VERS. 2022.10.14 CWT 315_MAN_EN

6

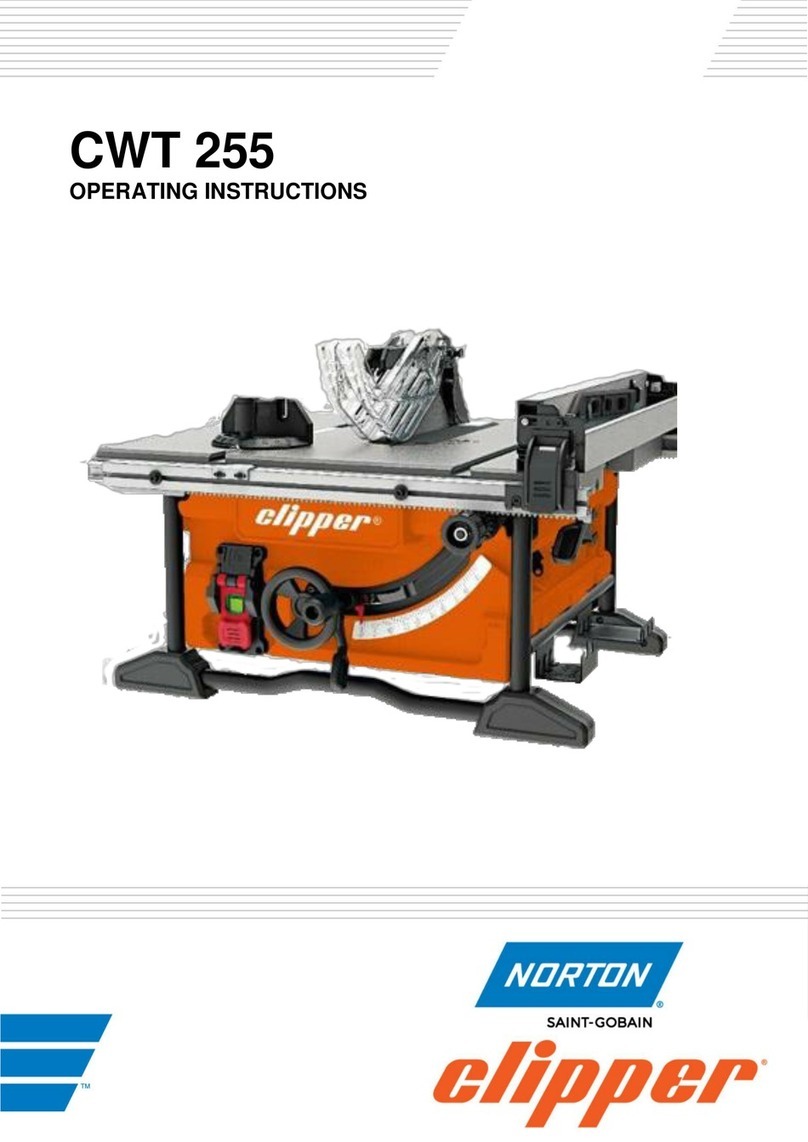

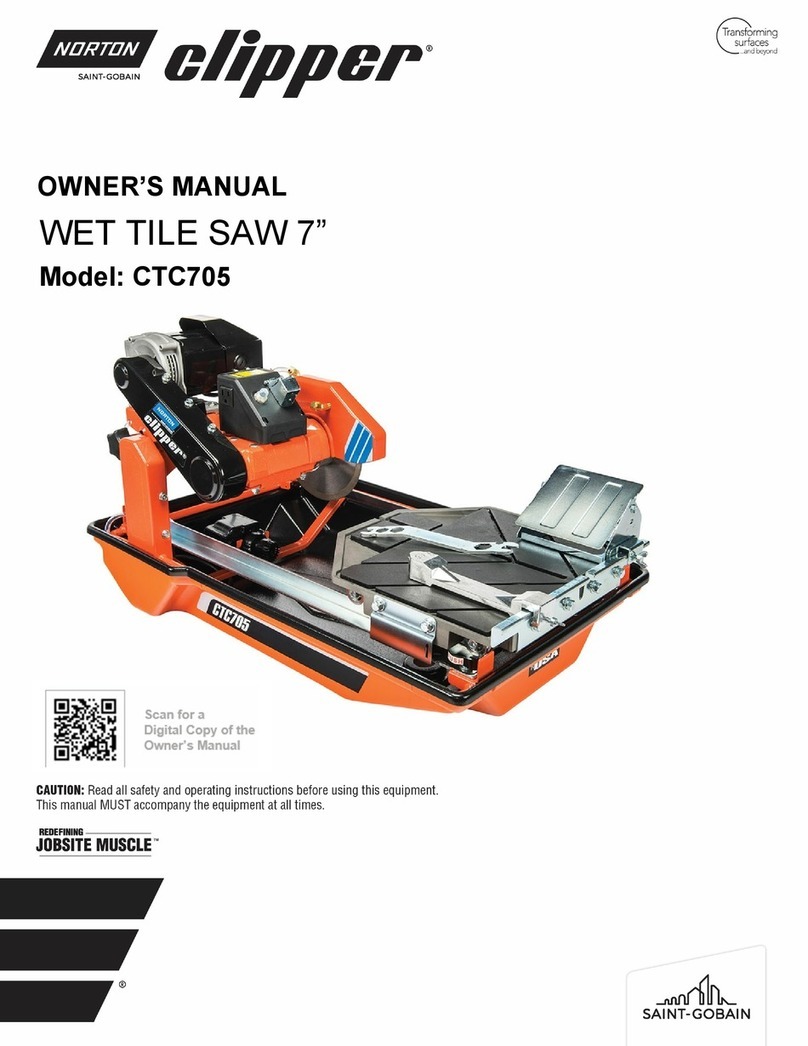

CWT 315

TABLE OF CONTENTS

PRODUCT DESCRIPTION:....................................................................................5

1 - GENERAL INFORMATION ....................................................................................7

1.1 PURPOSE OF THE MANUAL..........................................................................7

1.2 USERS OF THE MANUAL ...............................................................................7

1.3 PRESERVATION OF THE MANUAL ................................................................8

1.4 LIABILITY AND WARRANTY ..........................................................................8

1.5 MANUFACTURER'S DISCLAIMER .................................................................8

2- TECHNICAL INFORMATION...............................................................................9

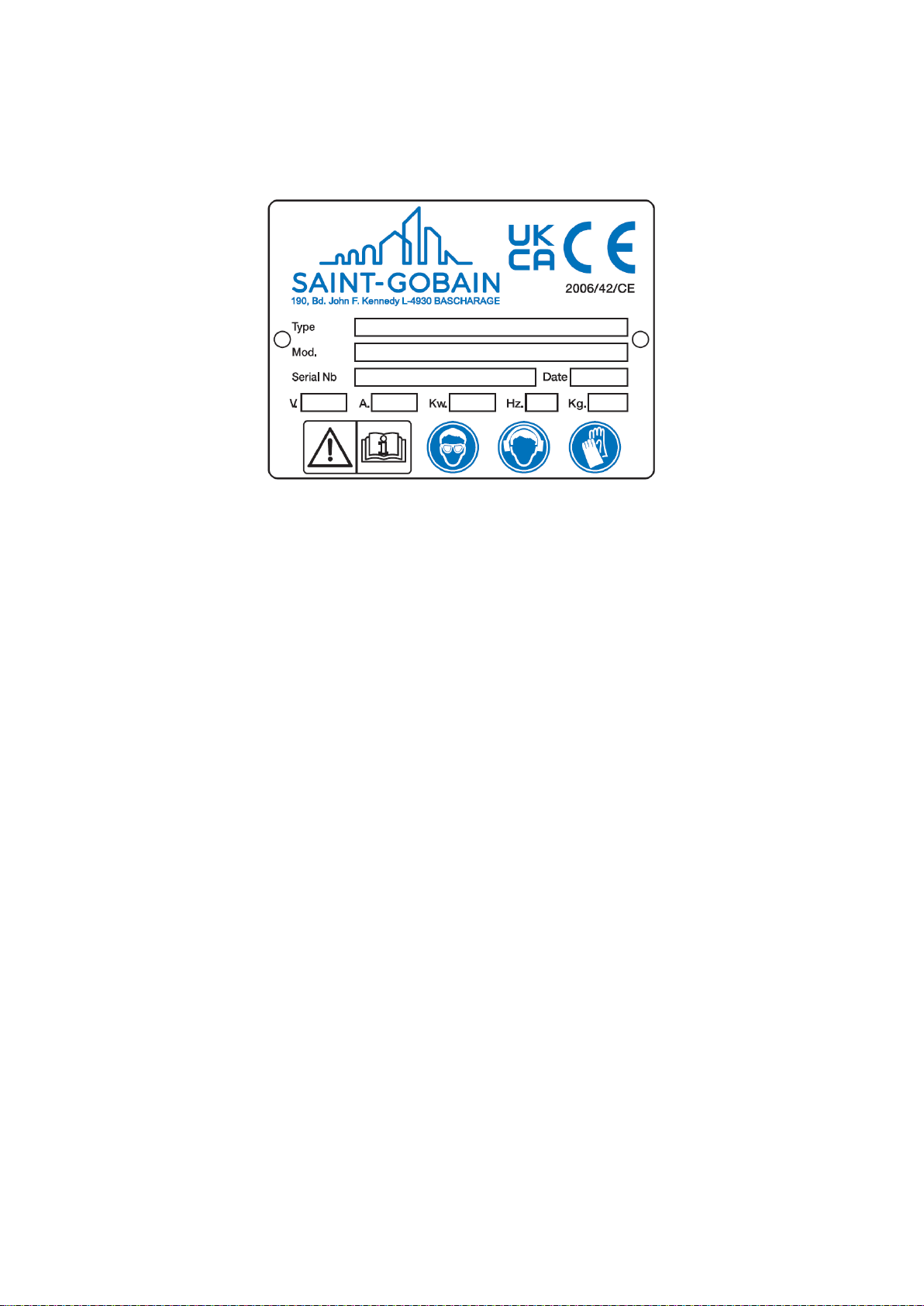

2.1 IDENTIFICATION .............................................................................................9

2.2 DESCRIPTION OF THE "Fixed blade" MACHINE..........................................9

2.3 DIMENSIONS AND FEATURES "Fixed blade model".................................11

3- GENERAL SAFETY RULES .................................................................................12

3.1 PREMISE........................................................................................................12

3.2 POSITIONING THE MACHINE (fig. 1)...........................................................13

3.3 SAFETY PRECAUTIONS...............................................................................14

3.4 SIGN DESCRIPTION FOR ALL MACHINES .................................................15

4 - HANDLING AND INSTALLATION .......................................................................17

4.1 TRANSPORTATION BY TRUCK ...................................................................17

4.2 LOADING UNLOADING AND HANDLING ....................................................17

4.3 PRELIMINARY CHECKS ...............................................................................18

5 - STARTING AND STOPPING................................................................................19

5.1 STARTING AND STOPPING THE MACHINE................................................19

5.2 INSTRUCTIONS FOR USING THE ELECTRICAL EQUIPMENT ..................20

5.3 ANOMALIES AND REMEDIES ......................................................................21

5.4 BLADE COVER CAP .....................................................................................22

6 - USE OF THE MACHINE.......................................................................................23

6.1 USE OF THE CIRCULAR SAW......................................................................23

6.2 CUTTING DISC...............................................................................................24

6.3 USE OF THE SQUARE GUIDE......................................................................25

6.4 LONGITUDINAL AND SIDE PUSHER...........................................................26

6.5 EXTENSION OF THE WORK BENCH ...........................................................27

6.6 STABILITY' OF THE MACHINE......................................................................28

6.7 CHIP DISCHARGE SLOT AND SUCTION MOUTH.......................................28

Periodically check that the slot is not blocked by chips.................................28

7 - MAINTENANCE....................................................................................................29

7.1 TRANSMISSION BELTS................................................................................29

7.2 REPLACEMENT OF THE BLADE (see details on page 33)........................29

It is not recommended to use blades with reduction rings.............................30

7.3 BRAKING TIME..............................................................................................30

Braking control test:...........................................................................................30

7.4 DESCRIPTION OF THE PERIODIC CHECKS TO BE CARRIED OUT ON

THE MACHINE BEFORE USE.......................................................................31

7.5 DISMANTLING ...............................................................................................31

8- SINGLE-PHASE WIRING DIAGRAM....................................................................32

Customer service................................................................................................33

Spare parts ..........................................................................................................34