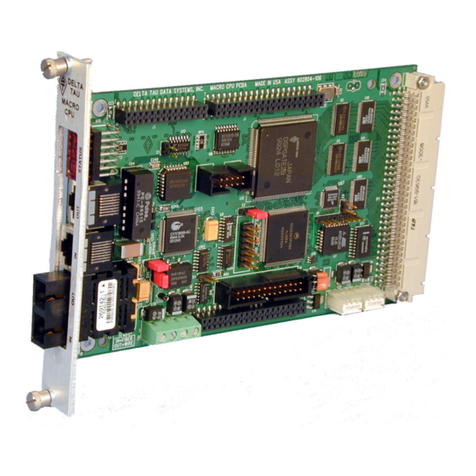

Accessory 24E2S

Table of Contents i

Table of Contents

INTRODUCTION .......................................................................................................................................................3

Features .....................................................................................................................................................................3

Board Configuration..................................................................................................................................................3

SPECIFICATIONS.....................................................................................................................................................4

Environmental Specifications....................................................................................................................................4

Physical Specifications..............................................................................................................................................4

Electrical Specifications............................................................................................................................................4

Agency Approval and Safety ....................................................................................................................................5

E-POINT JUMPER SETTINGS................................................................................................................................6

Acc-24E2S Jumpers*................................................................................................................................................6

HARDWARE SETUP .................................................................................................................................................7

Switch Configuration ................................................................................................................................................7

UMAC Address DIP Switch S1.............................................................................................................................7

MACRO Station Address DIP Switch S1 ..............................................................................................................7

Acc-24E2 Clock Settings ..........................................................................................................................................7

Resistor Pack Configuration......................................................................................................................................8

Differential or Single-Ended Encoder Selection...................................................................................................8

Termination Resistors...........................................................................................................................................8

Acc-24E2 Limit and Flag Wiring..............................................................................................................................9

Connecting Limits/Flags to the Acc-24E2............................................................................................................9

Loss of Encoder Circuit.............................................................................................................................................9

Acc-24E2S Discrete On-board Logic with UMAC Turbo CPU..........................................................................10

Acc-24E2S Discrete On-board Logic with UMAC MACRO CPU......................................................................10

Position Compare Port Driver IC ............................................................................................................................10

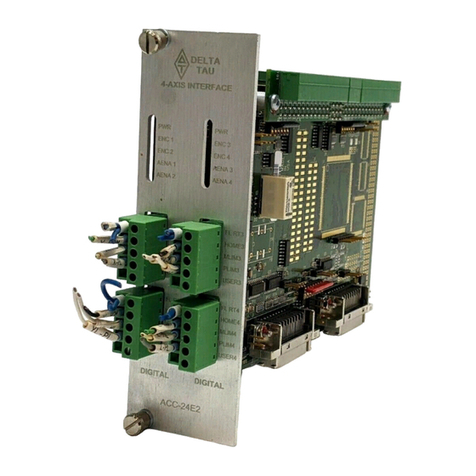

CONNECTIONS .......................................................................................................................................................11

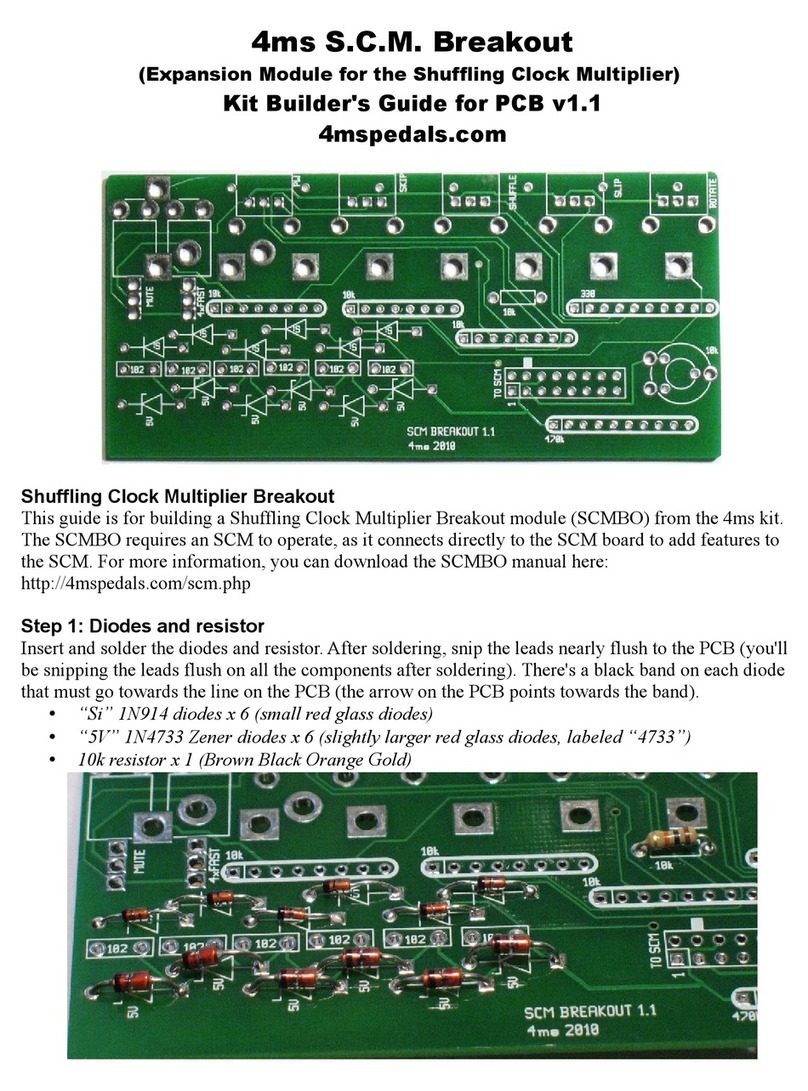

Acc-24E2S Terminal Block Layout Diagram .........................................................................................................11

Acc-24E2S DB15 Option Layout Diagram.............................................................................................................11

Mating Connectors ..................................................................................................................................................11

Terminal Block Connectors ................................................................................................................................11

5 Connector Option ............................................................................................................................................12

Indicators.................................................................................................................................................................12

Sample Wiring Diagrams........................................................................................................................................12

TTL Level Inputs and Outputs ............................................................................................................................12

Acc-24E2S Stepper Motor Outputs (TTL level) ..................................................................................................13

Position Limits, Home Flag, and User Flag.......................................................................................................13

UMAC SOFTWARE SETUP...................................................................................................................................14

System Configuration I-Variables...........................................................................................................................14

Servo IC Configuration I-Variables ........................................................................................................................14

Servo IC Numbering ...........................................................................................................................................14

Servo Channel Numbering..................................................................................................................................14

Multi-Channel I-Variables..................................................................................................................................15

Single-Channel I-Variables ................................................................................................................................15

Encoder Conversion Table I-Variables ..............................................................................................................16

Motor Addressing I-Variables ............................................................................................................................16

UMAC Turbo Example Setups ...............................................................................................................................19

ULTRALITE/MACRO STATION SETUP ............................................................................................................20

Hardware Setup for MACRO Station Use ..............................................................................................................20

Node-Specific Gate Array MI-variables.............................................................................................................20

Encoder/Timer n Decode Control (MSn,MI910) ....................................................................................................20

Flag Capture Control (MSn,MI911-MI913)............................................................................................................21