Set Clock Time & Date

Used to set the time and date since each insertion is tagged with the time and date.

Check Clock Time & Date

Used to check the time and date. If the CP200 has been off for more than about 1 or 2 weeks it

will lose its time and date.

Set Display Format

When reviewing insertion data on the CP200 there are two different view formats to choose

from: With depth indication and without depth indication. With depth indication turned on the

CP200 will display the depth of the data in the insertion on the top line and the corresponding

data below on the bottom line. Only 3 depths of information will display per page display re-

quiring up to 10 pages to show the complete insertion data, see Figure 6. Without depth indica-

tion the CP200 displays actual insertion data on both lines, allowing 6 depths of information to

display per page and requiring up to only 5 pages to show the complete insertion data, see

Figure 7.

Speed Abort Menu

Because the CP200 uses the ASAE standard S313.3 for measuring the soil density which speci-

fies a minimum speed of 0.2 metres per minute and a maximum speed of 2 metres per minute,

the CP200 has been included with the ability to enable speed abort alarms. The abort can be

disabled, however an audible beeping will let the user know that the cone index values may

not be an accurate representation of the actual soil density profile.

Set Maximum Depth

The Max Depth is the depth at which the CP200 will complete an insertion. It can be set up to a

maximum of 750mm in 25mm intervals.

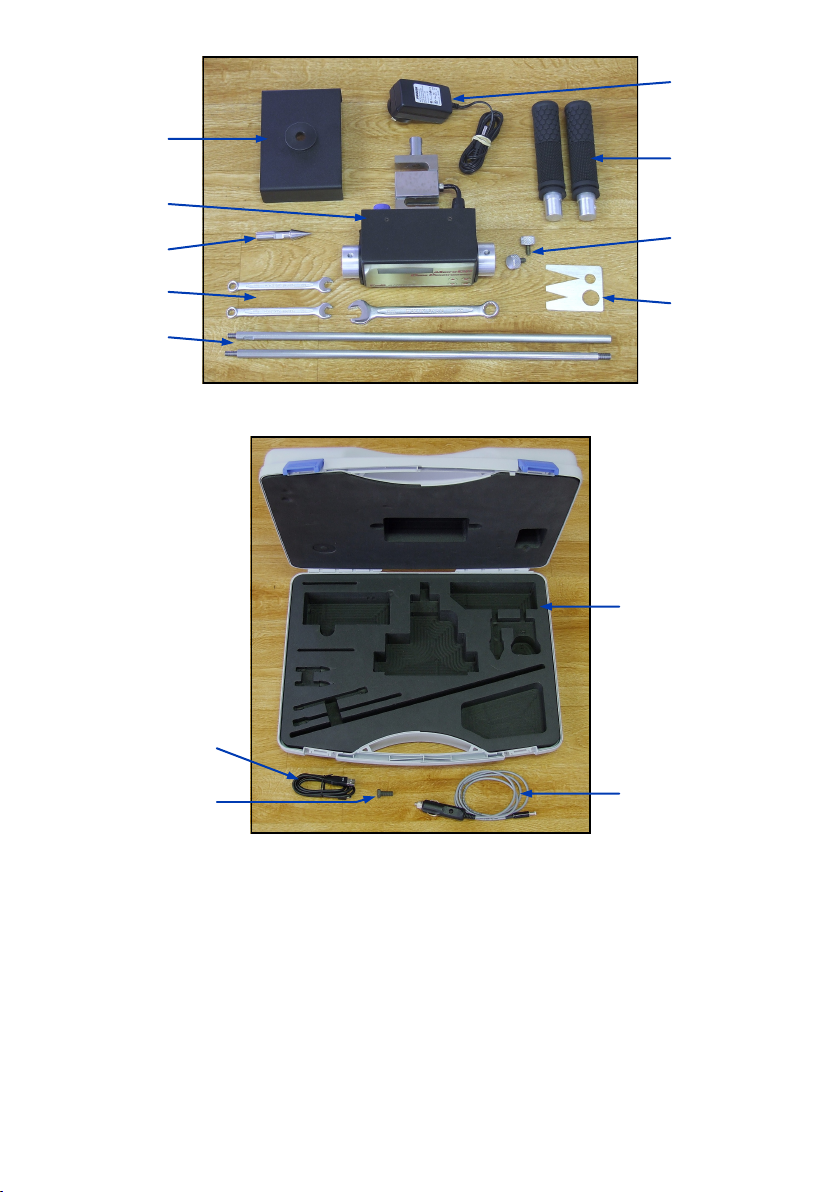

Calibration Menu

As well as containing the settings to calibrate the load and depth measurements, the calibra-

tion menu also includes checking both the load and depth in real time. See Appendix, page 12.

Setting Up

Power on

To turn the CP200 on, simply press and hold the ‘Enter’ button until the unit beeps. The first

thing it will display on the LCD Screen is the model, version and serial number, before changing

to the Start Screen.

Power off

To turn the CP200 off, simply press and hold the ‘Cancel’ button while the Start Screen is dis-

played until the unit beeps and turns off. The ‘Cancel’ button will not turn the unit off in any

other menu, but rather it will go back to the preceding menu or exit back to the Start Screen.

5

Figure 6 - With Depth Indication Figure 7 - Without Depth Indication