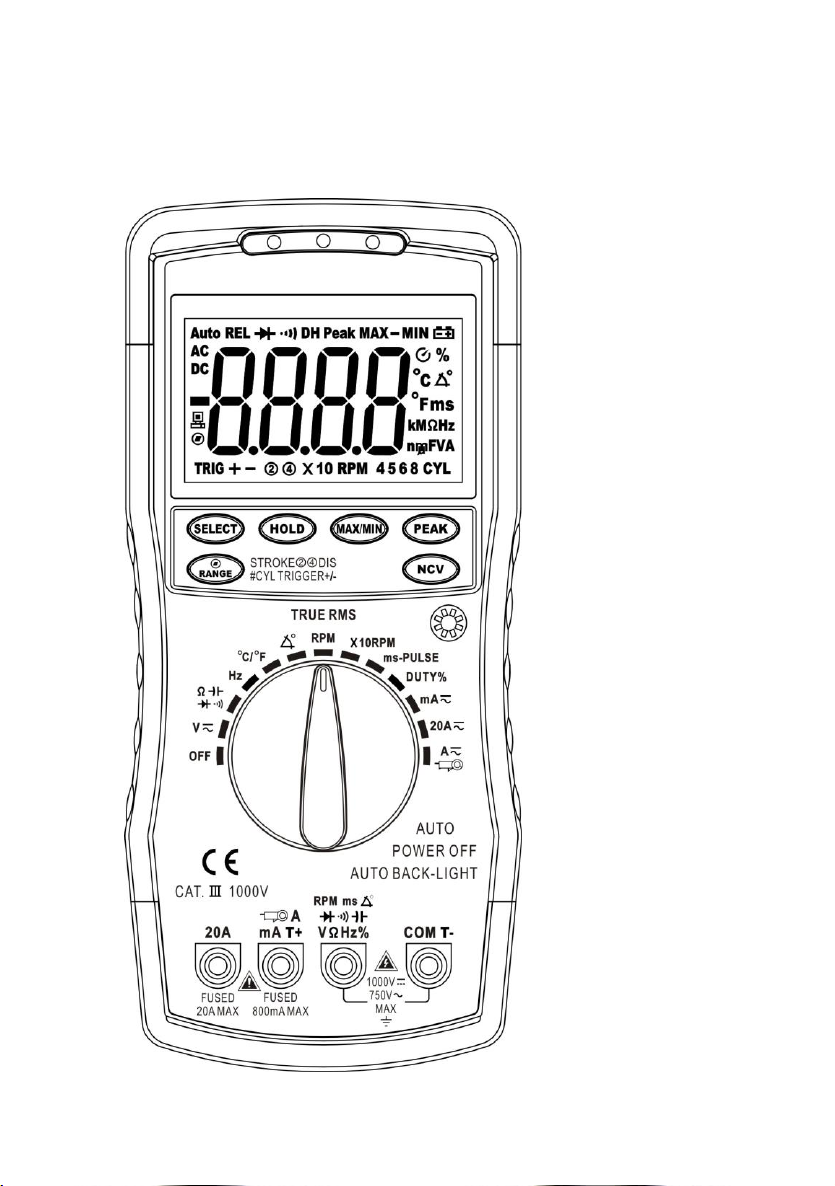

2.INTRODUCTION & SPECIFICATION

FUNCTION TERMINAL INPUT LIMIT

DC/AC Volts,1Ohm/Continuity/Diode,

CAP., Hz, % Duty, ms Dwell, RPM VΩHz

CAT III 1000V

DC, 750V AC

rms

AC/DC Current, Type-K TEMP. mA T+ 600mA DC/AC

AC/DC 20A 20A *20A DC/AC

* 20 Amp measurement for 30 seconds maximum.

Ohms can not be measured if voltage is present, ohms can be measured

only in a non-powered circuit. However, the meter is protected to 250 volts.

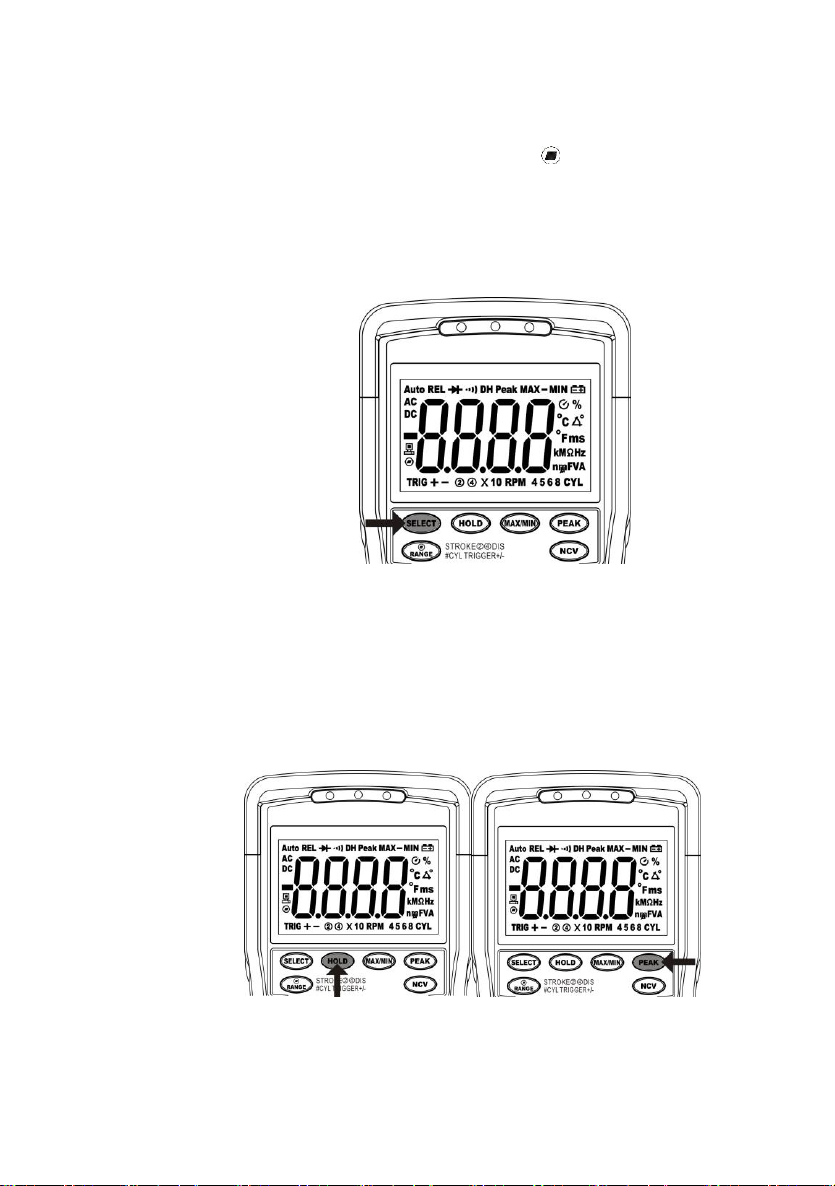

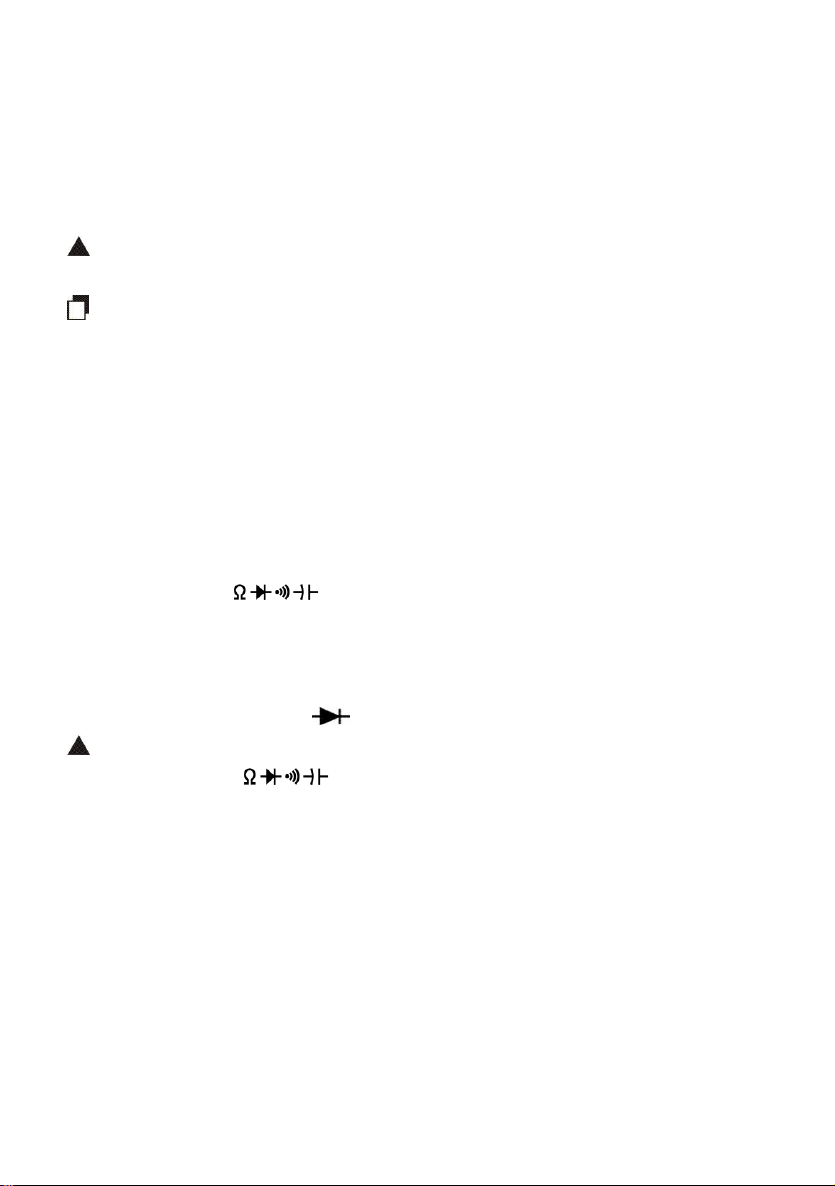

INTRODUCTION: Includes new generation, 12-function, auto-ranging

automotive diagnostic multimeter. Digital display gives accurate indication of

component outputs. Large, easy to read high contrast display with bright,

white backlight. Workshop-tough, durable bi-composite case with integral

stand and auto power shut-off. High speed processing circuitry reads

standard automotive parameters including duty cycle and pulse width making

this tool ideal for testing fuel injection systems. Features auto-ranging, and

data hold functions with overload protection on all ranges. Includes relative

functions including Min/Max and Peak Hold. Supplied with Inductive Coupler,

test probes and thermocouple in carry case.

SPECIFICATION...............................................Model No: 770J, 770K

Diode Check...........................Yes

Tach (RPM)...2-10cyl, 4-Stroke 60-9000 (x1)rpm, 600-12000 (x10)rpm

Auto Back-Light.....................Yes

Dwell:......................................................................................4/5/6/8cyl

Display Hold:..........................Yes

AC Voltage:...............................................600mV, 6V, 60V, 600V, 750V

Auto Ranging:........................Yes

DC Voltage:............................................600mV, 6V, 60V, 600V, 1000V

Inductive Coupler:..................Yes

AC Current:.............................................60mA, 600mA, 6A, 20A, 600A

Digits Height:......................24mm

DC Current:.............................................60mA, 600mA, 6A, 20A, 600A

Auto Power Off.......................Yes

Capacitance:..........10nF, 100nF, 1000nF , 10μF, 100μF, 10mF, 60mF

NCV detection.......................Yes

Frequency:................................................................0.001Hz-9.99MHz

Low Battery Indicator:.............Yes

Duty Cycle:.............................................................................1.0-99.0%

Batteries (supplied):.......9V (PP9)

Pulse Width:............................................................................0.1-10ms

Hi-Impact Case:......................Yes

Resistance:..........................600Ω, 6kΩ, 60kΩ, 600kΩ, 6MΩ, 60MΩ

Size (LxWxD):.......195x88x40mm

Continuity:....................................<50Ω Continuity Buzzer 2kHz

Weight(Include9V Battery):..350g

Temperature:.....................................-20 to +1000°C, -4 to +1832°F