Delta Membranes AlertMaxx2 Installation instructions

Installation & Operating Manual

Pump Station High Level Alarm

AlertMaxx2

Foul Water (DMS-299)

AlertMaxx2

AM2F-M-V3-10.17

Legal information/Copyright

All rights reserved. Contents provided herein must neither be distributed, copied, reproduced, edited or

processed for any other purpose, nor otherwise transmitted, published or made available to a third party without

express written consent from Delta Membranes.

Subject to technical modication without prior notice.

© Delta Membranes 2017

Delta House, Merlin Way, North Weald, Epping, Essex. CM16 6HR

01992 523 523

www.deltamembranes.com

T.

E.

W.

AlertMaxx2

3

Contents

1.0 AlertMaxx2 overview 4

2.0 Box contents 4

2.1 Cardboard box contents 4

2.2 AlertMaxx2 unit contents 4

3.0 Technical information 5

4.0 Health & Safety 5

5.0 Guarantee 5

6.0 Unit location 5

7.0 Mounting the AlertMaxx2 unit 5

8.0 Wiring schematic 6

9.0 Connecting mains power to the AlertMaxx2 7

10.0 Connecting a pump to the AlertMaxx2 8

11.0 Installing a pendant oat into a foul water chamber 9

12.0 Connecting a pendant oat to the AlertMaxx2 unit 10

13.0 Activating & testing the AlertMaxx2 unit 11

13.1 Connecting the ribbon cable 11

13.2 Turning on the AlertMaxx2 unit for the rst time 11

13.3 Testing the AlertMaxx2 unit 11

14.0 Connecting external devices 12

15.0 Energy monitoring 12

16.0 Servicing 12

17.0 Spares 12

18.0 Error codes 13

19.0 Troubleshooting 14

20.0 PPS Technical Department 14

21.0 Hi-PowerMaxx Connection 15

1.0 AlertMaxx2 overview

2.0 Box contents

4

AlertMaxx2

3.0 Technical information

AlertMaxx2 Specication

Size (without cable glands) W: 310mm x D: 170mm x H: 78mm

Weight (AlertMaxx2 unit) 1kg

Mains Supply 200-250V AC (50Hz)

Internal Battery Pb 6V - 1.2Ah

Alarm Sound Level 100db @ 30cm

Visual Display 2 x 7 Segment

Operating Temperature 5-40°C

Approximate Installation Time 30 minutes

IP Rating IP2X

2.1 Cardboard box contents

• 3 x Large Cable Glands & Nuts

• 5 x Large Blanking Plugs & Nuts

• 1 x Small Cable Gland & Nut

• 2 x Small Blanking Plugs & Nuts

• 1 x 6V Battery

2.2 AlertMaxx2 unit contents

• 1 x AlertMaxx2 Unit

• 1 x Chamber Location Sticker Sheet (For AlertMaxx2)

• 1 x Chamber Location Sticker Sheet (For Spurs)

• 1 x Installation & Operating Manual (this document)

• 1 x Homeowner Pack

• 1 x Pendant Float Switch

• 2 x Cable Ties

The AlertMaxx2 is an intelligent high level alarm, designed to alert home owners when the water level in their

pump chamber becomes too high. The unit will also inform home owners when a service is due on their pump

station.

CAUTION!

The AlertMaxx2 should only be installed by qualied personnel in accordance with the latest regulations.

AlertMaxx2

5

6.0 Unit location

The AlertMaxx2 must be positioned in an area where the alarm can be clearly heard and is permanently

accessible for servicing. The unit must be positioned where there is sucient air circulation to the front and base

vents. The AlertMaxx2 must not be located further than 10m from the pump/s it is being used in conjunction

with. If cable extensions are required, these must be selected in accordance with BS 7671:2008 ‘Requirements

for Electrical Installations’. If using in conjunction with a PowerMaxx battery backup, please ensure the units are

no further than a 20m cable length from each other. The AlertMaxx2 should be positioned in an area where

there is a good Wi-Fi signal strength.

7.0 Mounting the AlertMaxx2 unit

CAUTION!

The AlertMaxx2 unit is not waterproof and must be installed indoors or inside a kiosk.

1. Remove the screws from the front of the unit that secure the front fascia (the internal ribbon cable will be

disconnected on supply).

2. Using the 4 mounting holes provided, mark, drill and t suitable wall plugs in to the chosen wall for

installation (ensure correct wall plugs are used for the wall type).

3. Secure the AlertMaxx2 unit to the wall using appropriate screws for the wall plugs used.

PLEASE NOTE

When securing the unit to the wall, avoid overtightening the screws as this may cause the box to crack.

4.0 Health & Safety

In order to minimise the risk of ill health or accidents when installing and/or servicing pump chambers and

associated accessories, workers must be fully trained and competent. The following guidelines will help

safeguard matters:

• Assessing the risk and working in accordance with the control measures identied.

• Ensure electrical power to the equipment is isolated before carrying out installation or maintenance.

• A suitable rst aid kit must be close to hand.

• The electrical installation must comply with the requirements of BS 7671:2008 ‘Requirements for Electrical

Installations’ incorporating amendment 3:2015.

5.0 Guarantee

AlertMaxx2 is oered with a 24 month component guarantee. This guarantee only covers any defects in

workmanship, construction or material. This guarantee does not cover, defects caused by incorrect installation,

installer error, abnormal working conditions, misuse or neglect.

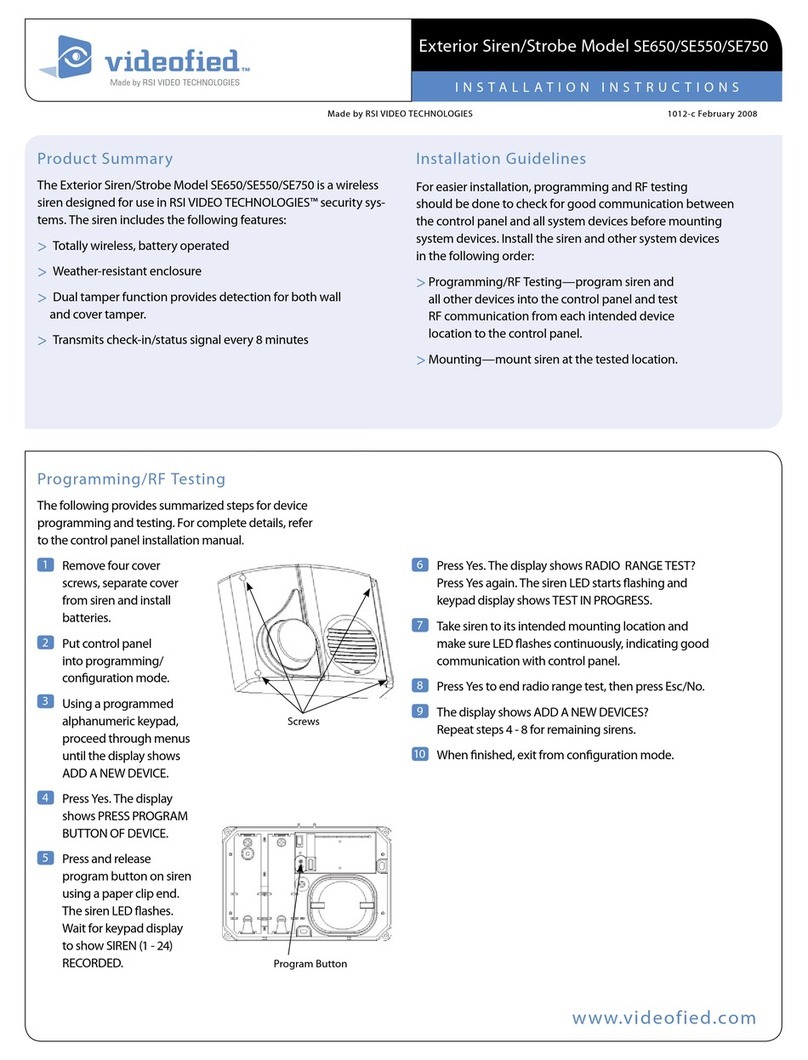

8.0 Wiring schematic

6

AlertMaxx2

The AlertMaxx2 is dierent from a standard high level alarm as the pump/s require to be fed through the unit.

This way of connectivity allows the AlertMaxx2 to collect various dierent parameters directly from the pumps

and when connected via Wi-Fi, this data can be used to intelligently plan maintenance and service schedules to

the specic pump station it is connected to (see page 15).

Figure 1. AlertMaxx2 wiring schematic

AlertMaxx2 High Level Alarm

(DMS-269-2)

For internal wiring of the high

level alarm, please refer to the

AlertMaxx2 instruction manual.

- The pump is supplied with a 10m cable.

- When only using the standard 10m

cable attached to the pump, the cable

duct should be no longer than 6m.

- If the cable duct requires to be longer

than 6m, please follow the cable

extension guide to select an appropriate

cable core diameter.

Finger Float Switch

Supplied with a 10m cable

The electrical installation must comply with the requirements of

BS 7671:2008 ‘Requirements for

Electrical Installations’ incorporating amendment 3:2015

Separate 16 Amp RCBO’s

13 Amp Non-switched

fused spur

AlertMaxx2

7

1. Insert 2 large cable glands into the far right hand side of the AlertMaxx2 unit.

2. Using the wiring schematic (gure 1), feed the mains power cable through the relevant cable gland

and connect the power cable to the corresponding terminal block on the main PCB (gure 2).

WARNING!

Ensure mains power is isolated before connecting and wiring to the AlertMaxx2 unit.

Figure 2. Connecting mains power

9.0 Connecting mains power to the AlertMaxx2

PLEASE NOTE

For ease of installation, each gland is located directly opposite its relevant terminal block.

Follow the internal sticker for wiring guidance.

10.0 Connecting a pump to the AlertMaxx2

8

AlertMaxx2

1. Using the remaining cable gland previously installed in section 9.0, feed the pump cable through the

gland and connect to the corresponding terminal block on the main PCB (gure 3).

Figure 3. Connecting pump

AlertMaxx2

9

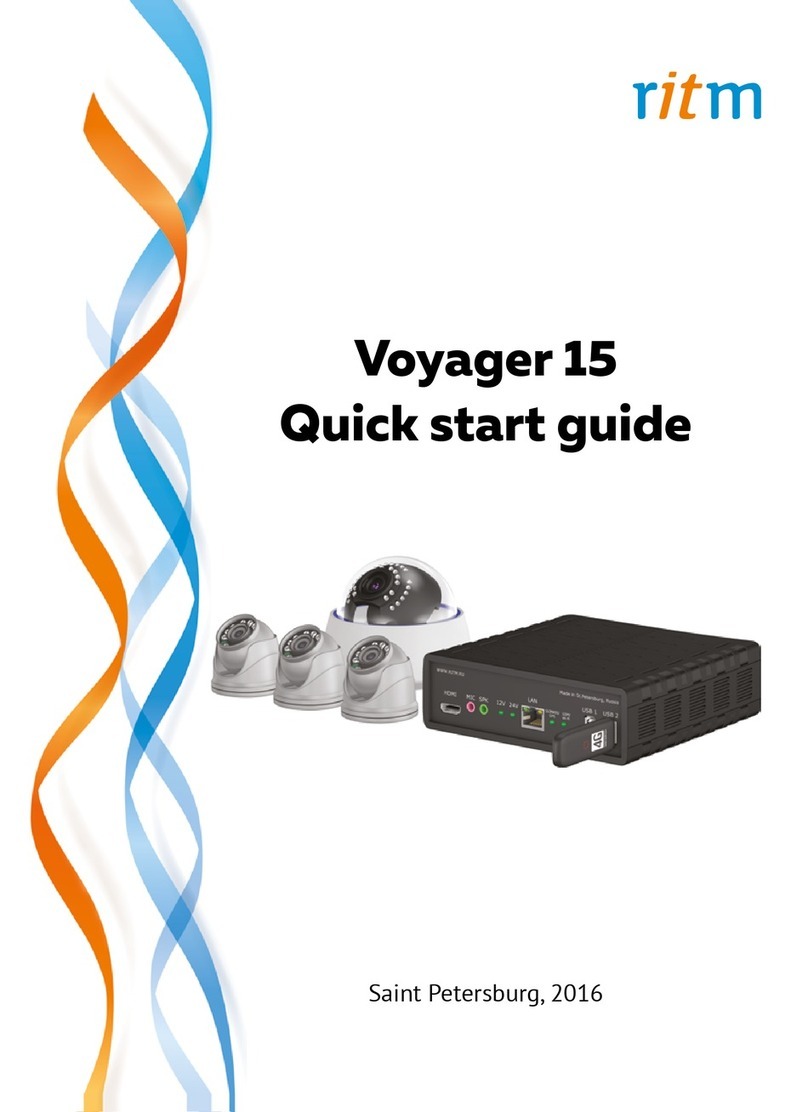

11.0 Installing a pendant oat into a foul water chamber

Figure 5. Foul Water Sump (DMS-165-1)Figure 4. Foul Water Float Switch

Option 1 - Free standing foul pump

1. Using the cable tie provided, attach the oat cable to the discharge arm allowing the bottom of the oat

switch to hang approximately 200mm above the base of the chamber (gure 5).

Option 2 - Guide rail mounted foul pump

1. Pull the oat cable through the oat weight.

2. Using a cable tie, secure the oat weight to the oat cable so there is 80mm of oat cable between the

top of the oat switch and the bottom of the oat weight.

3. Drill a hole through the oat bracket. Hang the pendant oat from the oat bracket so the bottom of the

oat switch hangs approximately 200mm from the base of the chamber. Once the pendant oat is at the

correct height, secure the oat cable to the oat bracket using a cable tie.

BROWN

BLACK

ENL

40

120

20

70

50

80

PLEASE NOTE

The pendant oat switch should be located in a position where the oat can pivot with rising water levels and

not become obstructed (gure 5).

200mm

12.0 Connecting a pendant oat to the AlertMaxx2 unit

10

AlertMaxx2

1. Using a draw cord, pull the oat cable through the cable duct on the chamber.

2. Insert a large cable gland into the far left hole of the AlertMaxx2 unit.

3. Pull the oat cable through the large cable gland on the AlertMaxx2 unit.

4. Connect the black and blue cables from the oat switch cable to the terminal strip (gure 6).

The brown cable should be disregarded and isolated to avoid possible shorting.

PLEASE NOTE

If the cable supplied with the oat switch is too short, the cable can be extended using a cable with a

minimum core cross sectional area of 1mm².

Figure 6. Wiring a pendant oat switch

PLEASE NOTE

Only the rst two (far left) inputs on the oat terminal block are used - Blue & Black

AlertMaxx2

11

13.0 Activating & testing the AlertMaxx2 unit

Before going through the testing process, ensure the mains power to the AlertMaxx2 unit is isolated.

13.2 Turning on the AlertMaxx2 unit for the rst time

1. Ensure the small black switch on the main PCB is set to the ‘NO-SEU’ position.

2. Remove the plastic covers on the battery terminals and connect the red and black leads from the PCB on

to the battery, red to red and black to black.

3. Resecure the battery to the unit by pressing the Velcro on the battery hard against the Velcro on the unit

until a ‘click’ is heard.

4. Once the battery has been connected, the alarm will beep three times and the display will pulse in a

left to right startup sequence.

5. After approximately 20-60 seconds, the display will ash a P1 error code.

6. Ret the front fascia.

7. Turn on the mains feed supplying the AlertMaxx2 unit, within 20 seconds the P1 code will disappear and

the green LED will ash once every 2 seconds.

13.3 Testing the AlertMaxx2 unit

1. Test the alarm by pressing and holding the ‘FUNC’ button for 3-5 seconds and release. The alarm will

sound and the display will show an F1 code.

2. Press the ‘RESET’ button to clear the error code and sound.

3. Test the oat switch by raising the oat switch to its upright position. The alarm will activate within

10-15 seconds.

4. Release the oat switch. The sounder will stop within 30 seconds and the display will ash an F3 code.

Press the ‘RESET’ button, the green LED will ash once every 2 seconds and the error code will clear.

5. Activate the oat switch on the pump to start the pump. The display will show a cycling graphic which

indicates the pump is running.

6. The activation & testing is now complete and the AlertMaxx2 unit is ready for use.

Once the AlertMaxx2 has been installed and fully tested, please apply one of the chamber location stickers,

(provided in the box), to the main label of the AlertMaxx2 fascia and one to its relevant fuse spur. This is to signify

which pump station the high level alarm is connected to and which spur/s feed it.

CAUTION!

If the battery is misconnected to the AlertMaxx2 (i.e. black to red), this will destroy the unit. This can

be detected by the manufacturer and will void the warranty.

13.1 Connecting the ribbon cable

On supply, the ribbon cable that is used to pass communication between the PCB on the fascia and the

motherboard is disconnected from the terminal on the motherboard.

This must be connected before proceeding to section 13.2

See highlighted area in PURPLE on gure 6 (page 10) for terminal block location.

14.0 Connecting external devices

12

AlertMaxx2

16.0 Servicing

The AlertMaxx2 will alert home owners when their pump station requires servicing. This is indicated by an S1

error code followed by one beep every minute. The beep can be muted by pressing the ‘RESET’ button (the

code will remain illuminated). The beep will return 7 days from pressing the ‘RESET’ button until a service

technician resets the alarm unit.

The AlertMaxx2 unit has a factory default service interval of 12 months.

The AlertMaxx2 unit has volt free contacts to connect external devices such as an alarm or beacon. When the

alarm is activated the relay sends a signal continuously.

The volt free relay is designed to accept devices with a maximum load of 0.5A and voltage up to 30V. If external

devices fall outside these parameters, the device must be powered by an external power supply.

You can use the AlertMaxx2 to power external devices with a maximum voltage of 6-7V.

17.0 Spares

Part No. Description

DMS-194 Pendant oat switch

DMS-275 Rechargeable 6V battery

Code Fault Action

S1 Pump Station Service Required Your pump station requires a service. The

AlertMaxx2 will beep every minute. Please contact

PPS to arrange a service visit.

S2 Battery Replacement

(AlertMaxx2)

The battery in the AlertMaxx2 needs to be replaced.

Please contact PPS to arrange a service visit.

S3 Battery Replacement

(Hi-PowerMaxx, if installed)

The battery in the Hi-PowerMaxx needs to be

replaced. Please contact PPS to arrange a service

visit.

15.0 Energy monitoring

The AlertMaxx2 monitors energy consumption from the pumps. This is measure in kWh and is viewable by

pressing the FUNC button for 1-2 seconds. If there are two pumps connected, the screen will alternate between

two gures showing each pump.

AlertMaxx2

18.0 Error codes

Code Fault Action

F1 Flood There is a high level in the pump station. Contact PPS

urgently.

F3 Flood has occurred There has been a high level in the pump station which

has returned back to normal. If this problem arises

again, contact PPS.

P1 Mains Failure There is a power failure to the pump. If you have had

a power cut this will return to normal when power

returns. If you have no PowerMaxx in place, there

is the potential of ooding. AlertMaxx2 will run on

battery power for 2 days. If you haven’t had a power

cut, try to restore power and if the problem persists,

contact PPS as soon as possible.

E1 Float/Cabling Error There is an error with the oat cabling which will need

to be rectied. Please contact PPS.

E2 Cannot nd the SEU card Please contact PPS to rectify.

E3 Problem with the SEU card Please contact PPS to rectify.

E4 No response from server Please contact PPS to rectify.

E5 Cannot nd PowerMaxx The AlertMaxx2 cannot communicate with the

PowerMaxx, the units will continue to work correctly

but data will not be transmitted. Please contact PPS to

rectify the cabling.

E7 No internal battery connected Connect a battery or contact PPS to rectify. If the

battery is depleted it will usually take 10 minutes of

charging before the unit will start. It will take 6 hours to

charge to 80%.

E8 SW error There is a software error on the AlertMaxx2 and

this will need to be updated. Please contact PPS to

update.

E9 SW error (panel cannot talk to

system)

There is a software error on the AlertMaxx2 and

this will need to be updated. Please contact PPS to

update.

CA Call PPS If you see this code, please contact PPS at your

earliest convenience.

PA PPS is aware of your situation

and will be in contact

If you see this code it means PPS are aware of the

situation at your property. PPS will be in contact.

13

14

AlertMaxx2

19.0 Troubleshooting

Fault Cause

The unit does not turn on. The battery is at - charge the battery by connecting

mains to the alarm unit.

Still doesn’t turn on after 3 minutes - alarm unit or

internal battery is faulty.

The decimal points on the displays jump from left to

right.

Low battery - charge the battery by connecting mains

to the alarm unit.

The alarm does not activate when the oat switch is

lifted.

Float switch cable is faulty - check oat switch

connections and cable for damage.

Float switch is broken - replace oat switch.

Float cable is broken - replace oat switch.

The alarm does not activate when pressing the

‘FUNC’ button for 3-5 seconds.

Faulty unit.

Alarm continuously active. Float has been incorrectly wired - check the cables

are connected correctly as per the internal label.

18.0 Error codes cont.

LED Meaning

GREEN slow

ash

All systems OK

BLUE slow

ash

Wi-Fi OK - connected to Gateway OK

BLUE fast

ash

Wi-Fi transmitting

BLUE xed Wi-Fi in setup mode

BLUE No light Wi-Fi not installed or not functioning

20.0 PPS Technical Department

If you are experiencing any technical issues, please contact the PPS Technical Department on 01279 757400

from 9:00am - 5:00pm or email info@ppsgroupuk.com.

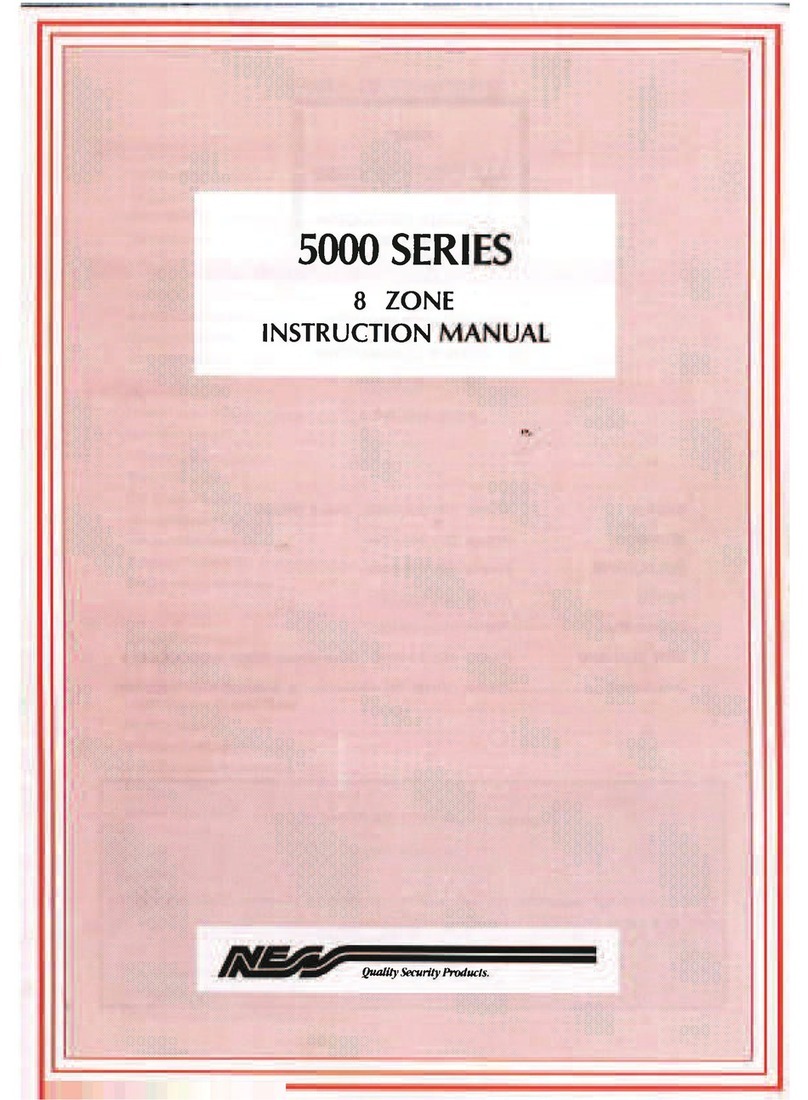

21.0 Hi-PowerMaxx Connection

AlertMaxx2

15

Figure 7. AlertMaxx2 Hi-PowerMaxx connection terminal

The AlertMaxx2 can be connected to a PowerMaxx, PowerMaxx+ or Hi-PowerMaxx to provide additional battery

backup and if connected via W-Fi, battery backup capacity and condition is fed directly to the PPS OpCentre.

The PowerMaxx, PowerMaxx+ and Hi-PowerMaxx are supplied with 3m of 4 core MaxxConnect family cable.

The AlertMaxx2 can only be connected to PowerMaxx, PowerMaxx+ and Hi-PowerMaxx which is

running the software version 3.0 or higher. This can be identied by the software identication sticker

on the back of the battery backup units.

Please refer to the battery backup instruction manual for nal connections.

PLEASE NOTE

For wiring the pumps, please refer to the Hi-PowerMaxx manual.

The AlertMaxx2 must be installed in series to the Hi-PowerMaxx - this means the AlertMaxx2 must

be installed in between the Hi-PowerMaxx & the pump/s.

All Delta Membrane pump systems are tted & can be maintained by our partners, Packaged Pump Systems.

With our long-term relationship we ensure that the system selected is t for your requirements, is delivered

on time, professionally installed & oers hassle free on-going operation & maintenance.

Precise

Fully trained in-house service engineers to maintain, enhance & replace equipment.

Passionate

Bespoke design, manufacturing & installation ensuring our equipment is t for every requirement.

Service

From tting to scheduled maintenance we ensure your needs come rst.

• Fully stocked vans

• Emergency breakdown service

• Out of hours service

• Planned maintenance

• Factory trained engineers

Unit 12, Haslemere Ind. Est., Pig Lane, Bishop’s Stortford. CM23 3HG

After Sales Service

Precise

Passionate

Service

01279 757 400

www.ppsgroupuk.com

T.

E.

W.

This manual suits for next models

1

Table of contents