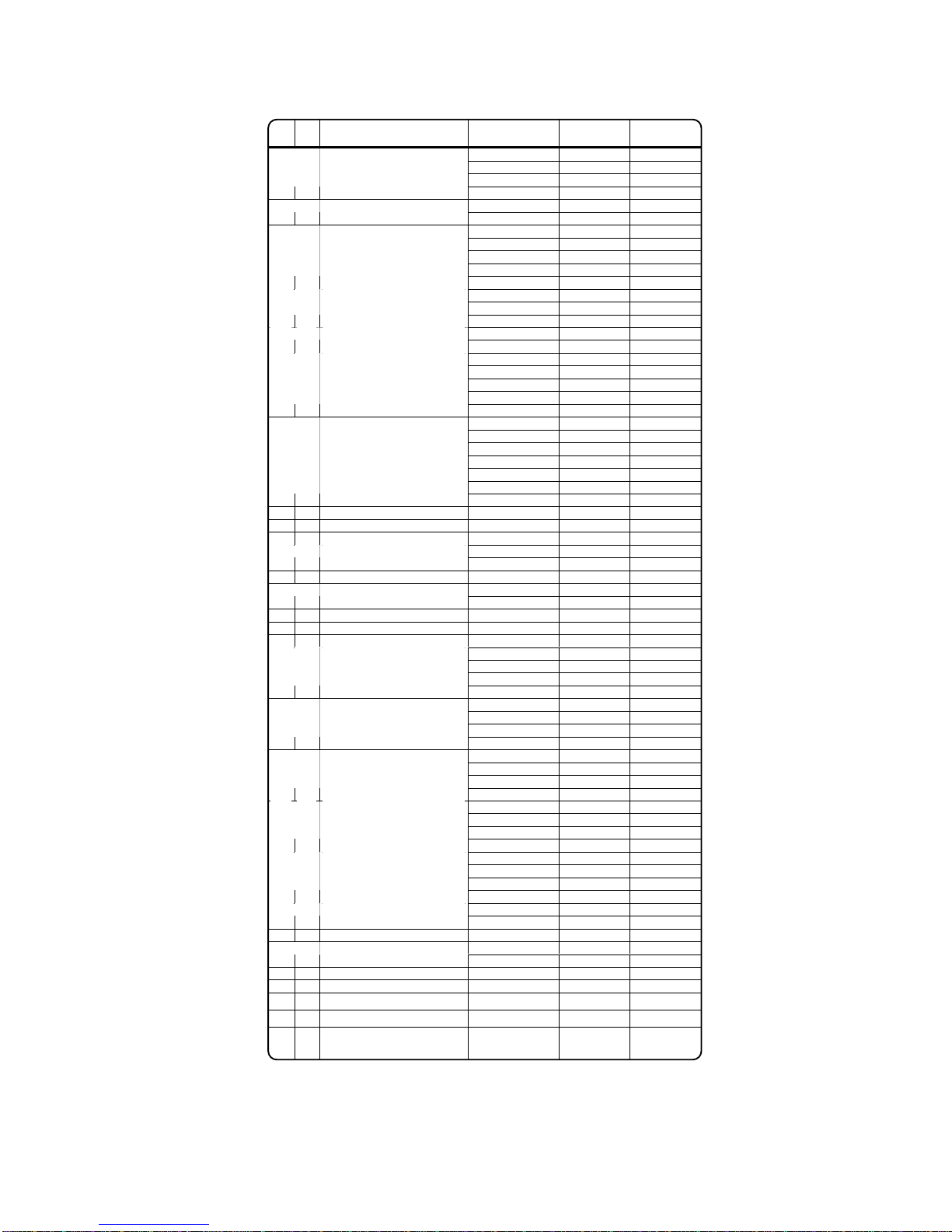

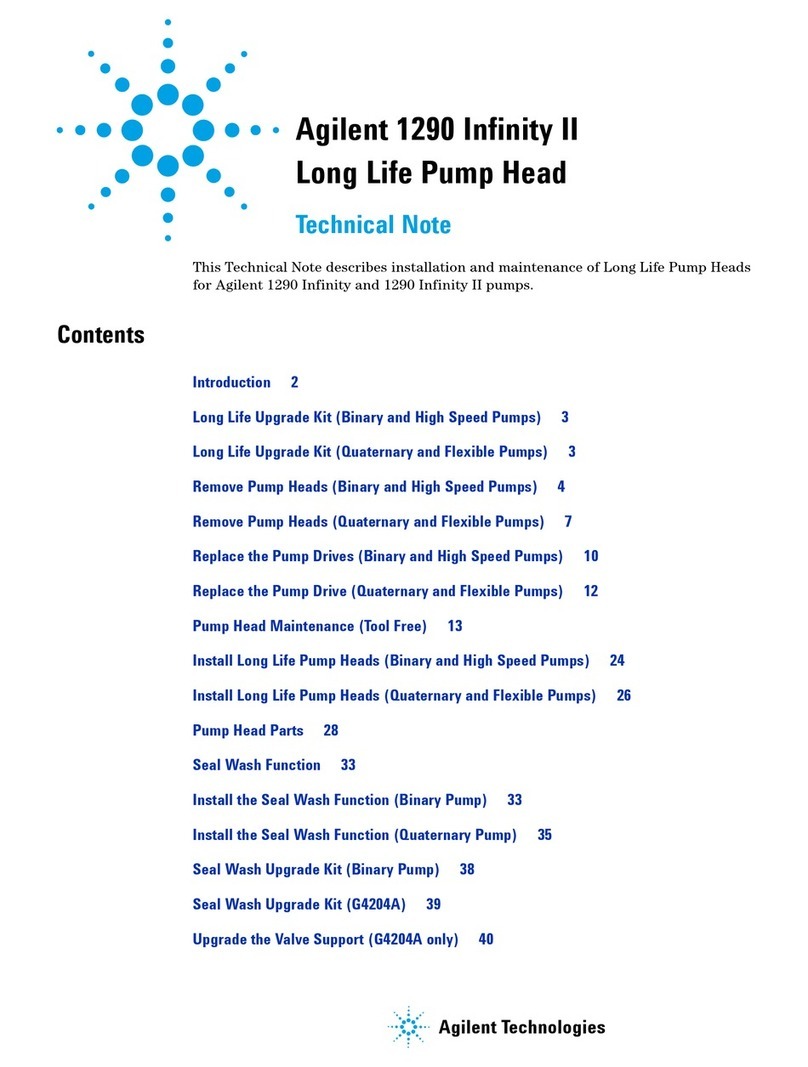

11I DELLMECO I AODD DIAPHRAGM PUMPS

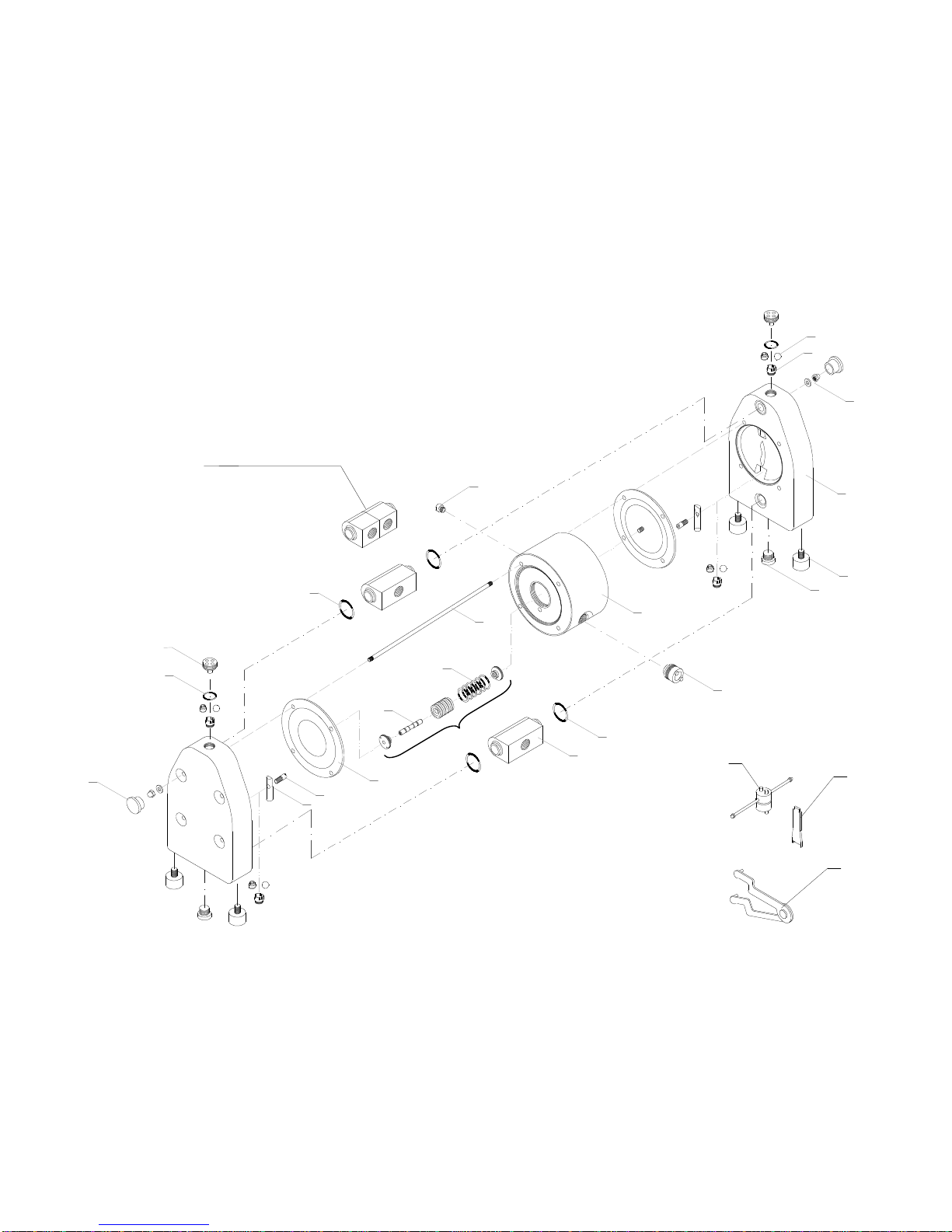

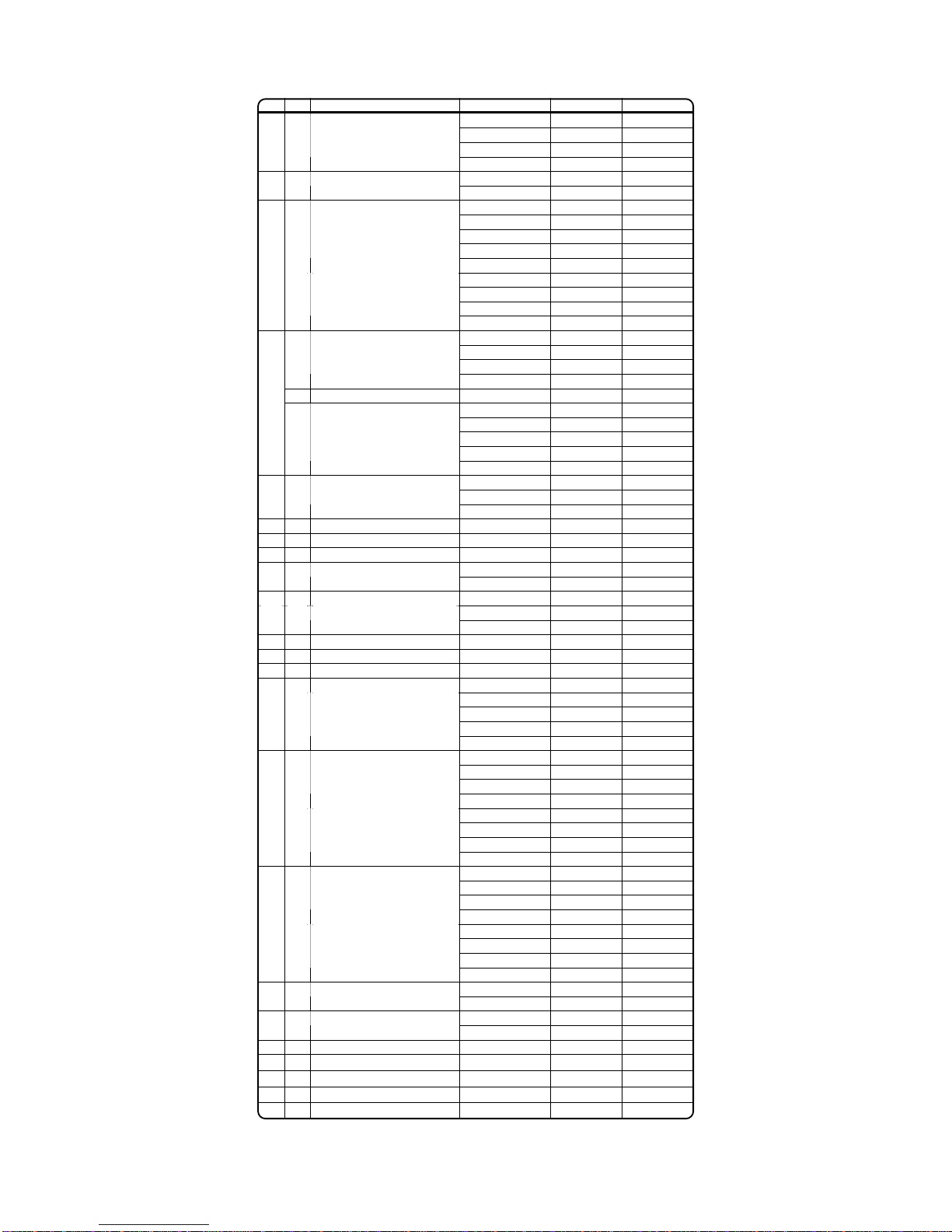

Spare parts list for DM 40/315 and DM 50/565 pumps

DM 40/315 DM 50/565

PE 2 40 01 20 2 50 01 20

PTFE 2 40 01 23 2 50 01 23

PE conductive 2 40 01 21 2 50 01 21

1. 2 Pump housing

PTFE conductive 2 40 01 24 2 50 01 24

PE 1 40 10 20 1 50 10 20

2. 1 Central housing PE conductive 1 40 10 21 1 50 10 21

PE 2 40 30 20 2 50 30 20

PTFE 2 40 30 23 2 50 30 23

PE conductive 2 40 30 21 2 50 30 21

PTFE conductive 2 40 30 24 2 50 30 24

3. 2 Suction/Discharge ports

AISI 316L 2 40 35 53 2 50 35 53

TFM/PTFE 1 40 50 05 1 50 50 05

EPDM 1 40 50 08 1 50 50 08

4. 2 Diaphragm

NBR 1 40 50 10 1 50 50 10

PE 2 40 56 20 2 50 56 20

5. 4 Cylinder valves PTFE 2 40 56 23 2 50 56 23

PTFE 1 40 60 23 1 50 60 23

EPDM 1 40 60 08 1 50 60 08

NBR 1 40 60 10 1 50 60 10

AISI 316 1 40 60 52 1 50 60 52

4 Valve balls

Polyurethane 1 40 60 07 1 50 60 07

EPDM/EPDM 2 40 70 08 2 50 70 08

FEP/FKM 2 40 70 04 2 50 70 04

NBR/NBR 2 40 70 10 2 50 70 10

PTFE/FKM 2 40 73 14 2 50 73 14

PTFE/EPDM 2 40 73 15 2 50 73 15

PTFE-c./FKM 2 40 73 16 2 50 73 16

7. 4 Sealing inlet/outlet - SET

PTFE-c./EPDM 2 40 73 17 2 50 73 17

9. 8 Housing bolt AISI 304 2 40 042 50 2 50 042 50

11. 4 Shock absorber NR/St37 1 40 69 06 1 40 69 06

12. 16 Nut with washer AISI 304 2 40 045 50 2 50 045 50

PET/NBR 1 40 020 31 1 40 020 31

13. 1 Air valve PET/FKM 1 40 020 32 1 40 020 32

14. 1 Shaft AISI 304 1 40 40 50 1 50 40 50

NBR 1 40 87 10 1 40 87 10

15. 6 O-ring FKM 1 40 87 09 1 40 87 09

16. 2 Central housing seal PE 1 40 85 22 1 50 85 22

17. 1 Muffler PE porous 1 40 99 35 1 50 99 35

18. 1 Air adapter PP 1 40 46 28 1 40 46 28

PE 2 40 54 20 2 50 54 20

PTFE 2 40 54 23 2 50 54 23

PE conductive 2 40 54 21 2 50 54 21

22. 4 Valve seat

PTFE conductive 2 40 54 24 2 50 54 24

PE 2 40 59 20 2 50 59 20

PTFE 2 40 59 23 2 50 59 23

PE conductive 2 40 59 21 2 50 59 21

24. 2 Plug lower

PTFE conductive 2 40 59 24 2 50 59 24

PE 2 40 055 20 2 50 055 20

PTFE 2 40 055 23 2 50 055 23

PE conductive 2 40 055 21 2 50 055 21

25. 2 Plug upper

PTFE conductive 2 40 055 24 2 50 055 24

PE 2 40 39 20 2 50 39 20

PTFE 2 40 39 23 2 50 39 23

PE conductive 2 40 39 21 2 50 39 21

26. 2 Valve stopper

PTFE conductive 2 40 39 24 2 50 39 24

PE 2 40 38 20 2 50 38 20

PTFE 2 40 38 23 2 50 38 23

PE conductive 2 40 38 21 2 50 38 21

27. 2 Bolt

PTFE conductive 2 40 38 24 2 50 38 24

FEP/FKM 2 40 78 04 2 50 78 04

28. 2 Plug upper sealing EPDM 2 40 78 08 2 50 78 08

30. 2 O-ring for central housing seal NBR 1 40 85 10 1 50 85 10

PE 1 40 11 20 1 50 11 20

35. 1 Central housing complete PE conductive 1 40 11 21 1 50 11 21

40. 1 DELLMECO nameplate Diverse 1 40 094 00 1 50 094 00

70. 16 Pump housing plug PE 2 40 058 20 2 50 058 20

82. 2 Shaft allen pin screw AISI 304 1 40 540 50 1 50 540 50

97. 1 Valve seat key AISI 304 1 40 254 50 1 50 254 50

99. 1 Upper/lower plugs and air valve

key (SK3, SK4) diverse 1 08 58 00 1 08 58 00