Delixi BK Series User manual

BK Series Control Transformer

User Manual

Standard: Q/DLX 361

□ Please carefully read this User Manual before installing and

operating the product, and keep this manual properly for future

reference

1. Overview

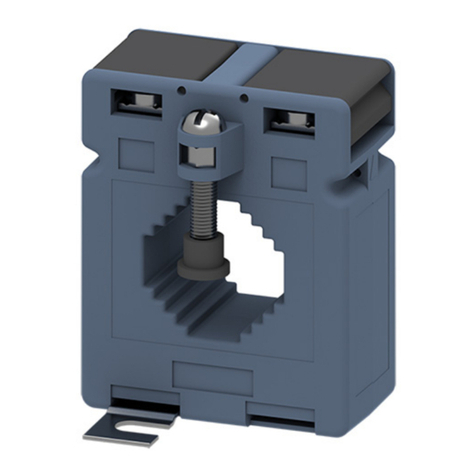

1.1 BK series control transformer (hereinafter referred to as transformer) has advantages of excellent performance,

reliable operation, and wide applicability, and it is usually used in the mechanical equipment as the power supply

for electrical control, lighting and indicator light.

1.2 Product standard: Q/DLX361

2. Ambient Temperature

2.1 The altitude does not exceed 2000m.

2.2 Ambient air temperature: the maximum temperature does not exceed 40℃, and the minimum temperature is not

below -5℃.

2.3 Relative air humidity: The average monthly maximum relative humidity of the wettest month is 90%, and the

average monthly temperature of that month is +25°C.

2.4 Installed in places where there are no harsh vibrations or bumps.

2.5 Installed in places where there is no explosive medium or the medium does not contain gas or conductive dust

that causes metal corrosion or damage to the insulation.

2.6 Installaed in places free from rain or snow.

2.7 The power supply voltage waveform is similar to a sine wave.

3 Model and Basic Parameters

3.1 Product model and its meanings

Rated capacity: VA

Control

Transformer

3.2 Transformer structure type

3.2.1 Transformers are divided into various specifications according to their different capacities and voltages, but

they are all transformers with single-phase multi-winding and with primary and secondary coupling wound

separately each other.

3.2.2 The coil of this series of transformers can accommodate all rated capacities when there is only one winding in

the primary and secondary winding; if there are multiple windings, each winding shall carry the given capacity;

however, the sum of the capacities of all windings shall not exceed the total capacity, as illustrated in Fig. 1, Fig. 2,

Fig. 3 and Fig. 4.

Primary

Iron core

Secondary

Fig. 1 Single winding

Primary

Iron core

Secondary

Fig. 2 Discrete winding

Primary

Iron core

Secondary

Fig. 3 Hybrid winding

Primary

Iron core

Secondary

Fig. 4 Continuous winding with a center tap

3.2.3 3.2.3 For example

3.2.3.1 The Fig. 1 shows that for BK-50 type, the capacity is 50VA, the input voltage is 380V, and the output voltage

is 36V, because the primary and secondary sides have only one winding, and this winding can carry full capacity of

50VA.

3.2.3.2 For example, Fig. 2 shows that for BK-200 type, the capacity is 200VA, the input voltage is 380V, and the

output voltage is 36V, 150VA and 24V, 50VA. Because the primary side e has only one winding, this winding shall

carry the rated capacity 200VA, and the secondary side has two separate single windings, and the capacity of each

winding has been indicted and they can carry their own capacity respectively, but the total capacity is 200VA.

3.2.3.3 For example, Fig. 3 shows that for BK-200 type, the capacity is 200VA, the input voltage is 380V, and the

output voltage is 36V, 24V. Because the primary side has only one winding, the capacity of this winding is the rated

capacity 200VA; there is a center tap in the secondary winding, so that only when the maximum voltage 36V of the

secondary side is used separately, the 200VA load can be carried. If there is 24V, the 200VA load cannot be carried,

but only 133VA load is carried. Because the total current on the secondary side is I2=

5.55А, the

capacity when the 24V is used separately is 24V = 24V*5.55А = 133VА. when 36V and 34V are both used, the

sum of the currents shall not be greater than 5.55A. In a word, regardless of whether the output voltage is used

separately or two sets are used simultaneously, the sum of the load currents cannot exceed the rated current of the

transformer.

3.2.3.4 For example, Fig. 4 shows that for BK-200 type, the capacity is 200VA, the input voltage is 380V, 220V,

and the output voltage is 110V, 36V, 24V, 6V. Fig. 4 shows that there is a center tap in primary and secondary

windings. The maximum operating current of the primary winding is I1=

0 .526А, so regardless of

whether the 220V or 380V is used, its current cannot exceed 0.526A; even when the 380V is used, the capacity of

this transformer is 200VA; when the 220V is used, the maximum capacity of this transformer is

х 220V =

116VА, so that a 200VA transformer becomes a 116VA transformer; at the same time, the secondary capacity is

reduced to 1l6VA. The maximum working current of he secondary winding depends on the working situations of

the primary winding; if the primary winding is connected to the 380V power supply, at this time the voltage of the

transformer shall be 200VA, so that the current of the secondary winding shall be I2=

1.8А.

When 110V is used separately, the capacity is 110V x 1.8A = 200VA

When 36V is used separately, the capacity is 36V x 1.8A = 65VA

When 24V is used separately, the capacity is 24V x 1.8A = 43VA

When 6V is used separately, the capacity is 6V x 1.8A = 11VA

When two or more sets of output voltages are used simultaneously, the sum of their currents must not be greater

than 1.8A. If the primary winding is connected to the 220V voltage, the voltage of the transformer shall be 116VA

rather than 200VA. Therefore, the current of the secondary winding is I2=

1.05A.

When 110V is used separately, the capacity is 110V x 1.05A = 116VA

When 36V is used separately, the capacity is 36V x 1.05A = 38VA

When 24V is used separately, the capacity is 24V x 1.05A = 25VA

When 6V is used separately, the capacity is 6V x 1.05A = 6.3VA

When two or more sets of voltages are used simultaneously, the sum of their currents must not be greater than

1.05A.

4 Outline Dimensions and Installation Dimensions

BK series

Capacity (VA)

Overall dimensions: LxW×H(mm)

Installation dimensions: L× W (mm)

5 Operation Instructions

5.1 Open the packing box, take out the manual and transformer, and carefully read the User Manual for proper

operation.

5.2 The transformer is reliably fixed in the appropriate position to prevent vibration and erosion.

5.3 Before use, test whether the circuit and grid voltages are rated input voltages, and the allowable deviation is

±5%; if greatly out of this range, it is considered to provide a voltage regulator at the front end to ensure the reliable

and normal operation of the transformer.

5.4 Select the wire with an appropriate cross-sectional area, connect the wire according to the mark, and turn on the

power after passing the inspection, so that the transformer can work normally. The nominal cross-sectional area of

the power cord is listed in the table below.

Input current at the rated output I, A

Nominal cross-sectional area mm²

6. Precautions

6.1 Before purchase, estimate the total capacity of the electrical appliances you use, and select the transformer with

a certain capacity by reference with the structure shown in Fig. 1 to Fig. 4 to ensure that the transformer is not burnt

at the instant start.

6.2 This transformer is designed and produced in strict accordance with relevant national standards. When a

transformer with multiple tap voltage is used, the calculation described in Section 3.2.4.4 Example is required; no

matter which transformer you use, the sum of its current cannot exceed the rated current of the transformer.

6.3 Before use, please carefully check whether various data marked on the nameplate and accessory instructions

meet your requirements, and power on the product after confirming that those parameters are correct.

6.4 After power-on, the transformer core and coil will heat up (but the temperature rise does not exceed 80K), and

this is a normal phenomenon. If the temperature rise exceeds 80K, or even the smoke rises, please cut off the power

supply, and re-check the capacity of the electrical appliance you use, and adjust it if necessary.

6.5 During transportation, avoid the collision as much as possible, and keep away from moisture. In use,

maintenance is required to ensure the service life of the transformer.

6.6 Before use, this series of transformers must be reliably grounded.

7. Ordering Notice

When purchasing a product, please clearly specify the following items:

7.1 Select an appropriate product according to the model, specification, capacity, primary and secondary voltage,

and capacity allocation of the secondary voltage or by reference with the examples shown in Fig. 1 to Fig. 4.

7.2 The outline dimensions and installation dimensions in this manual are the standard dimensions of transformers

produced by the company; if those dimensions are changed, please specify any changes when ordering.

8 Company Commitment

Under the condition that users follow the use and storage conditions and the product are well sealed, within 24

months from the production date, our company will provide repair and replacement service free of charge for any

damage or abnormal operation due to poor manufacture quality. A paid repair will be provided if the warranty

period expires. For any damage due to one of the following situations, a paid repair will be given even if within

the warranty period:

(1) Improper operation, maintenance, or storage;

(2) Modified without permission or improper repair;

(3) Damage due to falling off or caused during installation after purchase;

(4) Force majeure such as earthquakes, fires, lightning strikes, abnormal voltages, and secondary

disasters;

If you have any question, please contact the dealer or our company’s customer service department.

Customer service hotline:400-826-8008

Certificate

Zhejiang Delixi Electrical Co., Ltd.

Name: Control Transformer

Model: BK Series

This product passes the inspection and is allowed to

be shipped

Standard: Q/DLX 361

Inspector: Check 05

Production date: See product or package

Manufacturer: Zhejiang Delixi Electrical Co., Ltd.

Address: No. 155, Zhandong Road, Liushi Town, Yueqing City, Zhejiang 325604

Tel: (86-577) 61778888

Fax: (86-577) 61778000

Customer Service Hotline: 400-826-8008

www.delixi-electric.com

The first edition of this User Manual was issued in July 2022

Popular Transformer manuals by other brands

Monacor

Monacor PATL-100/XC quick start guide

Pulsar

Pulsar AWT830 Assembly instructions

enphase

enphase 400A Production CT Installation instruction

DiodeDrive

DiodeDrive LVT Series user manual

Eaton

Eaton COOPER POWER SERIES Installation and maintenance instructions

Digital Acoustics

Digital Acoustics IP7-SS40 installation instructions