Instruction manual Bermad surge anticipation manual

Model No 435

Bermad Water Technologies Rev 0 5/05/2015

7 Inglewood Drive , Thomastown Vic 3074

Ph (03) 9464 5949 4 www.bermad.com.au

Setting of the valve for operation

We suggest if there is any doubt in the operation or setting of the valve, you first

contact your irrigation supplier or Bermad for assistance.

1. Ensure the pipeline is fully charged and the pipe is full as in normal operation.

2. Ensure you have a copy of the pump curve to identify the operation of the

pumps.

3. Prior to opening the butterfly valve ensure the following is done to the Bermad

435 valve.

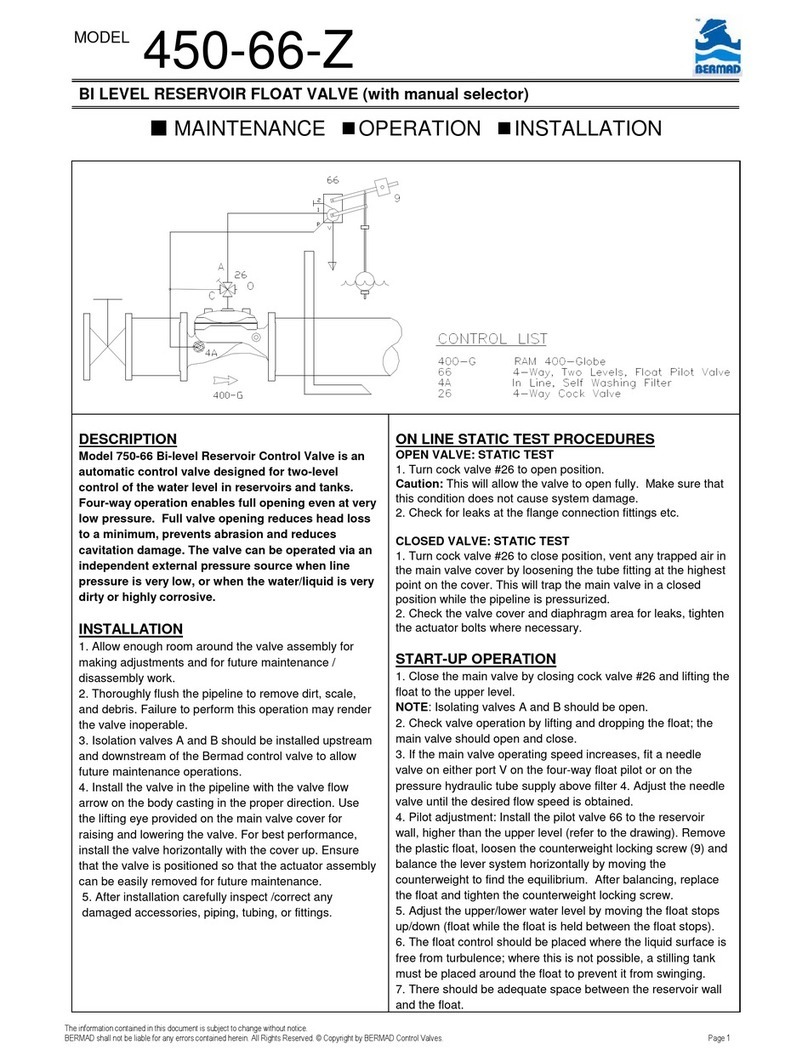

Open valve 1 and close valve 2

Turn adjustment bolt on low pressure pilot 2 anti-clockwise fully until

there is no tension on the spring.

Turn adjustment bolt clockwise fully.

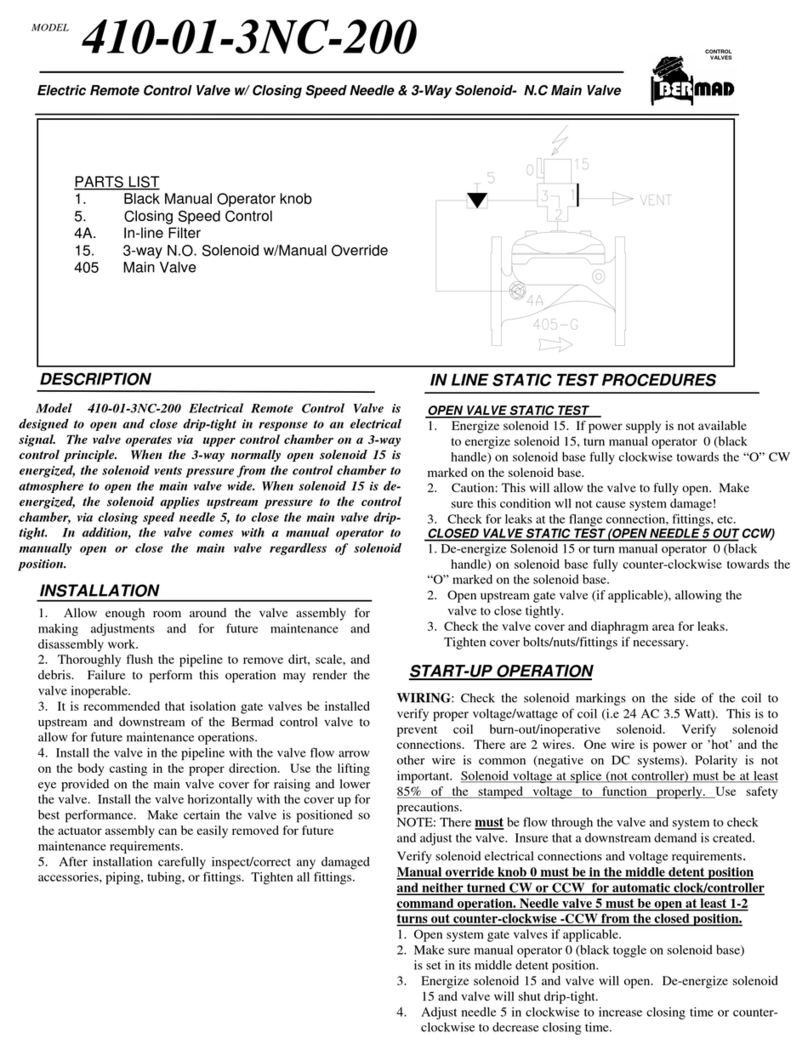

Turn needle valve on pilot #3 fully clockwise and tighten locknut.

Turn needle valve on pilot #2 clockwise fully and re-open ¼ of a turn.

4. Open the butterfly very slowly a small amount 1/8 turn to apply pressure to

the valve. When the pressure rises above 4m, the valve will open and as the

chamber fills, the valve will start to close as water enters the control chamber.

We suggest you carefully loosen a brass fitting on the copper tube to release

the air from the top chamber of the valve. Once the valve has closed and all

the milky water is gone, the valve is ready to be set.

5. The static pressure is now applied to the inlet side of the valve. Turn the low

pressure pilot adjustment bolt clockwise slowly until water starts to vent out

from the side of the pilot. The valve will start to open and will be limited as

the butterfly valve is only 1/8th open. Turn the adjustment bolt slowly anti-

clockwise until the water stops venting and the valve starts to close slowly.

Once the valve is closed continue to turn the adjustment bolt anti-clockwise

about 25% lower than the static pressure. For example if the static pressure

is 400Kpa, turn bolt anti-clockwise 1/2 of a turn. (remember 1 turn =

190Kpa).

6. Once the valve has closed, watch the pressure gauge to see that the valve

did not close too fast. If the valve closed too fast, you can adjust the needle

valve 21 on pilot #3. Turning clockwise to slow down. Anti-clockwise to

speed up.

7. It is time now to set the high pressure relief pilot. What we like to do is have

the valve open a small amount on pump start to relieve any upsurge. In some

pump stations there may not be an upsurge if the soft start is sensitive to the

system. When the pump starts, watch carefully to see how high the pressure

goes and then what it settles to when the pump is running. When the pump is

running, it is time to open valve 2 and set the pilot. Turn the adjustment bolt

anti-clockwise slowly until water vents to the down stream. Turn the bolt then

very slowly clockwise until the water stops venting.

8. It is now time to start and stop the pump several times to fine tune the

settings of the pilots. The valve is now set.