Delta Tau 3-4112 Series Quick user guide

This manual suits for next models

1

Table of contents

Other Delta Tau Computer Hardware manuals

Delta Tau

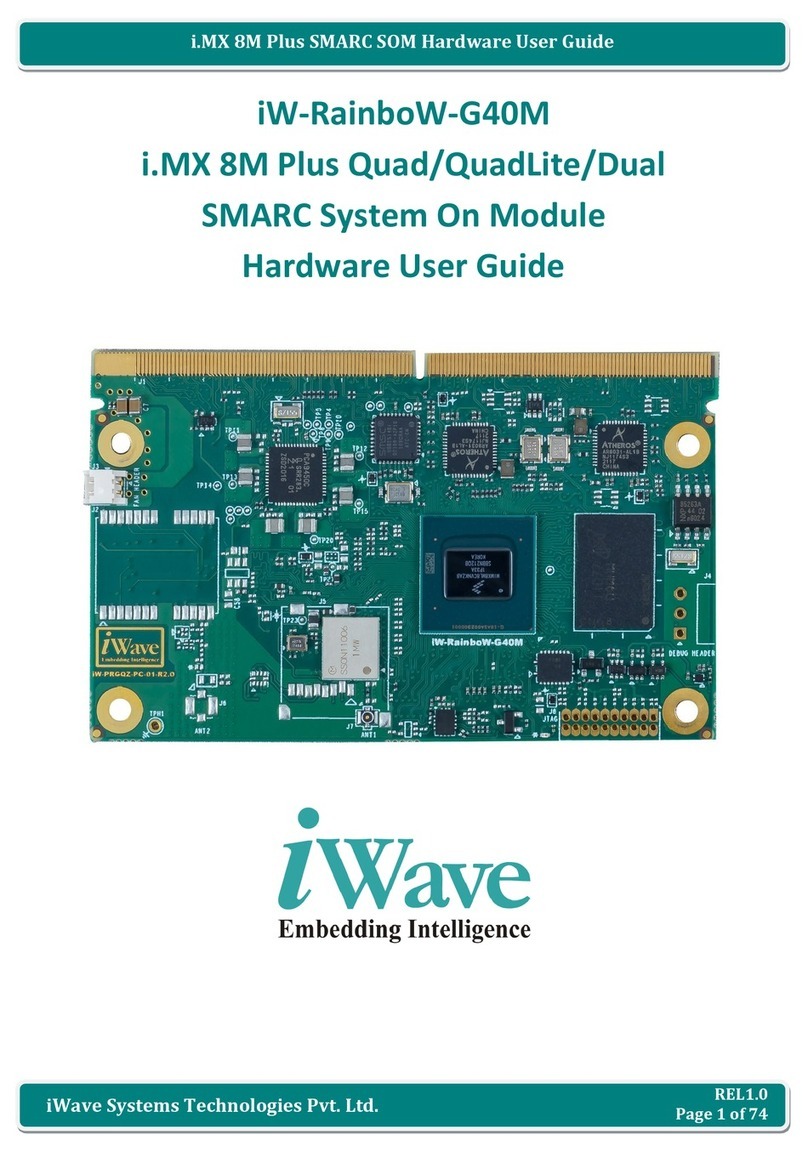

Delta Tau PMAC2A-PC/104 User manual

Delta Tau

Delta Tau 5XX-603869-XUXX Quick user guide

Delta Tau

Delta Tau PMAC2A-PC/104 Quick user guide

Delta Tau

Delta Tau TURBO 4AX-603625-XUXX Quick user guide

Delta Tau

Delta Tau 3-4045 Series Quick user guide

Delta Tau

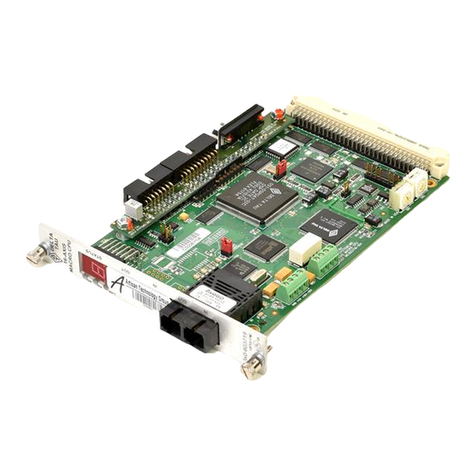

Delta Tau 24E2A User manual

Delta Tau

Delta Tau PMAC Pack Quick user guide

Delta Tau

Delta Tau 8F User manual

Delta Tau

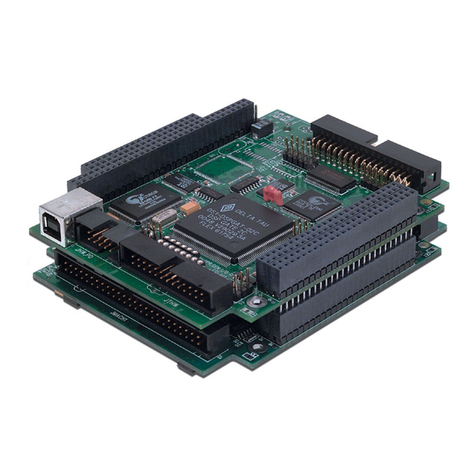

Delta Tau PMAC2-PC/104 User manual

Delta Tau

Delta Tau MACRO CPU BOARD 4Ax-602804-xHxx Quick user guide

Popular Computer Hardware manuals by other brands

Arbor Technology

Arbor Technology EmCORE-i55M0 Quick installation guide

Kontron

Kontron cPCI-MXS64 Technical reference manual

Powerleap

Powerleap PL-PROMMX PLUS manual

Arcam

Arcam A/V Processor XETA 2 Handbook

Inspired Energy

Inspired Energy ATA004N operating instructions

Supermicro

Supermicro SuperServer SYS-E100-12T-H Getting started guide