Delta UV ELP210/3AM Manual

This manual suits for next models

9

Table of contents

Popular Lighting Equipment manuals by other brands

Walter

Walter WaluCover installation instructions

Larson Electronics

Larson Electronics WAL-TL-3XTL-C-SOL-100C instruction manual

novostella

novostella NTA21 user guide

EuroLite

EuroLite LED IP FL-10 COB RGB 120 with Remote user manual

WalimeXPro

WalimeXPro Niova 800 Plus Daylight instruction manual

EGAmaster

EGAmaster MASTEREX 77780 instruction manual

HAMPTON BAY

HAMPTON BAY 407-669 instruction manual

North Light

North Light WX-31VLED44-200WW-10-1 manual

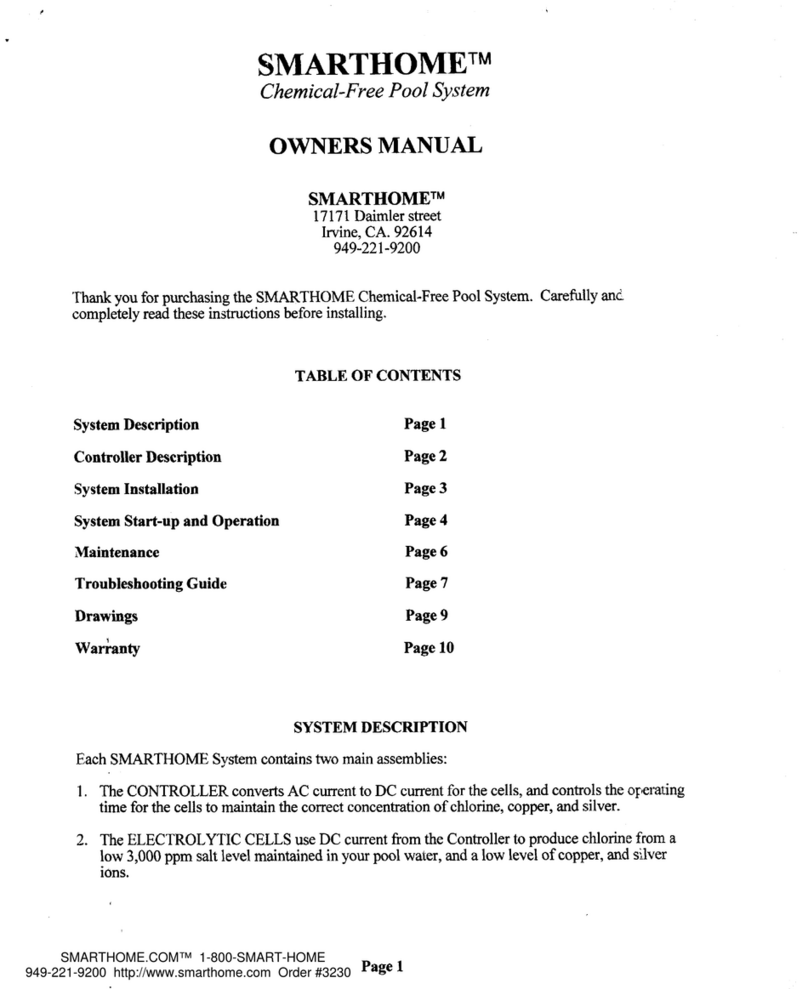

smart home

smart home Chemical-Free Pool System owner's manual

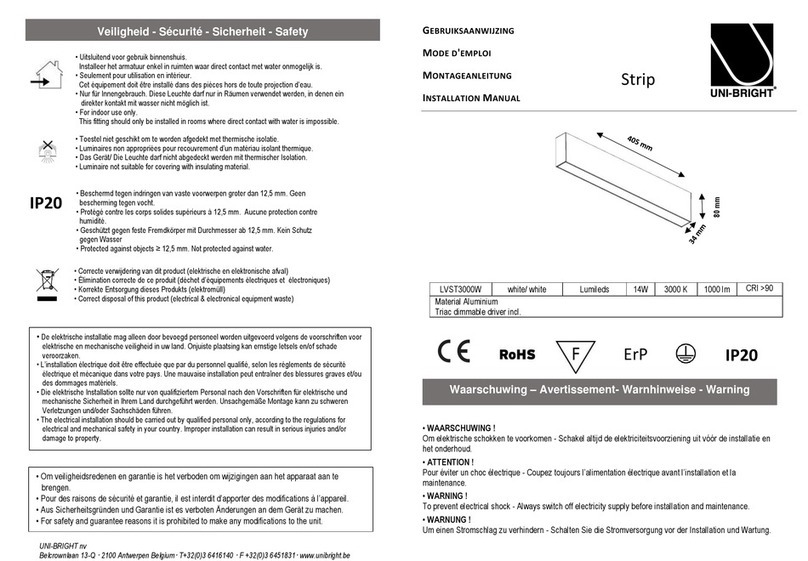

Unibright

Unibright LVST3000W installation manual

Expolite

Expolite Tour-BAR 64 Pre-Manual

viparspectra

viparspectra Reflector Series User instructions

ecoStage

ecoStage LED ZOOM PAR64 COB 200W user manual

NewGarden

NewGarden LOLA SLIM 180 Instructions for use

LIVARNO LUX

LIVARNO LUX 282449 Assembly, operating and safety instructions

Claypaky

Claypaky ALPHA SPOT QWO 800 instruction manual

Show Tec

Show Tec Scorpion Scan 260 manual

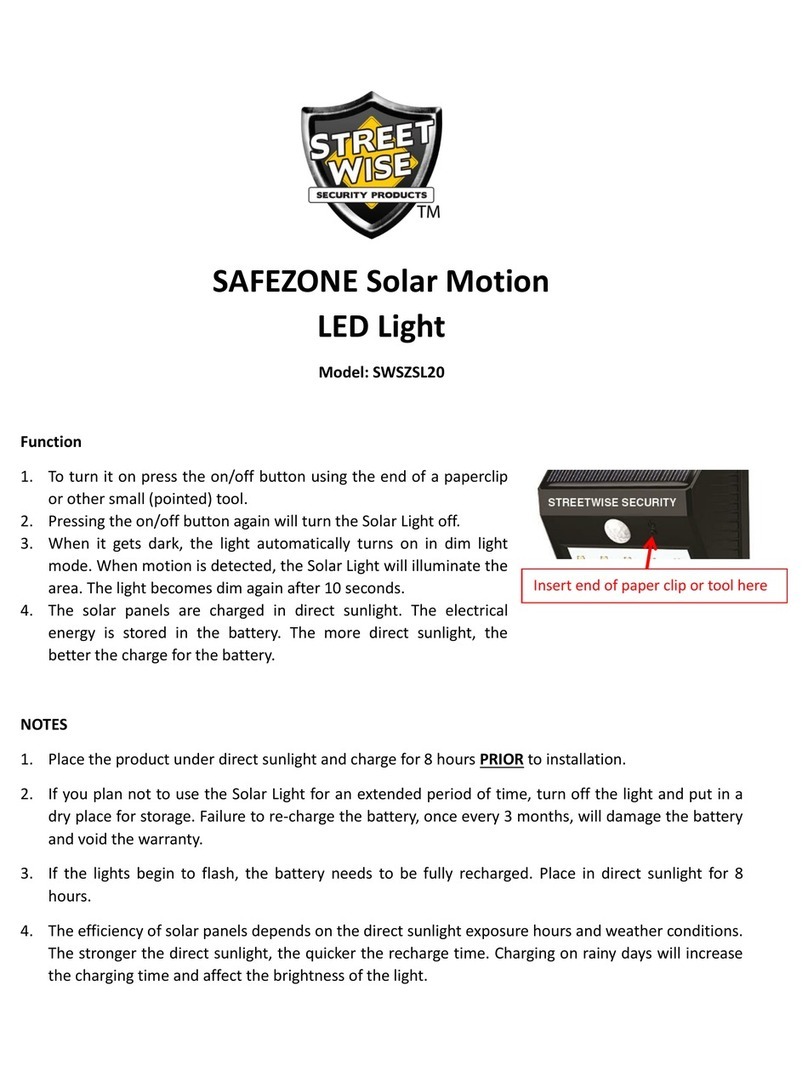

STREET WISE

STREET WISE SAFEZONE SWSZSL20 instructions