1. Clean wash and sanitise the tank at

temperatures below 50°C (122F). Do not

ll the tank with wort or liquid above 50°C

(122F)

2. Cleaners must be diluted to suitable

concentrations before use. If extended

contact time is expected, then users

must ensure that cleaners are chemically

compatible with PET, Silicone, EPDM,

Polypropylene and Stainless Steel.

Approved cleaners and sanitisers for use

on this fermenter include: ABC (Part code

9006) Sodium Percarbonate (Part codes

6172, 6141) Sodium Metasilicate (Part

code RET4533) Atomic 15 Foaming (Part

code 9001) Atomic 15 Annihilator (Part

code 9002) or Phosphoric acid-based

sanitisers.

3. Do not apply more than 2.4 bar (35 psi) to

the tank under any circumstance.

4. NEVER connect to an unregulated

pressure source.

5. If you connect an external pressure

source; ensure it has an independent

pressure release valve (PRV) pre-set

to below 2.4 bar (35 psi).

6. Use only the RED pressure release

valve supplied by MCH Australia Pty

Ltd on the pressure lid.

7. Do not tamper with the pressure relief

valve.

8. Do not use the tank under pressure

if it has been physically damaged i.e.

dropped on the ground

9. Do not expose to temperatures below

-2°C (28.5°F).

10. Keep the tank out of direct sunlight

and other sources of UV radiation.

11. The tank is pressure tested at

production and is marked with a date

for retesting. If it is being used under

pressure, then a hydrostatic test must

be conducted after every 24 months of

use to ensure that it is safe for reuse.

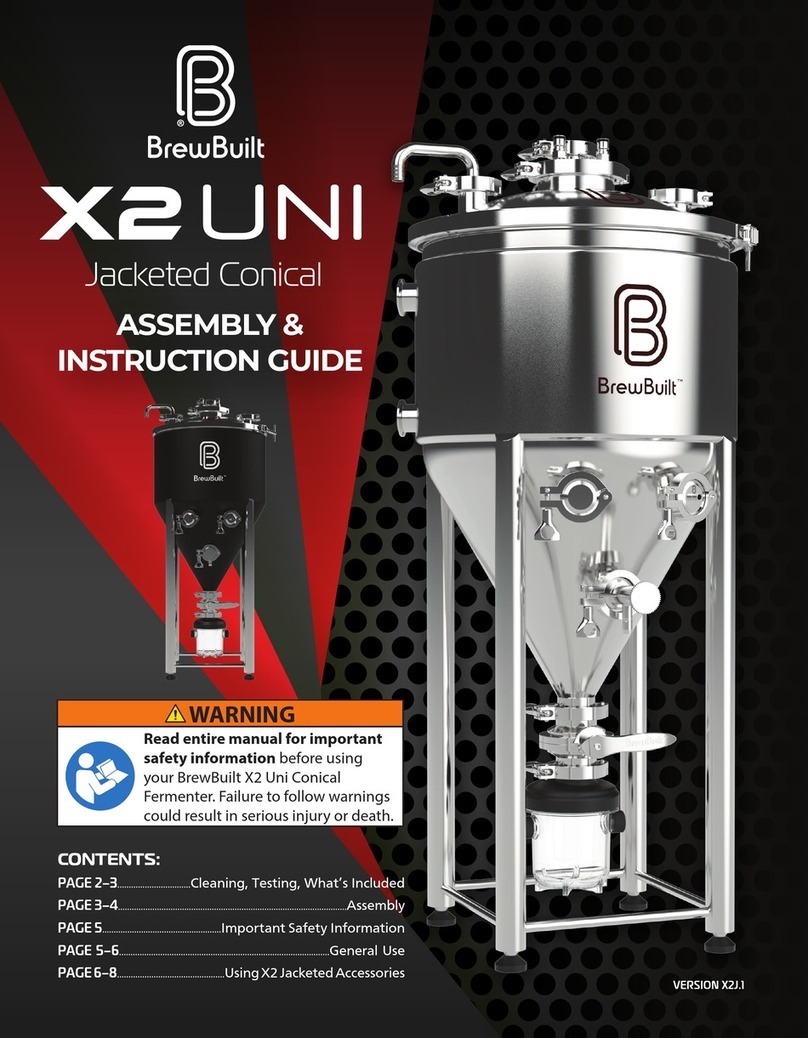

WARNINGS

PRESSURE LID ASSEMBLY INSTRUCTIONS

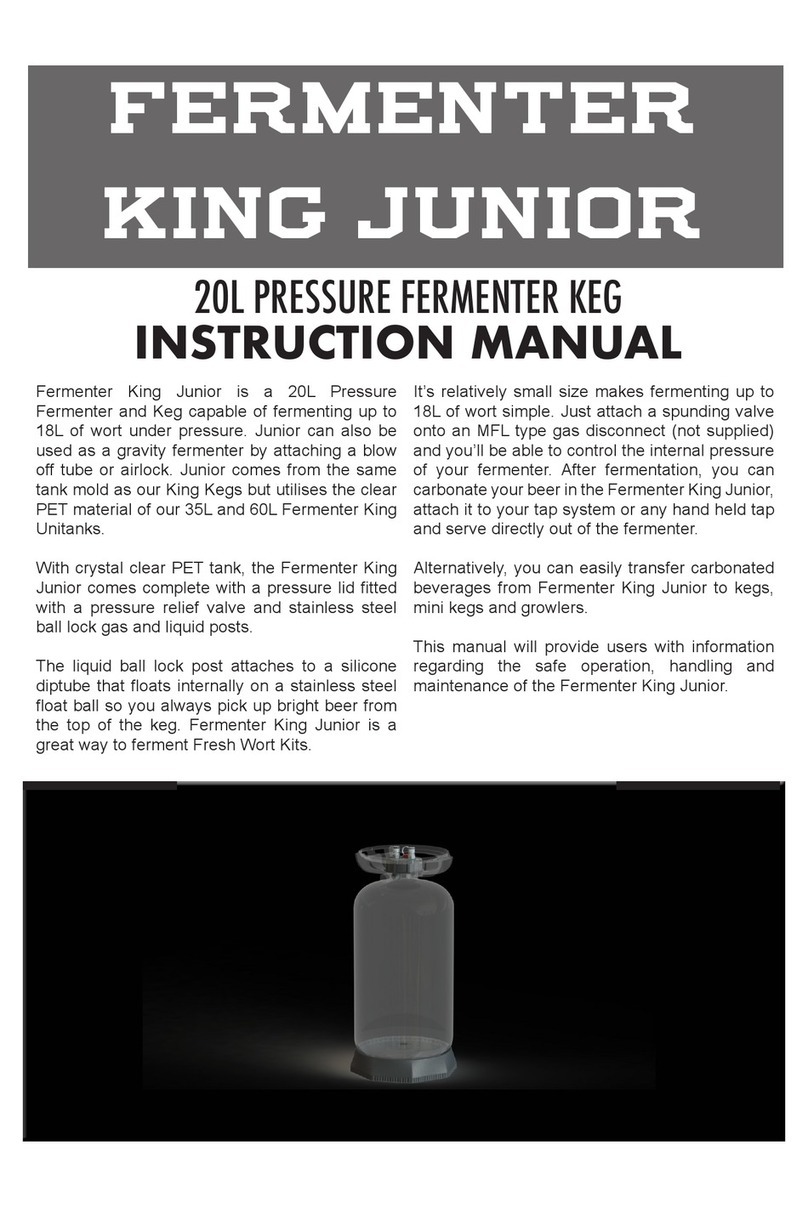

1. Clean and sanitise all components prior to

assembly.

2. Thread the red pressure release valve into

the pressure lid. Screw down rmly.

3. Ensure that the gas and liquid bulkhead

ttings are correctly assembled with the

post fully tightened onto the Pressure Lid.

Insert the bulkhead ttings into the holes in

the pressure lid and tighten the locknuts.

O-rings should be located on the top

surface of the lid for correct sealing.

4. Lubricate the silicone dip tube with some

non-rinse sanitiser and slide one end over

the stem of the liquid post bulkhead tting.

Slide the other end of the silicon tube over

the oating pickup tube.

5. Lubricate the entire silicone lid seal

with some food grade lubricant and t

to the underside of the Gravity Lid.

6. Place the pressure lid on the mouth

of the Fermenter and ensure that the

seal seats correctly.

7. Put a small amount of food grade

lubricant on the top outer ring of the

cap.

8. Place the top thread ring over the lid

and tighten rmly.

Attention: Ensure the ring pull on your

PRV is lying out of the way and not

against the posts on the lid as this could

result in a poor connection when attaching

disconnects.