liquids and solids. Delavan was relocated to L&J

Technologies corporate headquarters in Hillside, Illinois.

Today, the L&J family of companies is the world’s largest manufacturer

specializing in the monitoring, management, and control of bulk liquids.

L&J provides quality products for the Petroleum, Petrochemical,

Chemical, Food, Pharmaceutical, Pipeline, Steel, Water Treatment and

Biogas ( ) Industries.

Visit L&J Technologies on the internet at www.ljtechnologies.com

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

3

TABLE OF CONTENTS

1.0 Introduction...................................................................................... 4

1.1 Description................................................................................ 4

1.2 Principle of Operation ............................................................... 4

1.3 Specications............................................................................ 4

2.0 Installation........................................................................................ 4

2.1 Unpacking................................................................................. 4

2.2 Mechanical Installation ............................................................. 4

2.3 Electrical Installation ................................................................. 7

3.0 Operation.......................................................................................... 7

3.1 General ..................................................................................... 7

3.2 Controls and Indicators/Calibration........................................... 7

3.3 Start-Up .................................................................................... 8

4.0 Maintenance & Service ...................................................................8

4.1 Product Warranty ........................................................................8

4

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

1.0 INTRODUCTION

1.1 Description

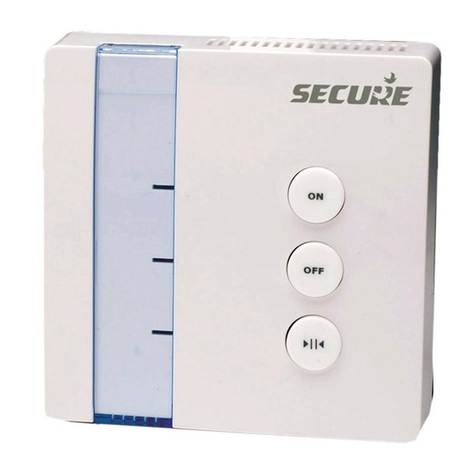

This device is a single point, electronic switch for ON-

OFF level control of liquids, at temperatures from -65ºF

(-54ºC) to 400ºF (204ºC) and pressures to 4000 psi.

Typical applications include, crude and rened petroleum,

hot asphalt, solvents, chemicals, liqueed air fractions, LPG,

LNG, and most other liquids

1.2 Principle of Operation

The SONAC/120 Switch is comprised of a sensor,

interconnecting cable and electronic control unit.

The sensor is a magnetostrictive device consisting of a

diaphragm, nickel drive tube, bias magnet, drive coil and

pickup coil. The sensor diaphragm is electronically driven

to oscillate at its resonant frequency with a high-velocity, low

amplitude motion. When the product level covers the sensor,

the diaphragm is dampened. This produces a change in the

output signal level from the sensor’s pickup coil. The control

amplier, which is in a regenerative feedback loop circuit

with the sensor, processes the signal change, and actuates

the output relay for the desired end function.

SELF-TESTING FEATURE: A logic network is included

in the feedback loop to “prove” the mechanical and electrical

integrity of the sensing circuit. If an open or short circuit

occurs in the sensor connecting cable, or control amplier,

the relay immediately transfers to the alarm condition.

1.3 Specications

Supply Voltage Normal Absolute Limits

115 VAC 95-135 VAC

230 VAC 190-270 VAC

or 12-24 VAC

12-24 VDC

Frequency, AC Power 50-60 Hz 45 Hz Minimum

Time Delay Standard, 50 ms to

Adjustable 15 seconds

Failsafe Switch selectable, High

or Low Level

Environmental Rating NEMA 4X, IP55

Control Unit

Temperature Amplier -40 to 75ºC

Sensor Temperature, Temperature and pressure

Pressure Rating limits vary with sensor

model. Consult SONAC/120

data sheet for specication

information.

Sensor Mounting/ 1” NPTM

Process Connection

Distance-Sensor to Control 150 ft (45.7M with PVC

Unit, Maximum

Insulated Cable (BLUE)

100ft (30.5M) with TFE

Insulated (WHITE)

Indicators Two, light emitting diodes (LED).

RED - Illuminated when product is

present at sensor

YELLOW - Illuminated when relay is

energized

Output Relay, DPDT 2 Form C Contracts

5 A at 120 VAC Non-Inductive

3 A at 240 VAC Non-Inductive

3 A at 24 VDC Non-Inductive

Shipping Weight Control: 5 Pounds (2.5 Kilograms)

Sensor: 1.6 Pounds (.68) Kilograms

2.2 Mechanical

AMPLIFIER HOUSING

.875

(22.2)

2.00

(51)

6.000

(152.4)

1.062

(27)

8.625

(219)

2.00

(51)

3.00

(76.2)

9.375

(238)

1/2” Condult knockout

8.187

(208)

5.179

(131.5)

INSTALLATION DRAWING

NOTE: DIMENSIONS IN PARENTHESES DENOTE MILLIMETERS

2.0 INSTALLATION

2.1 Unpacking

Remove the system from the shipping carton and check the

nameplate model number against the packing list before

destroying any packing material. Remove plastic protective

closures from sensor

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

5

SENSORS:

Basic installation dimensions for sensors are shown in gure

(1). Figure (2) shows a “Y” connection, gure (3) shows an

installation using conduit.

Mounting the sensor in the horizontal position is recommended.

If sensor must be mounted vertically (from top of tank or bin),

install the sensor at an angle (30º) to prevent entrapment

of air bubbles on the sensor face, which may cause false

responses.

1.9844

(50.4)

.875

(22.22)

1.50

(38.1)

2.500

(63.5)

Lanish, Tri-Clover

Tri-Clamp Type

16 amp (34) 1.5”

(38.1) pipe size

FIGURE 1

1-11 1/2 NPT

(25.4)

Stainless Steel

Sensor

625

(15.9)

1.3125

(33.3)

Cable Connector

.5625

(14.3)

Single Sensor, Sanitary Ladish Fitting

(USDA Approved for AAA Sanitary Service)

.5312

(13.5)

1.375

(35)

.875

(38.1)

1.50

(38.1)

1 NPT

(25.4) Hermetic Connetor

1.93

(49)

2.50

(63.5)

Single Sensor, Standard Hex Fitting

Verical Instal-

lation

1 NPT Fitting

(25.4)

Tank Wall

Installation for small

vessels or pipes.

1 NPT Fitting

(25.4)

Installation Suggestion

Sensor with

Conduit Attachment

Install sensor so sensor face is at least four inches away from

non-liquid surfaces, for pipe mounting, use “Y” connection.

Install the sensor so that the rear of the sensor, where the

cable attaches, is kept dry.

FIGURE 2

FIGURE 3

6

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

CABLE ASSEMBLIES:

Cable Assemblies, (BLUE ) P/N 23276,77,78 are PVC

Insulated, and are rated for service from -65ºF to +220ºF

(-54ºC to +104ºC).

Cable Assemblies, (WHITE) P/N 23273,74,75 are

TFE Insulated, and are rated for continuous service at

temperatures from -425ºF - 225ºC cryogenic to +400ºF

(204ºC)

CABLE LENGTH:

The maximum permissible cable length varies with the

type of cable used. For PVC insulated cable (BLUE), the

length must not exceed 150 ft. or 45.7M. Blue cable length

over 75ft or 22.8m must have capacitor C1 removed (see

Figure 4). For TFE insulated cable (WHITE), the length

must not exceed 100ft. or 30.5M. White cable length

over 50ft or 15.2m must have capacitor C1 removed

(see gure 4). If a eld splice must be made, use ONLY

splicing techniques approved for shield cables.

CONTROL UNIT:

The electronic control unit was designed for eld mounting

in wet, corrosive environments. Good installation practice is

to mount the unit in an accessible location, as free as possible

from vibration, temperature extremes, and corrosive vapors,

where it is protected from mechanical damage and accessible

for calibration and service. In wet service areas, to prevent

moisture accumulation in the enclosure, conduits should enter

the enclosure from below.

Figure 4

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

7

2.3 Electrical Installation

All electrical connections are made to the terminal strip in

the enclosure. Remove the cover, and the plug-in control

board, and wire the unit to power and control conduits in

accordance with applicable electrical codes. Refer to the

wiring diagram (2.3.1) for proper connections.

Do not substitute other cable for the special cable supplied by

DELAVAN for connection from the control unit to the sensor.

If the distance between the sensor and control exceeds the

stated cable length, consult the factory for specic installation

instructions.

DO NOT INSTALL, OR REMOVE THE PRINTED

CIRCUIT CARD WITH SYSTEM OR RELAY

CIRCUITS ENERGIZED, SERIOUS DAMAGE CAN

OCCUR TO CARD CONNECTIONS.

2.3.1 Terminal Designations:

Class I (Line Voltage) Terminals

1) Chassis Ground

2) Line Neutral

3) Line 115 VAC

4) Line 230 VAC

5) First set of Contacts N.C. (Power OFF)

6) Common

7) N.O.

8) Second set of Contacts N.C. (Power OFF)

9) Common

10) N.O.

Class II (Low Voltage) Terminals

11) Sensor (Black Lead)

12) Not Used

13) Sensor Shield (Bare Wire)

14) Not Used

15) Not Used

16) Low Voltage Input +24 v AC or DC

17) Low Voltage Input -

18) Not Used

19) Not Used

20) Sensor (White or Clear Lead)

3.0 OPERATION

3.1 General

3.2.1 Time Delay

A 20 turn potentiometer is furnished to adjust the time

delay between the sensor change of state (wet to dry

or dry to wet) and the relay actuation. The time delay

range is 50 milliseconds to approximately 15 seconds

maximum delay on and off.

3.2.2 Gain Control

A 20 turn potentiometer is furnished to match the

amplier gain with the sensor. CW rotation increases

the gain.

3.2.3 Liquid Level Indicator

A RED LED is illuminated when the product is pres-

ent at the sensor.

3.2.4 Relay Status Indicator

A YELLOW LED is illuminated when the relay is

energized.

3.2 Controls and Indicators

The Failsafe Switch determines the relay state when the

liquid is present. Failsafe high or failsafe low does not

indicate the physical location of the sensor installed in the

vessel.

This section contains the calibration and operational

information for the SONAC/120 Switch

3109

8

765

4

21 20

191817

1615

14

13

1211

ASSEMBLY NO: 42854

INSTR. MANUAL:

42858

RELAY CONTACTS

LOW

FAIL

SAFE

RELAY

FUNCTION

HIGH

FAIL

SAFE

SENSOR

STATUS

RELAY

STATUS

SONAC

NO

C

NC

NO

C

NC

230 VAC

115 VAC

GAIN

SENSOR

WHITE

LOW

VOLT

INPUT

SENSOR

SHIELD

TIME DELAY

SENSOR

BLACK

8

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

3.3 Calibration

3.3.1 Set Time Delay Control 20 turns

clock-wise Gain Control 20 turns counter-

clockwise.

3.3.2 With the product level below the

sensor,(sensor is dry) apply power to the

control unit.

3.3.3 At this condition the RED LED should be

on and disregard the YELLOW LED.

3.3.4 Turn the Gain Control clockwise until the

RED LED just goes out (this will be the lower edge

of the window). Counting the turns, continue turning

the Gain Control clockwise until the RED LED just

come on again (this will be the upper edge of the

window).a

3.3.5 Now turn the Gain Control ½ of the amount

counterclockwise (this will be in the center of the

window). SEE BELOW

3.3.6 Set the Failsafe Switch to the position

required for your application. (See 3.2.1)

3.3.7 Set the Time Delay to the value required by

your process by rotating time delay control CCW.

NOTE: Time Delay Control Position.

Full Clockwise - Greater than 10 seconds.

Full Counter-Clockwise - Less then 100

milliseconds.

3.3.8 System is calibrated

4.0 MAINTENANCE & SERVICE

4.1 One-Year Product Warranty

DELAVAN PROCESS INSTRUMENTATION, control

products will be replaced, put in good operating condition,

or the purchase price refunded, at the option of DELAVAN,

free of charges except transportation, if defective in their

manufacture, labeling, packaging, or shipping, and if notice

of said defect is received by DELAVAN within one year from

the date of shipment. The cost of such replacement, repair

or refund of purchase price shall be the exclusive remedy

for any breach of any warranty, and DELAVAN shall not be

liable to any person for consequential damages for injury or

commercial loss resulting from any breach of any warranty.

DELAVAN make no warranty of tness for a particular

purpose, and makes no other warranty, express or implied,

including implied warranty arising from course of dealing

or usage of trade.

3.3.1

3.3.5 set point

3.3.4

red on

gain pot rotation CW

3.3.4

red on

red out

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

9

Page intentionally left blank

10

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

5911 Buttereld Rd.

Hillside, IL 60162

PH: (708) 236-6000

FAX: (708) 236-6006

E-MAIL: [email protected]

REACHING NEW LEVELS

IN

PROCESS MEASUREMENT

Table of contents

Popular Switch manuals by other brands

Brocade Communications Systems

Brocade Communications Systems VDX 6940 Series Hardware installation guide

HP

HP ProCurve 8100fl Installation and getting started guide

Cisco

Cisco RSP7000 Installation and configuration

Rontan

Rontan PALM SWITCH-S SC22 user guide

D-Link

D-Link DES-3528 - xStack Switch - Stackable Hardware installation guide

iPuray

iPuray BRT-706 quick start guide