TABLEOFCONTENTS

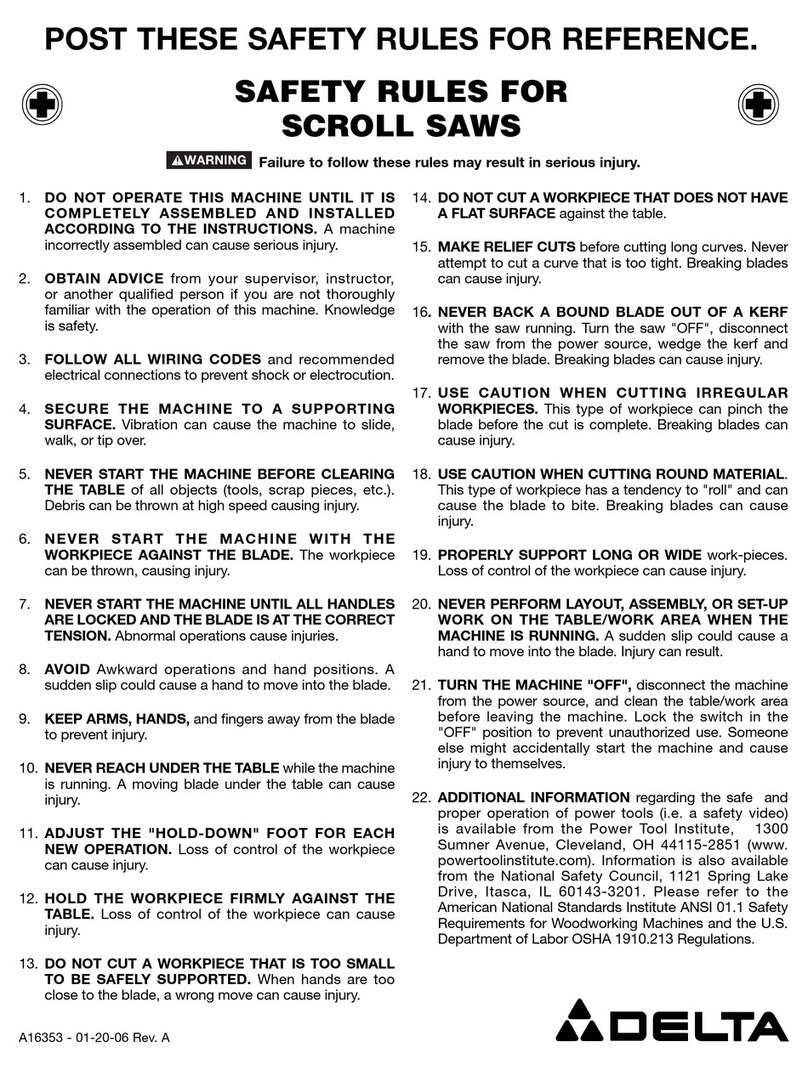

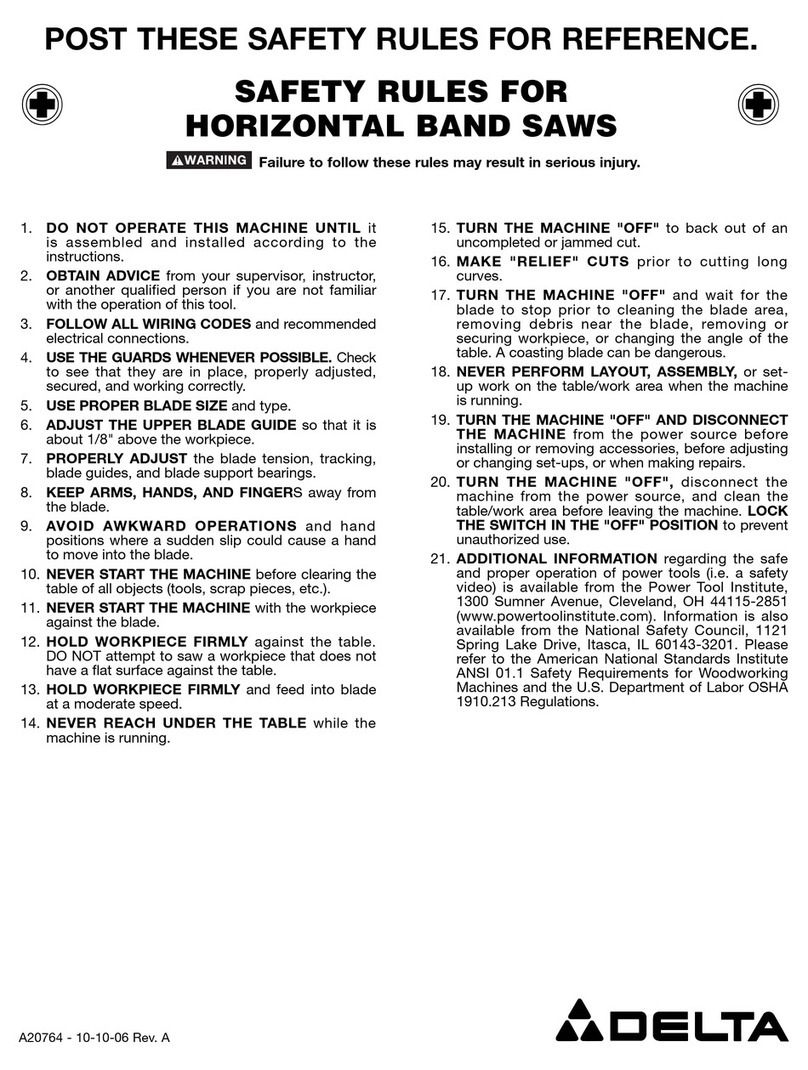

SAFETY

RULES.

ADDITIONALSAFETYRULES

FORCOMPOUND

MITERSAWS. ........4

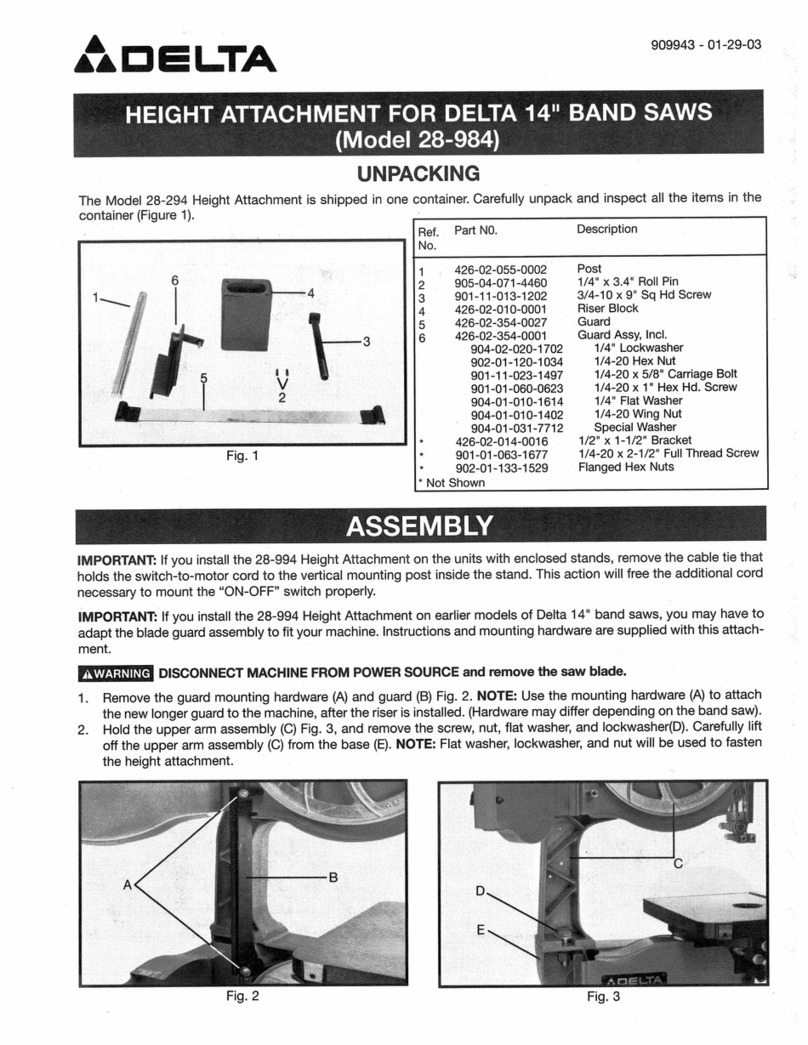

UNPACKING

ASSEMBLYINSTRUCTIONS. .....5

AssemblingTable

LockHandle .....5

RotatingTableTogO

Degree

Position ......5

MovingCuttinghead

ToTheUp

Position ....6

Assembling

Dust

Bag .......6

FASTENING

MACHINETOSUPPORTING

SURFACE .....6

CONNECTING

SAW

TOPOWERSOURCE

PowerConnections..... -...7

MotorSpecifications... -----7

Grounding

Instructions -----.7

EXTENSTONCORDS ......8

OPERATING

CONTROLS

AND

ADJUSTMENTS

StartingAnd

Stopping

Machine .-...8

LockingSwitch

lnThe"OFF"

Position .... .8

RotatingTableForMiterGutting.... """9

PointerAndScale ....9

AdjustingPointer ....9

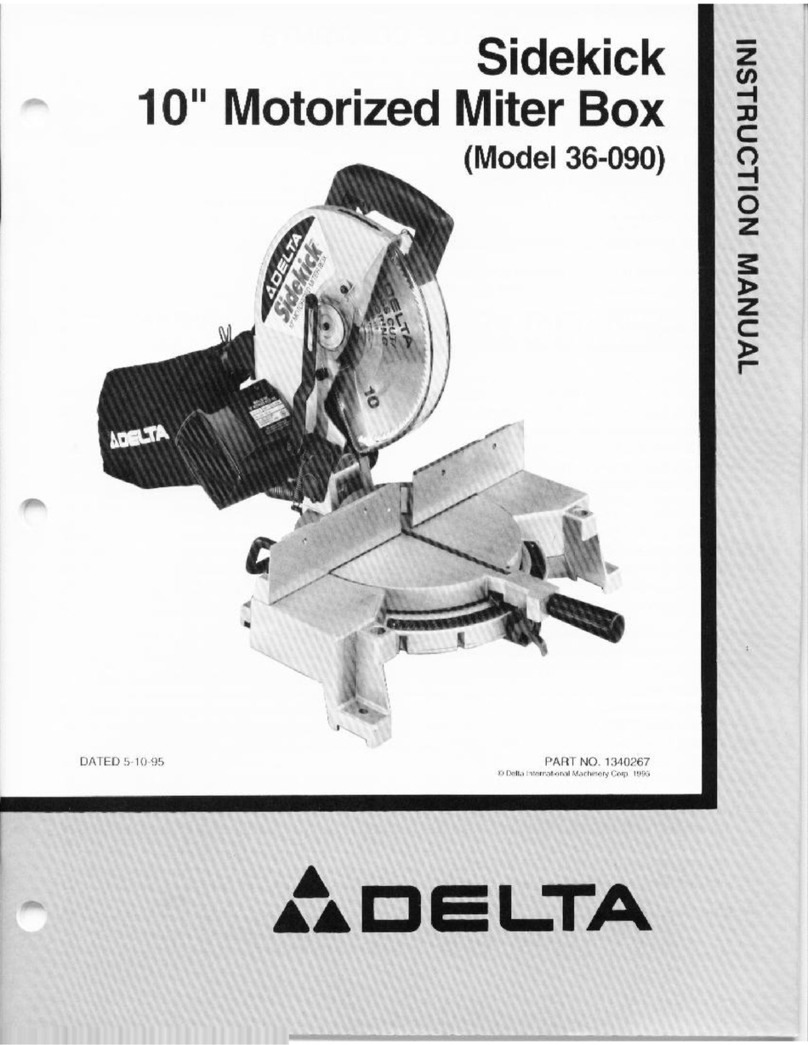

TiltingCuttinghead

ForBevelCutting .....10

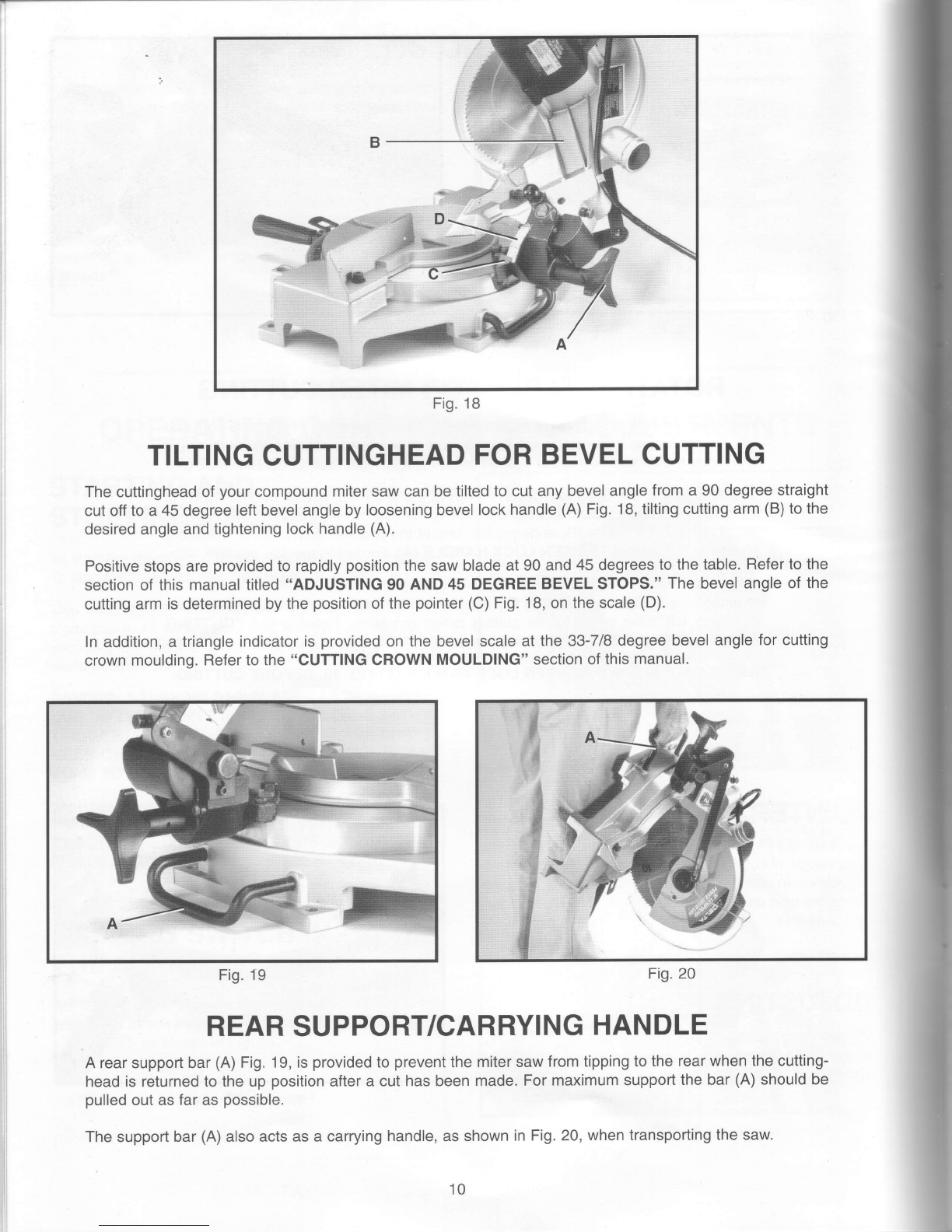

RearSupporVCarrying

Handle .....10

Adjusting

BladeParallel

ToTableSlot.. ... 11

Adjusting

Fence90

Degrees

ToBlade . ....11

Adiusting

DownwardTravel

OlSaw

Blade. .......11

Adjusting

90And

45Degree

BevelStops

.... ---.12

AdjustingTension

OfCuttinghead

ReturnSpring '.. -.. -.12

LockingCuttinghead

lnTheDown

Position ......13

TYPICALOPERATIONSAND

HELPFULHINTS. ........13

AuxiliaryWood

Fence. .--. -14

GeneralCutting

Operations .......14

CuttingAluminum ...15

Cutting

BowedMaterial ....15

Gutting

Crown

Moulding. ...16

MAINTENANCE

ChangingThe

Blade .----- -17

BrushInspectionAnd

Replacement. -'....18

rArtrlELTA

Delta

Building

Tradesand

HomeShop

Machinery

Two

YearLimited

Warranty

Deltawill repairor replace,at its expenseand at its option, any Deltamachine,

machinepart,or machineacces-

sory which in normai use has proven to be delective in workmanship or material,

provided that the customer

returnsthe product prepaid

to a Delta

factory servicecenteror authorized

servicestationwith proof of purchase

ol the product withih two years and provides Delta

with reasonable

opportunity to verify the allegeddefect by

inspeciion.Deltamay requirethat electric motors be returnedprepaid

to a motor manufacturer's

authorized

sta-

tion for inspeclion and repair or replacement.

Deltawill not be responsiblefor any asserteddefect which has

resulted

from normalwear,misuse,

abuseor repairor alteration

madeor specifically

authorized

by anyoneother

than an authorizedDeltaService

facility or representative.Under no circumstanceswill Deltabe liablefor inci-

dental or consequentialdamagesresulling from defectiveproducts,This warranty is Delta'ssole warranty and

sets forth the customer's exclusive remedy,

with respectto defectiveproducts; all other warranties,

express or

implied,

whetherof merchantability,

fitness for purpose,or otherwise,

areexpresslydisclaimedby Delta.