DEMA TITAN II T-812-LL User manual

I-1024

Rev. G-

4

Over

v

The Titan

applicatio

n

responds t

o

simple ins

t

from Con

c

Warn

i

4

3816

DEM

A

v

iew

warewash s

y

n

s. The system

o

detergent an

d

t

allation, set u

p

c

ent

r

ation to P

r

i

ngs

Installati

o

b

y natio

n

regulatio

n

For ques

t

ALL EL

THE A

P

All insta

l

devices.

A

p

lumbin

g

indicatin

g

ALWA

Y

CHEMI

C

3/

2

A

TITA

N

T.

8

y

stem controls

has an advan

c

d

rinse trigger

s

p

, and operatio

r

obeless. This

A

o

n of DEMA

p

n

al, city, count

y

n

s require that

t

ions, contact

a

E

CTRICAL

P

PLIED MAC

l

lations must c

o

A

pressure ind

i

g

codes in the

s

g

tee.

Y

S WEAR PR

O

C

AL PRODU

C

2

3/18

N

™ II

W

8

12 &

T

all chemical d

e

c

ed power sup

p

s

in the range

o

n. The Titan h

a

A

uto Switcho

v

p

roducts must

m

y

, parish, prov

i

a certified ele

c

a

certified elec

t

P

OWER MU

S

HINE.

o

nform to loc

a

i

cating tee is t

o

s

tate of Wisco

n

O

TECTIVE C

L

C

TS.

W

ARE

W

T

.813

S

e

livery functi

o

p

ly that will ac

c

o

f 20V–500V

5

a

s an Auto S

w

v

er feature virt

u

m

eet all applic

a

i

ncial or other

c

trical contrac

t

t

rician.

S

T BE TURN

E

a

l plumbing co

d

o

be installed

w

n

sin and any o

t

L

OTHING A

N

W

ASH

S

ERIE

S

o

ns for dish m

a

cept 100V–25

0

5

0/60Hz. The

T

w

itchove

r

featu

r

u

ally eliminat

e

able electrical

agencies. It is

t

or or enginee

r

E

D OFF TO

T

d

es and use ap

p

w

ith existing f

a

t

her state that

r

N

D EYEWEA

R

Page

1

CONT

R

S

a

chines and si

m

0

V 50/60Hz.

T

T

itan

has be

e

r

e that allows

a

e

s servicecalls

.

codes and reg

u

possible that

e

r

perform the e

l

T

HE DISPE

N

p

roved backfl

o

a

ucets accordi

n

r

equires the us

e

R

WHEN WO

R

1

of 16

R

OL

m

ilar warewas

h

T

he Titan

e

n designed fo

r

a

utomatic swit

c

.

u

lations establ

i

e

lectrical code

s

lectrical instal

l

N

SER AND T

O

o

w prevention

n

g to local

e

of a pressure

R

KING WIT

H

h

r

c

hing

i

shed

s

and

l

ation.

O

H

I-1024

Rev. G-43816 Page 2 of 16

3/23/18

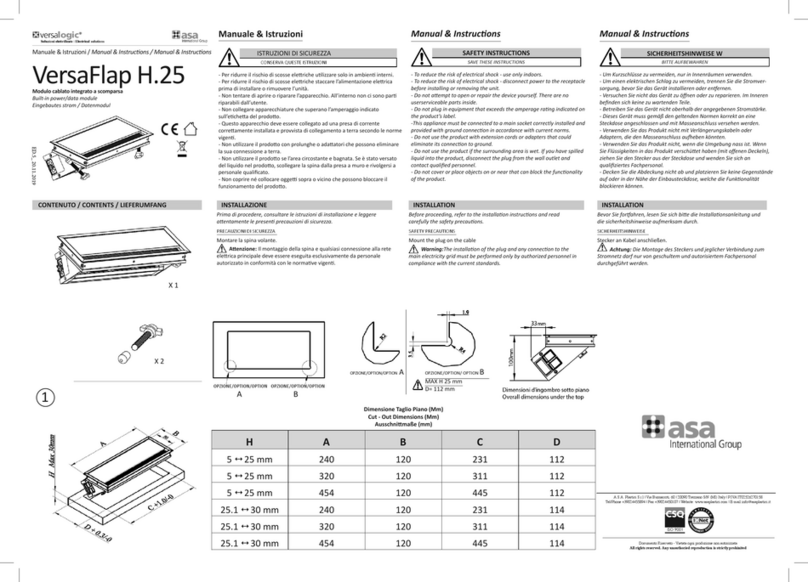

Specifications

Packing List

PART NO.

DESCRIPTION

T-812-LL

T-812-DL

T-813-LLL

T-813-DLL

904-8T Rinse Check Valve 1 1 1 1

80-55 Bulkhead Fitting with Liquid Feed

Injection Elbow ¼” 1 1

58-5 Overflow Elbow Kit 11

81-16-1 Tie Wrap 8” lg. 5 5 8 8

81-312-3 Pickup Tube Assembly 17” 2 1 3 2

81-182-1 ¼” x ¼” JG Union 4 2 6 4

25-68-20

100-12-SV1 20 ft. x 1/8”ID LDPE (detergent)

16 ft. x 1/16”ID Vinyl (rinse/san) 1

1 1

1 1

2 1

2

C-12V1

K

Conductivity Cell 1 1 1 1

904-8KY Sanitizer Check Valve 1 1

Operational Requirements For Indoor Use Only

Main Powe

r

100 VAC – 250 VAC 50/60 Hz 1.5 A

Trigger Signals 20VAC – 480VAC 50/60 Hz 200mA

Motors/Solenoid Valves 24VDC

Detergent Pump Rate 10oz/min (300ml/min)

Rinse/Sanitizer Pump Rate 0.5oz/min (15ml/min)

Operating Temp 4-30°C 40-100°F

Case Material ABS

Weight 3.8 kg 8.5 lbs

Max. Altitude 2000 M 6500 ft

Environmental Temp 0-40°C 32-104°F

Installation Category II

Pollution Category II

Overall Size

I-1024

Rev. G-

4

Parts Li

s

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

* - SE

4

3816

s

t

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

2

NOT SHO

W

NOT SHO

W

NOT SHO

W

NOT SHO

W

E PAGE 4 F

O

3/

2

DEMA

N

81-118-

3

81-118-1

81-118-

3

81-187-1

81-359-1

81-118-

2

81-360-1

81-118-1

81-181-

2

81-118-1

81-118-

2

81-118-1

81-306-

2

81-144-1

W

N82-23-1

W

N82-28-1

W

N84-65-6

6

W

N81-336-1

O

R BREAKD

O

2

3/18

N

O. DESC

R

3

1CONT

R

1-2 TRIGG

E

3

5POWE

R

MOUN

T

TITAN

I

2

9-2 RINSE

TITAN

I

2

TRIGG

2

PROB

E

8PUMP

M

2

9-1 MOTO

R

9SOLE

N

2

TRIGG

SIDE

M

MAGN

E

INDUC

T

6

PROD

U

POWE

R

O

WN

R

IPTION

R

OL BOARD

E

R BOARD

W

R

SUPPLY

(in

c

T

ING BRAC

K

I

I HOLE PLU

PUMP AND

M

I

I LABEL KIT

ERCABLE

R

E

CABLE

–

1

5

M

ODULE A

S

R

AND DET

E

N

OID VALVE

ER INPUT

C

M

ODULE JOI

N

E

TIC FIELD

R

T

IVE PROB

E

U

CT ALARM

R

CABLE

(LA

M

AND DISPL

A

W

ITH TERMI

cludes 84-125-7 pow

e

K

ET

G AND FITT

I

MOTORASS

R

EPLACEM

E

5

’ Lg.

S

SY. - SANIT

I

E

RGENT PU

M

KIT (For T-8

1

C

ABLE

(5

wire

N

TS

R

EADER KIT

E

KIT (SEE P

A

SENSOR KI

T

M

P CORD)

Page

3

A

Y ASSY.

NAL BLOCK

e

r supply adapter)

I

NG KIT

EMBLY - 15

E

NTKIT

(TRIG

I

ZER (For T-

8

M

P HEAD AS

1

1-D, T-812-

D

cable)

T

(SEE PAGE

A

GE 5 FOR I

T

(SEE PG 1

4

3

of 16

RPM *

GER

BOARDTOM

8

12-LLL, T-8

1

SEMBLY - 6

0

D

L, T-813-D

L

5 FOR INF

O

I

NFO)

4

FOR INFO)

M

AINBOARD)

1

2-DLL)

0

RPM *

L

L) *

O

)

)

I-1024

Rev. G-

4

4

3816

3/

2

2

3/18

ITEM NO. Q

T

1

1

2

1

3

1

4

4

5

1

6

1

7

1 P

A

ITEM NO.

Q

1

2

3

4

5

6

7

8

9

8

8

8

8

8

T

Y DEMA N

O

1

81-174-1

1

81-118-28

-

81-118-28

-

81-118-28

-

1

81-177-1

81-177-2

4

25-85-2

1

81-128-2

1

80-59-60

M

80-59-15

M

A

CK

81-17-5

KIT #

81-118-1

Q

TY DEMA N

O

1

81-146-

4

41-63-

2

1

81-180-

1

58-103-

2

1

81-195-

1

58-104-

2

2

41-40-

2

1

81-183-

1

81-178-

P

U

KIT #

8

1-118-29-1

CO

M

1-118-29-2

C

8

1-118-15

P

U

8

1-118-16

8

1-118-17

O

.

PU

M

-

1

2

R

-

2

-

3

DETERG

E

2

RINSE/SAN

I

2

M

K

M

K

VAL

V

1

9

O

.

1

2

1

2

J

.

1

2

2

1

1

Page

4

U

MP A

S

M

PLETE KIT (ITEMS

C

OMPLETE KIT (ITE

M

U

MP HEAD KIT DET

E

PUMP HEAD

PUMP HEAD KI

T

DE

S

M

P BORE ASSEM

B

R

OLLER BLOCK A

S

3 ROLLER BLO

2 ROLLER BLO

E

NT SQUEEZE T

U

ITIZER SQUEEZE

P

U

60 RPM GEAR

15 RPM GEAR M

O

SILICONE LUBE

V

E AS

S

DE

S

SOLENOID V

A

DE

S

VA

L

MACHINE S

VALVE ASSEM

B

.

G FITTING STR

A

PP

JG FITTING EL

B

SS SC

R

CABL

E

VALVE B

R

4

of 16

S

SEM

B

DESCRIPTION

1-7 WITH DETERG

E

M

S 1-7 WITH RINS

E

E

RGENT (2 ROLLE

R

KIT RINSE (3 ROLL

T

DETERGENT (2 R

O

S

CRIPTION

B

LY (COVER WIT

H

S

SEMBLY (SPRIN

G

CK ASSEMBLY (F

CK ASSEMBLY (F

U

BE (WITH JG FIT

T

TUBE (WITH JG F

SCREW

U

MP BASE

MOTOR (DETER

G

O

TOR (RINSE/SA

N

PACKET (NOT S

H

S

EMB

L

S

CRIPTION

A

LVE KIT (PART

S

S

CRIPTION

L

VE COVER

CREW (8-32 X 3

/

B

LY (ITEMS 4-6)

A

IGHT (1/4" TUB

E

JG ELBOW

B

OW (1/4" TUBE

X

R

EW (6-32 X 1/2"

E

STRAIN RELIE

F

R

ACKET ASSEM

B

B

LIES

E

NT/60 RPM MOTO

R

E

/15 RPM MOTOR)

R

SPRING LOADED

)

ER FIXED)

O

LLER FIXED)

H

WINDOW)

G

LOADED)

IXED)

IXED)

T

INGS # 81-176-1)

ITTINGS # 81-175

-

G

ENT)

N

ITIZER)

H

OWN)

L

Y

S

1-9)

/

8" SS)

E

X 1/4" NPT)

X

1/4" NPT)

)

F

B

LY

R

)

1)

I-1024

Rev. G-

4

Instal

l

WARNI

N

estab

l

codes

instal

l

ALL EL

E

MACHI

N

UNIT M

U

Dish Roo

m

Prior to in

chemicals.

through a

n

Mountin

g

1.

R

2.

M

3. S

l

Settin

g

u

p

1. L

m

2. P

r

3. I

f

1

2

w

pu

4. I

n

r

e

5. I

n

m

6. I

n

m

i

n

Connecti

n

1.

A

c

o

ri

n

2.

C

t

h

3.

M

m

Wirin

g

th

The follo

w

Ma

g

netic

may

b

e us

e

in the trig

g

or rinse va

p

ump or v

a

4

3816

l

ation

N

G: Installati

o

l

ished b

y

nat

i

and re

g

ulati

l

ation. For q

u

E

CTRICAL P

O

N

E PRIOR T

O

U

ST BE PRO

P

m

Surve

y

stallation, tak

e

Also, determ

i

n

onmetallic ½

”

the Titan

R

emove the M

o

M

ount the brac

k

l

ide the dispe

n

p

the Titan an

d

ocate the elect

r

m

anufacturer o

f

r

operly groun

d

f

the Titan[g

w

2

VIK probe o

r

w

ate

r

level, nor

m

u

mp intake, dr

a

n

stall the deter

g

e

ading of all c

h

n

stall the rinse

m

achine. If a ta

p

n

stall the sanit

i

m

anufacturer o

f

n

stalling this fi

t

ng

the Chemi

c

A

fte

r

mounting

o

ntainers. The

n

se and saniti

z

C

u

t

the tubing t

o

h

e chemical co

n

M

easure the le

n

m

achine. Cut th

e Titan to the

w

ing diagram i

s

WAR

N

power

UNIT

Field Sensors

e

d in place of

t

g

er wire spots

a

lves to measu

r

a

lve on the dis

p

3/

2

o

n of DEM

A

i

onal, cit

y

, c

o

ons require

t

u

estions, cont

a

O

WER MUS

T

O

BEGINNIN

G

P

ERLY GRO

U

e

a complete s

u

i

ne how the e

l

”

conduit syst

e

o

unting Bracke

k

et in an appro

p

n

ser onto the b

r

d

the Dish M

a

r

ical connecti

o

f

the machine t

d

the dispenser

w

ill be operatin

g

r

the Inductive

m

ally 1”-2” fr

o

a

ins and inco

m

g

ent injection

b

h

emicals enter

i

line injection

f

p

is not

p

rovid

e

i

zer injection f

i

f

the machine.

I

t

ting.

c

al Tubin

g

to

t

the dispenser,

detergent tubi

n

z

er tubing (10

0

o

the length re

q

n

tainer.

n

gth of tubing

n

e tubing to the

Dish Machin

e

s

included to h

e

N

ING: For sa

f

to the Titan

p

MUST BE G

R

- If trigger co

n

t

he trigger boa

r

a

s shown on t

h

r

e a magnetic

fi

p

enser.

2

3/18

A

products

m

o

unt

y

, parish,

t

hat a certifi

e

a

ct a certified

e

T

BE TURNE

G

INSTALL

A

U

NDED (EA

R

u

rvey of the

d

l

ectrical conn

e

e

m.

t

from the dis

p

p

riate place o

n

r

acket and atta

c

a

chine

o

n point. The i

n

o

determine if

to Earth grou

n

g

in the conce

n

Probe (82.28.

1

om

the bottom

m

ing water sup

p

b

ulkhead (80-

5

i

ng the wash t

a

f

itting (904-8T

)

e

d, follow the

m

i

tting (904-8K

Y

I

f a tap is not

p

t

he Titan

measure the l

e

n

g (25.68.20)

i

0

.12.SV1) whi

c

q

uired and, if

d

n

eeded to go f

r

length require

e

e

lp to install t

h

f

et

y

purposes

p

er the dish

m

R

OUNDED (

E

n

nection point

s

r

d and cable.

T

h

e wiring diagr

a

fi

eld when the

m

m

ust meet all

provincial o

r

e

d electrical

c

e

lectrician.

D OFF TO T

H

A

TION.

R

THED).

d

ish room. Det

e

e

ctions will b

e

p

enser.

n

the wall, awa

y

c

h the secure s

c

n

put power m

a

there arededi

c

n

d.

n

tration mode

l

1

) in the wash

of the tank an

d

p

ly. (This incl

u

5

5) fitting abo

v

a

nk.

)

into the rinse

m

anufacturer’

s

Y

) (if sanitize

r

p

rovided follo

w

e

ngth of tubing

i

s opaque in c

o

c

h is clear in c

o

d

esired, place t

h

r

om the dispen

s

d to reach the

c

h

e wires in the

disconnect m

a

m

achine manu

f

E

ARTHED).

s

cannot be es

t

T

he magnetic f

i

a

m. The magn

e

m

otors or valv

applicable

e

r

other a

g

en

c

c

ontractor or

H

E HEATIN

G

ermine the de

s

e

made. Main

a

y from splash

i

crew on the b

o

a

y be 100V –

2

c

ated terminal

s

locate the pro

p

tank. The pro

b

d

must be kept

u

des the probe

v

e the probe (i

f

e

line tap

p

rovi

d

s

recommenda

t

r

is used) into

t

w

the manufac

t

g

needed to go

f

o

lor and has a

l

o

lor and has a

s

h

e pickup tub

e

ser to the che

m

c

hemical injec

correct places

ain power to

t

f

acturer’s rec

t

ablished, the

m

i

eld sensors c

o

etic field sens

o

es are activate

d

Page

5

e

lectrical cod

c

ies. It is pos

s

en

g

ineer pe

r

G

ELEMEN

T

s

ired placeme

n

power and tri

i

ng and steam

f

o

ttom of thedi

s

2

50V 50/60Hz.

s

available for

t

p

er position fo

r

b

e must be ins

t

away from he

a

e

wire. Do not

l

f

a probe is us

e

d

ed by the ma

n

t

ions for instal

l

t

he rinse line t

a

t

urer’s recom

m

f

ro

m

the dispe

n

l

arger inside d

i

s

mall insidedi

a

e

on the tubing

m

ical injection

tion point on t

h

for proper po

w

t

he dish mac

h

ommendatio

n

m

agnetic field

o

nnect directly

o

rs can be pla

c

d which will t

r

5

of 16

es and re

g

u

l

s

ible that ele

c

r

form the ele

c

T

S AND DIS

H

n

t of the Titan

gger cords m

u

f

rom themach

i

s

penser.

Check with t

h

t

his installatio

n

r

the DEMA

C

t

alled below t

h

a

ting elements

l

ie against Dis

h

e

d) to obtain a

n

ufacture

r

of t

h

l

ing this fittin

g

a

p provided

by

m

endations for

n

se

r

to the che

m

i

ameter than t

h

a

meter.

before

p

lacin

g

point on the

h

e machine.

w

er for the uni

t

h

ine. Connect

n

s.

sensors (82.23

to the control

b

c

ed on wash m

o

r

igger the prop

l

ations

c

trical

c

trical

H

[g and

u

st run

i

ne.

h

e

n

.

C

-

h

e

,

h

Machine)

rapid

h

e

g

.

y

the

m

ical

h

e

g

in

t

.

.1)

b

oard

o

tors

er

I-1024

Rev. G-

4

The follo

w

the dish m

a

unit separ

a

it is neces

s

1.

C

s

h

P

2.

C

m

r

u

3.

C

r

e

Trigg

e

4

3816

w

ing steps will

a

chine that it i

s

a

tely from the

d

s

ary to have p

o

C

onnect power

h

ould be suppl

i

ower to the T

i

onnect the d

e

m

anufacturer’s

u

nning.

onnect the ri

n

e

commendatio

n

e

r Board I

n

3/

2

help to insure

s

being used i

n

d

ish machine.

T

o

wer to run the

t

o the Titan

pe

i

ed to the Tita

n

i

tan should n

o

e

ter

g

ent tri

gg

r

ecommendati

n

se tri

gg

er (bl

a

n

s. The Titan

s

ternal Wiri

n

2

3/18

the proper wir

i

n

conjunction

w

T

he following

setup that is p

r

e

r the dish mac

n

anytime the

d

o

t be supplied

g

er (brown a

n

ons. The Tita

n

a

ck and red

w

s

hould receive

n

g

BR

O

W

H

BL

A

RE

D

GR

E

i

ng of the unit

.

w

ith. DEMA E

three steps wi

l

r

ogrammed in

hine manufact

u

d

ish machine

p

via the wash

n

d white wir

e

n

should recei

v

w

ires) to the di

s

a rinse trigger

O

WN– WAS

H

ITE – WASH

A

CK – RINSE

D

– RINSE T

R

E

EN – EART

H

.

The unit sho

u

E

ngineering do

e

l

l insure that t

h

the unit.

t

urer’s recom

m

p

ower is on.

motor on the

e

s) to the dis

h

v

e a detergent

s

h machine p

e

any time the r

Magn

e

H

TRIGGER (

H

TRIGGER (R

E

TRIGGER (

H

R

IGGER (RET

U

H

GROUND

Page

6

u

ld be triggere

d

e

s not recom

m

h

e unit only re

c

m

endations. Co

n

dish machin

e

h

machine p

e

trigger any ti

m

e

r the dish ma

c

r

inse solenoid

i

e

tic Field

R

H

OT)

E

TURN)

H

OT)

U

RN)

E

C

6

of 16

d

to power on

f

m

end powering

c

eives power

w

n

stant power

e

.

e

r the dish m

m

e the wash

m

c

hine manufac

t

i

spowered.

R

eader Inte

r

DISH

MACHIN

E

E

LECTRIC

A

C

ONNECTI

O

POINT

f

rom

the

w

hen

achine

m

otor is

t

urer’s

r

nal Wiring

E

A

L

O

N

I-1024

Rev. G-

4

Initia

l

Following

display th

e

column a

n

again to s

e

the

b

ackli

g

* - Pressi

n

DEM

A

St. Lo

LAN

G

ENG

L

DET

E

RINS

E

SANI

* A d

e

DET

*** S

e

RAC

K

DES

C

ENT

E

** Pr

e

tri

g

E

N

NEW

*This

p

ress

e

entrie

s

CO

N

AUT

O

*Aut

o

corre

c

1

.

2

.

3

.

4

.

4

3816

l

Progra

m

in bold is the

i

e

company na

m

nd

then use ent

e

e

lect the new o

p

g

h

t

will turn o

ff

g will br

i

A

Engineering

uis, MO

G

UAGE

L

ISH

E

RGENT PR

I

E

PRIME*

T

IZER PRI

M

e

fault timer of

SP INPUT

*

e

e explanation

K

COUNT 00

0

C

ALE

E

R TO STAR

T

e

ssing enter in

h

g

ger becomes

i

N

TER during t

h

PROGRAM

option will on

e

d for two min

u

s

will be save

d

N

TROL MOD

E

O

SWITCHO

V

o

Switchover

s

c

tly.

.

Turn on Aut

o

.

Program the

s

.

Program le

g

i

t

Legiti

m

Initial

Recha

r

Dwell/

D

operat

i

.

Alarm Delay

times t

h

Exam

p

96 sec

3/

2

m

ming

i

nitial progra

m

m

e and illumin

a

er

to select th

e

p

tion. If a key

ff

. For helpful

T

i

ng up a blinkin

g

I

ME*

M

E*

two minutes

w

*

**

on page 13.

0

00

T

**

h

ibits all dispe

n

i

nactive after t

h

h

e de-scale cy

c

*

l

y be displaye

d

u

tes, NEW PR

O

d

.

E

V

ER

s

et-up requir

e

o

Switchover.

s

et point for c

o

t

imate probel

e

m

ate pro

b

eless

Char

g

e – am

o

rg

e Time – a

m

D

oor – how o

f

ons in door m

o

– must be set

f

h

e initial char

g

p

le: If initial c

h

(60 sec x 2 x .

8

2

3/18

m

ming menu a

s

a

te the backlig

h

e

option and

is not pressed

T

itan Tips, see

g

curser. This

m

Idioma

Portugu

e

DET. P

R

RINSE

P

SANITI

Z

w

ill stop the pu

m

DETER

G

(This is

a

DESCA

L

ENTER

T

n

ser functions

h

ree minutes

a

c

le will termin

a

SYSTE

M

d

if the dispen

s

O

GRAM mod

CONTR

O

CONCE

N

ments: for au

t

o

ncentration (p

r

e

ss mode settin

settings simul

a

o

unt of time (i

n

m

ount of time (

f

ten to recharg

o

de.

f

or less than 2

g

e.

h

arge is 1 min

o

8

).

s

it will appear

h

t. Use and

to step throu

g

within 10 sec

o

page 16. I902

m

eans you are in

e

s

R

IME PRIMI

N

P

RIME PRIMI

N

Z

ER PRIMIN

G

m

p if it is not

s

G

ENT STATU

S

a

view only re

c

L

E

T

O STOP

for three cycl

e

a

ccumulated r

u

a

te the de-scal

e

M

ACCESS

s

er has not bee

n

e will be exite

d

O

L MODE

N

TRATIO

N

t

o switchover

t

r

obe) mode.

gs.

a

te titration re

s

n

sec) needed

t

in sec) neede

d

e, dwell is for

times the initi

a

o

r 60 sec then

t

in the display

to step bet

w

g

h the option

s

o

nds the comp

a

lists the

p

rogr

a

editingmode. P

r

Idioma

Espanol

N

G

D

N

G

R

G

S

s

topped manu

a

S

DISPLA

Y

c

ord.) 0-4999

9

e

s for a door m

u

n time for a c

o

e

mode.

(SYSTEM

after

N

E

W

n programme

d

d

, the compan

y

C

P

t

o function pro

p

s

ults achieved

t

o reach a sim

u

d

to maintain a

conveyor mo

d

a

l charge. Rec

o

t

he recommen

d

Page

7

window. Pres

s

w

een the optio

n

s

elections to t

h

a

ny name will

b

a

mmable valu

e

r

ess agai

n

D

ET. PRIME

S

R

INSE PRIME

S

ANITIZER S

T

a

lly.

9

m

achine or unti

l

o

nveyor machi

n

ACCESS can

n

W

PROGRA

M

d

the first time.

y

logo will be

d

C

ONTROL M

O

P

ROBELESS

perly the follo

w

in probe mod

e

u

lated set poin

t

simulated set

p

d

e and door is

f

o

mmended set

t

d

ed alarm del

a

7

of 16

s

ing any key

w

n

s in the first

(

h

e right. Press

b

e displayed

a

e

s for all settin

g

n

to exit editing

.

Langue

F

rancais

S

TOPPED

STOPPED

T

OPPED

l

the detergent

n

e. Pressing

n

ot be entered

u

M

is completed

)

If no key is

d

isplayed, and

O

DE

w

ing must be

d

e

.

t

with a clean t

p

oint (top off)

f

or machine

t

ing at 80% o

f

a

y is 1 min, 36

w

ill

(

bold)

*

a

nd

g

s

.

u

ntil

)

all

d

one

ank

f

2

sec or

I-1024

Rev. G-

4

SWI

T

INA

C

MAC

H

CON

V

TRI

G

DET

E

NOT

E

RINS

E

durin

g

mode,

initial

The d

e

additi

v

rinse

a

DET

E

DIR

T

INA

C

* The

CO

M

NOT

E

with t

h

symb

o

ALA

R

5

CON

C

2

0

FEE

D

5

ALA

R

00:20

FEE

D

10:00

REC

H

00:01

4

3816

T

CHOVER A

L

C

TIVE

H

INE TYPE

V

EYOR

G

GER MODE

E

RGENT/RI

N

E

: Four trigge

r

E

ONLY, req

u

g

the rinse trig

g

the wash trig

g

charge will b

e

e

tergent opera

t

v

e is dispense

d

a

nd the deterg

e

E

RGENT/RIN

S

T

Y H2O ALA

R

C

TIVE

dirt

y

H2O al

PANY NAM

E

E

: Pressing

h

e and k

e

o

ls. Press

R

M VOLUM

E

0 – 1

0

C

. SET POIN

T

0

0 0 – 10

0

D

RATE 1 – 1

0

R

M DELAY

mm:ss

D

LIMIT

mm:ss

H

ARGE TIM

E

mm:ss

3/

2

L

ARM

N

SE

r

options are a

v

u

ires only a rin

s

g

er when usin

g

g

er may be co

n

e

dispensed du

r

t

es normally. I

n

d

following th

e

e

nt functions t

o

S

E is the defa

u

R

M

a

rm will ‘res

e

E

displays t

h

e

ys (press and

to save.

E

0

T

(C

o

0

0

(C

o

0

Th

e

(T

h

sta

r

b

e

s

(T

h

p

u

m

E

(T

h

ch

a

set

2

3/18

DEMA Eng

i

St. Louis,

M

SWITC

H

A

CTIV

E

SWITC

H

M

ACHI

N

DOOR

TRIGG

E

N

O TRI

G

v

ailable. DET

E

s

e trigger. Rin

s

g

RINSE ONL

Y

n

nected to the

m

r

ing

t

he fill cy

c

n

conveyor m

o

e

loss of the de

t

o

run wheneve

r

u

lt mode.

DIRTY

H

A

CTIV

E

e

t’ after the t

a

h

e current co

m

hold down to

o

ncentration s

e

o

ntrols the rat

e

e

default is 5.)

h

e time delay

b

r

ts when the c

o

s

et from 5 sec

o

h

e time delay

fr

m

p is stopped.

h

is is the time

d

a

rge is dispens

e

from 1 sec to

5

SERVICE

DISPENSE

R

i

neering

M

O

H

OVER ALAR

M

E

H

MESSAGE (

T

d

i

E

t

o

D

N

E TYPE

E

R MODE

G

GER INPU

T

E

RGENT/RIN

S

s

e functions o

p

Y

trigger. Wh

e

m

achine fill v

a

c

le. DETERG

E

o

de, the rinse r

u

t

ergent trigger

.

r

there is pow

e

H

20 ALARM

E

nk has been

d

m

pany name an

d

‘fast cycle’).

T

e

t point default

e

of approach t

b

efore a deterg

e

o

ncentration is

o

nds to 10 mi

n

r

om when the

c

It may be set

f

d

etergent will

b

e

d. This time i

s

5

min. The de

f

R

SOON

M

(This allow

s

Auto Switc

h

switches fr

o

Setting it t

o

T

his allows th

e

isplayed when

E

nter displays t

h

o

be changed,

l

D

OWN key

s

(This allows

mode. The

s

Programmi

n

TRIGGER

T

DETERG

E

S

E allows the

t

p

erate normall

y

e

n using RINS

E

a

lve. When the

E

NT ONLY, r

e

u

ns with the tr

.

NO TRIGG

E

e

r to the dispe

n

Press “E

N

how long

alarm sou

n

d

rained and r

e

(Insert

d

allows it to

b

T

he empty ‘sp

a

is 50)

t

o the set

p

oin

t

e

nt alarm will

below the set

p

n

utes. The defa

u

c

oncentration

a

f

rom 5 sec to 1

b

e dispensed i

n

s

not used in t

h

f

ault is 1 seco

n

Page

8

s

a message to

b

h

over is enabl

e

o

m concentrat

i

o

inactive will

i

e

entry of a cu

s

n

a switch over

t

he current me

s

l

etter by letter,

s

.

the selection

o

s

tatus may onl

y

n

g mode. Con

v

MODE

E

NT ONLY

R

t

raditional tw

o

y

and detergen

t

E

ONLY trigg

fill valve bec

o

e

quires only a

d

r

igger. In door

E

R INPUT, wil

n

ser.

N

TER” and inp

u

dish machine

s

n

ds.* (1 hr. m

e

filled. (All m

o

your compan

y

b

e changed, le

t

a

ce’ is betwee

n

t

to help contr

o

sound in conc

e

p

oint and is n

o

u

lt setting is 5

a

larm starts u

n

0 min. The de

f

n

probeless m

o

h

e no trigger d

o

n

d.)

8

of 16

b

e displayed i

f

e

d and the con

t

i

on to

p

robeles

i

nhibit the dis

p

s

tom message

t

occurs. Pressi

n

s

sage and allo

w

with the UP

o

f Door o

r

Co

n

y

be changed i

n

v

eyor is the de

f

TRIGGER

MO

R

INSE ONL

Y

o

trigger input.

t

functions oc

c

er in PROBE

L

o

mes active, t

h

d

etergent trig

g

mode, the rins

l cause both t

h

u

t time to indi

c

s

hould run be

fo

in – 4 hrs. m

a

o

des)

y

name here.)

t

ter by letter,

n

theand !

o

l overshoot.

e

ntration mod

e

o

t increasing. I

t

minutes.)

n

til the deterge

n

f

ault is 10min

.

o

de after the in

o

or mode. It

m

f

t

rol

s.

p

lay.)

t

o be

n

g

w

s it

and

n

veyo

r

n

f

ault.)

O

DE

Y

c

ur

L

ESS

h

e

g

er.

e

h

e

c

ate

fo

re

a

x)

e

. It

t

may

n

t

.

)

itial

m

aybe

I-1024

Rev. G-

4

(Eit

h

DEA

D

1

DWE

L

01:30

INIT

I

00:20

CHA

R

01:00

DET

E

INA

C

DET

E

LIQ

U

NOT

E

p

robe

l

the Pr

o

b

owl

w

b

owl

s

then

p

dispe

n

mess

a

succe

s

inacti

v

**Th

e

of cle

a

conce

n

RINS

E

50

RINS

E

0

RINS

E

--

4

3816

h

er DEAD C

Y

D

CYCLES

1

0-10

L

L TIME

mm:ss

I

AL CHARG

E

mm:ss

R

GE CLOC

K

hh:mm

(

Everything i

n

E

RGENT AL

A

C

TIVE

E

RGENT TY

P

U

ID

DET.

A

CAL

CH

E

: The DETE

R

l

ess, the DET

E

o

be installed.

(

w

ith the lid on

s

o that the con

t

p

rompts the us

e

n

ses chemical

s

a

ge is displaye

d

s

s message is

d

v

e.

e

unit will ask

f

a

n water and a

n

tration at full

E

SPEED

0 – 10

0

E

DELAY

0 – 15

s

E

LIMIT

15 – 7

0

3/

2

Y

CLES or D

W

(D

o

no

las

t

(C

o

ad

d

E

(T

h

tri

g

an

o

ma

n

fro

m

K

(S

e

dis

p

n

this block is

d

A

RM

P

E

A

LARM CAL.

CH

EM ENTER

R

GENT ALA

R

E

RGENT AL

A

(

ProbelessMo

d

the capsule.

W

t

rol can measu

e

r to remove t

h

s

o that the dis

p

d

. If the two r

e

d

isplayed. If th

e

f

or a set point

t

full charge. It

charge is 400,

(T

h

0

% du

r

(T

h

s

It

m

(T

h

0

s act

i

ini

t

ca

u

sec

2

3/18

W

ELL TIME

w

o

or machine

o

d

etergent is di

s

t

dead cycle. T

o

nve

y

or mac

h

d

ing a recharg

e

h

is is the dispe

n

g

gered by a m

a

o

pen probe w

h

n

ual (v1.3 & l

a

m

1 sec to 10

m

e

t this to how l

o

p

ensed. It ma

y

d

isplayed in Pr

o

DETER

G

A

CTIV

E

DETER

G

DR

Y

(Only dis

p

DET.

AL

CAL W

A

DET. A

L

CALIB

R

R

M CALABR

A

A

RM is active,

a

d

e) Pressing

W

hen this isd

o

re the base co

n

h

e lid from the

p

enser can me

a

e

adings are su

f

e

readings are

t

o be entered.

T

is recommend

then it would

h

e speed of the

r

ing adjustmen

t

h

is is the time

f

m

ay be set fro

m

h

is is the maxi

m

i

ve and reache

d

t

ial charge. It

m

u

ses the rinse l

i

onds. The def

a

w

ill display de

p

o

nl

y

. Set for h

o

s

pensed. Dete

r

h

e default is 1

h

ine onl

y

. Set

f

e

. The default i

n

se time of th

e

in dispenser p

o

h

en the deterg

e

a

ter), or the c

h

m

in. The defa

u

o

ng the dish

m

y

be from 5 mi

n

o

beless Mode

G

ENT ALAR

M

G

ENT TYPE

p

layed if alar

m

L

ARM CAL.

A

TER ENTER

L

ARM CAL.

R

ATING

A

TION setting

a

nd the deterg

e

p

rompts

t

o

ne pressing

n

ductivity. A c

chemical caps

u

a

sure the cond

u

f

ficiently diffe

r

the same, a fa

i

T

he set point s

h

ed to be about

be recommen

d

rinse motor

m

t

. The default

i

f

rom when a ri

n

m

0 seconds to

m

um time the

r

d

, it will caus

e

m

ay be set fro

m

i

mit to be inac

t

a

ult for conve

y

p

ending on M

a

o

w many ‘dea

d

rgent will dis

p

dead cycle.)

f

or how long t

h

s 90 seconds.)

e

initial charge

o

wer interrupt

i

e

nt alarm is act

h

arge clock ti

m

u

lt is 15 sec.)

m

achine should

n

utes to 16 ho

u

only. Otherwi

s

M

DETERG

E

M

ANUAL

m

is active)

DET. AL

A

SUCCES

S

is only availa

b

e

nt type is dry

.

t

he user to pla

c

again cau

s

alibration mes

u

le and place

i

u

ctivity of the

c

r

ent, an alarm

s

i

l message is d

hould be som

e

75% of the c

o

d

ed to set the s

m

ay be set fro

m

i

s 50.)

nse trigger is

r

15 seconds. T

h

r

inse pump wi

l

e

the next char

g

m

15 sec. to 70

t

ive. The defa

u

y

or machines i

s

Page

9

a

chine Type s

e

d

cycles’ (or d

o

p

ense on the fi

r

h

e machine wi

l

in probeless

m

i

on, the rinse l

i

t

ive and deterg

m

e being reach

e

be ‘off’ befor

e

u

rs. The defau

l

s

e continue be

l

E

NT TYPE

DET.

A

CALI

B

A

RM CAL.

D

S

FUL

F

b

le when the c

.

This is used i

c

e the deterge

n

s

es water to b

e

sage is displa

y

i

t in the bowl.

P

c

hemical/wate

r

s

et point is cal

c

d

isplayed and t

h

e

where betwee

n

o

ncentration at

s

et point at 30

0

m

0 to 100. The

r

eceived until

t

h

e default is 0

l

l be allowed t

o

g

e in probeles

s

sec. Advanci

n

u

lt for door ma

s

inactive.

9

of 16

e

lected earlier)

o

or closings)

w

r

st cycle after

t

l

l run before

m

ode. The tim

e

i

mit beingreac

ent type is set

t

e

d. It may be

s

e

an ‘initial ch

a

l

t is 1hour.)

l

ow the block.

)

A

LARM CAL.

B

RATING

D

ET. ALARM

C

F

AILED

ontrol mode i

s

n conjunction

n

t capsule in t

h

e

passed throu

g

y

ed. The contr

o

P

ressing enter

r

mix. A calib

r

c

ulated and a

h

e alarm is set

n

the concentr

a

full charge. If

0

.

motor runsd

u

t

he rinse pump

sec.)

o

run. If the li

m

s

mode to be a

n

n

g beyond 30

s

chines is 18

w

here

t

he

e

is

hed,

t

o

s

et

a

rge is

)

C

A

L.

s

set to

with

h

e

g

h the

o

l

again

r

ation

to

a

tion

the

u

ring

starts.

m

i

t

is

n

s

ec.

I-1024

Rev. G-43816 Page 10 of 16

3/23/18

RINSE LENGTH (The length of the rinse cycle for one rack. In a conveyor machine this isused

12 5 – 75s for the Rack Counter. Every time the rinse runs for this time a rack is counted.

In a door machine using only a detergent trigger, this is the length of the rinse

cycle following the loss of the trigger. The default is 12 seconds.)

SANITIZER SPEED (The sanitizer speed may be set from 0 to100. The sanitizer pump is active

5 0 – 100% during adjustment. Setting the speed to 0 will cause other sanitizer settings to be

skipped and the prime function will not be available.)

SANITIZER MODE SANITIZER MODE

RUN WITH RINSE RUN WITH DET.

ENTER NEW CODE ENTER PROG CODE

LEFT ACCEPTS 0000 NEW CODESAVED

0000 OTHER TO REJECT

COMMENTS AND CLARIFICATIONS

SYSTEM ACCESS

This option will only be displayed if the dispenser has already been programmed. Press ENTER. You will be

prompted for an access code. If no key is pressed for 30 minutes, SYSTEM ACCESS mode will be exited, the

company logo will be displayed and all entries will be saved.

Code Reset

This is not a menu option and cannot be done from the keypad. If, for any reason, the codes are forgotten, the access

codes can be cleared. Turn the power to the dispenser off. Open the front cover of the dispenser. Take the four

screws out to lift the board out. There are two solder points on the back of the board. Connect them together with an

insulated wire and turn on the power. Next, turn the power back off. Remove the connection from the two solder

points. When the power is turned back on, the prompts will ask for a NEW PROGRAM. All of the program

previously input will be retained. When the Programming code is requested, it will default to 0000 and may be

reentered.

NOTE: All previous programs will NOT be erased.

Press at any of the submenu options to get to the System Access Menu.

External Alarm, (Aux. Alarm)

There are two .250” (6.4mm) spade terminals on the left side of the control board. There is a 24VDC 500mA output for

an external alarm (buzzer, relay, etc.). (+) is the top terminal, (-) is the bottom terminal.

These terminals are on anytime an alarm situation is activated.

When sitting idle, the control will display the company logo with the backlight off. When triggers are received, they

will be displayed with the backlight on for five seconds and then replaced with the company logo. The trigger

message(s) will be replaced with any alarm messages if alarms occur. The alarm messages will remain, with the

backlight on, until the alarms are cleared. An audible alarm will sound if there is an alarm condition and a trigger is

present. Pressing any key will mute the alarm until the next trigger. The alarm will automatically mute when

triggers are lost.

I-1024

Rev. G-

4

Modi

f

For helpfu

NOT

E

MOD

ENT

E

LAN

G

ENG

L

DET

E

* A d

e

RINS

E

SANI

DET

*** S

e

RAC

K

DES

C

ENT

E

** Pr

e

tri

g

E

N

SYS

T

DISP

E

PAR

A

CON

C

PAR

A

PRO

B

PAR

A

RINS

E

PAR

A

SANI

T

PAR

A

DIA

G

END

P

PRES

DEM

A

St. Lo

4

3816

f

y Progr

a

l

Titan Tips, s

e

E

: TO M

O

IFICATION,

E

R TO ACC

E

G

UAGE

L

ISH

E

RGENT PR

I

e

fault timer of

E

PRIME *

TIZER PRI

M

SP INPUT

*

e

e explanation

K

COUNT 00

0

C

ALE

E

R TO STAR

T

e

ssing enter i

n

g

ger becomes

N

TER during t

h

T

EM ACCES

S

S

Y

E

NSER SET

U

A

METERS

C

ENTRATIO

N

A

METERS

B

LESS

A

METERS

E

CONTROL

A

METERS

T

IZER SET

U

A

METERS

G

ONSTIC MO

D

P

ROGRAMM

S ENTER

A

Engineering

uis, MO

3/

2

a

mmin

g

e

e page 16. I9

0

O

DIFY PR

O

USE THE A

R

E

PT CHANG

E

I

ME *

two minutes

w

M

E *

*

**

on page 13.

0

00

T

**

n

hibits all dis

p

inactive afte

r

h

e de-scale cy

c

S

Y

STEM ACC

E

U

P

N

P

D

E

I

NG

2

3/18

g

(Syste

m

0

2 also has all

p

O

GRAMMIN

G

R

ROWS TO

G

E

S.

Idioma

Portugu

e

DET. P

R

w

ill stop the pu

m

RINSE

P

SANITI

Z

DETER

G

0-49999

DESCA

L

ENTER

T

p

enser functio

n

r

three minut

e

c

le will termin

a

E

SS allows y

o

N

OTE:

T

directly

t

headin

g

Press

the head

i

p

rogram

m

m

Acces

s

p

rogrammable

G

, PRESS

G

ET TO TH

E

e

s

R

IME PRIMIN

G

m

p if it is not

s

P

RIME PRIMI

N

Z

ER PRIMIN

G

G

ENT STATU

S

L

E

T

O STOP

n

s for three c

y

e

s accumulate

d

a

te the de-scal

e

(NOTE: SY

S

N

EW PROG

R

o

u to enter any

T

o see what is

t

o a parameter

,

g

block below

s

, then you

c

i

ng block and

a

m

ed under N

E

DISPENSER

S

PARAMET

E

s

)

values for all

ON TH

E

SELECTIO

N

Idioma

Espanol

NG

DET. PRI

ME

s

topped manu

a

N

G RINSE PR

I

G

S

S

DISPLAY

y

cles for a d

o

d

run time f

o

e

mode.

S

TEM ACCE

S

R

AM is compl

e

of the below l

i

listed under e

a

,

look for the

p

s

uch as this o

n

c

an step thr

o

a

djust any sett

i

E

W PROGRA

M

SET UP

E

RS

Page

1

settings listed.

E OPTION

N

DESIRED

T

ME

STOPPED

a

lly.

I

ME STOPPE

D

S

ANITIZER S

T

o

or machine o

r

o

r a conveyor

S

S cannot be e

e

ted.)

i

sted paramet

e

a

ch of these p

a

p

arameter liste

d

n

e.

ough everythi

n

ings that were

i

M

.

1

1 of 16

NEEDING

T

HEN PRES

S

Langue

Francais

D

T

OPPED

r

until the de

t

machine. P

r

n

t

ered until a

ft

e

rs.

a

rameters, or t

o

d

in bold in a

n

gunder

initially

S

t

ergent

r

essing

ft

e

r

o

go

I-1024

Rev. G-

4

ENT

E

0000

PRO

G

* -

F

or t

h

indic

a

is des

i

CON

T

AUT

O

*See

P

SWI

T

INA

C

MAC

H

CON

V

TRI

G

DET

E

NOT

E

RINS

E

durin

g

norm

a

follo

w

functi

o

DIR

T

INA

C

CO

M

NOT

E

with

t

symb

o

ALA

R

2

ENT

E

RET

U

SYS

T

CON

C

398

FEE

D

5

CONC

E

PARA

M

DIS

P

PA

R

4

3816

E

R CODE

G

RAMING

M

will bring

u

h

e following s

e

a

te. This sectio

n

i

red on a topic

,

T

ROL MOD

E

O

SWITCHO

V

P

a

g

e 6 for sp

e

T

CHOVER A

L

C

TIVE

H

INE TYPE

V

EYOR

G

GER MODE

E

RGENT/RI

N

E

: Four trigge

r

E

ONLY, req

u

g

the rinse trig

g

a

lly. In convey

o

w

ing the loss o

f

o

ns to run wh

e

T

Y H2O ALA

R

C

TIVE

PANY NAM

E

E

: Pressing “

E

t

he and

o

ls. Press to sa

v

R

M VOLUM

E

0-1

0

E

R NEW CO

D

U

RN TO

T

EMACCESS

C

. SET POIN

T

0 –

1

D

RATE

1 – 10

E

NTRATIO

N

M

ETERS

P

ENSER SET

R

AMETERS

3/

2

M

ODE*

u

p a blinking c

u

e

ctions, check

n

will be for r

e

,

please check

E

V

ER

cific instructi

o

L

ARM

N

SE

r

options are a

v

u

ires only a rin

s

g

er. DETERG

E

o

r mode, the r

i

f

the detergent

e

never there is

p

R

M

E

E

NTER” displ

a

keys (press

a

v

e.

E

0

D

E E

N

T

1

000

N

UP

2

3/18

u

rser. This mea

n

RACK CO

U

00002

the initial pro

g

e

ference of the

the initial pro

g

CONTR

O

CONCE

N

o

ns for Auto

S

SWITC

H

A

CTIV

E

M

ACHI

N

DOOR

TRIGG

E

NO TRI

G

v

ailable. DET

E

s

e trigger. Rin

s

E

NT ONLY, r

e

i

nse runs with

t

trigger. NO T

R

p

ower to the

d

DIRTY

H

A

CTIV

E

a

ys the curren

t

a

nd hold dow

n

N

TER USER C

O

DEMA

St. Lou

i

n

s you are in edi

t

U

N

T

g

ramming sec

change in or

d

g

ramming sec

t

O

L MODE

N

TRATIO

N

S

witchover

H

OVER

A

LAR

M

N

E TYPE

E

R MODE

G

GER INPUT

E

RGENT/RIN

S

s

e functions o

p

e

quires only a

t

he trigger. In

d

R

IGGER INP

U

d

ispenser. DE

T

H

20 ALARM

E

t

company na

m

n

to ‘fast cycl

O

DE

LEFT

Engineering

i

s, MO

t

ingmode. Press

R

L

E

c

tion for detai

l

d

er of some of

t

t

ion for that to

p

C

P

M

S

TRIGGER

M

DETERGE

N

S

E allows the

t

p

erate normall

y

detergent trig

g

door mode, th

e

U

T will cause

b

T

ERGENT/RI

N

m

e and allow

s

e’). The emp

t

ACCEPTS 00

0

Page

1

s

a

R

ACK COUN

T

E

FT TO RESE

l

ed accounts o

f

t

he settings. I

f

p

ic.

C

ONTROL

MO

P

ROBLESS

S

WITC

H

M

ES

S

M

ODE TR

I

N

T ONLY RI

N

t

raditional two

y

and detergen

t

g

er. The deter

g

e

rinse additiv

e

b

oth the rinse

a

N

SE is the def

a

s

it to be cha

n

t

y ‘space’ is

b

0

0 NEW COD

E

1

2 of 16

a

gain to exit edi

T

T

f

what these s

e

f

detailed infor

m

O

DE

S

AGE

I

GGER

M

OD

E

N

SEONLY

o

trigger input.

t

functions oc

c

g

ent operates

e

is dispensed

a

nd the deterg

e

a

ult mode.

n

ged, letter by

b

etween the

E

SAVED

ting.

e

ttings

m

ation

E

c

ur

e

nt

letter,

and !

I-1024

Rev. G-43816 Page 13 of 16

3/23/18

ALARM DELAY (5 seconds to 10 minutes)

02:00 mm:ss

FEED LIMIT (5 seconds to 10 minutes)

10:00 mm:ss

RETURN TO

SYSTEM ACCESS

RECHARGE TIME (1 second to 5 minutes)

00:01 mm:ss

(Either DEAD CYCLES or DWELL TIME will display depending on weather DOOR or CONVEYOR was

selected earlier under MACHINE TYPE)

INITIAL CHARGE (1 second to 10 minutes)

00:15 mm:ss

CHARGE CLOCK (10 minutes to 16 hours)

01:00 hh:mm

(Everything in this block is displayed in Probeless Mode only. Otherwise continue below the block.)

RETURN TO

SYSTEM ACCESS

RINSE SPEED

50 0 – 100%

RINSE DELAY

1 0 – 15s

RINSE LIMIT

-- 15 – 70s

RINSE LENGTH (The length of the rinse cycle for one rack.)

12 5- 75s

PROBELESS

PARAMETERS

1 0-10

DWELL TIME (Conveyor machineonly.)

01:30 mm:ss

(Door machine onl

y

.)DEAD CYCLES

DETERGENT ALARM

INACTIVE

D

ETERGENT ALARM

A

CTIVE

D

ETERGENT ALARM

M

ANUAL

DETERGENT TYPE

LI

Q

UID DETERGENT TYPE

DRY

N

ote: When detergent type is liquid, the alarm is active, and the control is set to probeless, use a DEMA

82.15.1 Low Level Probe connected to the probe input.

D

ET. ALARM CAL.

CAL CHEM ENTER

D

ET. ALARM CAL.

CAL WATER ENTER

DET. ALARM CAL.

CALIBRATING

DET. ALARM CAL.

CALIBRATIN

G

D

ET. ALARM CAL.

SUCCESSFUL DET. ALARM CAL.

F

AILED

RINSE CONTROL

PARAMETERS

I-1024

Rev. G-43816 Page 14 of 16

3/23/18

RETURN TO

SYSTEM ACCESS

SANITIZER SPEED

5 0 – 100%

SANITIZER MODE SANITIZER MODE

RUN WITH RINSE RUN WITH DET.

RETURN TO

SYSTEM ACCESS

(No alarms are active in DIAGNOSTIC MODE. The control

functions will operate normally.)

DET SP INPUT (This screen displays the detergent status. The first character in the second line

C + 0398 0000 is “P” if the dispenser is in probeless mode and “C” for concentration mode.The

next character is only displayed when a trigger is present. When a trigger is

present “I” is displayed during an initial charge, “D” during a dwell or dead

cycle, “T” during a recharge, “+” when the pump is running in concentration

mode, or “-” when the pump is not running during concentration mode. The next

number is the set point in concentration mode or the alarm point in probeless

mode. The other number is the detergent sensor or probe reading.)

FEED OVER UNDER FEED OVER UNDER (**See NOTE)

0000 0000 LEFT TO RESET

PROBE OPEN SHORT PROBE OPEN SHORT (***See second NOTE)

0000 0000 LEFT TO RESET

RETURN TO

SYSTEM ACCESS

** NOTE: This screen displays the total switchover count for OVER and UNDER feedings. The number

below OVER is the count of switchovers caused by the dispenser feeding more than twice the INITIAL

CHARGE time without reaching the set point. The number below UNDER is the count of switchovers

caused by the concentration remaining above the set point for more than four times the DWELL TIME

or DEAD CYCLES. The OVER count is usually caused by a “scaled” probe, a leaky drain, a leaky water

supply valve, or excessive splashing of rinse water into the wash tank. The UNDER count is most often

caused by no make-up water being added or extreme wash tank contamination (very high soil load). A

large number of counts in either of these areas are a reason to review the dispenser setup especially the

PROBELESS Parameters.

*** NOTE: This screen displays the total switchover counts for an open probe or a shorted probe. Note

that a probe must be shorted for at least 30 seconds before it is counted. This gives the short (usually

flatware) time to clear. An open probe counts immediately.

END PROGRAMMING?

PRESS ENTER

DIAGNOSTIC MODE

SANITIZER SET UP

PARAMETERS

I-1024

Rev. G-43816 Page 15 of 16

3/23/18

Helpful Tips on the Titan Warewash System

Inductive Probe (82.28.1): The inductive probe is particularly useful for situations where the C-12VIK probe is

experiencing considerable scale build up. The inductive probe is not affected by the scale build-up that the C-12VIK

would experience in a typical wash tank and does not need regular cleaning. There is also a temperature adjustment

feature on the probe that can be set to change the amount of soap for the temperature of the water. See instruction

sheet I-889 for more information.

Magnetic Field Sensors (82.23.1): If trigger connection points cannot be established, the magnetic field sensors

(82.23.1) may be used in place of the trigger board and trigger wires. The magnetic field sensors connect directly to

the control board as shown on the wiring diagram. The magnetic field sensors can be placed on wash motors or rinse

valves to measure a magnetic field when the motors or valves are activated which will trigger the proper pump or

valve on the dispenser. See instruction sheet I-888 for more information.

Product Alarm Sensors: The product alarm sensors are non-contact sensors to detect out of product conditions on

the detergent, rinse, and/or sanitizer. These sensors are plugged into the appropriate connectors at the bottom of the

control board. No programming or calibration is required. The detergent alarm sensor functions in addition to any

other alarm conditions.

Auto Switchover: This feature allows for the automatic switching from Concentration to Probeless in the case of a

probe fault or inconsistent concentration readings. Conditions that can activate this feature are: (1) An Open Probe;

(2) A Closed Probe; or (3) Detergent not feeding properly, too much or too little detergent. The Titan will

automatically switch back to concentration once it detects proper probe conditions.

An OPEN probe is when a probe wire is disconnected or there is lime buildup on the tips of the probe. This will

cause an Auto Switchover. A CLOSED probe is when something for example, a piece of flatware, may be lying

across the probe tips. The Titan will wait 30 seconds to see if the short will clear. This will cause an Auto

Switchover.

If the Titan is reading an increase in detergent strength and does not reach set point in twice the time of the initial

charge setting for probeless mode, then the Titan will Auto Switch to probeless mode. (Note: Factory default for

this initial charge is 15 seconds. This may not be enough time for the wash tank to reach its concentration

level. Watch the wash tank reach its level and determine the time it takes, then use this as the setting for the

initial charge in probeless to help from using the Auto Switchover feature when not necessary). This is an

OVER feed condition. This is usually caused by a partially scaled probe, a leaking drain, a leaking water supply

valve, or excessive splashing of rinse water into the wash tank. This over feed condition is usually caused by

excessive wash tank dilution.

If the Titan is reading an excessive amount of detergent in the wash tank and the input is not lowering to the set

point in either 8 times the dwell time for conveyor mode or four times the dead cycles in door mode, then the Titan

will Auto Switch to probeless mode. (Note: The factory default for dwell time is 90 seconds and for dead cycles

is 1). This is an UNDER feed condition. This is usually caused by no make-up water being added or extreme wash

tank contamination (very high soil load or washing salt shakers).

Feed Rate: Another possible cause of unnecessary Auto-Switchover is that the feed rate is not properly adjusted for

the tank size or feeding location. The purpose of the feed rate in concentration mode is to initially charge the tank to

obtain the set point without excessive over shoot. Factory Titans are set for a feed rate of 5 which is about a 4

second feed and a ½ second pause all the way to the set point. If the feed rate is too high, it will over charge the

wash tank and if the input does not return to the set point in 4 times the dwell time or dead cycles, the Titan switches

to probeless mode. To minimize this, set the feed rate as low as possible to achieve the initial charge as close to the

set point as possible. Water temp, pressure, discharge tube length, and probe placement can affect this feed time as

well.

Alarm Delay – There are several detergents that are used by chemical companies that do not mix well with water

and will drop out of solution and settle at the bottom of the tank. When the machine is cycled again, the Titan will

read the higher concentration solution and turn the alarm delay off. It will then see no increase in concentration,

since the INPUT reading is below the set point. This is not a defect in the unit. It is due to the detergent. The Alarm

Delay setting should be changed to a few seconds before the end of the cycle to insure it will alarm.

When in Auto Switchover, the alarm delay should be set for less than 2 times the initial charge time or

approximately 80% of two times the initial charge time.

I-1024

Rev. G-43816 Page 16 of 16

3/23/18

Troubleshooting

S

y

mptom Probable Cause Remed

y

No power is being supplied

to the unit 1. Trigger Cables connected to the wrong

place on the machine.

2. Switch on bottom of unit is turned off.

(Some units may not have aswitch)

3. Power is not cycling on the machine

properly.

4. Trigger/Power cable is damaged from

installation.

1. Check wiring diagram for proper connection and

contact dish machine manufacturer for correct

trigger placement.

2. Make sure switch is turned on.

3. Check with the dish machine manufacturer if all

power should have been restored to the unit to see

if there is an issue with the machine.

4. Turn power to the dish machine off and inspect the

cable for any possible damage done.

Pumps are not priming like

they should be or not

holding a prime

1. Hole in the tubing from the chemical

container to the pump head.

2. Hole in the squeeze tube in the pump

head.

3. Fitting is not tight on the tubing

1. Check the tubing from the chemical container to

the pump head for leaks by feeling the tubing for

chemical that has leaked out. Replace the tube if

necessary.

2. Replace the squeeze tube after inspecting it for a

possible hole or leak.

3. Check both the inlet and outlet fitting and tighten if

necessary to create a good seal.

Pump over feeding 1. If in concentration or probe mode,

feed rate may not be setcorrectly.

2. If in concentration or probe mode,

probe cable may not be connected