Delfin MTL202DS Installation instructions

Equipment classification: Industrial vacuum cleaners

Operator’s and maintenance manual

Original and official manual

Rev.17/12/2019

Read this manual carefully before using the vacuum cleaner

MTL202DS

MTL202DSLP

Introduction

The manual must be kept with the vacuum cleaner in case of resale!

© Copyright DELFIN S.r.l.

2019

This manual provides all the information needed to use and service your vacuum cleaner. Good

operation and durability depend on proper maintenance and careful use.

Before leaving the factory, this particular model has undergone stringent tests to ensure utmost

reliability. Always check however to make sure the vacuum cleaner has not been damaged during

transport in such a way as to affect operation and safety.

This manual should be considered an integral part of the vacuum cleaner and must be kept

together with the unit until this is scrapped. In case of loss of or damage to the manual, ask

DELFIN

for a new copy.

The technical details contained in this manual are the property of

DELFIN

and should be deemed

of a confidential nature.

Even partial reproduction of the graphic project, the text and the illustrations is legally forbidden.

Some details shown in the illustrations in this manual may be different from those of your vacuum

cleaner. Some component parts may have been removed for greater clarity.

For easier reference, this manual is split into sections, identifiable by specific graphic symbols.

The subjects dealt with in this manual are those expressly required by "

Machine Directive

2006/42/CE

"and the technical details shown are those provided by the manufacturer at the time

of compilation. For ATEX Vacuums, the reference directive is the 2014/34/EU.

This manual must be kept in a place accessible to all the personnel charged with operating and

servicing the vacuum cleaner.

In case of any doubts, always immediately phone the

After-Sales Service

.

The competent Law Court for all disputes is that of TURIN (Italy).

TECHNICAL SERVICE

Our engineers are available to help you in case any problem occurs.

Please call +39 011. 800550

Contents

Information section

1.1 Identification of main parts .......................................................................................................................... - 1 -

1.2 Accessories provided......................................................................................................................................- 3 -

1.3 Identification details of manufacturer .....................................................................................................- 6 -

1.4 Marking plate ......................................................................................................................................................- 6 -

1.5 Intended uses....................................................................................................................................................- 7 -

1.6 Allowed environmental conditions............................................................................................................- 7 -

1.7 Storage..................................................................................................................................................................- 7 -

1.8 Scrapping .............................................................................................................................................................- 7 -

1.9 Technical details............................................................................................................................................... - 8 -

1.10 Handling...............................................................................................................................................................- 11 -

1.11 Warranty.............................................................................................................................................................. - 12 -

Safety section

2.1 Safety details....................................................................................................................................................- 13 -

2.2 Safety warnings...............................................................................................................................................- 14 -

2.3 Safety plates and symbols..........................................................................................................................- 18 -

2.4 Outstanding risks ............................................................................................................................................ - 19 -

2.5Applied directives ...........................................................................................................................................- 19 -

Operation section

3.1 Installation......................................................................................................................................................... - 20 -

3.2 Description of controls ................................................................................................................................ - 23 -

3.3 Work cycle......................................................................................................................................................... - 24 -

3.4 Releasing and removing the removable container/Removal and placing of the waste bag......... - 26 -

3.5 Filter cleaning system DUSTOP............................................................................................................... - 28 -

Maintenance section

4.1 Informative notes........................................................................................................................................... - 30 -

4.2 General safety warnings............................................................................................................................. - 30 -

4.3 Maintenance operations ..............................................................................................................................- 31 -

4.4 Replacing the filters...................................................................................................................................... - 33 -

4.5 Troubleshooting ............................................................................................................................................. - 35 -

Spare parts section

5.1 Recommended spare parts ........................................................................................................................- 37 -

Information Section

- 1 - EN

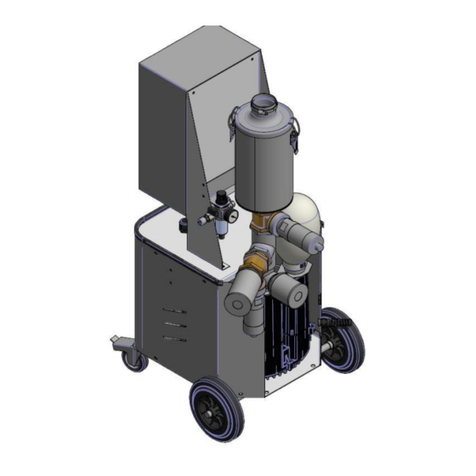

1.1 Identification of main parts

1)ON/OFF switches

2)Motor head

3)Push handle

4)Dustop filter cleaning system

5)Filtering chamber

6)Suction point with cap

7)Fixed wheels

8)Castors

9)Removable vacuumed material container

10)Release fastener

2

3

8

6

5

7

4

1

9

MTL202DS

10

Information Section

- 2 - EN

1)Motor head

2)Push handle

3)Dustop filter cleaning system

4)Filtering chamber

5)Removable vacuumed material Longopac® container

6)Fixed wheels

7)Castors

8)Longopac® bag

9)Suction pipe coupling point

10)Release fastener

1

5

4

6

3

2

7

8

9

10

MTL202DSLP

Information Section

- 3 - EN

1.2 Accessories provided

Remark: these filters must be checked every six months. In case they are worn it will be

necessary to replace them with new ones, to be requested as spare parts to

DELFIN S.r.l.

DELFIN

S.r.l. will accept no responsibility in case of use of

NON-ORIGINAL

filters.

FI.0232.0000

D. 340 H350 "M" CAT.FILTER CARTRIDGE FILTER FOR

MTL 202 DS PTFE

(only spare part)

Information Section

- 4 - EN

MODELLI/MODELS

ACCESSORI OPZIONALI/OPTIONAL

ACCESSORIES

MTL202DS

MTL202DSLP

EL/SYST –Remote

control/avviamento locale remoto

✓

✓

PN/SYST –Pneumatic

control/Avviamento locale

pneumatico

✓

✓

M –Class M filter/Filtro classe M

H- Absolute heap filter/ filtro

assoluto Hepa

✓FI.0013.0000

✓FI.0013.0000

ANT M –Antistatic filter class

M/filtro antistatico classe M

✓FI.0233.0000

✓FI.0233.0000

PTFE –PTFE coated filter calss

M/filtro PTFE classe M

NOMEX- Heat resistant filter (up to

200°C)/Filtro resistente alte

temperature (fino a 200°C)

CA –Activated carbon filter –Filtro

carboni attivi

CA+H - Activated carbon filter and

absolute filter/ filtro carboni attivi

con filtro assoluto

X –Stainless steel tank/Contenitore

Inox

✓

XX –Stainless steel tank and filter

chamber/ Contenitore e camera

inox

✓

✓

XXX - Stainless steel tank, filter

chamber,cover and frame in

stainless steel AISI304/ Contenitore

, camera filtrante e struttura Inox

CHX –Stainless steel chassis/

Carrello Inox

✓

CTX –Stainless steel sieve

grid/Cestello grigliato Inox

FLT- Floating device/Galleggiante

MT –Earth grounding/Messa a terra

✓

✓

LONGOPAC –Longopac bagging

system- Sistema insaccamento

Longopac

CIC –Cyclone for filter

protection/Ciclone per protezione

filtro

SGB –Sieve grid basket/ Cestello

grigliato

CHASSIS-Chassis with castors and

push handle/Carrello con route e

manico di spinta

HDX-Hardox abrasion plate/piastra

Hardox

IP –Internal polishing for filter

chamber and tank/lucidatura a

specchio interno per camera e

contenitore

BSK- Abs accessory basket and

doublebend holder/cesta per

accessori e clip per doppia curva

GR/VA- sieve grid and discharge

valve/Cestello grigliato e valvola di

scarico

PUMP- Eletrical discharge

pump/Pompa elettrica di scarico

Information Section

- 5 - EN

MODELLI/MODELS

ACCESSORI OPZIONALI/OPTIONAL

ACCESSORIES

MTL202DS

MTL202DS

AUT/PUMP- Automatic discharge

with pump/ scarico automatic con

pompa a contenitore pieno

C/INFORC- Fork lift intakes /

Inforcabile con muletto

SIL/SUP- Additional

silencer/Silenziaore addizionale

C/COMP- compressor installed on

board/ con compressore installato a

bordo

LOC/REM- Remote control/

avviamento locale-remoto

SP- single phase vacuum unit/unità

aspirante monofase

BAG- Dust bagging system/

Sistema insaccamento

✓

SD- Sliding damper for Dustop/

Valvola a ghigliottina per systema

Dustop

✓

DEPR –Pressure differential kit for

use of disposable bag/ kit

depressore sacchetto monouso

PPL300-PPL oil filtration kit 300

micron/Kit filtro PPL olio 300 micron

PPL100- PPL oil filtration kit 100

micron/kit filtro PPL olio 100 micron

OWR –Oil and water proof

cartridge/cartuccia idro-olio

repellente

OMK –Oil Mists filter kit/Kit filtro

nebbie oleose

PR.DIFF-pressure differential

switch/Pressostato differenziale

INVERTER- Equipped with

inverter/Equipaggiato con inverter

MANUAL / Manual

shaker/scuotifiltro manuale

SELF CLEAN- Filter shaker with

push button/scuotifiltro con

pulsante

DUSTOP- Filter cleaning system

using differential pressure/ Sistema

di pulizia filtro tramite pressione

differenziale

AUT –Automatic filter shaking

cleaning for pocket filter/Scuotifiltro

automatic per filtro a tasche

PN- Automatic pneumatic filter

cleaning system/Sistema di pulizia

automatic in controcorrente d’aria

Information Section

- 6 - EN

1.3 Identification details of manufacturer

Delfin S.r.l.

Strada della Merla, 49/a

10036 Settimo Torinese (TO) Italy

Tel. +39 011-8005500

Fax +39 011-8005506

www.delfinvacuums.it

delfin@delfinvacuums.it

1.4 Marking plate

In compliance with the

Machine Directive 2006/42/CE

on vacuum cleaners, the machine is fitted

with

CE

plates.

When contacting the manufacturer or dealer, always quote the details shown on the vacuum

cleaner plate.

Information Section

- 7 - EN

1.5 Intended uses

These specific vacuum cleaner models have been designed, built and protected for vacuuming

dusts and solid materials only, using special filters.

For ATEX vacuums, antistatic filters are used according to ATEX Directive 2014/34/EU.

Warning!

Always use specific filters for the type of dust or materials to be vacuumed.

Any other use is considered

IMPROPER

.

The vacuum cleaner is in any case intended for professional industrial use.

1.6 Allowed environmental conditions

To ensure the correct operation of the vacuum cleaner, this must be positioned protected against

atmospheric agents (rain, hail, snow, fog, dusts in suspension, etc.) with an environmental running

temperature between 5°C and 45°C and relative humidity not above 70%.

The work environment must be clean, well-enough lit and devoid of explosive atmosphere.

1.7 Storage

Remove the filter and clean it, empty the container (in case of Longopac vacuums: replace the

bag) and store the vacuum cleaner in a place protected against atmospheric agents with a

temperature between 0°C and 40°C. Cover with a nylon sheet to prevent accumulation of dust.

1.8 Scrapping

In case of scrapping, all the component parts of the vacuum cleaner will have to be disposed of

through adequate disposal channels in accordance with applicable legislation.

Before scrapping, all plastic and rubber parts will have to be separated from the electrical

material. Parts made of plastic, aluminium and steel only may be recycled if collected by special

centres.

Information Section

- 8 - EN

1.9 Technical details

Model

MTL202DS

MTL202DS 2kW

115V

MTL202DSLP

MTL202DSLP

2kW 115V

Power

kW

2,3

2

2,3

2

Voltage

Volts

230 /50-60 Hz

115/50-60Hz

230/50-60 Hz

115/50-60Hz

Max.

vacuums

rate

mm

H2O

2.500

2.250

2.500

2.250

Max. air

flow rate

m3/h

360

350

360

350

Noise level

(*)

dB (A)

76

76

76

76

Filter type

Polyester cat. “M”

Polyester cat. “M”

Polyester cat. “M”

Polyester cat. “M”

Filter

surface

cm2

30.000

30.000

30.000

30.000

Capacity

lt

20

20

Longopac

Longopac

Suction

inlet

Ø

50

50

50

50

Dimensions

cm.

59 x 48 x 110

59 x 48 x 110

50 x 48 x 125

50 x 48 x 125

Information Section

- 9 - EN

Model

MTL202DSLP 2kW

230V

MTL202DSLP

1 MOT

MTL202DS 1,5kW 115V

Power

kW

2 (2x1000)

1,15

1,5 (2X750W)

Voltage

Volts

230/ 50-60 Hz

230/50-60Hz

115

Max. vacuums

rate

mm H2O

2.350

2.500

2.050

Max. air flow

rate

m3/h

360

180

300

Noise level (*)

dB (A)

75

74

76

Filter type

Polyester cat. “M”

Polyester cat. “M”

Polyester cat. “M”

Filter surface

cm2

30.000

30.000

30.000

Capacity

lt

Longopac

Longopac

20

Suction inlet

Ø

50

50

50

Dimensions

cm.

59 x 48 x 110

59 x 48 x 110

59 x 48 x 110

Information Section

- 10 - EN

(*) Noise level

Noise level readings were taken in accordance with the provisions of

Machine Directive

2006/42/CE

standards.

Sound tests performed on this specific vacuum cleaner model have been taken from a distance of

1 meter and from a height of 1,60 meters, showing an acoustic pressure no higher than the one

indicates in the table.

The vibrations transmitted by the machine are lower than 2,5 m2/s.

Attention!

Pursuant to articles L.D. 81/08, workers exposed to sound pressure levels above 85 dB (A) must

be protected by special individual protection devices.

It is therefore necessary, if such working conditions exist, to provide workers with such approved

individual protection devices and to inform them of the risks relating to noise exposure.

Information Section

- 11 - EN

1.10 Handling

The machine is supplied in a strong cardboard box secured with straps.

Transport the package using a fork-lift truck of adequate lifting capacity and make sure it is stable

and that weight is properly distributed on the forks.

Before starting to move, make sure the transit area is free and that there are no moving objects

on the packaging.

During movement, keep the load low for greater stability and safety.

When starting up the vacuum cleaner, move this by means of the wheels supplied.

The appliance must never be moved using fork-lift trucks or other equipment that lifts it off the

floor.

If for any reason the need arises to lift and transport the vacuum cleaner, this operation must be

performed under the responsibility of the user. The user is therefore invited to secure the load as

he best thinks fit to ensure the operation is performed in total safety.

A

(cm)

B

(cm)

H

(cm)

Weight

(package included )

Kg

MTL202DS

60

70

130

44

MTL202DSLP

57

67

150

54

A

B

H

Information Section

- 12 - EN

1.11 Warranty

DELFIN

guarantees this vacuum cleaner model for a period of 24 months from the date of

purchase indicated on the tax document at the time of delivery of the vacuum cleaner by the

seller.

The warranty shall be invalidated in the event of the vacuum cleaner having been repaired by

unauthorised third parties or of equipment or accessories being used that have not been

supplied by

DELFIN

or which have not been recommended or approved by

DELFIN

or whose

serial number has been removed or altered during the warranty period.

DELFIN

undertakes to repair or replace, free of charge, those parts which, during the warranty

period show manufacturing faults. Repairs shall be made in the

DELFIN

facilities only or in a

Technical Assistance Centre

indicated by us and machines shall be sent to us carriage free

(transport costs to be paid by the user, unless otherwise agreed).

The warranty does not cover any cleaning of working parts.

Faults not directly attributable to materials or manufacture shall be examined only in our facility

or in a

Technical Assistance Centre

indicated by us. If claims appear unjustified, all the costs

relating to repair and/or replacement of parts shall be charged to the buyer.

The purchase tax document shall be shown to the technical personnel making the repairs and

must accompany the vacuum cleaner dispatched for repair.

The warranty does not cover: accidental damage, caused by transport or carelessness or

inadequate treatment, or improper use not in compliance with the instructions in the instruction

manual, or in any case by occurrences not dependent on normal operation or use of the vacuum

cleaner.

DELFIN

declines all responsibility for any damage to persons or things caused by bad or

improper use of the vacuum cleaner.

All disputes shall be referred to the Law Court of Turin (Italy).

The manufacturer declines all liability in the following cases:

➢

Failure to send the warranty Certificate

➢

Failure to follow the instructions

➢

Use of non-original spare parts

➢

Failure to service the machine properly

Safety Section

- 13 - EN

2.1 Safety details

The person in charge of safety shall be responsible for informing workers about the risks

associated with vacuum cleaner operation.

The obligation also exists of training workers so they are able to protect themselves and others.

Failure to observe basic safety regulations and Warnings could cause accidents during vacuum

cleaner operation, maintenance and repair. Accidents can often be avoided by recognising

potentially dangerous situations before these occur. Operators should be aware of potential

hazards and be trained and skilled enough. They should also have the tools necessary to perform

these duties properly.

DELFIN

shall under no circumstances be deemed liable for accidents or damage caused by use of

the vacuum cleaner by personnel not properly trained or who use it in an improper manner, as well

as by even partial failure to comply with the safety regulations and intervention procedures

indicated in this manual.

The safety Warnings and warning notices are indicated in this manual and on the product.

Unless these hazard messages are heeded, the operator could become involved in accidents with

serious consequences for him/herself and for other people.

The safety messages are highlighted by the following symbols:

Attention!

Unless these messages are heeded, operator injuries could occur.

Warning!

Unless these messages are heeded, vacuum cleaner damage could occur.

DELFIN

cannot foresee all possible circumstances capable of representing a potential hazard. The

warnings in this manual and on the products should not therefore be deemed exhaustive. In the

event of tools, procedures, work or machining methods being used that are not explicitly

recommended by

DELFIN

, make sure no hazards exist for operators and others.

Only ever use original DELFIN spare parts.

DELFIN

declines all liability in the event of non-original spare parts being used.

Safety Section

- 14 - EN

2.2 Safety warnings

Attention!

The following indications are, by themselves, not enough to fully protect against all the hazards

that could arise during vacuum cleaner operation. These will have to be integrated with common

sense and the experience of the operator, both of which are crucial factors for preventing

accidents. Each section of this manual lists further specific safety warnings for the various

operations.

Maintenance jobs must always be performed with the power plug detached from the power

point.

The employer must inform and train the user according to the provisions of applicable laws.

Before using the machine, prepare and train yourself by reading this manual carefully. Use of the

machine by untrained and unauthorised persons is forbidden.

Using the machine to vacuum toxic substances is forbidden unless this has been equipped with

special filters required for the specific type of dusts. Such filters must be explicitly requested by

you.

If the machine is used to vacuum toxic-harmful substances, the container must be emptied and

the filters cleaned using adequate individual protection devices, selected according to the type of

substances to be vacuumed.

Do not vacuum flammable materials or substances or which could cause explosions (fuels,

solvents, etc.). To vacuum such materials, the machine must be built with Anti-explosion Motor

and Electric System and this must be requested by you explicitly.

Do not vacuum corrosive substances unless the machine is equipped with containers suitable for

this purpose (

Stainless-steel AISI 304

).

Use of the machine without the supplied filters is not recommended.

If the filters are correctly fitted, the machine will not eject any objects.

Never rest miscellaneous materials on the horizontal protection guard.

The machine casing containing moving parts must not be removed by the user.

When using the machine, mind other people, especially children.

Use the machine cautiously on slopes and ramps.

Do not change direction on gradients.

Make sure the parked machine remains stable by operating the braked wheel.

During cleaning operations, maintenance jobs or when changing parts, the starter switch must be

off and the machine must be disconnected from the power mains by removing the cable from the

socket.

Only skilled persons should carry out repairs.

Safety Section

- 15 - EN

During use, mind the power supply cables and avoid crushing or pulling these.

Periodically check the mains power cable to ensure this is not damaged.

In the event of the cable being damaged, the machine must not be used.

In the event of the cable, plugs or couplings being replaced, make sure these are protected against

water spray and check mechanical strength.

Never pull the machine by means of the power cable and the vacuum pipe.

Motor brushes and burnt-out fuses must be replaced by

DELFIN

or authorised dealers. Always use

original spare parts.

The user is responsible for disposing of vacuumed substances in accordance with applicable laws.

After 10 years of use, we recommend sending the machine for a complete overhaul to

DELFIN S.r.l.

The machine is supplied with: instruction manual, Exploded Spare Parts drawing, Test Sheet,

Warranty Slip, Approval Certificate.

In the event of Customers fitting a tool to the machine not supplied by

DELFIN

, make sure the

safety conditions required by

Machine Directive 2006/42/CE

are complied with and in any event,

DELFIN

is unable to accept liability for any problems arising from use of such tool.

The vacuum cleaner must not be operated in a corrosive or explosive environment.

Always make sure the vacuum cleaner is free of all foreign materials such as debris, oil, equipment

and other objects that could affect operation and cause injury to persons.

Avoid using flammable or toxic solvents such as petrol, benzene, ether and alcohol for cleaning.

Avoid prolonged contact with solvents and inhaling their vapours. Avoid use close to open flames

or sources of heat.

Never use the vacuum cleaner without the filter.

Do not vacuum lit cigarette ends. The filter could be damaged.

Do not vacuum petrol or flammable liquids in general.

Make sure all the guards and protection devices are in place and that all the safety devices are in

place and working properly.

Do not wear loose or hanging clothing such as ties, scarves or torn garments that could become

trapped and be sucked up by the cleaner.

Do not open the vacuum container with the machine running.

The manual should always be kept handy for reference so the operating cycle can be checked

every time there are doubts. In the event of this manual being lost or damaged, ask

DELFIN

for a

new copy.

Safety Section

- 16 - EN

Structural damage and improper alterations or repairs could change the protection capacity of the

vacuum

cleaner and therefore cancel this certification.

Any alterations to the appliance must only be made by

DELFIN

engineers.

During maintenance jobs, affix a notice to the appliance indicating

"MACHINE BEING SERVICED,

DO NOT START".

Climbing on the cleaner is forbidden.

Never touch electric wires, switches, buttons, etc. with wet hands.

Before connecting to the power mains, make sure the power voltage and frequency are those

shown on the machine plate.

Make power connections to a mains supply with efficient earth system.

In the event of an extension being used, make sure this is in perfect condition, marked

CE

and that

the cross section of the cable is suitable for the vacuum cleaner power input.

When restoring original working conditions, the appointed personnel should make sure that at the

end of the operating procedure, proper vacuum cleaner operation safety conditions are restored,

especially the safety devices and the protective guards.

Only adult persons should use the vacuum cleaner.

During vacuuming operations, always brake the vacuum cleaner using the special revolving

wheel lock.

In case of vacuums with grounding system, connect the grounding clamp with a conductive

surface connected with the earth.

For ATEX Vacuums:

•Connect the grounding clamp with a conductive surface connected with the earth.

•Do not manumit the vacuum/pressure relief valve.

•All maintenance operations must be executed in non-classified atmosphere.

•Do not vacuum incandescent or burning material.

•The operator must always wear antistatic cloths and shoes. The floor of the area to be

vacuumed must be antistatic.

•The opening of the dust collection container must be executed in non-classified atmosphere

area, after having disconnected and unplugged the machine and only after 10 minutes from

unplugging.

Safety Section

- 17 - EN

•It is prohibited to vacuum toxic substances unless the machine is provided with the

necessary specific filters for the type of dust to be vacuumed. Such specific filters must be

expressly required by the Customer for supply.

•Do not vacuum flammable or explosive substances gases or liquids (fuels, solvents etc.).

•Do not vacuum corrosive substances unless the machine is equipped with suitable containers

(

Stainless-steel AISI 304

).

•Do not suck lighted cigarettes, cigarette stubs or incandescent materials.

•Do not vacuum sources of ignition.

•The supply cable tap must be correctly plug in the current outlet in NON CLASSIFIED

atmosphere, or rather in a safety place.

For LONGOPAC Vacuums:

•If the machine is used to vacuum toxic-harmful substances, the Longopac® container must

be emptied and the filters cleaned using adequate individual protection devices, selected

according to the type of substances to be vacuumed.

•Do not open the vacuum Longopac® container with the machine running.

This manual suits for next models

1

Table of contents

Other Delfin Vacuum Cleaner manuals

Delfin

Delfin MISTRAL 352 DS Installation instructions

Delfin

Delfin D/G 1 Z22 Operating instructions

Delfin

Delfin DG150 SE Installation instructions

Delfin

Delfin MISTRAL 501 WD Installation instructions

Delfin

Delfin ESD.MTL-0468 Installation instructions

Delfin

Delfin DG 70 EXP Z22 Installation instructions

Delfin

Delfin MTL501WD Installation instructions

Delfin

Delfin DM35 SGA Installation instructions

Delfin

Delfin DM32BL Installation instructions

Delfin

Delfin HV102 User manual