Deltafan Ex User manual

Deltafan

Wojciech Franczak

Brzeźnica 234B, 34-114 Brzeźnica

Phone: +48 33 879 20 38

Fax: +48 33 879 22 65

E-mai : biuro@de tafan.p

INSTRUCTION MANUAL

for „DELTAFAN wall fans

***/R/*-*/**/***/Ex type

The instruction manual should be read before starting up the fan.

Version 2

Brzeźnica 2010

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 2/14

List of contents

Page

1. GENERAL PRECAUTIONS _____________________________________________________________________3

2. GENERAL SAFETY RULES______________________________________________________________________ 3

3. GENERAL INFORMATION _____________________________________________________________________4

4. TECHNICAL DATA _____________________________________________________________________________5

4.1 DEVICE DESCRIPTION AND CONSTRUCTION __________________________________________________5

4.2 MARKING _____________________________________________________________________________6

4.3 NOMINAL PARAMETERS _________________________________________________________________ 6

4.4 LOCATION_____________________________________________________________________________8

4.5 OPERATION ___________________________________________________________________________8

4.6 POWER SUPPLY OF FAN MOTOR ______________________________________________________________ 9

5. TRANSPORT AND HANDLING _________________________________________________________________10

6. INSPECTIONS AND MAINTENANCE ____________________________________________________________10

6.1 THE SMALL INSPECTION_________________________________________________________________11

6.2 THE MAIN INSPECTION _________________________________________________________________11

7. DISPOSAL ________________________________________________________________________________12

8. WARRANTY CONDITIONS____________________________________________________________________12

9. MANUFACTURER __________________________________________________________________________12

10. RATING PLATE __________________________________________________________________________13

11. DECLARATION OF CONFORMITY ____________________________________________________________14

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 3/14

NOTE!

Fans are not equipped with a power cord. The user should provide a power cord, which must

meet requirements included in applicable directives and standards harmonized with given

directives

1. GENERAL PRECAUTIONS

−This instruction manua is an integra part of the device. Information and data inc uded must be strict y

fo owed throughout the entire service ife of the device and must be enc osed, shou d the device be used

by another user. If the instruction manua is damaged or ost, p ease contact our company to obtain

another copy.

−After the device is unpacked, check if the fan is comp ete and a parts are intact. If the device is damaged

or some parts are missing, p ease contact our dea er. In no case should the incomplete device be installed

or started up!

−The device is designed for venti ation of rooms and must be used according y. Otherwise, any c aims wi be

rejected. Mechanica damages caused by peop e or anima s, incorrect insta ation, fai ure to fo ow the

ru es or incorrect use are not subject to warranty c aims.

−Repairs and maintenance shou d be performed by qua ified personne . Any modifications and tampering

with the device are forbidden, since it may cause serious consequences, which the manufacture cannot be

he d responsib e for.

−The device requires the use of origina parts on y. Damages caused by using incorrect, unorigina materia s

and other accessories are not subject to warranty c aims.

−P ant insta ations (e ectric, venti ation) shou d be correct y connected to the device and shou d not hinder

its operation in any manner.

−Designers, engineers, fitters and users shou d be aware of a responsibi ities re ated to ega provisions and

standards in the designing, insta ation, operation and repairs of the device.

−The company cannot be he d responsib e for any damages caused as a resu t of the fai ure to observe

instructions and information (in particu ar, as a resu t of misinterpretation) inc uded in the instruction

manua and concerning the operation and use of the device.

2. GENERAL SAFETY RULES

P ease remember that using devices supp ied with e ectric energy requires the observation of a number of the

fo owing genera safety ru es:

The device shou d not be touched, if parts of the cover are wet or moist.

The e ectric insta ation, which the device is connected to, shou d be performed according to

regu ations in force, must be technica y operationa and possess va id and required by regu ations

tests and certificates.

When beginning any activities re ated to c eaning and maintenance, make sure that the main

switch is disengaged and check whether the device is ive!

It is forbidden to modify protections of the device.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 4/14

In no case shou d any objects be p aced between the protection screen and rotor.

Great caution shou d be exercised, because outside motor temperature can be high. Touching it

can cause burns.

It is forbidden to use connectors, mu tip e sockets and extensions in order to connect the device to

the e ectric supp y.

The safe operation of e ectric devices in exp osion endangered areas depends main y on their

proper se ection to exp osion hazard conditions, correct insta ation and power supp y, protection

against short-cuts and over oads, and then, on proper usage. If one of the conditions is not

satisfied, the safety wi not be ensured or be very expensive to obtain.

E ectric devices marked with Ex, of proper parameters and certified as exp osion-proof according

to the ATEX 94/9/WE directive shou d be used in exp osion endangered areas.

3. GENERAL INFORMATION

A fan is a rotor device, which receives mechanica energy and by means of one or a few rotors equipped with

b ades uses the energy to constant y transfer a medium. Therewith, the va ue of transferred work per a mass

unit does not exceed the norma va ue of 25 [kJ/kg].

Wa fans of the type ***/R/*-*/**/***/Ex from De tafan are designed to operate in spaces, where there is a

danger of exp osive atmosphere occurrence as a resu t of the existence of gas, air, mist and vapour mixtures

rated as the group II.

The fans are inc uded in the device group II category 2G. The devices are designed and produced according to

the requirements of the Directive 94/9/WE (ATEX) and harmonized standards assigned to the Directives:

• PN-EN 60079-0:2009,

• PN-EN 60079-7:2008,

• PN-EN 13463-2010,

• PN-EN 13463-5:2005,

• PN-EN 14986:2009.

Additiona means were providing in the construction of fans to ensure enhanced safety in case of excessive

temperature, occurrence of arches and sparks both inside and outside of the motor, and outside e ements

during norma operation.

The fans meets the temperature c ass of T3 and T4 – that is, the maximum temperature of any fan part in the

most unfavourab e but permissib e conditions does not exceed 200°C and 135°C, respective y. The temperature

c ass of a fan depends of an e ectric motor used in the fan.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 5/14

4. TECHNICAL DATA

4.1 DEVICE DESCRIPTION AND CONSTRUCTION

The „DELTAFAN” wa fans of the type ***/R/*-*/**/***/Ex are devices with short housing designed to be

mounted in a wa . The main task of such fans is to discharge exp osive mixtures of gas or f ammab e f uid

vapour with air from the room being venti ated.

The fan housing consists of e ements made of we ded stee sheets. Supporting arms are screwed to the front

part of the housing. Asynchronous e ectric motor adapted to continuous operation (S-1) in exp osion

endangered areas of the iso ation c ass F and protection degree IP56 is mounted to the supporting arms. The

supporting arms are made of stee sheets coated with powder epoxy-po yester paint „ALESTA EP KP-E45” of the

surface resistance of 2x105-106 [Ω].

The fan rotor is made of antistatic po yamide (PAGAS), die cast and reinforced with g ass fibre (b ades) and

si umin a oy (A Si 12 Cu), a so die cast (fan hub). The fan rotor is mounted direct y on the e ectric motor shaft.

Rotors of such type are adapted to operate in a potentia exp osive atmosphere and meets the requirements

re ated to the ATEX Directive.

From the air intake side of the fan there is the protection screen preventing foreign bodies IP20 from entering.

The protection screen is made of stee wire (St3S grade) according to the standard PN-67/M-80026. The wire is

coated with powder epoxy-po yester paint „ALESTA EP KP-E45” of the surface resistance of 2x105-106 [Ω].

Fig. 1 „DELTAFAN” wa fan of the type***/R/*-*/**/***/Ex

1. Fan b ade,

2. Rotor hub,

3. Short housing,

4. E ectric motor,

5. Motor shaft,

6. Protection screen from the motor side,

7. Motor supporting arms.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 6/14

4.2 MARKING

„DELTAFAN” wa fans of the type:

4.3 NOMINAL PARAMETERS

The aerodynamic characteristics were deve oped on the basis of investigations in a aboratory of

Mu ti-Wing (Denmark). Due to the extensiveness of the materia , the data – the dependency of the air

vo ume f ow on the fan compression, in particu ar – for a fans are pub ished in the cata ogue and are

avai ab e on our regu ar y updated website at www.de tafan.p . The se ection of a fan for a particu ar

app ication shou d be carried out by a competent person, so that the fan operation point in not

ocated in the unstab e operation area (the so ca ed fan sta phenomenon).

Common parameters for a fans in the series of types:

• Protection degree IP20 (from the fan air intake side)

IP56 (fan drive)

• Working temperature -20°C ≤Tamb≤ +40°C

• Re ative humidity up to 95%

e

xp osion

-

proof bui d

230 - power supp y vo tage 230V,50Hz

400 - power supp y vo tage 400V,50Hz

b ade inc ination ang e

number of rotor b ades

wa fan

fan diameter

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 7/14

• Power data given in the tab e concerns the power on the e ectric motor shaft.

• The current va ue is given for the star motor connection.

• The eve of acoustic pressure in the distance of 1m from the fan with spherica form of sound propagation.

Fan type

Rotation

s

Output

Power

Current

Temp.

class

Noise

level

Motor type

Dimensions [mm]

tE

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 8/14

4.4 LOCATION

The device mounting ocation must be estab ished in a design by a competent person. Technica requirements

and regu ations in force must be met to obtain permissions (among others, re ated to a bui ding, architectonic

and fire-proof provisions, environmenta egis ation). Prior to the device fitting and insta ation it is

recommended to obtain a necessary permissions.

The fo owing conditions must be met to ensure the correct insta ation of a device:

the device shou d be used according to its purpose,

the device shou d be bui t in a construction capab e of supporting the fan weight,

proper distances must be maintained to ensure correct air f ow and free access during maintenance works,

simp e activities and device operation monitoring are permitted,

the fan shou d be protected on the other side of a room being venti ated by means of a protection screen

preventing any objects from entering and damaging the fan during operation. The protection screen shou d

be adapted to exp osion-proof working conditions,

in order to protect against accidenta contact with device moveab e parts it is forbidden to remove fan

protecting e ements, that is, protection screen insta ed.

4.5 OPERATION

The fan can operate in vo tage variations not exceeding 5% of the motor rated vo tage. A rating is re ated to

rated vo tage. If vo tage variations exceed 5% of the rated vo tage, the motor shou d not be started.

The fan motor has protection rating of IP 56, which prevents so ids and water from entering its inside in the

scope specified in the standard IEC 60034-5.

The motor can be used for constant operation on y, which means ight and rare start-ups not causing serious

motor heating. The use of a protection c amp depends of e ectric shock protection app ied according to

standards in force.

The following should be checked before connecting the motor:

The rated vo tage of the motor must correspond to the vo tage of a power supp y network

(network vo tage variations cannot exceed ±5 % of the rated vo tage).

Connections for correct winding on the termina box.

Mounting and continuity of the protection connection.

The motor shou d have correct over oad protection, whose current-time characteristic guarantees

that the motor wi be disconnected from the supp y vo tage in a time shorter than time tE

specified for it at a current equa to the motor starting current.

The motor iso ation resistance cannot be ess than 20MΩ in the co d state. In case when the motor

is moist (when the motor iso ation resistance is ess than 20MΩ) it shou d be dried in the

temperature be ow 353K (+ 80°C).

The motor rotation direction shou d be consistent with the rotation direction of a device being

driven; in typica motors the rotation direction is c ockwise – ooking from the motor driving side.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 9/14

During operation special attention should be paid to the following:

The access of coo ing air from the motor housing cannot be hindered. The housing may have worse

conducting properties due to the sticking of dust and dirt partic es to the fan surface. Therefore,

the housing surface shou d be periodica y c eaned with a cotton c oth.

During the operation specia attention shou d be paid to motor operation and immediate y

disconnect the motor from the supp y network in case of:

excessive motor vibrations,

considerab e decrease of rotationa speed,

excessive heating up of the motor or bearings.

4.6 THE POWER SUPPLY OF THE FAN MOTOR

The „DELTAFAN” wa fans of the type ***/R/*-*/**/***/Ex are equipped with asynchronous motors in the

exp osion-proof version with certificates of EC type examinations (ATEX). In order to connect the device to the

e ectric insta ation, power supp y cab es or wires shou d be ead out through proper cab e out ets of the motor

termina box.

Power supp y cab es shou d be connected according to given diagrams and observing the fo owing conditions:

The motors are designed for the basic vo tage of 230/400V and can be connected to the network of the

inter- ead vo tage of 3x400V ±5% with the star motor winding connection (Y) or to the network of the inter-

ead vo tage of 3x230V ±5% with de ta motor winding connection (Δ).

The insta ation must have correct y se ected over oad and short-cut protection.

The insta ation must have efficient protection against e ectric shocks.

Leads of the e ectric insta ation are to be ead through iso ation bushings in the motor termina box.

Authorised personne shou d check whether ead dimensions are appropriate to the maximum consumption

of the e ectric power, but their cross-section shou d not be ess than 1mm

2

.

The device shou d a ways be earthed. The fan operation without connected PE eads is forbidden. Protection

eads PE (shou d of co our ye ow-green) shou d be connected to the termina marked with the symbo .

A ways make sure that the earthing ead is onger than the power supp y ead so that it is the ast ead in case

of accidenta disconnection (tear out).

Before starting up the device, check the connections for correctness and consistency with the enc osed

e ectric diagram. Switching on the power supp y without previous checking the connections is forbidden.

The explosion-proof motors of a standard reinforced construction do not have a thermal protection.

However, the motors can be additionally protected against overheating by means of three thermistors

(one for each phase) P-(TC)120-B connected in series, whose leads-out should be connected to an external

protection circuit or to an electronic resistance relay. When the set temperature is exceeded, the circuit

should disconnect the device from the power supply network. It is recommended that the protection

circuit accounted for the temperature growth caused by multiple fan motor start-ups.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 10/14

Fig. 2 The connection diagram for the wa fans powered by the three-phase inter- ead current 3x400V 50Hz (star)

and 3x230V 50Hz (de ta).

Delta connection Star connection

5. TRANSPORT AND HANDLING

Transport and hand ing must be performed with great caution to prevent the device from damaging.

Fans shou d be transported on covered means of transportation, in wooden boxes, on meta pa ets or

carton packages protecting against water and moisture.

The packaging shou d maintain fans in new, factory condition during storage and transportation, and ensure

the correct operation of the fan, when it is de ivered to the insta ation ocation.

When packing, specia attention shou d be paid to stabi ity and inertia of the fan in its packaging.

Fans and their parts shou d not be stored in a room with chemica substances causing meta corrosion.

Fans shou d be stored in dry and permeab e to air containers, free from gases, f uids and caustic vapours,

which are harmfu to motor iso ation and other fan parts.

Fans cannot be stored in rooms, where chemica ferti izers, ch orinated imes, acids, chemica substances,

etc. are stored.

The ambient temperature in the room, where fans are stored, cannot be ower than 278K (+5°C), and

re ative humidity cannot exceed 70%.

6. INSPECTIONS AND MAINTENANCE

Each working fan shou d be subjected to periodica inspections:

sma inspection – every 12 months,

main inspection:

omotors of the rotationa speed of n = 1500 rpm -

- after 6000 working hours

omotors of the rotationa speed of n = 1000 rpm -

- after 7000 working hours, but no se dom than every 3 years.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 11/14

6.1 THE SMALL INSPECTION

visua inspection, and motor and protection equipment c eaning without disassemb y, as ong as the

inspection does not necessitate it,

resistance measurement of motor winding iso ation,

efficiency measurement of resetting or protection connection resistance,

resistance measurement of power supp y cab e iso ation,

checking the correct setting of over oad protection,

discharge the condensate:

opu out the rubber p ug from the drain ho e in both p ates to discharge water and re-p ug both ho es.

6.2 THE MAIN INSPECTION

motor remova consisting in performing the be ow activities in the fo owing order:

ounscrew the three screws mounting the fan cover,

oremova of the fan from the shaft using a pu er,

ounscrew the three bo ts ho ding bearing p ates,

oremova of bearing p ates using specia pu ers or by ight y tapping the protruding p ate ogs with a

wooden hammer,

oremova of the rotor with bearings,

oremova of bearing from the motor shaft using three-arm pu ers – on y when it is necessary to rep ace

them.

Bearings should be absolutely replaced after 40000 motor working hours.

Doub e-sided y c osed ba bearings (2Z) that do not require grease fi ing are used in the motor (bearings are

factory greased by the manufacturer).

Motor Bearing type

63 63 6202 2Z

71 71 6203 2Z

80 80 6204 2Z

checking the stator winding condition, which shou d be carefu y c eaned and b own out with compressed

air; winding faces cannot have damaged spots, faces must be we stiffened; if necessary they shou d be

coated with an e ectric iso ation paint without so vent PK-155 and we dried in the temperature be ow 373 K

(+ 100°C),

check the iso ation resistance between particu ar winding phases and between the winding and motor

housing,

check the correct setting of the motor overload protection,

it is forbidden to replace any motor elements and make any modification. If a repair is necessary (motor

rewinding), it can be done by the manufacturer or a authorised company,

the motor shou d be insta ed in the reverse order.

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 12/14

Note:

A activities re ated to disassemb y, inspection and assemb y shou d be performed in such a manner not to

damage the winding, ocks in the p ates, body and other motor parts.

When the inspection is carried out and the motor is refitted, it shou d be subjected to the fo owing tests:

measure the winding resistance,

check the connections,

measure the iso ation resistance in the co d state,

the motor shou d be tested on the id e gear for two hours and, if possib e, perform the test under rated oad

as ong as the motor temperature stops to visib y increase. Test resu ts shou d be noted and kept for future

reference.

The above tests should be performed according to the standard EN 60034-1.

Note:

A activities re ated to inspections and technica commissioning, inc uding checking the e ectrica iso ation

strength (high vo tage tests) shou d be performed by a trained and qua ified person.

7. DISPOSAL

In the countries of the European Union and other European countries, there are separate systems of waste

segregation designed for disposa of e ectric and e ectronic equipment. By such a pro-eco ogica attitude you

prevent potentia negative inf uences on the natura environment and human hea th, which can occur as a

resu t of the inappropriate storage and disposa process of such products. We a so save natura resources

through materia management. To obtain more detai ed information on e ectronic materia processing and

recyc ing, p ease contact your oca city or commune ha , oca e ectric and e ectronic equipment disposa p ant.

8. WARRANTY CONDITIONS

The „DELTAFAN” wa fans of the type ***/R/*-*/**/***/Ex are covered with the manufacturer warranty

according to the conditions and provisions set out in the de ivery contract or the factory certificate.

9. MANUFACTURER

Deltafan

Wojciech Franczak

Brzeźnica 234B

34-114 Brzeźnica

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 13/14

10. RATING PLATE

INSTRUCTION MANUAL

for „DELTAFAN” wa fans of the type: ***/R/*-*/**/***/Ex Page 14/14

11. DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

Manufacturer: Deltafan Wojciech Franczak

Brzeźnica 234B

34-114 Brzeźnica

We hereby dec are with the so e responsibi ity that the product:

The „DELTAFAN wall fans of the type ***/R/*-*/**/***/Ex

II 2G c T4

II 2G Ex e II T3 or T4

marked with the sign conforms with the requirements of the Directive 94/9/WE (ATEX) and the

Machinery Directive 2006/42/WE,

and consistent with the requirements of the fo owing harmonized standards:

•PN-EN 60079-0:2009,

•PN-EN 60079-7:2010,

•PN-EN 13463-2010,

•PN-EN 13463-5:2005,

•PN-EN 14986:2009,

•PN-EN ISO 12100-1:2005

•PN-EN ISO 12100-2:2005/A1:2009

In the process of the product design, the requirements of the Directive 94/9/EC (ATEX) Machinery Directive

2006/42/WE are accounted for.

Certified by: Notified Body no. 1461

Ośrodek Badań Atestacji i Certyfikacji OBAC Sp. z o.o. G iwice 44-100, u . Jasna 31

Certificates of the CE type examination:

The comp ete device: OBAC/028/ATEX/05 X,

The components: KEMA 03 ATEX 2180,

KEMA 03 ATEX 2181,

KEMA 03 ATEX 2176,

KEMA 03 ATEX 2177,

KEMA 03 ATEX 2178,

KEMA 03 ATEX 2179.

Date: 31.08.2010

Signature: Wojciech Franczak

This manual suits for next models

21

Table of contents

Popular Fan manuals by other brands

S&P

S&P ARTIC-400 PRC User instruction

Jata

Jata JVVP3055 Instructions of use

QuietCool

QuietCool AFG SMT PRO-2.0 owner's guide

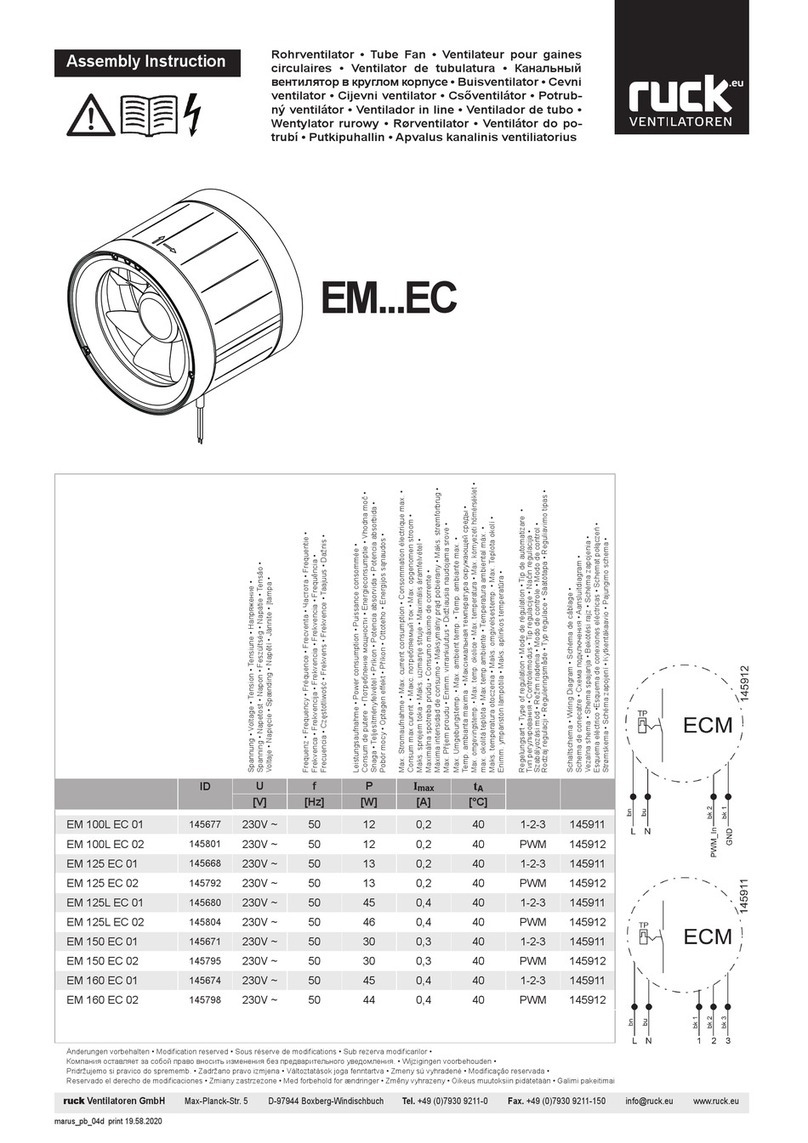

Ruck Ventilatoren

Ruck Ventilatoren EM 100L EC 01 Assembly instruction

Argo

Argo Polifemo BREEZE operating instructions

LUCCI Air

LUCCI Air POLIS 216162 Installation operation & maintenance

Flexit

Flexit Eq 2 Assembly and operation instructions

Honeywell

Honeywell TURBO FORCE HT-906 Series owner's manual

Linea

Linea DOMO DO8132 Instruction booklet

Hunter

Hunter Hunter Ceiling fans Installation and operation manual

Panasonic

Panasonic WhisperGreen FV-08VKML3 installation instructions

Klimawent

Klimawent SMART-EC-1300 Use and maintenance manual