DEMA CHEMASTER DM-813-LLL-1T User manual

DEMA I-668 Pg. 1 of 9

Rev C-28236

INSTRUCTION MANUAL FOR DEMA CHEMASTERTM

DM-813-LLL-1T, DM-813-LLL-2T, DM-813-DLL-1T and

DM-813-DLL-2T

Introduction

The Chemaster series is a comprehensive range of single and dual function units for Industrial

DishWashing, Trash Treatment, and Chemical Transfer etc.

Units are encased in a heavy-duty plastic housing with a sealed cover that has a Mylar label for access of

external control and visibility of indicators. Options range from powerful long lasting peristaltic pumps

for liquid products to solenoid valves for dry products.

Pumps are available in three sizes and are coupled to 15, 60 or 105 rpm motor/gear boxes that yield flow

from .02oz/min. (0.5ml/min.) to 47oz/min. (1.4 liters/min). In addition to these units, original equipment

manufactured pump/motors are available in sizes up to 1 ½ GPM (6 LPM) and are available with different

tubing material for individual applications.

.

All units are equipped with a built in transformer (single or dual) depending on the model, with primary

voltages of 120,208, 240/50-60Hz and secondary voltage of 24/50-60Hz for maximum safety and

reliability. Circuit boards for detergent control are available as probe units, variable speed and timed

units; combined with a variable speed board for the rinse (second pump). Various combinations may be

constructed from this range of components.

All units are packaged with installation kits and this instruction.

System Features

-Heavy Duty ABS Plastic Case

-Splash proof heavy duty Mylar label(Customized labels are available)

-External access to prime function

-Special low current output on Speed Control units

-Metal motor/gear boxes with 2000 plus hours of brush life

-Patent Pending on control software

-Components are interchangeable within the industry

-Separate 40VA transformer for each motor

-Longer pump tubing life due to special elastomer formula

Operating Mode

The conductivity control is designed with unique software that maintains a high degree of accuracy due to

its way of controlling the dispensing device (pump or solenoid valve).

After the controller is engaged, the indicator turns red (power on). When the indicator turns yellow, the

unit is in calculation mode. During this cycle the unit checks values received from the probe and

calculates whether or not to start the pump/solenoid valve. If additional chemical is needed, the control

operates the dispensing device in an on/off cycle mode: Green light is on for 7seconds and then off for 7

DEMA I-668 Pg. 2 of 9

Rev C-28236

seconds until the desired set point is reached. If a larger change in concentration occurs, the control will

calculate again and the yellow light comes on. This cycle is repeated until the concentration set point is

reached.

When the dispensing device is operating (green light on) the unit will go into an alarm condition and the

low detergent alarm will activate if the set point is not reached within the time set by switch #1.

Depending on the setting of switch #3, the device will keep on operating during alarm or it will shut off.

On a single tank machine, this operation will reset at each cycle’s end. If tunnel, flight or conveyor

machines are selected, the calculating mode is automatically started every 60 seconds to insure the correct

concentration level is kept.

The rinse control is connected parallel to the rinse solenoid valve or peristaltic pump for rinse aid

injection to the machine. Turning a motor speed potentiometer on the rinse control board controls the

chemical volume. This means by turning the potentiometer, the number of revolutions the pump makes or

the length of time the solenoid stays open are varied. For calibration information see “Detergent, Rinse

Aid and Sanitizer Calibration”.

Installation of the Chemaster System

Dishroom Survey

Prior to installation, take a complete survey of the dishroom to determine where to place the unit and

chemical and how the electrical connections will be made.

1. Locate the electrical connection point. The power must be 240V, 60Hz max 2A per section

(detergent and rinse). Check with the manufacturer of the machine to determine if there are

preconnected terminals available for this installation.

2. Mount the Chemaster unit on a flat vertical surface, away from splashing and steam

originating from the machine. The unit must be placed so that it can be easily observed and

serviced.

3. Locate the proper position for the probe in the wash tank. The probe must be installed below

the water level, normally 1-2” (30-50 mm) from the bottom of the tank. Probe must be kept

away from heating elements, pump intake, drains and incoming water supply.

4. Install the detergent injection fitting above the probe to obtain a rapid reading of all chemicals

entering the wash tank. Install the rinse line injection fitting into the 1/8” NPT threaded hole

normally provided by the manufacturer of the machine. If a hole in the rinse line is not

available but the wall of the pipe is thick enough, drill a hole 11/32” (8.7mm) dia. and tap to

1/8” NPT. If this is done into a thin pipe wall (copper) use a saddle clamp instead.

Note: A better mixture of the chemical and water will occur if the rinse injection is

mounted before the booster heater.

DEMA I-668 Pg. 3 of 9

Rev C-28236

Electrical Installation

This product is designed only to be used as described in this instruction sheet. Adhere to all warnings and

cautions identified in this document.

WARNING: Electrical and grounding installation of DEMA products must comply with

electrical codes and regulations established by national, city, county, parish, provincial or

other agencies. It is possible that electrical codes and regulations require that a certified

electrical contractor or engineer perform the electrical installation.

For questions, contact a certified electrician.

DISCONNECT ALL ELECTRICAL POWER TO THE DISPENSER AND THE APPLIED

MACHINE WHEN SERVICING- FOLLOW LOCKOUT / TAGOUT PROCEDURES.

WARNING: Installations must conform to all local and national plumbing codes and use

approved backflow prevention and pressure relief devices where required.

ALWAYS DISCONNECT DISPENSER FROM WATER SOURCE WHEN DISPENSER

IS NOT IN USE.

Always read SDS for all chemicals used and follow personal protective guidelines.

Note: All European installations must be carried out by a certified electrical engineer. All

other installations must be installed according to local country, city, state, or provincial

electrical codes. For questions please contact a local contractor.

1. BEFORE GOING ANY FURTHER, ALL ELECTRICAL POWER MUST BE TURNED OFF

TO THE DISH MACHINE AND ANY OTHER CIRCUIT THAT IS TO BE USED FOR THIS

INSTALLATION. LOCKOUT AND TAG PROCEDURES SHOULD BE OBSERVED WHEN

INSTALLING THIS DEVICE. NEVER OPEN THE CHEMASTER UNLESS POWER HAS

BEEN TURNED OFF. SIGNALS MAY BE PRESENT FROM DISH MACHINE, EVEN

WITH THE POWER TURNED OFF. ONLY USE ELECTRICAL CODE APPROVED

INSULATED WIRING AND ELECTRICAL FIXTURES WITH THIS INSTALLATION.

2. Install the power to the detergent board of the Chemaster, using the correct cable (refer to local

electrical code). In most applications, the pump contactor on the dish machine can be used to

power the detergent control. The power may be 120, 208 or 240V 50/60Hz. Route the cable away

from heaters and sharp edges. The cable should be mounted into the Chemaster enclosure using an

appropriate strain relief or conduit fitting. The cable should be connected to the proper detergent

terminal connections.

Note: A Nonmetallic enclosure does not provide grounding between conduit connections. Use

grounding type bushings and jumper wires.

3. Repeat step number 2 for the rinse side of the unit, connecting in parallel to the rinse solenoid

valve of the machine.

4. Route a two-core cable from the terminals on the detergent board marked Probe, through the

enclosed cable gland, to the probe. Fasten the two leads to the probe using the enclosed

compression fittings. Connection must be tight but over tightening can damage the probe.

DEMA I-668 Pg. 4 of 9

Rev C-28236

Tubing Connections

Included in the installation kit is a roll of LDPE tubing to connect from the chemical container, via the

pump, and to the fittings of the machine.

Measure the length of the tubing needed on the suction side from the container to the pump and cut the

tubing to proper length. Install the tubing to the pickup tubes (Grey PVC) through the compression nut,

and tighten the nut. Route the tubing to the suction side of the pump. An arrow on the faceplate indicates

the flow direction. Push the tubing into the pump and squeeze tube approximately1/2-3/4” (15-20mm).

Secure the tubing together by tightening a cable tie around the squeeze tube. Use the same procedure on

the outlet of the squeeze tubing and route the LDPE tubing to the injection points of the machine and

through the compression nut. Tighten the nut properly. Cut off all excess tubing and keep tubing away

from hot surfaces and sharp edges to prevent damage or leakage. At this point the installation is

complete.

System Set Up

On the concentration control circuit board there is a set of switches that must be set to their correct values

to obtain a proper operation.

Switch One=Type Dish machine

On=Single tank machine (door machine)

Off=Tunnel, Flight, or Conveyor machine

When ON is selected the low-level alarm is signaled after 30 seconds of continuous pump

operation.

When OFF is selected the alarm is signaled after 120 seconds of pump operation.

Switch Two=Operating Range

On=High range 3150 – 20,000 MHOS (Siemens)

Off=Low range 1050-6700 MHOS (Siemens)

The concentration point is set by turning the potentiometer clockwise to increase, and

counterclockwise to decrease (see figure on page 4).

Switch Three=Feed Limit Operation

On=Feed limit active (shuts off device after 240 seconds if tunnel machine is selected, when alarm

is activated.

Off=Override does not stop pump when alarm is activated.

On a single tank machine the alarm is being reset each 50-70 seconds.

Switch Four=Alarm Volume

On=High volume (approx. 50 dB)

Off=Low volume (approx. 25 dB)

(Other levels may be available upon special request)

Switch Five=Chemical Type Select

On=Liquid chemical

Off=Dry/Powder chemical

Switch Six=Solenoid Select

On=Two solenoids in use

Off=One solenoid in use

DEMA I-668 Pg. 5 of 9

Rev C-28236

The Chemaster control is designed with the ability to operate with two chemical bowls and

automatically select the full chemical bowl.

Detergent and Rinse Calibration

Detergent Feed Set Up

There are two popular methods for setting up detergent feed.

1.

a. Turn the potentiometer fully counterclockwise to the minimum position.

b. Remove the pick up tube from the chemical container, or the powder canister from the Universal

bowl. This will prevent unnecessary use of the chemical during set up.

c. Determine the correct dosage of chemical; see manufacturer’s data sheet, and the amount of water

in wash tank. If this figure is not available calculate the size of the tank, height x depth x

width=volume. Take the chemical manufacturers recommended dosage and multiply by the

amount of water in the tank. This equals the correct amount of chemical in the tank called the set

point. Manually add the correct amount of chemical to the tank.

d. Start the machine and let it run for a full cycle, and then restart. During the second cycle, slowly

turn the potentiometer clockwise until the unit starts to dispense chemicals. Continue to slowly

turn the potentiometer clockwise until the pump operation stops. This operation now has the

correct set point and the control will maintain this set point during all cycles by adding chemicals

when needed.

e. Check for the correct concentration by using an alkalinity titration test kit (DEMA #81-53) or a

separate conductivity meter if the µmho or µS level is known. Adjust as necessary.

2.

a. Turn the potentiometer counterclockwise and then turn the pot to position 7 or 8. Run the

machine through one cycle and titrate a sample of the solution using DEMA kit # 81-53.

b. If the concentration (number of drops) is not high enough turn the pot to 10 or 11 and run the

machine through another cycle. When the wash pump stops, open the door and titrate another

sample of the solution.

c. If the concentration is still not high enough turn the pot to 1 or 2. Run the machine through

another cycle.

d. Repeat this process until you achieve the concentration you are looking for.

Rinse Aid Calibration

Prior to calibration the system must be primed. The system is primed when the chemical has filled the

tubing up to the injection point. On the rinse side this can only be done during the time the rinse solenoid

is active. On the front cover there is a button called prime. By depressing this, the pump will run at

maximum speed. This may have to be done several times to ensure the chemical has filled up the entire

tubing system.

1. Place the pick up tube into a graduated cylinder and fill with chemical to an easily read level.

2. By use of the potentiometer labeled “Rinse” set the pump speed according to the chemical

manufacturer’s recommendations e.g. (2 oz/10 seconds). Calculation = 2oz x 6= 12oz/min. 12 oz

divided by the capacity of the pump per revolution (1.5) =8 revolutions per minute or 8/6=1.4

revolutions per 10 seconds (the rinse cycle).

3. Confirm the supply rate of the rinse pump using a graduated cylinder. Make any necessary

adjustments to pump rate by use of potentiometer labeled “rinse”.

DEMA I-668 Pg. 6 of 9

Rev C-28236

4. The rinse delay may be set, by adjusting the potentiometer labeled “rinse delay” on the rinse board. A

0-12 second delay may be set.

5. There are 18 seconds of rinse limit available when the “rinse limit” jumper is in the on position.

When the jumper is in the off position, there is no rinse limit. This means that the rinse pump will run

through the entire rinse cycle, when jumper is in the off position.

Sanitizer Calibration

Prior to calibration the system must be primed. The system is primed when the chemical has filled the

tubing up to the injection point. On the rinse side this can only be done during the time the rinse solenoid

is active. On the front cover there is a button called prime. By depressing this, the pump will run at

maximum speed. This may have to be done several times to ensure the chemical has filled up the entire

tubing system.

1. Place the pick up tube into a graduated cylinder and fill with chemical to an easily read level.

2. By use of the potentiometer labeled “sani” set the pump speed according to the chemical

manufacturer’s recommendations e.g. (2 oz/10 seconds). Calculation = 2oz x 6= 12oz/min. 12 oz

divided by the capacity of the pump per revolution (1.5) =8 revolutions per minute or 8/6=1.4

revolutions per 10 seconds (the rinse cycle).

3. Confirm the supply rate of the rinse pump using a graduated cylinder. Make any necessary

adjustments to pump rate by use of potentiometer labeled “sani”.

After all output of chemical products have been calibrated, the Chemaster is ready for use

DEMA I-668 Pg. 7 of 9

Rev C-28236

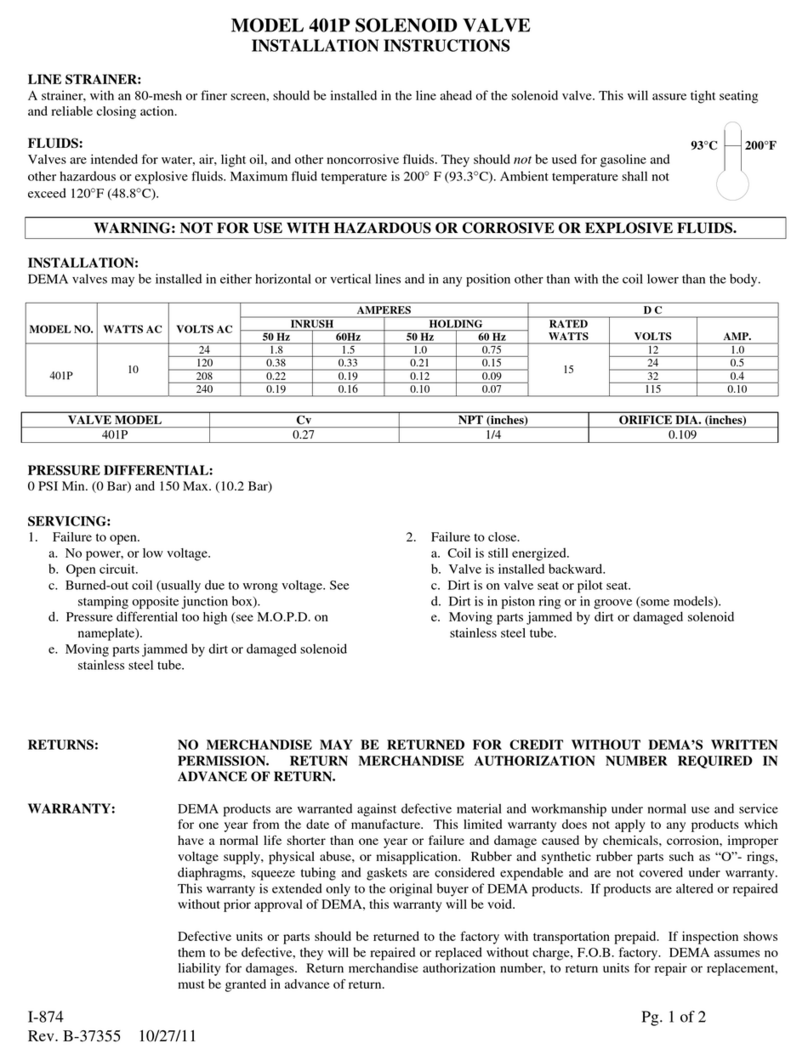

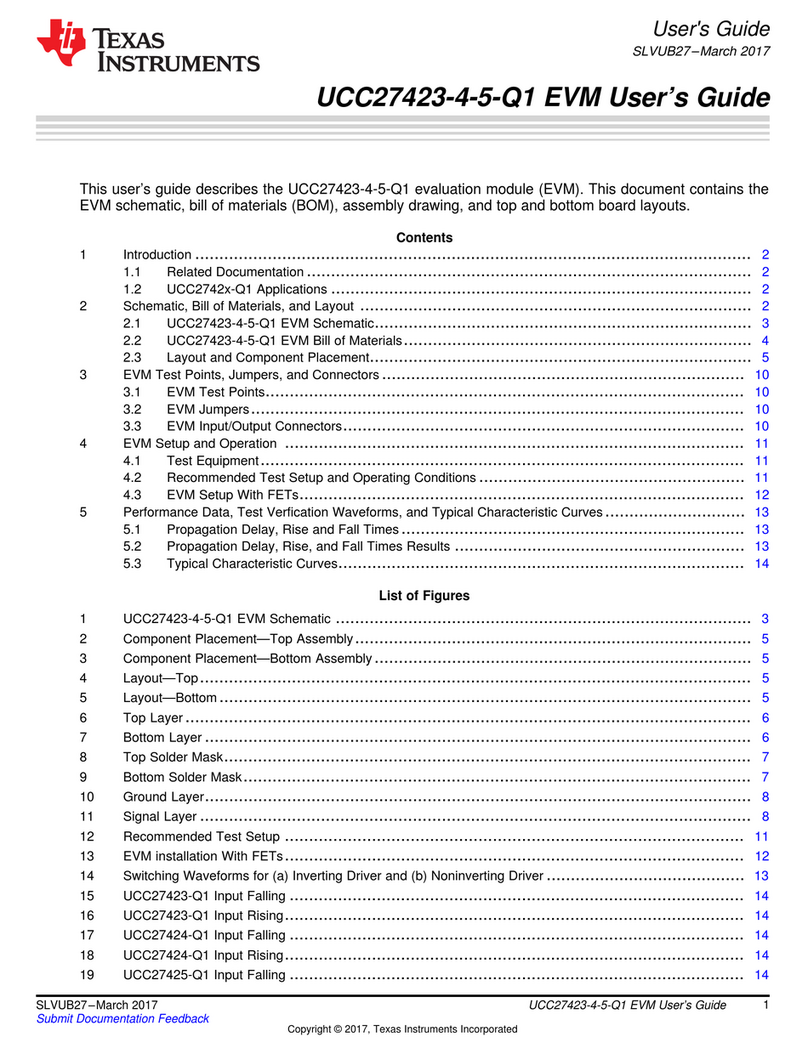

DM-813-LLL-1T and DM-813-DLL-1T Schematic

(1 Transformer)

24VDC RINSE OUT

+++

UNUSED

BACKUP

PROBE

24VAC

24VDC DET OUT

24VAC IN

24VAC OUT

LINE

120VAC RETURN

208VAC RETURN

240VAC RETURN

1

2

PRESSURE

SWITCH

FUSE

1A. 250V

RINSE

MOTOR

DETERGENT

MOTOR OR

SOLENOID

VALVE

(SEE DRAWING FOR PART NO.)

(SEE DRAWING FOR PART NO.)

(SEE DRAWING FOR PART NO.)

TERMINAL BLOCK &

BRACKET ASSY.

BLACK

WHITE

BLUE

RED

DETERGENT

CONCENTRATION BOARD

80-68-3

RINSE CONTROL BOARD

80-69-6

40 VA

TRANSFORMER

80-70 ORANGE

ORANGE

20774-1

(81-94-1)

20774-2

(81-94-2)

X20753-1

(81-32-1)

X20753-2

(81-32-2)

BLACK

RED

ORANGE

20774-1

(81-94-1)

BLACK

RED

ORANGE

ORANGE

X20753-1 (81-32-1) MOTOR

X20753-6 (81-32-6) VALVE

X20753-2 (81-32-2) MOTOR

X20753-7 (81-32-7) VALVE

BLACK

RED X20753-2

(81-32-2)

X20753-1

(81-32-1)

+

24VDC SANI OUT

(SEE DRAWING FOR PART NO.)

MOTOR

SANITIZER

20759-2

(81-36-2)

25457-16 (81-34-16) FUSE

20758-1 (81-35) FUSE HOLDER

24158-2 (81-16-2)

TIE WRAP

=

DEMA I-668 Pg. 8 of 9

Rev C-28236

DM-813-LLL-1T and DM-813-DLL-2T Schematic

(2 Transformers)

24VDC RINSE OUT

+++

UNUSED

24VDC SANI OUT

BACKUP

PROBE

24VAC IN

24VDC DET OUT

24VAC IN

24VAC OUT

LINE

120VAC RETURN

208VAC RETURN

240VAC RETURN

FUSE

1A. 250V

RINSE

MOTOR

DETERGENT

MOTOR OR

SOLENOID

VALVE

(SEE DRAWING

FOR PART NO.)

(SEE DRAWING FOR PART NO.)

(SEE DRAWING FOR PART NO.)

TERMINAL BLOCK &

BRACKET ASSY.

BLACK

WHITE

BLUE

RED

DETERGENT

CONCENTRATION BOARD

80-68-3

RINSE CONTROL BOARD

80-69-6

40 VA

TRANSFORMER

80-70

X20753-1

(81-32-1)

X20753-2

(81-32-2)

BLACK RED

BLACK

RED

ORANGE

ORANGE

X20753-1 (81-32-1) MOTOR

X20753-6 (81-32-6) VALVE

X20753-2 (81-32-2) MOTOR

X20753-7 (81-32-7) VALVE

25457-16 (81-34-16) FUSE

20758-1 (81-35) FUSE HOLDER

20759-2

(81-36-2)

ORANGE

ORANGE

20759-2

(81-36-2)

RED

1A. 250V

FUSE

BLUE

25457-16 (81-34-16) FUSE

20758-1 (81-35) FUSE HOLDER

WHITE

BLACK

208VAC RETURN

(SEE DRAWING FOR PART NO.)

TERMINAL BLOCK &

BRACKET ASSY.

240VAC RETURN

LINE

120VAC RETURN

40 VA

TRANSFORMER

80-70

SANITIZER

MOTOR

(SEE DRAWING FOR PART NO.)

BLACK

RED X20753-2

(81-32-2)

X20753-1

(81-32-1)

+

=24158-2 (81-16-2)

TIE WRAP

DEMA I-668 Pg. 9 of 9

Rev C-28236

Technical Specifications

Connection Voltage 250V/50-60 Hz Max. 2A/per section

Control Voltage 24V/50-60 Hz 40 VA/per section

Motor Voltage 24 VDC

Case ABS plastic with Mylar label

Size WxHxD 8.5”x 8”x4.125” (21.6x20.3x10.5cm)

(case w/out pumps and solenoids)

Shipping Weight Varies per model

Installation Method With keyhole slots to a flat vertical surface

Detergent Control

Probe Model Measures using conductivity probe C-12

Concentration Range Low 1050-6700µmhos

Concentration Range High 3150-20000µmhos

Pulse Feed Rate Dry or Liquid 5 sec. ON & 5 sec. OFF

Alarm Door Mode 30 seconds

Alarm Conveyor Mode 120 seconds

Overfeed Pump Shutoff 240 seconds (conveyor mode only)

Buzzer Volume HIGH Approx. 50 dB

Buzzer Volume LOW Approx. 25 dB

Variable Speed Model (rinse and detergent)

Operating mode Continuous with power on

Signal voltage N/A

Output voltage Approx. 30 VDC

Adjustment range % 10-100%

Peristaltic Pumps

Motor voltage 24 VDC

Power consumption Max. 40 VA 1.6 A

Motor gearbox 15, 60 or 100 rpm (depending on model)

Material Metal

Squeeze tubing material EPDM, opt. Viton, Santoprene

Squeeze tubing size ID Rinse: 1/8” (3.2mm)

Detergent: 3/16” (4.8mm)

Pump output Rinse Max. 1.15oz/min (34ml/min)

Pump output Detergent Max. 7.27oz/min (215ml/min)

DEMA I-668 Pg. 10 of 9

Rev C-28236

Chemaster Trouble Shooting Guide

UNIT DOES NOT TURN ON:

*Check power source.

*Check fuses.

*Visually inspect all electrical components for signs of over heating.

*Ensure proper power to transformers.

*Ensure proper output from transformers (24Vac).

WILL NOT DISPENSE:

*Check for power available.

*Check concentration set point.

*Check probe for corrosion and connection.

*Check power to gear/motor.

*Check pump roller block for obstruction or damage.

*Check tubing for damage.

*Verify chemical supply is sufficient.

*Ensure pick up tube is free from obstruction and in chemical.

*Inspect squeeze tube for damage.

TOO MUCH OR TOO LITTLE DETERGENT:

*Check concentration set point.

*Check supply tubing for damage or obstruction.

*Check probe for corrosion and connection.

*Is pump rotating at the proper speed?

*Is the supply tubing holding prime?

*Does the squeeze tube need to be lubricated?

SUPPLY TUBING NOT HOLDING PRIME:

*Check direction of flow from inlet and outlet for supply.

*Inspect tube for holes or cracks.

*Check compression fitting between tubing and pick up tube for tightness.

*Check connection of squeeze tube and supply tubing for air leaks.

*Is roller tightly pressed to squeeze tube?

Return Policy

No merchandise may be returned for credit without DEMA Engineering Company’s written permission.

Return Merchandise Authorization (RMA) number required in advance of return.

Warranty

DEMA products are warranted against defective material and workmanship under normal use and

service for one year from the date of manufacture. This limited warranty does not apply to products that

have a normal life shorter than one year or failure and damage caused by chemicals, corrosion, improper

voltage supply, physical abuse or misapplication. Rubber and synthetic parts such as “O”-rings,

diaphragms, squeeze tubing and gaskets are considered expendable and are not covered under warranty.

This warranty is extended only to the original buyer of DEMA products. If products are altered or

repaired without prior approval of DEMA, this warranty will be void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection

shows them to be defective, they will be repaired or replaced without charge. F.O.B. factory DEMA

assumes no liability for damages. Return merchandise authorization number to return units for repair or

replacement must be granted in advance of return.

This manual suits for next models

3

Table of contents

Other DEMA Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens SCALANCE W788C-2 operating instructions

V2

V2 City7 instruction manual

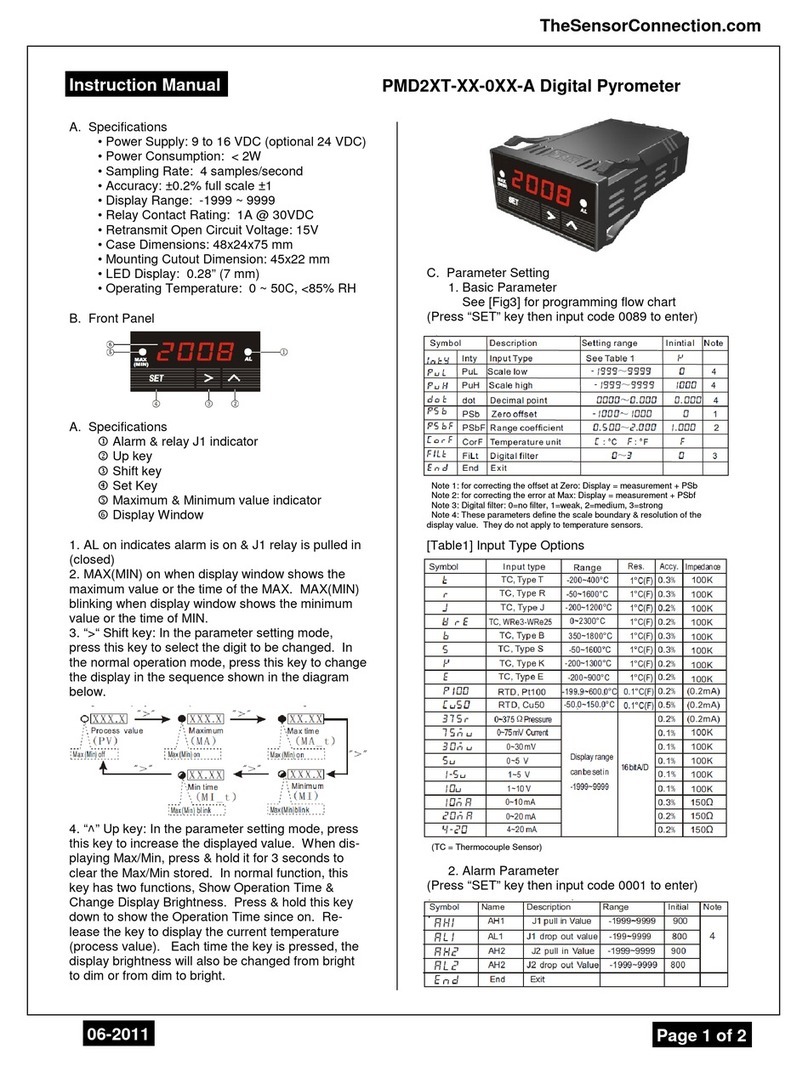

The Sensor Connection

The Sensor Connection PMD2XT-XX-0XX-A Series instruction manual

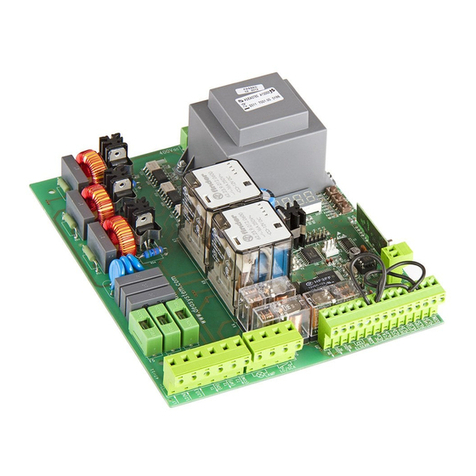

Dea

Dea 400RR Operating instructions and warnings

SMC Networks

SMC Networks EX260 Series Operation manual

NCR

NCR 7358-K704 Kit instructions