Dematech Dema-Craft 60l. User manual

Dematech (Pty) Ltd

13 Michigan Street, Airport Industria, Cape Town 7490, South Africa

www.dematechsa.com

DEMA-CRAFT

60l BREWING SYSTEM

Read all the instructions carefully & keep this

manual for future reference.

Never submerge the brewing vessel. To clean

the exterior, use a damp cloth. Always protect

the electric power cable from water.

Do not switch on the machine if the vessel is

empty. The machine does have a dry-boil cut-

off switch to turn the element off if it overheats

(when there is no water) but the element &

electronics may still be damaged. The warranty

does not cover damage due to dry-boil.

Do not use this device if the cord or plug is

damaged.

Switch off the brewing vessel correctly before

removing the plug.

Only move the brewing vessel when the power

is shut off & it is empty (no water inside the

unit).

Do not turn the pump on for more than 5 min-

utes at a time during wort boiling (bubbles will

cause the pump to idle & wear out under high

temperature). It is not recommended to use the

pump for pumping out the wort aer cooling

(rather use the tap on the front of the unit).

Hops & trub may enter the pump, potentially

blocking & damaging the system.

02

01 05

06

03

07

08

04

Safety Instructions

Hello & Welcome. Thank you for purchasing Dematech's Dema-Cra 60l.

Please follow the instructions and safety precautions carefully in this

manual to get the best use from our brewing system. We highly suggest that

you use this process for your rst few batches before adjusting your brewing style.

Check the product’s rating label & make sure

the brewing vessel voltage is t for your outlet

voltage before use. This appliance requires a

13amp-16amp plug.

02

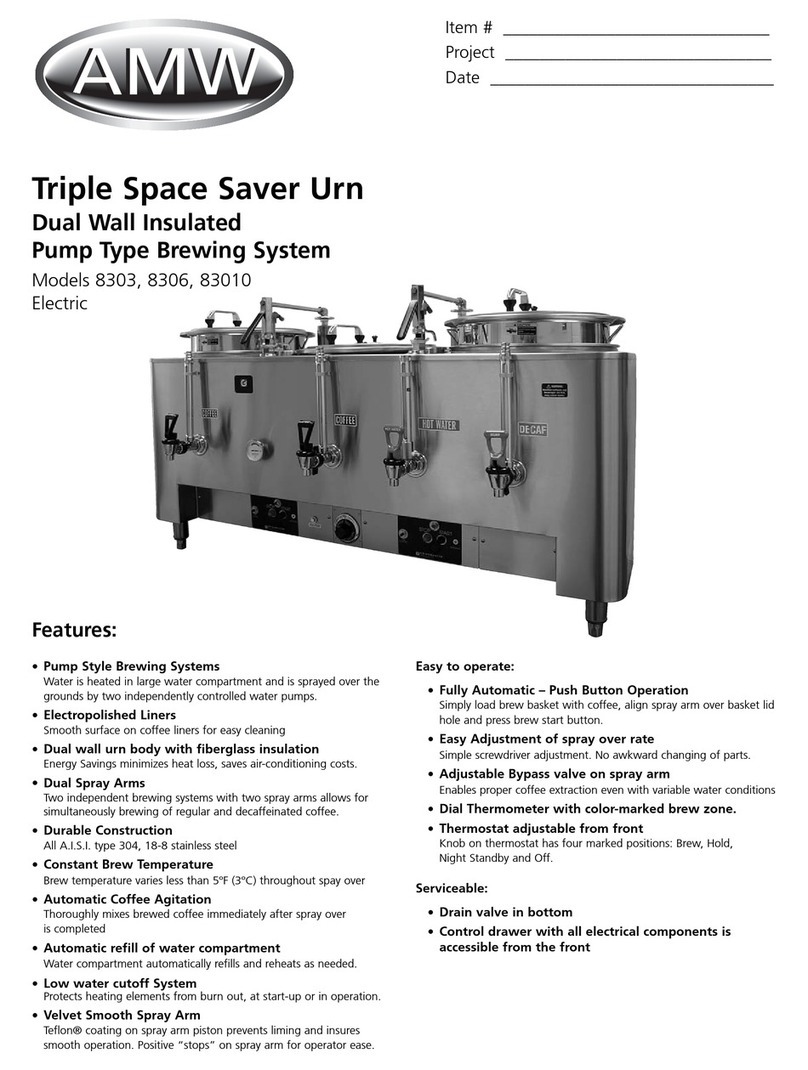

Top sparge plate for grain basket Glass lid cover with hole for circulation

13m Chiller coil

Bottom sparge plate for grain basket Filter tube

Whirlpool arm

White screw cap cover Telescopic overow tube for half batches

Hop spider

Grain basket Screw nut

Grain paddle

Circulation pipe (Cam-lock connector)

Grain basket handle

Bottom small tube

Thermowell

Digital Controller

Switches (PCB & Pump)

Faucet

Circulation Tube

Cam-lock connector

Circulation Valve

Built-in pump

03

01

01

01 02 03 04 05

02 03 04 05 06 07 08 09 10 11

07

01

02 08

02

03 09

03

04 10

04

05

06

11

05

What’s in the box?

PARTS

ADDITIONAL ACCESSORIES

Valve Operation:

This valve is to open and close the wort circulation from the

pump. It is also used to adjust the wort ow during mashing.

Tap Operation:

To OPEN, pull the safety latch upwards and turn the

lever 90° counterclockwise. To CLOSE, pull the safety

latch up and turn the lever clockwise by 90°.

Circulation tube assembly:

Adjust the ow rate using the blue valve. If the ow is too fast, the grain basket will overow down the central pipe, and the bottom

of the boiler may run dry. Adjust the ow until the ow from the pump matches the speed at which the wort ows through the grain.

This may need to be adjusted during the mash.

SWITCH ON SWITCH OFF

CLOSED OPENING OPEN

Insert circulation pipe

into the cam-lock

connector

To lock, push the

Cam-lock levers down

Direct the hose

through the glass lid

Switch Operation:

The switch “PCB” is the ON/OFF switch for the power to the

digital controller that controls the heating elements. The switch

“PUMP” is the ON/OFF switch for the pump. The red light is

visible when switched on.

Now it’s locked & ready

to use

04

Operating Instructions

Valve Operation:

Grain basket overow assembly:

Secure the overow pipe into the bottom sparge plate by inserting

the larger, threaded end of the overow pipe through the hole in the

bottom plate and securing the nut from the bottom. Make sure that the

nut is only nger tight. Then attach the smaller nut on the top of the over-

ow pipe.

The white grain stopper cap is only used while mashing in so that the milled grain

cannot fall into the overow pipe. Remove this cap when all grains have been added.

Components

prepared

Use the handle to lower the

grain basket into the Dema-

Cra. Make sure that the sup-

ports on the basket are hooked

onto the support ring

When adding the mash water

and grains, remove the top

sparge plate and add the grain

stopper

When the mashing is

completed, use the

handle to li the grain

basket up and hook its

bottom

Install the top

sparge plate; white

screw cap cover at

the top

Use the screw to

connect the bottom

sparge plate with

telescopic overow tube

05

Bazooka mesh lter assembly on tap Bottom little tube assembly

Note: Please insert this tube into the pump before using the machine to prevent the malt from clogging the pump inlet.

Control Panel and Key Functions

Temp button Press to set target temperature for each step

Power button Press to set power for each step

Timer button Press to set timer for each step

- button Press to reduce the value

+ button Press to increase the value

Start/Stop Press to start or stop the program

Manual/Pause Press to enter manual mode

Press to pause the program on manual mode

Auto/Pause Press to enter auto mode

Press to pause the program on Auto mode

S/P: W Set the power

S/T: Set the temperature

-H When ashing, the brewing vessel is heating up to the target temperature

06

How to use the controller?

Manual mode settings

1. Switch on the PCB switch, then press the

MANUAL/PAUSE button to enter manual mode.

3. Press the POWER button. The power set-point (S/P: XXXXW) at the bottom le of the screen will ash and you can use the – and +

buttons to set your wattage. We recommend 3000W for raising temperature up between steps. 1500W during your mashing phase to

maintain mash temperature. And once boiling, drop to 2500W to maintain a rolling boil.

4. Press the TIMER button. The time (XX min) at the top right of the screen will be ashing and you can use the – and + buttons to set

your countdown timer. Once the TEMP, POWER and TIMER have been set, press the START/STOP button to start the machine. The H

– symbol at the top le of the screen will ash to show that the machine is heating. The machine will then heat the liquid up to your

temperature set-point. Once it reaches the set-point, the machine will chime and start the countdown timer while maintaining the

set-point temperature. The time will ash while the timer is counting down.

NOTE:

The H – symbol will continue ashing even when the elements are off. Once the timer reaches zero, the machine will chime and

the word END will ash on the screen. Press the START/STOP button to stop the chime. To edit any of the TEMP, POWER or TIMER

settings, press the MANUAL/PAUSE button again. To return to your program aer adjusting any of the settings, press the MANUAL/

PAUSE button again

2. Press the TEMP button. The temperature set-point (S/T: XX.X°C)

at the bottom right of the screen will ash and you can use the –

and + buttons to set your temperature.

07

1. 2.

3. 4.

08

5.The default boiling temperature is 100 °C. The timer will not be triggered if temperature does not indicate 100°C .

If the machine starts to boil, but shows a lower temp on the display (i.e. if you are brewing at a higher altitude than sea level),

make the following adjustment to set the temp at 100 °C and trigger the timer.

Press START/STOP until only the temperature is displayed on the screen. Press “-” and “+” button together for 5 seconds and then

release, the display will show the C1 (temperature offset for celsius) or F2 (temperature offset for fahrenheit).

Press the MANUAL/PAUSE button until the display shows C2 (boil temperature offset for celsius) or F2 (boil temperature offset

for fahrenheit). Temperature correction range is from 0 to +10 or 0 to +50. If you set C2 to 6 then the unit will begin the boiling

stage of the program at 94 °C.

6. Press MANUAL/PAUSE button during heating to go back to the edit page. You can edit Temp/Power/Timer, then press the

MANUAL/PAUSE button again to resume.

NOTE: Long press TEMP for 5 seconds, to switch between degrees Centigrade and Fahrenheit. This operation only can be

preceded when you switch on the machine before any setting.

1. Switch on the PCB switch, then press the AUTO/

PAUSE button to enter auto mode. S1 (Stage 1) will be

displayed in the top le corner of the screen.

3. Press the POWER button. The power set-point (S/P:

XXXXW) at the bottom le of the screen will ash and

you can use the – and + buttons to set your wattage.

We recommend 3000W for raising temperature up

between steps. 1500W during your mashing phase to

maintain mash temperature. And once boiling, drop to

2500W to maintain a rolling boil.

4. Press the TIMER button. The time (XX min) at the top right

of the screen will ashing and you can use the – and + buttons

to set your countdown timer.

2. Press the TEMP button. The temperature set-point (S/T:

XX.X°C) at the bottom right of the screen will ash and you

can use the – and + buttons to set your temperature.

5.

1.

3.

2.

4.

6.

Auto mode settings

09

5. Aer you have set the parameters for S1, press

AUTO/PAUSE button again. S2 (Stage 2) will be

displayed in the top le corner of the screen. Set the

TEMP, POWER and TIMER parameters as above.

6. Repeat this process for S1 through S9.

When you have programmed all of the mashing steps for your

recipe, press the temp button and then the + button. When

the temperature reaches 100C °C (or lower if you changed the

C2 value) the program will go into the boiling step.

7. The step where you set the temperature to “boiling”

will always be the last step in the program and all

subsequent steps will be ignored.

9. When you have entered all of your steps, press the

START/STOP button to conrm the above step mashing

settings.

10. At the end of each step, the machine will chime

and will not proceed to the next step until AUTO/

PAUSE is pressed.

11. Pressing the AUTO/PAUSE button will stop the

element and timer working temporarily and pause the

current step, while paused you can edit the settings for

the step. Press AUTO/PAUSE to continue.

12. Press the START/STOP button when in auto mode

to skip the current step.

8. Aer setting the boiling step, you can set the hop remind-

ers. Press - or + to set the time at which the hop reminder

will chime. Setting it at 60min means that the reminder will

chime 60 minutes BEFORE the end of the boil. Press the

TIMER button to set further hop reminders (up to 9 in total).

The reminder for the rst hop addition cannot be longer than

the boil time (i.e. you cannot have a 60 min reminder if your

boil time is 30 min).

5.

8.

6.

10

1. Aer setting your brewing recipe in auto mode, press STOP button until you are back at the main page (only the temperature is dis-

played).

2. Press MANUAL/PAUSE button to enter the manual mode edit page

3. To save the settings that you have just set in auto mode, long press the MANUAL/PAUSE button for 5 seconds then release it. The ma-

chine will chime to conrm that the settings have been saved.

4. To start a new brewing recipe, go to the main page (only the temperature is displayed) and long press the POWER and TIMER buttons

for 5s. R0 (recipe 0) will display at the top le of the screen.

5. Press “-” or “+” to scroll between the recipes. Press the Start/Stop button to conrm the selected recipe and return to the main page.

6. Press the AUTO/PAUSE button to enter the chosen recipe edit page and then you can proceed as above.

Press the AUTO/PAUSE button to enter auto mode. S1 (Stage 1) will be displayed in the top le corner of the screen. Here you can

edit the temperature, power and timer

Press TIMER button to set the subsequent hop reminders (up to 9 in total)

Press the START/STOP button until you are back at the main page (only the temperature is displayed). Long press the POWER and

TIMER buttons for 5 seconds. R0 (recipe 0) will display at the top le of the screen

Press the AUTO/PAUSE button to enter chosen recipe edit page. Here you can edit the Power/Timer/Temp settings or press the START/

STOP button to start the selected recipe

Press the - or + buttons to scroll between the recipes

Press the START/STOP button to conrm the selected recipe and return to the main page

Press the START/STOP button to conrm the above step mashing settings

and start the program

Press TIMER button to set 2nd hops reminder. Press timer again for 3rd,

4th, 5th...9th setting.

1. Press the START/STOP button to conrm

the above step mashing settings and start

the program

If you would like to skip the hop

reminder settings, press START/

STOP button to conrm the

previous settings and start the

program

Press the AUTO/PAUSE button again to

go to the next stage (S2 to S9)

In the boiling step, press the AUTO/

PAUSE button again to set the hop

reminders

Recipe selection in auto mode

11

Saving brewing recipes

LET’S GET BREWING!

Feel free to contact one of our

experienced brewmasters for advice &

suggestions as well as exciting brewing

recipes in various beer styles. We also offer a

wide range of ingredients that work perfectly

for the Dema-Cra 60l. Visit our website at

www.dematechsa.com or reach out at info@

dematechsa.com. Follow the brewing process

example on this page for your convenience.

Make sure that the brewing vessel is positioned on a stable and secure surface before

brewing as a full vessel contains boiling hot liquids and can weigh up to 70kg

12

• Always clean the brewing vessel before and aer use.

• Attach the Bazooka lter to the inside tail of the tap using the

included hose clamp.

• Add the required quantity of strike water before switching the

brewing vessel on.

• Insert the bottom sparge plate into the malt pipe and then insert

the malt pipe into the brewing vessel.

• Heat up the water to your strike temperature in either manual or

auto mode.

• Add the milled grain into grain basket and stir it gently.

• Once your grain is well mixed and completely saturated, gently

place the top sparge plate on top of your mash.

• Switch on the pump to circulate the wort through your grain bed.

If the wort is over owing through the central overow pipe,

reduce the pump ow by using the blue valve.

• Aer mashing, carefully li the malt pipe with the included

handle, and gently set the feet of the malt pipe down onto the

support ring on the boiler.

• If you are sparging, you can gently pour your sparge water into

the malt pipe and let it run through your grain. Leave the grain

to drain into boiler for at least 10mins aer sparging before

removing.

• Heat up the wort to boiling temperature.

• Add the hops etc. at the correct times according to your recipe.

• Immerse your wort chiller into the boiling wort 10 minutes

before the end of the boil to sanitise it.

• Aer the boil is nished, cool down the wort to the pitching

temperature stated in your recipe before transferring to your

fermenting vessel via the tap and bazooka lter on the front of

the machine.

Follow this maintenance guide:

13

• Place 10-20L of water into the machine and heat to 60C. Dissolve

a brewing cleaner such as DemaClean into the warm water and

recirculate it through the pump for 15 minutes while you clean

the inside of your Demacra with a so cloth.

• Do not use sharp metal implements to remove any residue. Use a

so cloth or so scouring pad to clean the inside of the boiler.

• Any wort residue on the base of the boiler should be cleaned off

before next use.

• Aer cleaning rinse the machine well, including ushing the

pump by connecting a hose to the pump outlet.

• Do not get water on any electronic parts of the machine.

• Do not immerse the machine in water.

• To clean the outside of the brewing vessel, simply use a damp,

so cloth.

Ingredients stuck in the pump

C1-- temperature offset

ERR-1 shown on display

Failing to reach 100

C2-- boiling point offset

ERR-2 shown on display

Flush the pump by connecting a hose to the outlet of the pump.

If that fails, dismantle the pump to remove the ingredients

Put the lid on to see if it comes to a boil. If that fails, do a tem-

perature correction as described below

Press “-” and “+” at the same time enter into the C1 tempera-

ture correction setting. Setting range is from -10 to +10. This

is a temperature offset if the probe is reading the temperature

incorrectly

Press “-” and “+” at the same time enter into the C1 tempera-

ture corrected setting and then press the AUTO/PAUSE button

to enter into the C2 temperature correction setting. This is a

temperature offset for the boiling

This error is displayed if the temperature reading is lower than

-20 °C. This is most oen due to a loose probe connection. To

rectify, open the bottom of the machine and check if the sensor

is loose

This error is displayed if the temperature reading is higher than

120 °C, it is an overheat/boil-dry warning temperature only

Troubleshooting tips

Electric Circuit

14

Altitude in meters Altitude in feet Temperature in deg C Temperature in deg. Fahrenheit

0 m. 0 ft. 100 ºC 212 ºC

152 m. 500 ft. 99.5 ºC 211 ºF

305 m. 1000 ft 99 ºC 210 ºF

457 m. 1500 ft. 98.5 ºC 209 ºF

610 m. 2000 ft. 98 ºC 208 ºF

762 m. 2500 ft. 97.5 ºC 207 ºF

914 m. 3000 ft 97 ºC 206 ºF

1067 m. 3500 ft. 96 ºC 205.5 ºF

1219 m. 4000 ft. 95.5 ºC 204 ºF

1372 m. 4500 ft. 95 ºC 203.5 ºF

1524 m. 5000 ft. 94.5 ºC 202 ºF

1676 m. 5500 ft. 94 ºC 201.5 ºF

1829 m. 6000 ft. 93.5 ºC 200.5 ºF

1981 m. 6500 ft. 93 ºC 199.5 ºF

2134 m. 7000 ft. 92.5 ºC 198.5 ºF

2286 m. 7500 ft. 92 ºC 198 ºF

2438 m. 8000 ft. 91.5 ºC 197 ºF

2591 m. 8500 ft. 91 ºC 196 ºF

2743 m. 9000 ft. 90.5 ºC 195 ºF

2895 m. 9500 ft. 90 ºC 194 ºF

3048 m. 10000 ft. 89.5 ºC 193 ºF

What temperature should you boil at?

15

Check your location elevation here:

www.whatismyelevation.com

Next, check the below list to see which temperature you should boil at.:

DEMATECH IS A TURN-KEY SOLUTION PROVIDER TO THE CRAFT BEER AND SOFT DRINK INDUSTRY

OFFERING EVERYTHING FROM BREWING EQUIPMENT TO BOTTLING LINES AND PROCUREMENT SERVICES

At Dematech we provide top quality solutions for the processing & packaging of beverages

CRAFT BREWING HOME & PUB BREWING SOFT DRINK PLANT BEVERAGE

DEVELOPMENT &

PROCESSING

RAW MATERIALS &

PRODUCTS

TECHNICAL SERVICES

Dematech (Pty) Ltd

13 Michigan Street, Airport Industria, Cape Town 7490, South Africa

www.dematechsa.com

Table of contents

Popular Brewing System manuals by other brands

Blichmann Engineering

Blichmann Engineering Fermenator F3-7 NPT Operation, Assembly & maintenance manual

Keurig

Keurig K-SELECT Use & care guide

Klarstein

Klarstein Brauheld Pro 30 manual

Curtis

Curtis G4 TPX Series user guide

Fetco

Fetco CBS-2231 Users guide and operator instructions

Speidel

Speidel Braumeister PLUS 10 litres Original instruction manual