1. WARNING !

1.1 These hinges can be adjusted to close a 6’ wide gate, but are optimized to close a 4’ wide

gate (or smaller) when supplied with a low friction latch to conform with B.O.C.A.

specifications. However, like all mechanical devices, with age and wear, these hinges

will require periodic lubrication, readjustment and eventual replacement.

Just as you manually lock your home or car for security, you must also manually verify

the gate is secured each time, as the self-closing motion could be hampered by wind, an

obstruction, etc. Remember ,where children’s safety is involved, double check all

barriers to prevent accidents.

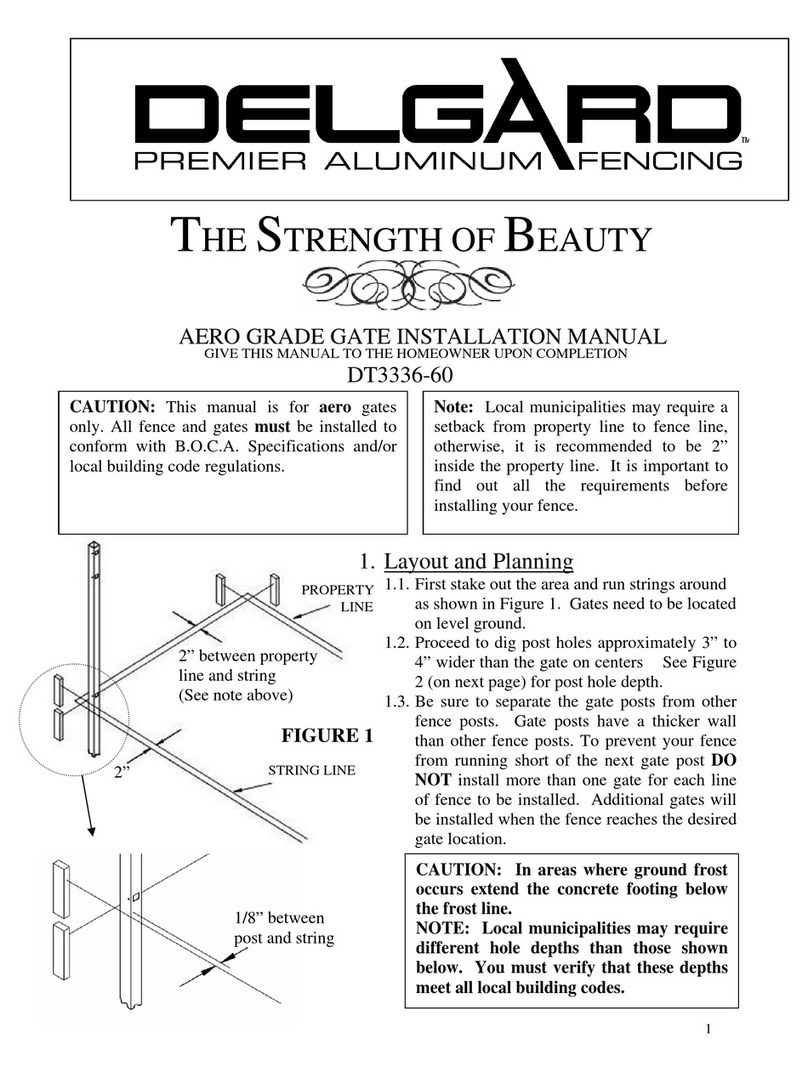

2. INSTALLATION (See Fig. 1)

2.1

width RESIDENTIAL, X'TRA & AERO COMMERCIAL

(LIGHT USAGE) (HEAVY USAGE)

height UP TO 4' +4' UP TO 6' UP TO 4' +4' UP TO 6'

3' 2 2 2 2

4' 2 2 2 2

5' 2 2 2 3

6' 2 2 3 4

7' N/A N/A 3 4

8' N/A N/A 3 4

NOTE: Not recommended to be used on gates over 6' wide.

2.2 Place the gate on blocks at the correct elevation and clamp the hinge post leafs to the

post. Make sure the tabs are flush with gate post. The hinges should be placed within

1/4” of the gate top and bottom rails or as far apart as possible for the best performance.

Remove the gate and verify that the hinge post leafs are completely flush and plumb with

the mounting surface, to avoid binding. Attach the hinges to the post by drilling 7/64”

pilot holes and fastening with the screws provided. If a third hinge is used it

should be located below the top hinge and a fourth hinge should be located above the

bottom hinge.

2.3 Center the gate into the opening. Check elevation, plumb and clearance, and clamp the

gate to the hinge gate leafs. Drill 7/64” pilot holes and attach with the screws provided.

2.4 If the hinge is mounted on a flat surface you may need to shim out the hinge post

leafs so that the hinge does not rub or bind against the mounting surface.

2.5 The enclosed screws are intended for securing the hinge to Delgard posts & gates.

If the hinge is mounted to a masonry column, wood, etc., ask your local building supply

dealer to recommend appropriate fasteners for your mounting application.

2.6 Add 4 drops of graphite film lubricant to the top of each hinge, taking care to remove

any excess lubricant from painted surfaces.

2.6 Test the gate for smooth free swinging operation, then proceed to install the latch

hardware as needed.

Note: See page 4 for adjustment procedure

2

3

+