Delos DS10-1V User manual

DS10-1V MultiFunction

(Version 2.0)

Safety attention:

If the optical Linear Scale used with the digital readout is damaged, do

not use a Linear Scale of other brand. Because the performance,

specification and connection of the products of different and can not be

connected without the instruction of specialized technical personnel,

otherwise, trouble will be caused to the digital readout.

To prevent electric shock or fire, moisture or directly sprayed cooling

liquid must be avoid. In case of any smoke or peculiar smell from the

digital readout, please unplug the power plug immediately, otherwise,

fire or electric shock may be caused. In such a case, do not try to repair

it, please contact Delos or distributors.

Digital readout is a precise measuring device used with an optical

Linear Scale. When it is in use, if the connection between the Linear

Scale and the digital readout is broken or damaged externally, incorrect

measuring values may be resulted. Therefore, the user should be

careful.

Do not try to repair or modify the digital readout, otherwise, failure,

fault or injury may occur. In case of any abnormal condition, please

contact Delos or distributor.

Dear Users:

Thank you fo r purchasing DS10- 1V series digital readouts. The digital

readout is applicable for the machines such as millers, lathes, boring

machines, grinding machines and EDM, etc.. Read all the instructions in

the manual carefully before used and strictly follow them. Keep the manual

for future references.

1. Operation Instructions

1.1 Illustration of Panel and keyboard ..................2

1.2 General Operations.......................................2

1. Zeroing ...................................................2

2. Toggle Unit between inch and mm ..............2

3. Absolute / Incremental ..............................3

4. Enter coordinate .......................................3

5. Linear compensation ................................3

6. 1/2 Function ..............................................3

7. Toggle Between R/D display Mode...............3

2. Parameters settings

2.1 PA-00 Encoder type setting.............................4

2.2 PA-01 Resolution setting................................4

2.3 PA-02 Direction setting ..................................4

2.4 PA-03 UART mode setting ..............................4

2.5 PA-04 Accuracy of imperial unit ......................5

2.6 PA-05 Limit Enable / disable ...........................5

2.7 PA-06 Soft lower Limit value............................5

2.8 PA-07 Soft Upper Limit value ..........................6

2.9 PA-08 Restore Factory Settings ......................6

3. RS232 communication protocol.............................7

4. Relay output ........................................................8

5. Appendix ..............................................................9

Contents

1

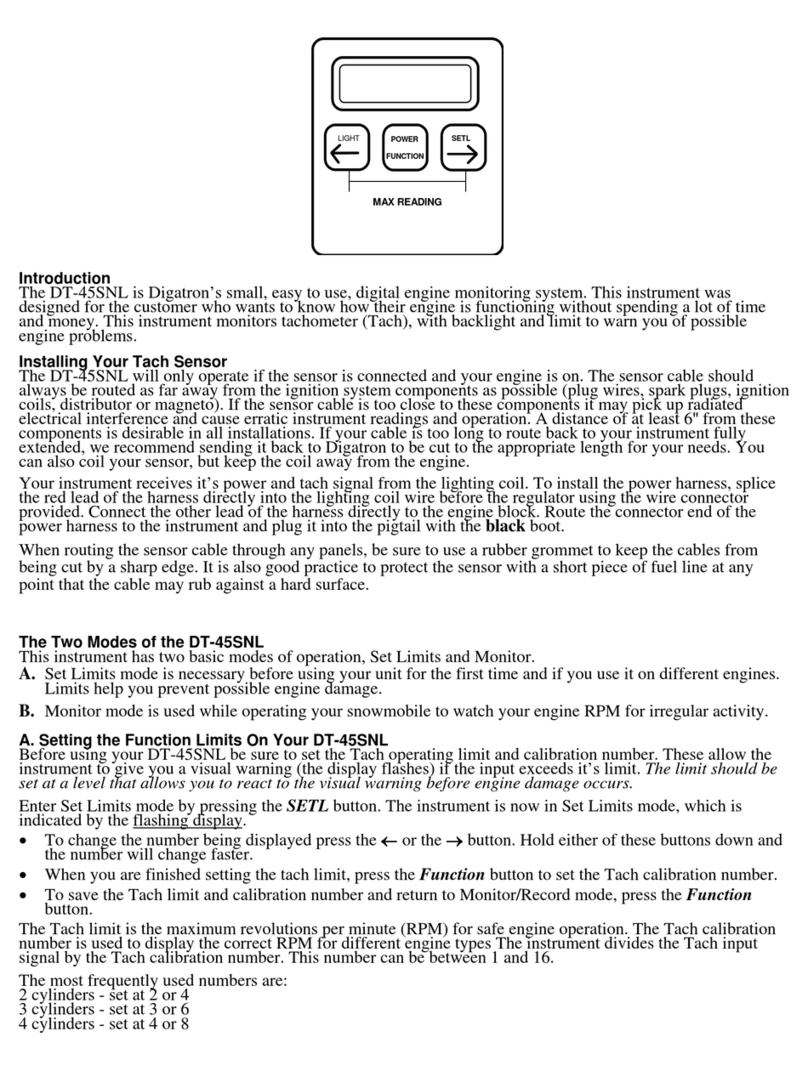

1.1 Illustration of Panel and key board

ABS /I NC

INC H/ MM D/ R RE F

Fn

SET

CLS

ENT

R

D

78 9

6

5

4

1 2 3

0.

1

2

MM

INCH

ABS

INC

Key to realize processing operation and parameter

programming On the operation panel; According to

different processing operations, the single key has

double functions, some functions need to be two key

combination for achieve different operation;

Specific operation, please see the processing

operation and parameter programming;

1.2 General Operations

1、Z eroing

Press [CLS], Zeroing is to set the current point in

normal display;

2、 Toggle Unit between inches and mm

Press [mm/inch], Display unit can be toggled between

mm and inch, a mm/inch LED will be appear of the right

at the same time; Light indicator is the inches unit;

Otherwise, is mm;

3、 Absolute/lncremental

Press [ABS/INC], Display coordinate can be toggled

between ABS to INC coordinate, A ABS/INC LED will

appear of the right; Light indicator is the ABS

coordinate; otherwise, is the INC coordinate.

1. Operation Instructions

2

1. Operation Instructions

4、Enter coordinate

Preset a value to current position for a designated axis

in normal display state; Press [SET] key to input state ;

then press data key, Input data value;

5、Linearity Compensation

Press [SET], then [MM/INCH], which indicates the step

is to Linear Compensation, then Input the Linear

Compensation value . Compensate the linear error to

make display value equals to standard value;

The calculation of compensation rectifying coefficient:

(Measurement I Standard value) x 1000.000

Coefficient^

Standard value Example for X axis:

Measurement 200.020mm Standard value 200.000mm

Rectifying coefficient

= ( 200.020-200 ) * 1000 /200 =-0.01 mm/m

6、1/2 Function

Set the center of work piece as datum by halving the

displayed value. Press [SET], then Press [1/2], in turn

to value the axis display value , The position is

the work-piece's center.

7、Toggle Between R/D Display Mode

Press[SET],then press [R/D],Display the data will be

radius and diameter of processing mode, A D/R LED will

be appear of the right; Light indicator is the diameter;

Otherwise, is the radius。

3

2.Parameters setting

Note:

Press key [.] to enter initial system and self-check after

DRO powers on in 1 second; then Parameters settings

display in the arameters window; press [R/D] and

[ММ/INCH] to select the item you want to change of

the step; press [Enter] key to enter the modification

program. Press [.] key to Exit.

2.1 PA-00 Select the encoder type: Linear or Rotary Encoder

Parameters: Linear or Rotary

Operations:

Windows displays PA-00 , Press [Enter] key to enter ;

Press [CLS] key to toggle Linear or Rotary ,

Press the [Enter] to confirm your choice

and Windows displays PA-00, Press the [R/D] key to the next step;

2.2 PA-01 Set the resolution for Encoder:

Parameters: 0.1; 0.2; 0.5; 1; 2; 2.5; 5.0; 10.0; for Linear Encoder

and input value for Rotary Encoder

Operations:

Windows displays PA-01 , Press [Enter] key to enter ;

For linear encoder : Press [CLS] key to select the resolution ,

For Rotary encoder: Press [SET] key then press numeric number

to input the parameter for rotary encoder;

when the input numeric number is positive,

the unit is degree; when the input numeric number

is negative, the unit is degree/minute/second;

Press the [Enter] to confirm your choice

and Windows displays PA-01,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

2.3 PA-02 Set the counting direction of the counter :

Parameters: dir-0 or dir-1

Operations:

Windows displays PA-02 , Press [Enter] key to enter ;

Press [CLS] key to toggle dir-0 or dir-1,

Press the [Enter] to confirm your choice

and Windows displays PA-02,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

4

2.Parameters setting

2.4 PA-03 UART mode type:

Parameters: UArt-0 (BIN format) or UArt-1 (ASCII format)

Operations:

Windows displays PA-03 , Press [Enter] key to enter ;

Press [CLS] key to toggle UArt-0 or UArt-1 ,

Press the [Enter] to confirm your choice

and Windows displays PA-03,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

2.5 PA-04 Accuracy adjustment of imperial unit:

Parameters: INCH-4 ( 4 bits decimal points )

or INCH-5 ( 5 bits decimal points )

Operations:

Windows displays PA-04 , Press [Enter] key to enter ;

Press [CLS] key to toggle INCH-4 or INCH-5 ,

Press the [Enter] to confirm your choice

and Windows displays PA-04,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

2.6 PA-05 Enable soft Limit function:

Parameters: ON (for enable) or OFF(for disable)

Operations:

Windows displays PA-05 , Press [Enter] key to enter ;

Press [CLS] key to toggle ON or OFF ,

Press the [Enter] to confirm your choice

and Windows displays PA-05,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

2.7 PA-06 input lower Soft Limit value:

Parameters:

Operations:

Windows displays PA-06 , Press [Enter] key to enter ;

Press [SET] key then press numeric number

to input lower soft limit value;

Press the [Enter] to confirm your choice

and Windows displays PA-06,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

5

6

2.Parameters setting

2.8 PA-07 input Upper Soft Limit value

Parameters:

Operations:

Windows displays PA-07 , Press [Enter] key to enter ;

Press [SET] key then press numeric number

to input upper soft limit value;

Press the [Enter] to confirm your choice

and Windows displays PA-07,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

2.9 PA-08 Restore factor y default

(PINCoder : 2019)

Parameters:

Operations:

Windows displays PA-08 ,

Press [Enter] key to enter ;

Windows display : “ PinCode”

input : 2019 then press [Enter];

Windows display: “CLS---”

and then Windows displays PA-08,

Press the [MM/INCH] key to the last step;

Press the [R/D] key to the next step;

Default Parameters;

3.RS232 communication Protocol

3.1 Transpor t protocols : 9600, 8, N, 1

(1) single transmit data: Data receiver(PC) transmit “R”(52H)

to DRO electronic box which well transmit data single. DRO

electronic box receive each 52H, then transmit a set of data

(current showing value).

(2) Continuous transmit data: Data receiver(PC) transmit “U”(55H)

to DRO electronic box which will transmit data continuous.

It will transmit when ever showing value changed.

(3)Stop to transmit data: DRO electronic box received 53H,

then stop to transmit data. When enter in continuous

transmit data state, it must be transmit 53H to stop it,

then can receive other orders.

3.2 ASCII code number for mat:

[Blank] X [sign-bit][Value][Value][Value][Value][Value][Decimal Point]

[Value][Value][Value][Blank] Y [sign-bit][Value][Value][Value][Value]

[Value][Decimal Point][Value][Value][Value][Blank] Z [sign-bit][Value]

[Value][Value][Value][Value][Decimal Point][Value][Value][Value]

[LF 0AH]

Decimal point position unfixed, along with set-up resolution changed,

for example:

X+1234.567 (resolution = 1,2,5,10) (Decimal point behind three figures)

X+123.4567(resolution = 0.5, 0.1) (Decimal point behind four figures)

X+123.4567 (I/M = I INCH I/M = M METRIC)

(Inch more than one decimal point compare Metric)

3.3 Transmission line 1.5m wire, the following is

the connection method:

PC connector DRO connector

1 1

RX 2 RX 2

TX 3 TX 3

4 4

Gnd 5 Gnd 5

7

4. Relay output

8

DSUB-9

1 2 3 45

6789

pin

1

2

3

4

5

6

7

8

9

ON

COM

OFF

EXP

Color

Red

Yellow

Black

State

Relay output DB9

5.Appendix

DIMENSIONS

ABS /I NC

INC H/ MM D/ R RE F

Fn

SET

CLS

ENT

R

D

78 9

6

5

4

1 2 3

0.

DS -1 V

1

2

MM

INCH

ABS

INC

252

94

119

Mechanical

Eelectrical Features

DSUB-9

1 2 3 45

6789

pin PP

signalsignal

EIA422

1

2

3

4

5

6

7

8

9

OV OV

GND GND

A A

5V 5V

B B

R R

A

B

R

Resolutions for Linear Scale

Resolutions for Rotary Encoder

Power Supply

Axis Display

Signal input per axis

Maximum input frequency

Operating Temperature

Storage Temperature

Relative Humidity

Vibration Resistance

Protection Class(EN60529)

Weight

10--0.1um

0.001--1"

100VAC--230VAC±10% / 15 VA

7 Segment LED H = 17mm

A / B quadrature signals

500KHz

0 – 50

-20 – 70

95% (not condensed)

25 m/s (55 – 2000Hz)

IP42

2.1 Kg

o

2

o

oo

9

Table of contents

Popular Measuring Instrument manuals by other brands

Keysight

Keysight N5224B Service guide

Bosch

Bosch GLM 50 C Professional Operating/safety instructions

Trotec

Trotec TA 300 quick start guide

Vega

Vega VEGAFLEX 81 operating instructions

nal von minden

nal von minden Reactif Touch manual

PCB Piezotronics

PCB Piezotronics IMI Sensors 600A12 Installation and operating manual

Digatron

Digatron DT-45SNL manual

Canary

Canary pro II user manual

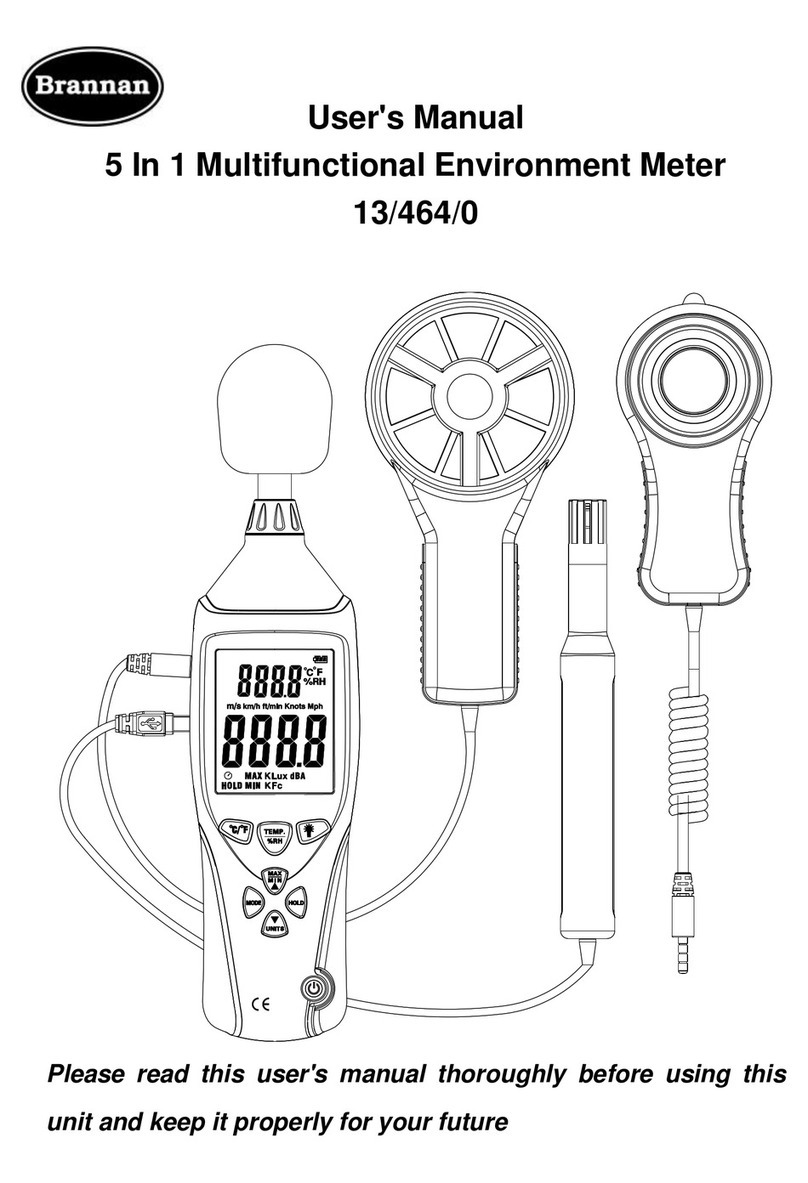

Brannan

Brannan 13/464/0 user manual

Endress+Hauser

Endress+Hauser Proline Promag H 100 EtherNet/IP Brief operating instructions

York Survey Supply

York Survey Supply 261640 operating instructions

Endress+Hauser

Endress+Hauser Prothermo NMT 539 operating instructions