8

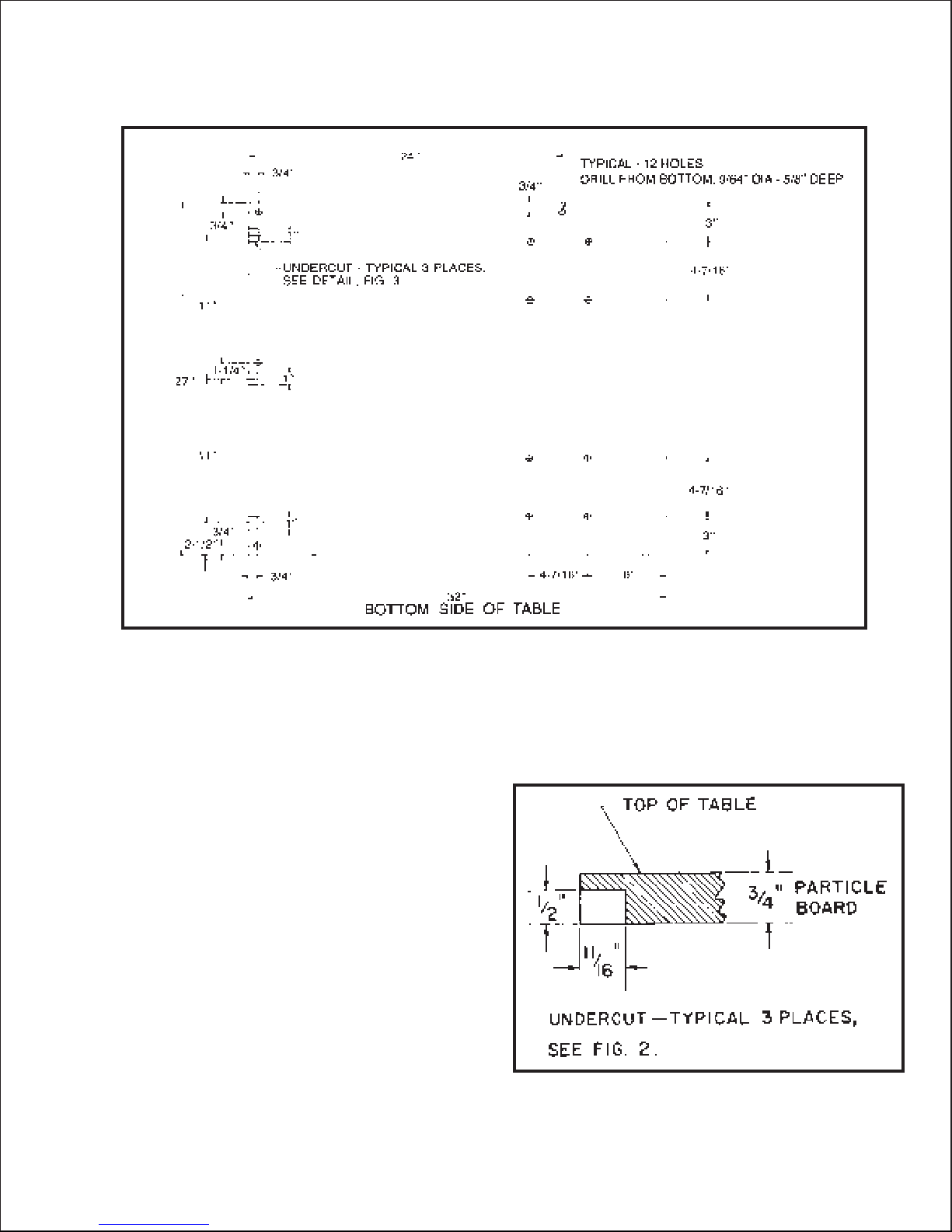

Fig. 20

Fig. 21

Fig. 22

Fig. 23

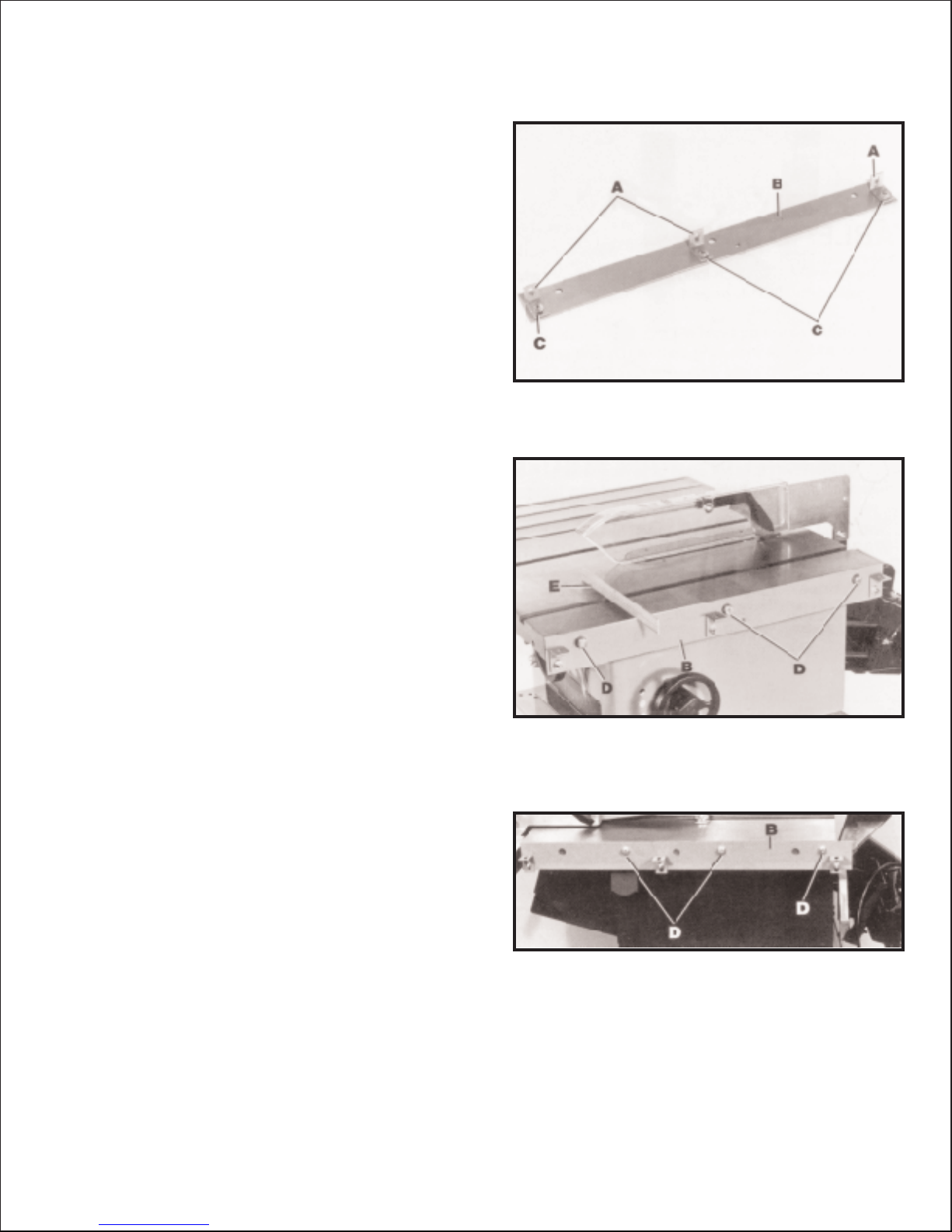

7. Slide template (A) Fig. 20, lef t or right, along the t able

until the line (C) on the template marked lineup with right

side of blade is aligned with the lef t edge of the straight

edge (B). Make sure the fold in the template is along the

top front edge of the t able and t ape the template to the

table.

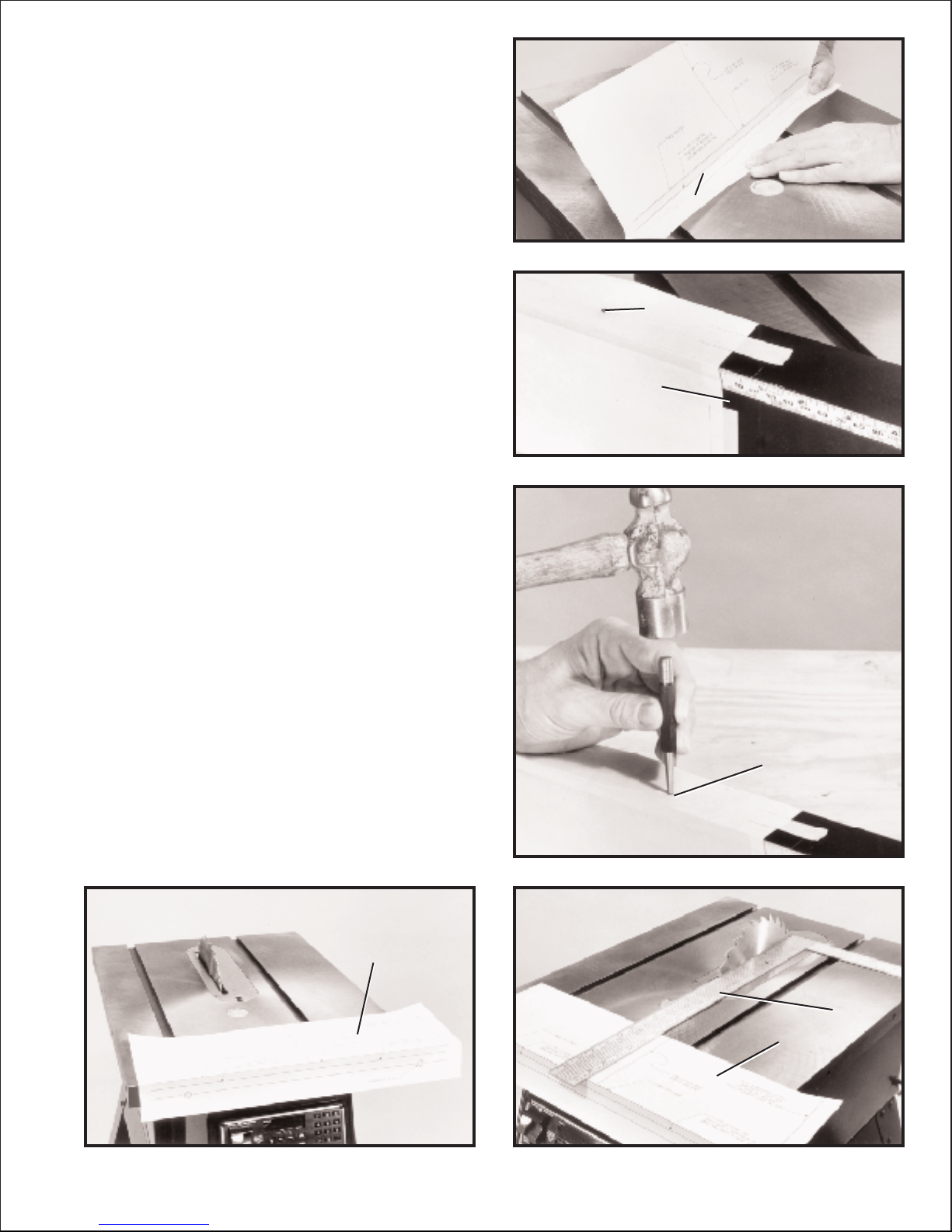

8. Check to see if the two holes (D) Fig. 21, illustrated

on the template match the holes on the front edge of your

saw t able.

A. If the location of the holes in your saw t able

match the holes (D) Fig. 21, illustrated on the tem -

plate and are 7/16 in diameter, remove the template

and proceed to STEP 13.IMPORTANT: IF HOLES

IN FRONT OF SAW ARE THREADED, THEY MUST

BE DRILLED OUT.

B. If the location of the holes in your saw t able

match the holes (D) Fig. 21, illustrated on the

template but are not 7/16 in diameter, remove the

template and enlarge the holes in the t able by drilling

them out. Then proceed to STEP 13.

C. If the location of the holes in your saw t able do

not match holes (D) Fig. 21, illustrated on the tem -

plate, it will be necessary to drill two new 7/16 diam -

eter holes in the saw t able at locations indicated at

(D), on the template, providing structural ribs or

existing holes in the t able do not interfere with the

two new holes. Center punch to locate the two new

holes to be drilled and remove the template. Drill the

two new 7/16 diameter holes in the t able and pro -

ceed to STEP 13.

D. If structural ribs or existing holes in the saw t able

prevent drilling holes at the locations shown on tem -

plate at (D) Fig. 22, it will be necessary to move one

or both of the holes, making sure the new holes are

on the same center line as holes (D). Mark the loca -

tion of new hole(s) (E) on the template, as shown in

Fig. 22. Center punch the location of the new hole(s),

remove the template, drill the new hole(s) in the t able

and proceed to STEP 9.

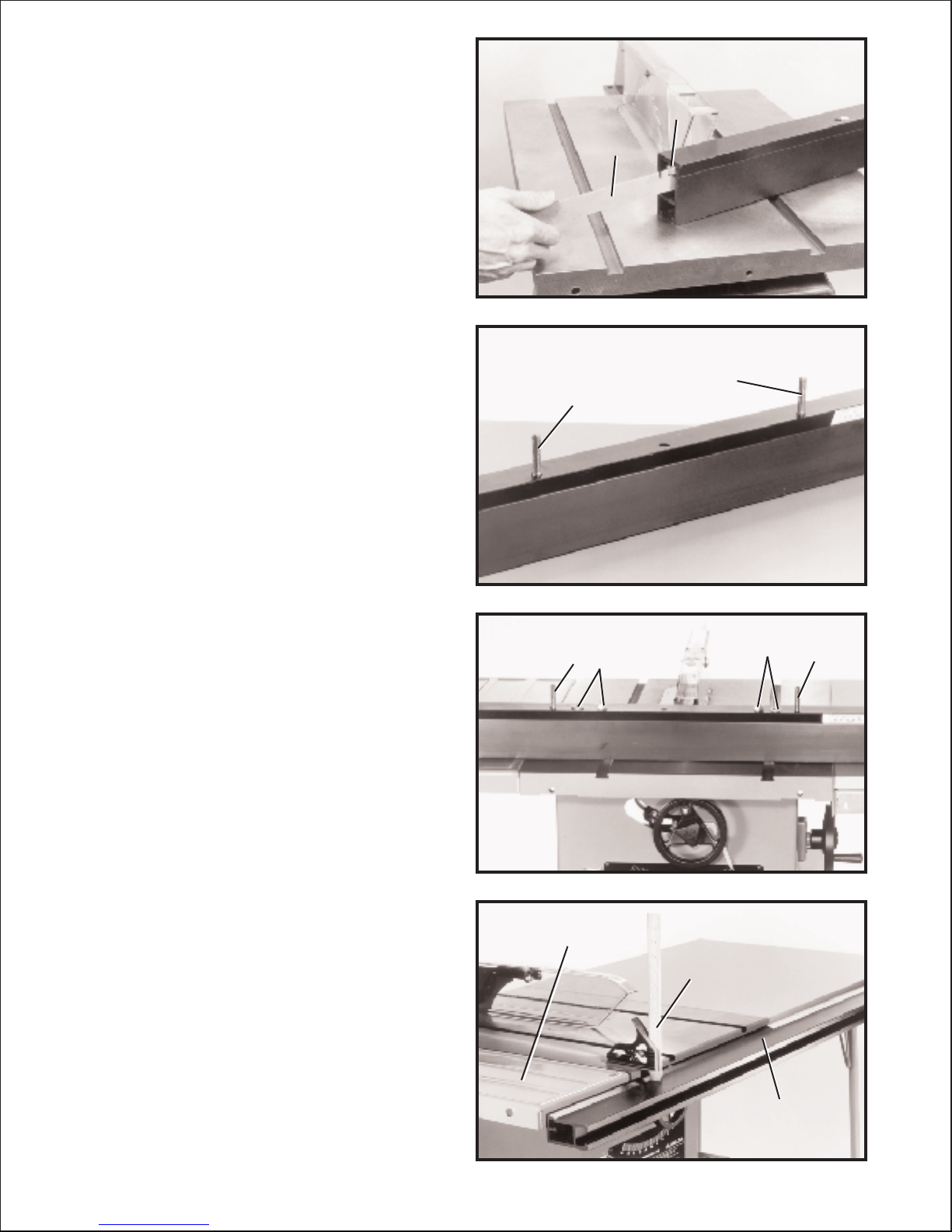

9. Cut the template along the line marked 0 (zero on

guide rail scale), as shown in Fig. 23.

C

B

A

DD

D

E