DEMA D5M Series User manual

Thank you for choosing D5M series ,D6B series multi-function and high-performance inverter

produced by Zhejiang Dema Electric Co., Ltd.

Faulty operation of inverter during installation, wiring and operation may cause an accident,

please read the Instruction Manual carefully before using so as to master correct using

method, thus avoiding personal injury and property loss due to improper operation. After

reading, please keep the Instruction Manual well for future maintenance, protection and

application in other situations.

For your safety, please ask professional electrical engineering personnel to install and debug

the inverter and adjust the parameters.

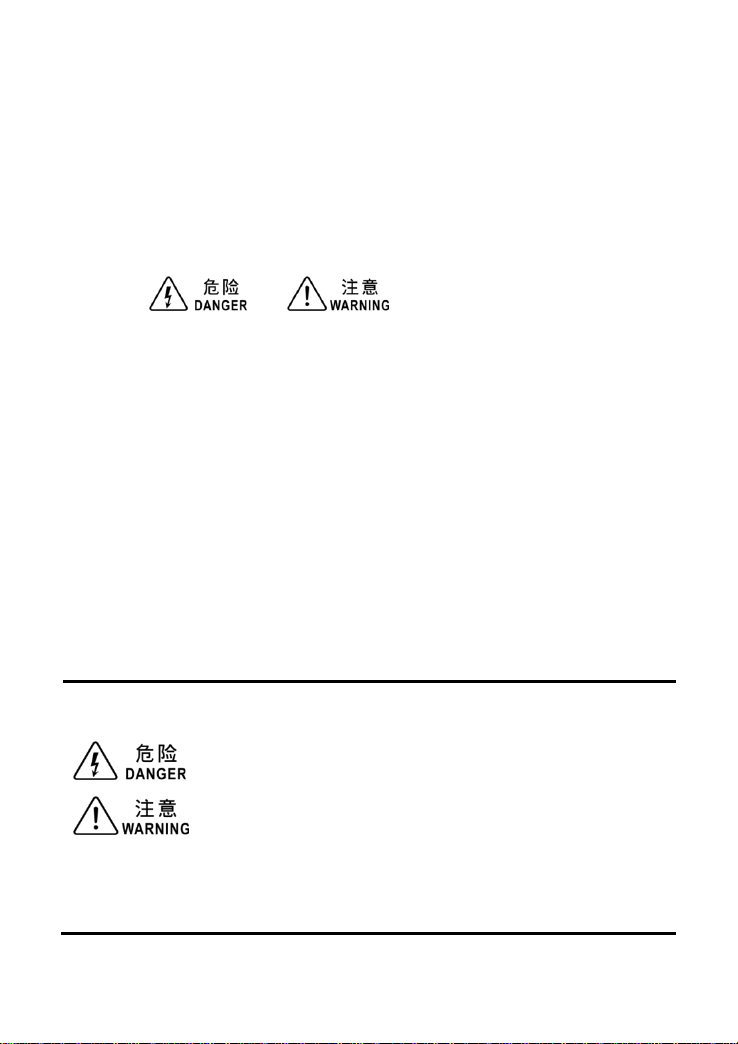

Signs like and in the Manual remind you of precautions

when carrying, installing, operating and checking the inverter, please strictly follow the

labeled warnings to realize the safety in use.

Refer to the Manual in case of any doubts; for the problems unsolved, please contact the

Company directly or our distributors, we will assign professionals to serve you sincerely.

Version No.: 1.0

Date: February 10, 2012

Zhejiang Dema Electric Co., Ltd. is always dedicated to perfecting the products and

reserves the right to modify the Manual without notice.

Safety level in the Manual refers to "danger" and "warning" with the signs respectively as

below:

:Casualties may be caused if failing to use as required.

:Personal injury or damage to the inverter or mechanical system may

be caused if failing to use as required.

Make sure the contents with safety signs are observed. For different situations, "Warning"

may also cause serious results, so it is necessary to abide by the precautions in

Instruction Manual.

2

●Turn the power off before wiring.

●After cutting off AC power, high voltage still exists in the inverter before the

charging indicator goes out, so it is dangerous to touch internal circuit and components.

●Don't check the components and signal on circuit board during operation.

●Don't dismantle or change the internal connection, wiring or components of inverter

at will.

●Don't control buttons with wet hands to avoid electric shock.

●Earthing terminal of the inverter shall be grounded properly.

●It is prohibited to change and replace the control panel and components at will so

as to prevent electric shock, explosion and other dangers.

●Since semiconductor parts inside the inverter are easily damaged by high voltage,

it is prohibited to perform voltage withstand test to them.

●It is prohibited to connect the output terminal U.V.W of inverter to AC power.

●Don't touch the inverter and brake resistor when the power is turned on or

disconnected before long in high temperature, so as to avoid scalding.

●Voltage applied to each terminal only can be that required in the Instruction Manual

to prevent bursting, damage and so on.

●Don't touch the main circuit boards CMOS and IC of the inverter since they are

easily influenced and damaged by static electricity.

●Only qualified professionals can install, debug and maintain the inverter.

●Scrapped inverter shall be disposed as industrial wastes, and burning is prohibited.

●After long-term storage, the inverter must undergo checking and commissioning

before being used.

●The inverter can be easily set for high-speed operation, before the setting, please

check whether the characteristics of motor and machine are suitable for such high-speed

operation.

Table of Contents

1

Table of Contents

No.1 Safety Cautions..........................................................................................................1

1.1 Unpacking inspection..........................................................................................1

1.2 Installation ..........................................................................................................2

1.3 Use.....................................................................................................................2

1.4 Storage...............................................................................................................3

No.2 Product Introduction...................................................................................................4

2.1 Specification of D5M series.................................................................................4

2.2 General specification of the product ....................................................................4

No.3 Wiring ........................................................................................................................7

3.1 Arrangement of main circuit terminals..................................................................7

3.2 Arrangement of control terminals.........................................................................7

3.3 Description of main circuit terminals....................................................................7

3.4 Description of control terminals ...........................................................................8

3.5 Description of jumper function.............................................................................8

3.6 Basic wiring diagram.........................................................................................10

No.4 Manipulator Description............................................................................................12

4.1 Description of operation panel appearance and key function .............................12

4.2 Description of indicator functions.......................................................................12

4.3 Description of displayed items...........................................................................13

No.5 Function List ............................................................................................................14

5.1 Basic function parameters.................................................................................14

5.2 Application function parameters.........................................................................15

5.3 Functional parameters of input/output terminals ................................................16

5.4 Functional parameters of analog quantity.......................................................... 18

5.5 Functional parameters of multi-segment speed .................................................19

5.6 Protection function parameters..........................................................................21

5.7 Function parameters of constant-pressure water supply.................................... 21

5.8 Motor function parameters ................................................................................ 22

5.9 PID function parameters....................................................................................22

5.10 Communication function parameters ...............................................................23

5.11 Monitoring function parameters .......................................................................23

No.6 Detailed Function Descriptions...........................................................................25

Table of Contents

2

6.1 Basic function parameters.................................................................................25

6.2 Application function parameters.........................................................................30

6.3 Functional parameter of input/output terminals ..................................................35

6.4 Functional parameter of analog quantity............................................................45

6.5 Functional parameters of multi-segment speed..................................................48

6.6 Protection function parameters..........................................................................56

6.7 Function parameters of constant-pressure water supply ....................................59

6.8 Motor function parameters.................................................................................62

6.9 PID function parameters....................................................................................65

6.10 Communication function parameters................................................................67

6.11 Monitoring function parameters........................................................................74

NO.7 Maintenance and Fault Information..........................................................................76

7.1 Maintenance and inspection cautions................................................................76

7.2 Regular inspection items...................................................................................76

7.3 Fault information and fault clearing....................................................................77

7.4 Fault and analysis.............................................................................................78

7.5 Common anomalies and countermeasures........................................................80

No.8 Selection and Configuration of Peripheral Facilities...................................................82

8.1 Options.............................................................................................................82

8.2 Configuration.....................................................................................................83

Annex...............................................................................................................................85

Annex I Examples of SimpleApplication..................................................................85

Annex II External and Installation Dimensions.........................................................91

Warranty and Services....................................................................................................108

NO.1 Safety Cautions

1

No.1 Safety Cautions

1.1 Unpacking inspection

D5M series ,D6B series multi-function and high-performance inverter has passed test and

quality inspection before delivery. After purchasing it and prior to unpacking, please check

whether the package is damaged due to improper transportation, and whether the

specification and model are in conformity with the ordered machine, in case of any problem,

please contact the supplier.

1. Inspection after unpacking

(1) There is a Dema inverter, an instruction manual, a warranty card and a certificate of

approval inside.

(2) Check the nameplate at side of the inverter to make sure the product in hand is the right

one.

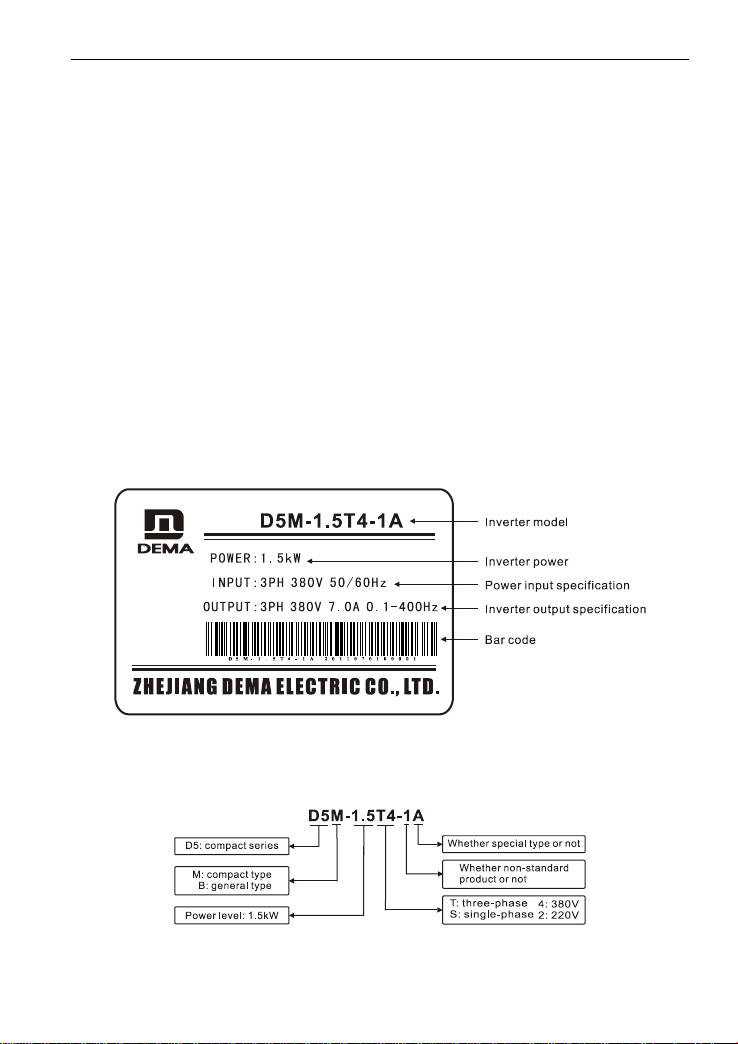

2. Introduction of D5M series nameplate

Figure 1-1 Introduction of D5M series ,D6B Series Nameplate

3. Model specification

Figure 1-2 Inverter Model Specification

NO.1 Safety Cautions

2

1.2 Installation

●Ambient temperature ranges from -5℃to 40℃, high temperature and moist shall be

prevented with the humidity less than 90% (non-condensation).

●Electromagnetic interference shall be prevented and interference source shall be kept

away.

●Water drop, steam, dust, cotton dust, and metal powder, as well as oil, salt and corrosive

gas shall be prevented entering.

●It is prohibited to install the inverter in environment with inflammable and explosive gas, as

well as liquid and solid.

●It is unallowable to install air switch, contactor, capacitor or piezoresistor concerned and

other devices at output side, so as to avoid inverter fault and damage to tripping protection or

components.

●The inverter shall adopt independent power supply rather than sharing power supply with

electric welder, so as to prevent the damage to inverter protection.

●To facilitate cooling and maintenance, the inverter shall be installed vertically with enough

space around to ensure ventilation.

●Installation wall shall be made of non-combustible materials like iron plate which shall be

prevented from vibration to cause damage to the inverter.

●If several inverters are installed up and down in one cabinet, certain spacing shall be kept

and baffle plate shall be set there between.

1.3 Use

1. Before energizing

●Voltage of the power supply selected must have the same specification with the input

voltage of inverter.

●PE refers to earthing terminal, please make sure the motor and inverter are grounded

properly to ensure safety.

●Do not set contactor between power supply and inverter to control startup or stop of inverter,

otherwise life time of the inverted will be impacted.

●Wiring of main circuit terminal shall be correct, L1.L2.L3 refer to power input terminals

which are prohibited to be mixed with U.V.W., otherwise, damage to the inverter may be

caused during energizing.

2. Energizing

●It is prohibited to plug and unplug the connector on inverter to prevent surge entering the

control panel and causing damage to the inverter.

●It is necessary to put the cover in place to prevent electric shock causing personal injury.

3. Running

NO.1 Safety Cautions

3

●It is prohibited to enable or disconnect motor unit during the running of inverter, so as to

prevent overcurrent tripping even burning the main circuit.

●It is prohibited to remove the front cover of inverter during energizing to prevent electric

shock causing personal injury.

●When the failure restart function is started, the motor will restart automatically after the

running stops; please keep away from the machine at this time to avoid accident.

●Stop switch will not be enabled until beingset, which is different from the emergency switch

in use, please pay attention to it.

1.4 Storage

●Temperature of the storage environment shall range from -20℃to +65℃;

●Relative humidity of the storage environment shall range from 0% to 95% in dry place

without condensation or dust;

●There shall be no corrosive gas and liquid in the storage environment, it shall be put on

shelter preferably with proper package;

●Long-term storage of inverter may cause deterioration of electrolytic capacitor, so it is

necessary to switch it on over 5h once a year at least, and the voltage must rise to rated

voltage value via a voltage regulator when inputting.

NO.2 Product Introduction

4

No.2 Product Introduction

2.1 Specification of D5M series

Model

Input voltage

Power

(KW)

Capacity of

driver (KVA)

Output

current (A)

Applicable

motor (KW)

D5M-0.4S2-1A

Single-phase 220V 50Hz

0.4

1.0

2.5

0.4

D5M-0.75S2-1A

Single-phase 220V 50Hz

0.75

2.0

5.0

0.75

D5M-1.5S2-1A

Single-phase 220V 50Hz

1.5

2.8

7.0

1.5

D5M-2.2S2-1A

Single-phase 220V 50Hz

2.2

4.4

11

2.2

D5M-3.7S2-1A

Single-phase 220V 50Hz

3.7

6.8

17

3.7

D5M-5.5S2-1A

Single-phase 220V 50Hz

5.5

10

25

5.5

D5M-0.4T4-1A

Three-phase 380V 50Hz

0.4

1.2

1.2

0.4

D5M-0.75T4-1A

Three-phase 380V 50Hz

0.75

2.2

2.7

0.75

D5M-1.5T4-1A

Three-phase 380V 50Hz

1.5

3.2

4.0

1.5

D5M-2.2T4-1A

Three-phase 380V 50Hz

2.2

4.0

5.0

2.2

D5M-3.7T4-1A

Three-phase 380V 50Hz

3.7

6.8

8.5

3.7

D5M-5.5T4-1A

Three-phase 380V 50Hz

5.5

10

12.5

5.5

D5M-7.5T4-1A

Three-phase 380V 50Hz

7.5

14

17.5

7.5

D5M-11T4-1A

Three-phase 380V 50Hz

11

19

24

11

D5M-15T4-1A

Three-phase 380V 50Hz

15

26

33

15

D5M-18.5T4-1A

Three-phase 380V 50Hz

18.5

32

40

18.5

2.2 General specification of the product

Name

D5M series

Control mode

V/F curve control

Input power

380V power: 380±15% 220V power:

220±15%

Four digital display and status

indicator

Display frequency, current, rotating speed,

voltage, counter, temperature, forward/reverse

NO.2 Product Introduction

5

status, fault, etc.

Communication control

RS-485

Operating temperature

-10~40℃

Humidity

Relative humidity ranging from 0 to 95% (without

condensation)

Vibration

Below 0.5G

Frequency

control

Range

0.10-400.00Hz

Accuracy

Digital type: 0.01% (-10-40℃); analog type: 0.1%

(25±10℃)

Setting resolution

Digital type: 0.01Hz; analog type: 1% of the

maximum operating frequency

Output resolution

0.01Hz

Keyboard setting

mode

Set as directly

Analog setting

mode

External voltage 0-5V, 0-10V, 4-20mA, 0-20mA.

Other functions

Three hopping frequencies (lower-frequency limit,

startup frequency and stop frequency) can be set

respectively

General

control

Acceleration/decele

ration control

4 optional acceleration/deceleration time (0.1-6500

seconds)

V/F curve

V/F curve can be set optionally

Torque control

Torque can be set rising with the maximum of

10.0%, and it can reach 150% when starting at

1.0Hz

Multi-function input

terminal

6-way programmable input; realize the functions

like 8-segment speed control, program running,

4-segment acceleration/deceleration switching,

UP, DOWN function, counter, external emergency

stop, etc.

Multi-function

output terminal

1-way programmable output; realize running, zero

speed, counter, external exception, program

running and other indications as well as alarm.

Other functions

Automatic voltage regulation (AVR), deceleration

stop or free stop, DC brake, automatic reset and

restart, frequency tracking, PLC program control,

transverse control, draft control, automatic

energy-saving running, carrier regulation (up to

20KHz), etc.

NO.2 Product Introduction

6

Protection

Function

Overload protection

Electric relay protection motor driver (constant

torque: 150% per minute, fans: 120% per minute).

FUSE protection

In case of fuse, the motor stops running

Over voltage

220V: DC voltage>390V 380V: DC

voltage>800V

Low voltage

220V: DC voltage<200V 380V: DC

voltage<400V

Restart after

transient stop

Restart after transient stop through frequency

tracking mode

Stall prevention

Stall prevention during acceleration/deceleration

Short circuit of

output terminal

Electronic circuit protection

Other functions

Overheating protection of radiating fin, reverse

limit, direct startup after operating, fault reset,

parameter locking, etc.

NO.3 Wiring

7

No.3 Wiring

3.1 Arrangement of main circuit terminals

L1

L2

L3

DC+

DB

U

V

W

[Note] Screws on main control board serve as PE terminals for that of 0.4-1.5kW.

3.2 Arrangement of control terminals

FA

FB

FC

X6

X5

X4

X3

X2

X1

GND

AI1

AI2

12V

A0

3.3 Description of main circuit terminals

Symbol of

terminal

Name of terminal

Description

L1.L2.L3

Input power terminal

Connected to three-phase 380V power

(single-phase 220V grade machine is

connected via terminals L1 and L2)

U.V.W

Inverter output terminal

Connected to three-phase motor.

DC+

DC output + terminal

DC bus output terminal is used for connecting

external brake unit or common DC bus

system. (DC- is not provided for partial

models)

DC-

DC output - terminal

DB

Brake output terminal

Connecting brake resistor between DB and

DC+.

PE

Earthing terminal

Inverter housing earthing terminal must be

earthed.

NO.3 Wiring

8

3.4 Description of control terminals

Symbol of

terminal

Function of terminal

Description

X1

Multi-function digital input

terminals 1-6

Set as forward during delivery

X2

Set as reverse during delivery

X3

Set as reset during delivery

X4

Set as high speed during delivery

X5

Set as medium speed during delivery

X6

Set as low speed during delivery

GND

Digital/analog/communication

and power earthing terminals

Isolation of GND inside from PE

12V

+12V power supply

Maximum output current: 150mA

AI1

Analog voltage input

Input voltage range: 0-+10V

AI2

Analog current/voltage input,

selecting via jumper1, default to

current input

Input current range: 0-+20mA

Input voltage range: 0-+10V

A0

Analog voltage output

Output voltage range: 0-+10V

FA、FB、FC

Multi-function relay output

FA-FC: normally open, FB-FC:

normally closed

Contact specification: 250VAC/3A,

30VDC/3A

RS+ RS-

RS485 communication interface

Available connection of 1-32 RS485

sites

3.5 Description of jumper function

No.

Function

Ex-factory setting

J1

Selection of AI2 input type

V: Voltage mode mA: Current mode

mA

J2

Selection of X1-X6 wiring mode

NPN type or PNP type

NPN

Wiring mode of multi-function digital input terminals X1-X6:

(1) When NPN type wiring mode is adopted for external equipment, leakage type logic is

induced and the current flows out from input terminal (sourcing current) as shown in Figure

3-1, at the same time parameter P067=0 is required.

NO.3 Wiring

9

[Note] NPN type wiring mode shall be adopted in case of P067=0.

Figure 3-1 NPN Type Wiring Mode

(2) When PNP type wiring mode is adopted for external equipment, source-type logic is

induced, and the current flows into from input terminal (sinking current) as shown in Figure

3-2, at the same time parameter P067=1 is required.

[Note] PNP type wiring mode shall be adopted in case of P067=1, at this time 9v

above at input terminal is high level.

Figure 3-2 PNP Type Wiring Mode

NO.3 Wiring

10

3.6 Basic wiring diagram

Inverter wiring involves main circuit and control circuit. The user can raise the cover of

housing, at this time main circuit terminal and control circuit terminal shall be viewed, and the

user must conduct correct connection as per wiring circuit below.

Figure 3-3 below refers to standard wiring diagram of ex-factory D5M series.

Figure 3-3 Standard Wiring of D5M series ,D6B series Inverter

NO.3 Wiring

11

1. Main circuit wiring

●During wiring, please select wire diameter specification and conduct wiring as per those

specified by electrical engineering laws so as to ensure the safety.

●For power supply wiring, prefer shielded wire or spool, and earth isolating layer or both

ends of spool.

●Be sure to install air circuit breaker NFB between the power and input terminal (L1.L2.L3).

(In case of applying leakage switch, please use the breaker with high frequency solution)

●Do not connect AC power to inverter output terminal (U.V.W).

●Prevent output wire touching metallic part of inverter housing; otherwise, earth short-circuit

may be induced.

●Do not apply phase-shifting capacitor, LC, RC noise filter or other elements to output end of

inverter.

●Indispensably make main circuit wiring of inverter away from other control equipment.

●When the wire between inverter and motor exceeds 15m (220V grade) or 30m (380V

grade), extremely high dV/dT shall emerge inside motor coil and it shall produce damage to

layer insulation of the motor, so it is necessary to useAC motor dedicated to inverter or install

reactor onto inverter side.

●In case of long distance between inverter and motor, reduce carrier frequency, for the

larger the carrier frequency is, the larger the higher harmonic leakage current becomes,

which shall produce adverse effect on the inverter and other equipment.

2. Control circuit wiring

●It is not allowed to place signal wire and main circuit wire inside the same slot.

●Supply cord of signal wire should be shielded wire with the size of 0.5-2.0mm.

●Control terminal on control board should be correctly used as required.

3. Earth wire

●Please properly earth terminal PE of earth wire.

220V grade: The third type earthing (earthing resistance is below 100)

380V grade: Particularly the third type earthing (earthing resistance is below 10)

●Use earth wire as per fundamental length and size specified by electrical equipment

technology.

●Absolutely avoid sharing earth electrode with welding machine, power generating machine

and other large-scale power equipment and make earth wire away from power line of

large-scale equipment as much as possible.

●Earth wire must be short to the utmost extent.

NO.4 Manipulator Description

12

No.4 Manipulator Description

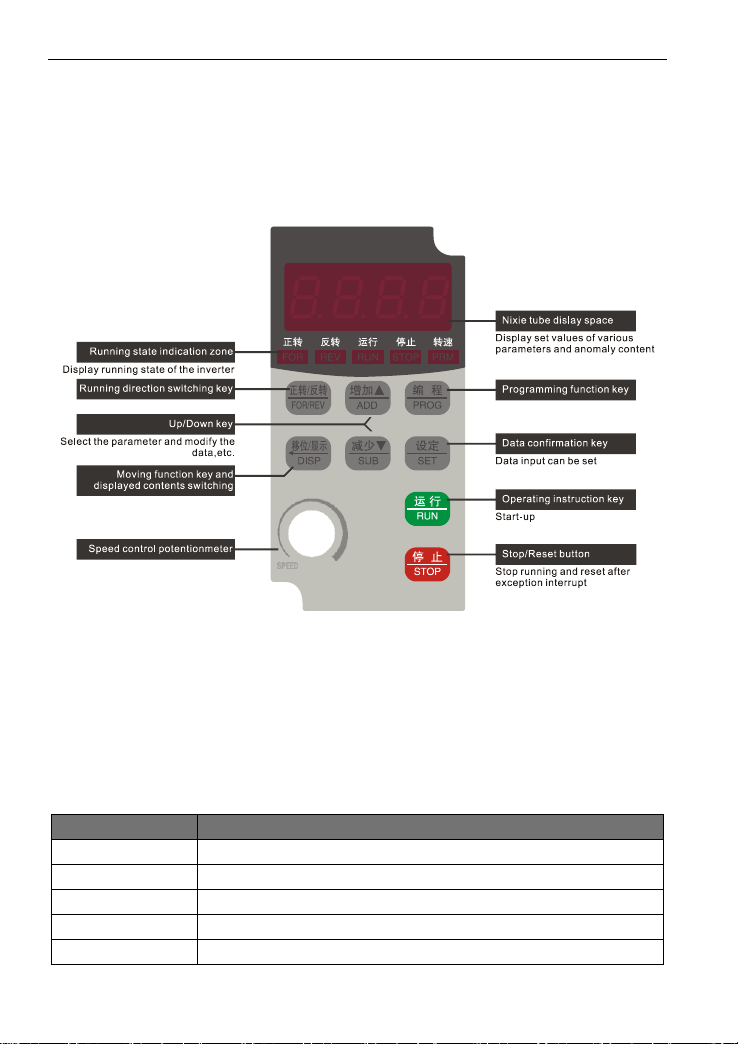

4.1 Description of operation panel appearance and key function

Figure 4-1 D5M Series Digital Manipulator

[Note] Two switching modes of forward and reverse rotation are provided for D5M:

1) Press and hold down the key FOR/REV;

2) Press the key Program (PROG), then use the keys ▲and ▼to select; enter

parameter setting interface if pressing the key Program (PROG) again.

4.2 Description of indicator functions

Indicator

Function description

FOR

Motor forward

REV

Motor reverse

RUN

Motor is running

STOP

Motor is stopped

PRM

Display motor speed

NO.4 Manipulator Description

13

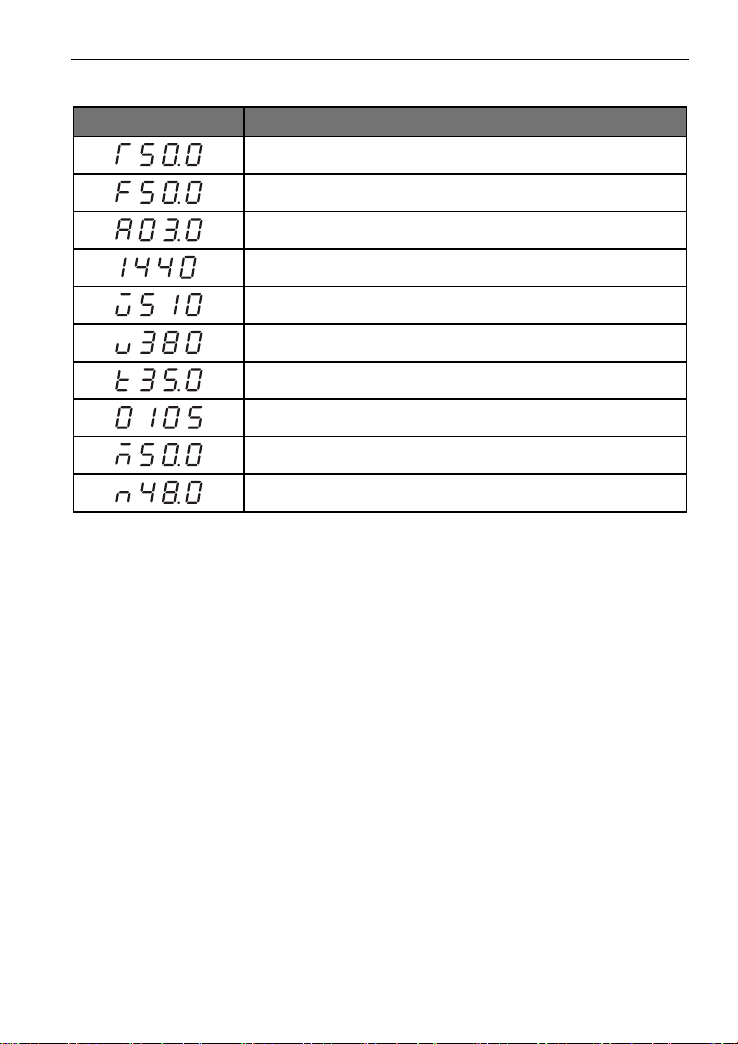

4.3 Description of displayed items

Displayed content

Description

Output frequency is 50.0Hz at this time

Set frequency is 50.0Hz

Output current is 3.0A at this time

Output speed is 1440r/min and speed light turns on at this time

DC voltage is 510V at this time

AC voltage is 380V at this time

Inverter temperature is 35.0℃at this time

Counter value is 105 at this time

PID target value is 50.0%

PID feedback value is 48.0%

NO.5 Function List

14

No.5 Function List

Description of special symbols:

* indicates that this parameter content has various set values or it shall be specifically set

based on actual situation.

Ex-factory value refers to parameter value set during delivery of inverter or parameter value

refreshed while the user restores ex-factory operation.

Alteration refers to alternative attribute of the parameter. ○indicates that the alteration is

available during shutdown and operating, ×indicates that the alteration is unavailable

during operating, and Δrefers to read-only parameter which cannot be altered by the user.

5.1 Basic function parameters

Function

code

Name of function

Setting range and data content

Ex-factory

value

Alteration

P000

Parameter locking

0: Invalid 1: Valid

0

╳

P001

Control mode

0: Manipulator

1: External terminal

2: Communication port

0

╳

P002

Frequency setting

selection

0: Manipulator

1: External terminal

2: Communication port

3: Manipulator potentiometer

0

╳

P003

Main frequency

0.00-400.00 Hz

*

○

P004

Reference

frequency

0.01-400.00 Hz

50.00

╳

P005

Maximum operating

frequency

10.00-400.00 Hz

50.00

╳

P006

Intermediate

frequency

0.01-400.00 Hz

2.5/3.0

╳

P007

Minimum frequency

0.01-20.00 Hz

0.50

╳

P008

Maximum voltage

0.1V-*

220/380

╳

P009

Intermediate voltage

0.1V-*

*

╳

P010

Low-frequency

torque boost voltage

0.1V-50.0V

*

╳

P011

Lower frequency

0.00-400.00 Hz

0

○

NO.5 Function List

15

limit

P012

Reserve

P013

Parameter resetting

8 restore ex-factory value

00

╳

P014

Acceleration time I

0.1-6500.0s

*

○

P015

Deceleration time I

0.1-6500.0s

*

○

P016

Acceleration time II

0.1-6500.0s

*

○

P017

Deceleration time II

0.1-6500.0s

*

○

P018

Acceleration time III

0.1-6500.0s

*

○

P019

Deceleration time III

0.1-6500.0s

*

○

P020

Acceleration time IV

0.1-6500.0s

*

○

P021

Deceleration time IV

0.1-6500.0s

*

○

P022

Reserve

5.2 Application function parameters

Function

code

Name of function

Setting range and data content

Ex-factory

value

Alteration

P023

Reverse prohibit

0: Reverse prohibit

1: Reverse allow

1

╳

P024

Stop key is valid or not

0: STOP invalid

1: STOP valid

1

╳

P025

Start mode

0: Start from starting frequency

1: Frequency tracking start

0

╳

P026

Stop mode

0: Decelerate stop

1: Free running stop

0

╳

P027

Starting frequency

0.10-30.0 Hz

0.5

╳

P028

Stop frequency

0.10-30.0 Hz

0.5

╳

P029

Start braking time

0.0-25.0s

0.0

╳

P030

Stop braking time

0.0-25.0s

0.0

╳

P031

DC braking level

0.0-20.0%

2.0

╳

P032

Frequency tracking

time

0.1-20.0s

5.0

╳

P033

Current tracking

frequency level

0-200%

150

╳

P034

Voltage rise time

during frequency

tracking

0 .1-10.0s

0.5

○

P035-P040

Reserve

P041

Carrier frequency

0-15

*

╳

NO.5 Function List

16

P042

Jogging frequency

0.00-400.00 Hz

5.00

○

P043

S curve time

0.0-6500.0s

0.0

○

5.3 Functional parameters of input/output terminals

Function

code

Function name

Setting range and data content

Ex-factory

value

Alteration

P044

FOR(X1) function

0: Invalid 1: Run 2: Forward

3: Reverse 4: Stop

5: Forward/reverse

6: Inching 7: Inching forward

8: Inching reverse

9: External control timer I

10: External control timer II

11: Setting frequency is forced

to P003

12: Radiator or motor

overheating

13: Emergency stop 14: Reset

15-16:Reserve

17: Acceleration/deceleration

time selection I

18: Acceleration/deceleration

time selection II

19: Multi-segment speed I

20: Multi-segment speed II

21: Multi-segment speed III

22: High speed

23:Medium speed

24: Low speed 25: PID

allowed

26: Multi-segment speed IV

27: UP 28:DOWN

29: Draft allowed 30: Reserve

31:Pulse counter

32: Pulse counter resets

02

╳

P045

REV(X2) function

03

╳

P046

RST(X3) function

14

╳

P047

SPH(X4) function

22

╳

P048

SPM(X5) function

23

╳

P049

SPL(X6) function

24

╳

P050

Y1 output function

0: Invalid

1: Indication during running

2: Zero-speed indication

3:Fault indication

01

○

P051

Y2 output function

05

○

P052

Output function (KA and

KC are terminals)

00

○

This manual suits for next models

16

Table of contents

Popular Inverter manuals by other brands

Goodwe

Goodwe GW9900-MS-30 Quick installation guide

Magnum Energy

Magnum Energy MagnaSine Hybrid owner's manual

Trannergy

Trannergy PVI 5400TL user manual

Stober

Stober POSYDYN SDS 4281 Supplementary Documentation

Power Electronics

Power Electronics SD 500 Series Hardware and installation manual

Perfect power systems

Perfect power systems WM.20A01OP manual

Magnum Dimensions

Magnum Dimensions CSW2012-X owner's manual

Stanley

Stanley Pc100 instruction manual

hpmont

hpmont HD31-4T2P2P user manual

Endress

Endress ESE Series Use and maintenance manual

CAC / BDP

CAC / BDP FOR BYPASS AND FAN POWERED HUMIDIFIERS owner's manual

Westerbeke

Westerbeke 10.0KW-60Hz Service manual